How does a loader crane work?

The installation combines two types of equipment - a classic crane installation and a truck capable of transporting a certain volume of cargo. The manipulator is placed on a car, tractor or trailed chassis. The functional attachment that performs a specific type of work may change, but the overall design remains the same. For example, instead of a crane, a cradle can be used to lift people, and in some cases, a device for driving piles.

✎ Functional application of the manipulator

The installation is capable of transporting cargo and carrying out all types of loading and unloading operations in accordance with the lifting capabilities of the crane and chassis, as well as the size of the body of a specific piece of equipment.

The only obstacle to transportation can be the weight and size of the cargo. Used in construction, logistics, housing and communal services, and during emergency work. Depending on the interchangeable working attachments, it can perform a variety of tasks, including reloading timber or scrap metal, lifting a cradle, and driving piles.

✎ Replacement equipment

The crane-manipulator is a universal type of equipment. The list of replacement equipment includes quite a lot of devices of various types, including:

- various types of grips;

- classic crane hook;

- pallet forks;

- cradle for lifting people;

- grab devices;

- devices for driving piles.

We select a truck crane based on lifting capacity. Classification of truck cranes by lifting capacity

One of the main parameters when choosing a truck crane for rent for construction and loading and unloading work is its lifting capacity. This characteristic indicates the maximum permissible mass of cargo that special equipment can lift and carry over a certain distance. For ease of work, along with a structured description of other characteristics of truck crane equipment, there is a classification of these special vehicles by load capacity.Truck cranes with a lifting capacity of 16 tons

The most modest tonnage characteristics are distinguished by truck cranes with a lifting capacity of 16 tons. They are often used for work on small construction sites, mainly in low-rise construction. With their help, floors, reinforced concrete slabs are laid, and pallets with bricks and mortar are supplied.

Truck cranes with a lifting capacity of 20–25 tons

This type of truck crane with greater power and capabilities is used, as a rule, for loading, installing cabins and other work that requires the use of a telescopic retractable boom in a range of up to 35 meters.

Truck cranes with a lifting capacity of 35–40 tons

It is more advisable to lift heavier loads to greater heights with cranes designed for 35 - 40 tons. Such special vehicles are often used in bridge construction. They are designed to lift loads to a height of up to 45 meters, are maneuverable and economical, and therefore can often be seen on large construction sites.

Truck cranes with a lifting capacity of 65–70 tons

These powerful machines are used primarily for lifting large, heavy loads to heights of up to 55 meters and above. The lifting capacity is compensated by more modest maneuverability characteristics and impressive dimensions, but since such truck cranes are usually used throughout the entire construction period of the facility, the requirements for their ergonomics are much softer than for less powerful machines.

Truck cranes with a lifting capacity of 90–120 tons

The rarest are truck cranes, the maximum lifting capacity of which is the maximum permissible 90 - 120 tons. These machines are designed to perform extra-heavy work and lift large loads to a height of more than 70 meters. This is an ideal option for large-scale construction, since the use of such equipment greatly reduces the cost of the construction process itself and reduces the time required to carry out the necessary work.

In total, the classification of the lifting capacity of truck cranes includes 10 groups. The most powerful are machines with a lifting capacity of up to 250 tons. During the construction of residential buildings, such mechanisms are practically not used due to their low maneuverability, impressive dimensions, increased requirements for safe operation, and simply because they are inexpedient.

Selecting a truck crane based on lifting capacity

In fact, the carrying capacity of a machine is a more complex value than it seems at first glance. This is not just the maximum permissible weight of the working load, but the weight with which the truck crane is able to work effectively in any of the positions of its rotating part.

This value is established and calculated based on the total mass of the heaviest load with all attachments located at a certain reach. As a rule, the lifting capacity of a truck crane is greater than or equal to the sum of the masses of all loads, lifting devices and mounting elements.

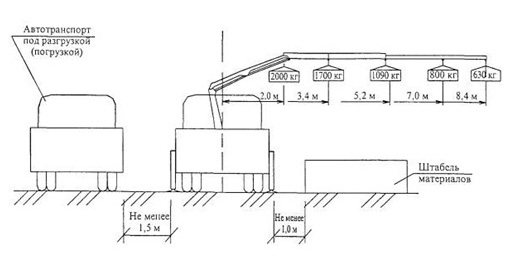

Installation of truck crane equipment at a construction site

The installation of a truck crane is calculated based on the reach and length of the boom and the distance from the edge of the object to the middle of the heaviest loads. The dimensions of the special equipment itself are also taken into account.

The parking area for the truck crane must be prepared in advance and meet all technical safety standards. It is preferable that this be a flat surface of well-compacted soil.

Other classifications of truck cranes

In addition to classification by load capacity, truck crane equipment is classified according to:

- type of suspension of boom equipment;

- drive, types of drive;

- nutrition.

Based on the type of boom suspension, truck cranes are divided into special vehicles with hard and soft types. The rigid type involves the use of a hydraulic drive, which makes it possible to adjust the boom reach and the angle of inclination of the equipment. With the flexible type, the boom is fixed on steel cables.

Depending on the type of drive, truck cranes can be divided into single- and multi-engine. It is the type of drive that has the main influence on the operation of all components and mechanisms. Single-engine truck cranes have one engine located in a vehicle. Multi-engine ones are equipped with several engines responsible for the operation of each mechanism, autonomous and not connected in any way with each other.

According to the type of power supply, truck cranes are mechanical, hydraulic and electric. The work of the first is provided by the engine, the second by the pumping station, and the generator set is responsible for powering the third.

Back to list

Technical characteristics of the crane

The list of main characteristics of the crane includes:

- maximum distances for the height of lifting and lowering the load;

- maximum permissible turning radius of the crane;

- distance of the maximum and minimum reach of the manipulator boom;

- load capacity at different boom extension values;

- load moment value;

- type of suspension;

- features of telescopic boom extension;

- number of edges on retractable elements.

The decisive factors for a manipulator installation are the load capacity of the chassis, the boom radius and the load moment indicator.

To one degree or another, all characteristics of special equipment are important. For example, not taking into account the size of the loading area can significantly affect the ability to complete the task. An experienced CMU user only needs to familiarize himself with the load-height characteristics diagram. Using this scheme, it is easy to determine the effectiveness of the manipulator in performing a particular task.

✎ The magnitude of the load moment and lifting capacity

Depending on the load capacity, installations are divided into appropriate categories. The division is quite arbitrary, but the following classification can be taken as a basis:

- load capacity up to 1 ton;

- from 1 to 10 tons or medium lifting capacity;

- heavy manipulators over 10 tons.

This parameter is the load moment, which takes into account the ability of the boom to lift a particular weight depending on the distance to which it is extended. If the crane’s lifting capacity is 10 tons, this does not mean that the installation will be able to lift this weight by 2.5 m or 12.5 m. The law of leverage comes into play. To determine the load moment, it is necessary to multiply the boom radius and the load capacity of the manipulator.

✎ Types of boom equipment

CMUs have booms of various designs. Types of cranes-manipulators are divided into two options - articulated and retractable and cable. They are also called rigid and flexible suspension. A winch is used as a working element for a cable crane, and a hook on the head of the last link of the boom is used for a hinged crane.

As an additional division, the main indicator of which is the type of boom folding, the designation is used:

- L-shaped;

- Z-shaped.

Each of these designs has advantages and disadvantages.

The articulated and retractable device is characterized by high maneuverability and versatility. There are no barriers for them; the boom of the manipulator is capable of penetrating even door and window openings on the floors of a building. Another advantage of the design is its compact placement in the chassis body. At the same time, the main area of the body remains free for stowing cargo. Cranes equipped with a winch allow you to work on objects without paying attention to the height of the side of the chassis body or the presence of a high fence behind which the load is located. They can retrieve the lifted property from places located below the chassis level. In addition, these CMUs provide more accurate loading and unloading operations and high productivity with a significant boom reach. When moving, the crane boom is located along the chassis, which saves the resource of the front suspension.

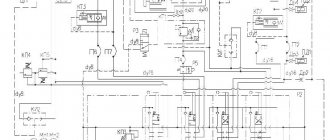

✎ Control

There are several options for controlling the CMU. With the help of a convenient and functional system, it is easier to fulfill the loading requirements of the crane platform. There are several options for controlling the robotic arm's workflow, including:

- using a remote control, which is used on some modern models;

- the use of controls located on the CMU on both sides of the crane installation;

- using levers located near the base of the boom, the operator’s seat is also located there.

✎ Retractable supports

With the help of outriggers, the stability of the CMU chassis is ensured when performing loading and unloading operations.

These devices come in both automatic and mechanical types. To install automatic devices, the use of a manipulator hydraulic motor is required. With its help, special hydraulic cylinders are activated, which fix the retractable supports. Mechanical devices are manually aligned and then secured to ensure safety.

✎ Chassis types

There are several types of chassis on which the manipulator structure is installed. The procedure for allowing workers to service cranes also depends on the type of chassis used. The main reason for choosing a particular chassis is the list of tasks for which the equipment is intended. The most common types of chassis include:

- based on a truck;

- on the platform of a caterpillar or wheeled tractor;

- on a trailer base.

Generally accepted classifications of modern truck cranes

The modern construction industry cannot do without the use of various special equipment, including truck cranes. Therefore, it is hardly surprising that the rental of modern truck cranes in Moscow is such a big success among contracting companies. Truck cranes are able to perform a wide range of different tasks, in particular lifting large and oversized cargo, transporting them in a horizontal plane, and so on. Indeed, the scope of application of modern truck cranes is very extensive.

According to experts, before renting reliable specialized equipment in Moscow at competitive prices, including truck cranes, it is recommended to familiarize yourself with the generally accepted classifications of truck cranes.

Generally accepted classifications of modern truck cranes

The classification of truck cranes can be based on various parameters, for example, the level of lifting capacity of this type of special equipment, the type of drive of the truck crane mechanisms, design features of the suspension, and so on.

Classification of truck cranes by lifting capacity

According to this classification, all modern truck cranes are divided into the following 5 groups:

1. Truck cranes with a lifting capacity of up to 4 tons. 2. Truck cranes with a lifting capacity of up to 8 tons. 3. Truck cranes with a lifting capacity of up to 12 tons. 4. Truck cranes with a lifting capacity of up to 16 tons. 5. Extra-heavy truck cranes with a lifting capacity exceeding 25 tons.

Classification of truck cranes by type of main mechanisms

In this case, all truck cranes can be divided into the following types:

1. Truck cranes with single-engine drives. In this case, all the mechanisms of the truck crane are powered by one engine. A mechanical transmission drives the main actuators.

2. Truck cranes with individual multi-motor drives. Here, each individual mechanism (the boom lifting mechanism and the vehicle movement) is equipped with its own motor. Individual motors can be powered from:

— directly from the car engine (motor cranes with mechanical drive); — generator set (vehicle cranes with electric drive); — pumping station (truck cranes equipped with hydraulic drive).

Classification of truck cranes according to the design features of the boom equipment suspension

According to this classification, truck cranes are divided into:

1. Truck cranes with a rigid suspension (hydraulic cylinders are used) 2. Truck cranes with a flexible suspension (a rope system is used).

Classification according to the design features of the truck crane base

In this case, truck cranes can be two-axle, three-axle, four-axle, and so on.

Main manufacturers

The Russian market is dominated by domestic and Korean manufacturers.

They ideally combine the requirements of the price-quality indicator. It is worth highlighting the equipment of Velmash-S, JSC BAKM and JSC Inman. An additional advantage of our equipment is the absence of problems with inexpensive and high-quality spare parts. Among the Korean equipment, one can highlight the following: “Kanglim”. Japanese and European brands are distinguished by high quality and even higher prices. The Swedish company HIAB produces manipulators capable of operating in a wide temperature range.

Added: 07/07/2020

Technical characteristics of the portal crane "Albatross"

| Manufacturer | VEB Kranbau Eberswalde (GDR) |

| Crane type | reloading |

| Boom type | articulated with straight trunk |

| Maximum load capacity, t: | |

| reach 8—32 m | 10 |

| reach 10-16 m | 20 |

| Boom radius, m: | |

| greatest | 32 |

| least | 8 |

| Travel speed m/min | |

| load 10 t | 63 |

| load 20 t | 32 |

| descent | 90 |

| turret rotation, rpm: | 1,6 |

| hoist ascent/lower, m/min | 63 |

| horizontal movement, m/min | 32 |

| Maximum lifting height from the crane runway level, m: | |

| to the center of the hook suspension with a load of 10 t | 25 |

| to the center of the hook suspension with a load of 20 t | 22 |

| to the bottom edge of the open grab | 22 |

| to the bottom of the lifting electromagnet | 22 |

| Maximum lowering depth from the level of the crane runway, m: | |

| to the center of the hook suspension with a load of 10 t | 15 |

| to the center of the hook suspension with a load of 20 t | 8 |

| to the bottom edge of the open grab | 15 |

| to the bottom of the lifting electromagnet | 11 |

| Portal dimensions, m: | |

| Track | 10,5 |

| Base | 10,5 |

| Largest rear dimension of the turning part, m | 6,5 |

| Number of wheels: | |

| general | 16 |

| including drive | 8 |

| Maximum wheel pressure on rail, kN (tf): | |

| with cargo | 234 (23,4) |

| without load | 199 (19,9) |

| Weight of a crane with a hook suspension with a lifting capacity of 10 t) | 183 |

| Drive unit | electric |

| Current | alternating three-phase |

| Voltage, V | 380 |

| Restrictions on working with a crane: | |

| with a load of 10t | at a wind speed of no more than 15 m/s |

| with a load of 20 t | at a wind speed of no more than 12 m/s |

| Minimum temperature | not lower than -30°С |

| The greatest slope of the rail track: | |

| transverse | 1: 2000 |

| longitudinal | 1: 2000 |