Both during the construction of new buildings and during the reconstruction of old ones, there comes a time when it is necessary to carry out high-altitude work on vertical surfaces, sometimes at a fairly high altitude. To carry them out, you need a type of equipment such as a façade lift. Before his appearance, the workers climbed down, tied with ropes, and worked while sitting on a fixed board. The occupation was quite risky and required training and experience. Facade lifts have made this work less risky and more productive.

The platform of such a lift can accommodate from 1 to 6 workers with a supply of consumables and necessary tools, and at the same time it can move freely both vertically and horizontally. At the same time, the lift has several safety systems, so its use turns high-altitude work from a dangerous attraction into a completely ordinary routine activity. Installation of facade systems of any kind, decorative finishing of the facade, painting or cleaning it, washing windows of the upper floors cannot be done without it. When working on chimneys or ships, bridges or dams under construction, their help is invaluable. The facade lift has become today a necessary equipment for any high-rise construction or other similar types of work.

Specifications

Construction lifts or façade cradles are used to equip the façade. This device is used to transport workers, machinery, and building materials along the outer wall of a multi-story building. The cradle can only be installed if the façade of the building does not have protruding elements. The lifts are equipped with safety equipment for working at heights.

Lifts vary in technical parameters. The main indicator on which work productivity depends is the maximum load weight. For a facade lift, this figure ranges from 350 to 550 kg. The ZLP 630 cradle is made in the form of a metal platform with a fence 1.5-2 m high. The lifting occurs on 2 ropes, which are located on the sides of the cradle. The reach of the console should determine the free movement of the platform along the wall.

There are counterweights on the roof, the mass of which depends on the size of the platform and load capacity. The movement of the structure is carried out through the operation of an electromagnetic motor and a winch. The motor power is selected depending on the load capacity of the cradle.

A standard construction facade lift is designed to lift 1-3 workers. The lifting height of the cradle ranges from 2 to 200 m. The lifting speed is regulated by the gearbox. The speed ranges from 5 to 10 m/s. To ensure safe work, 2 safety cables and a catcher are installed, which is an insulated block that stops the winch when the cable breaks or the cradle tilts.

Disc brakes ensure the platform quickly stops when overloaded. The lift is supported on two beams or consoles mounted on 4 cables. 2 main cables, and 2 safety cables. 2 drums are installed under the platform, and a winch moves along them. New designs are provided with a power source, which ensures autonomy of operation at height.

Lift equipment

Construction hoists are equipped with electrical equipment, a frame, safety catchers, safety ropes, a portable remote control and a lifting mechanism. The ends of the frame, mounted from durable pipes, are equipped with rope rollers, which perform a protective and lifting function. The lifting mechanism in the form of a special winch is located under the working platform.

There is an opinion that facade cradles are morally outdated, however, they are still in high demand. This is explained by the fact that the risk of construction and repair work is reduced to a minimum when using this equipment. The speed and productivity of work also increases.

Popular models

Facade lift 3851b has the following technical characteristics:

- load capacity - 300 kg;

- platform length - 6 m;

- maximum lifting height - 150 m;

- consoles have lengths of 0.9 m, 1.5 m and 2.5 m.

Lifts 3851-B with a non-demountable frame are used for work at heights, for lifting workers and loads during the repair and construction of buildings. The façade lift kit includes LEF-500 winches, catchers and spare parts. The lifting speed is 9.7 m/min. Electric motor power - 1.1 kW. The dimensions of the working platform are 5.4x0.86x1.01 m.

Operation of façade cradles

Construction hoists are secured using special high-strength bolts. This helps equipment, loads and workers move freely to the desired height.

The carrying capacity of the cradle is the main criterion that you should pay attention to when choosing a unit. Thus, Russian forklifts are capable of withstanding a load of three hundred kilograms. And foreign ones weigh four hundred kilograms or more. The mobility and light weight of the lifts makes it possible to move between different construction sites without disassembling the unit. They are transported in special vehicles in full force.

Installation

Installation and assembly of the façade lift is carried out according to the rules. Workers installing the roof console must exercise caution. When working on the roof, you must be secured with a rope. To install the cradle, you need to check the strength of the connections of the nodes; all fasteners must be securely tightened.

You also need to make sure that there is lubrication in the winches, rollers, and blocks. The cradle must have 2 manual drive handles. There must be the necessary supply of ropes. The consoles must be positioned so that the beams are in a horizontal position, the distance between the console axes is 4200 mm and the console overhang is 550 mm from the wall to the rope axis.

After being attached to the consoles, the lifting ropes are threaded into the winch drums and pulled to the ground with a load weighing 20 kg. Then the cradle is installed, connected to the power supply and checked for readiness for use. You can connect the cable to the power source at the bottom or in the middle of the house. When the cable comes out of the window, you need to put a support so that the cable does not break. If the cable length is more than 30 m, it is suspended from the platform with a steel cable.

After suspending the platform, you need to check the electric drive lock, raise the cradle 200-300 mm from the ground and check the stability of the consoles. Check that the lift height limiters are securely installed. Check the operation of the adjustment buttons and systems that eliminate misalignment. Check the operation of mechanisms and brakes. Assembly takes place with the participation of workers who will work on the lift and under the supervision of the foreman.

Installation of a façade lift

The construction cradle consists of the following components and mechanisms.

✔ Platform (frame). Includes decking and fencing welded from rolled metal.

✔ Support part with consoles. Mounted on the roof of the building. A metal cable is attached to the consoles, on which the cradle is suspended.

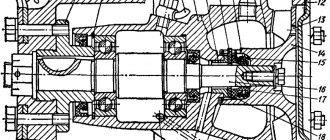

✔ Lifting mechanism. Consists of an electric motor, a double-drum friction winch with a built-in gearbox.

✔ Working and safety cables (2 pcs. each).

✔ brake system, including catchers, shoe and disc brakes.

✔ Manual drive. Used to move the construction platform manually during a power outage.

✔ Control panel.

The raising and lowering of the construction cradle occurs when the winch drums rotate, which are in contact with the lifting cables.

Due to the frictional force, the drums “roll” along the cables, lowering or raising the cradle. Control is carried out using a push-button remote control.

The safety of operation of the façade lift is ensured by a reliable braking system. If the working cables break, the catchers are activated, and the construction and installation cradle hangs on the safety ropes.

In the event of an emergency power outage, a spring shoe brake comes into effect, instantly stopping the movement of the lift. When the load torque exceeds the standard values, the disc brake is activated.

If there is no electricity, the lift cradle can be moved using a manual drive.

Advantages of a construction cradle

✔ Simplicity, reliability, safety.

✔ Virtually unlimited lifting height due to the location of the support part on the roof of the task. The lifting height depends only on the length of the ropes.

✔ Ability to work on facades with protruding structures thanks to extended consoles.

✔ Quick installation.

✔ Easy to control.

A facade lift is a simple, effective, safe mechanism that has no alternative in many types of construction work.

Lift test

Testing of facade lifts begins with checking the functionality of the system. First, static tests of the lift are carried out. To do this, raise the apparatus to a height of 150 mm. A test weight weighing 1260 kg must be placed on the platform flooring, distributed over the entire area, and held in this position for 10 minutes. This is how they check the reliability of the brakes that should hold the cradle. The platform should not lower itself. Then you need to put the device on the ground. Check for any deformation of the mechanisms.

Then the lift is dynamically tested. A counterweight weighing 693 kg is placed on the floor with a console overhang of 1.05 m. The remote control is turned on. The device is raised and lowered five times to a height of 3 m, making 3 stops. The cradle should stop immediately when you press the up or down buttons.

Spontaneous lowering of the platform is unacceptable. Then the brakes are tested. Having installed the load, raise the cradle to a height of 500 mm. Raise the brake handle of the left winch up. The platform will gradually descend on the left side. Release the handle. Then the downward movement should stop. Then do the same to test the right winch.

Tower tours

In essence, these are mobile tower-type scaffolds, convenient for carrying out small amounts of work. They allow 2-3 workers to work at a height of up to 20 m. The load on the deck can reach 250-350 kg.

Pros:

- mobility (easy to move around the site);

- speed of installation;

- small dimensions for transportation and storage;

- versatility for a wide range of works (from construction, repairs to use at public events);

- low cost.

Minuses:

- not suitable for large volumes of work;

- do not facilitate the lifting of loads and people;

- relatively low achievable height.

Stationary mast lifts

Mast lifts are a structure of two or three masts along which the working platform moves upward. The length of the working platform and the height of the masts can usually be adjusted within wide limits. This equipment allows construction and finishing work to be carried out across the entire width of the facade at a height of up to 100 m or more. The platform's load capacity can reach several tons.

Pros:

- allow you to quickly perform large volumes of work;

- spacious platforms that lift enough materials and workers;

- reliability and safety of the design;

- do not cover the façade of the building.

Minuses:

- high price;

- require lengthy installation;

- a source of electricity is required.

Features of the ZLP model

This is the most common lift for performing facade work. The design is made according to traditional principles, as is the power base with electric motors. The advantages of the series include an optimized platform structure, a reliable interaction scheme between mechanics, cables and winches, as well as a wide range of protective systems. For example, the ZLP facade lift has safety locks on the winches. At the same time, the cradle allows for certain possibilities for reconstruction, thereby allowing installation operations to be carried out in non-standard conditions. In practice, such lifts are used not only in working with facade surfaces, but also in arranging elevators, when welding ship structures, in working on dams, etc.

Scaffolding

Attached scaffolding is good for capital construction and repairs. They make it possible to employ a large number of workers and provide simultaneous access to a significant part of the facade. The height of scaffolding can reach 100 meters or more, the load on one deck can be from 200 to 350 kg.

Pros:

- suitable for large volumes of work;

- reliability, design safety;

- do not require energy sources;

- reusable.

Minuses:

- installation duration;

- do not facilitate the lifting of loads and people;

- spoil the appearance of the building;

Features of model 3851B

This is a development of the Tver enterprise "TEMZ", which is in many ways similar to the ZLP modifications, but has several features. First of all, the developers paid special attention to consoles. They can be adjusted in reach, which makes the cradle almost universal in terms of use on different buildings. The design of the roof and roof covering will not matter. As for working capabilities, this version of the façade lift lifts up to 300 kg, has a modest motor power of 1100 W, and reaches its highest point at 150 m. As you can see, in terms of performance, the cradle is not impressive, but this drawback is compensated by mobility and flexibility in management.

Scissor lifts

The working platform is raised using X-shaped mechanisms resembling scissors. The maximum height of the platform is the same as that of telescopic lifts, but the load capacity is several times higher (usually 300-500 kg). 2-3 people can work at the same time.

Pros:

- compactness;

- high level of security;

- good load capacity.

Minuses:

- small capacity;

- electricity required.