Modern technologies that are being introduced into the agricultural sector have led to the fact that almost every cattle owner strives to accustom a cow to a milking machine. With the advent of special equipment, the process of milk extraction has become significantly faster and easier. The equipment costs quickly pay off, which is why the device instantly gained popularity among farmers.

Methods of machine milking of cows

There are 3 main ways of producing milk:

- natural;

- machine;

- manual.

In the natural method, when the calf sucks the udder on its own, milk is released due to the vacuum that forms in the calf’s mouth. For the manual method, this process is due to the squeezing of milk from the teat tank directly by hand by a worker or the owner of the animal. And the machine method involves artificial suction or squeezing using a special milking machine.

The process of milk ejection itself occurs quickly. It is important that the cow is milked as much as possible - the amount of residual fluid in the udder should be minimal. To fulfill this main requirement, there are a number of rules for machine and manual milking, which consist of:

- preparatory;

- basic;

- additional procedures.

Preliminary preparation consists of treating the udder with clean warm water, followed by wiping and massage, milking a small amount of milk into a special container, connecting and setting up the apparatus and putting milking cups on the animal’s teats. Professional milking operators perform the entire list of procedures in less than a minute.

The main part is the direct extraction of milk. Machine milking is the process of extracting milk from the udder using special equipment. The whole process takes on average 4-6 minutes, including machine dodoing.

The final stage consists of a series of final procedures - turning off the equipment, removing the glasses from the udder and final treatment of the teats with an antiseptic.

When machine milking occurs, milk is extracted from the udder teat using a milking cup. In this case, he performs the function of a calf sucking milk or a milkman who mechanically acts on him. There are two types of milking cups:

- single-chamber - an outdated type that is still used in production;

- two-chamber – modern glasses with high efficiency and minimal trauma.

Regardless of the chosen method of obtaining milk, the product is released in cycles in separate portions. This is explained by the physiology of the animal. The time period during which one portion of milk comes out is called the milking cycle or pulse by experts. It is divided into beats. They are defined as the period during which one interaction of an animal with a machine takes place.

Types of milking machines.

The industry produces a fairly large range of milking machines for different market segments. There are domestic and foreign equipment manufacturers on the market. They are characterized by productivity, degree of automation, and adjustments. Manufacturers produce inexpensive devices for small individual farms with an affordable price, with a productivity of 1-7 milked cows per hour, and powerful units capable of simultaneously milking two or more cows on large dairy farms with a productivity of up to 30 cows per hour or more. Milking machines are powered by an electric current network, which ensures the operation of vacuum blowers and automation.

The principle is the same in all milking machines, but there are two-stroke and three-stroke units. The use of three-stroke milking machines provides better milk yield results, since in the cycles of creating a vacuum differential pressure, which ensure the extraction of milk from the udder, a pause mode is provided, which is ultimately better tolerated by animals and makes the milking process more comfortable for them. In addition to productivity, milking machines differ in the degree of automation of the milking process and are equipped with various sensors. Our video shows examples of different devices.

Principles of machine milking of cows

The principle of hardware milk production is based on the various physiological characteristics of the cow. The principle of stimulation for the milk letdown reflex has been known for thousands of years.

In the process of milking milk with special glasses, exactly as with the natural sucking of the udder by a calf, the nerve cells and receptors that are located on the nipples are activated. They are most sensitive to pressure, and when it is present, an impulse is transmitted to the brain to release oxytocin. After a few seconds, it enters the animal’s udder through the circulatory system.

Technologies for machine milking of cows must comply with the following zootechnical requirements:

- they do not start milking if the cow has not let in milk;

- the preparatory stage should last no longer than 60 seconds;

- milking takes a little more than 4 minutes, but no longer than 6 minutes;

- the optimal speed of milking a cow is 2-3 liters per minute;

- during the period of maximum milk production, milk comes out of the nipples completely;

- the process should be adjusted so that there is no need for manual milking;

- Proper machine milking of cows does not cause any harmful effects on the udder and health of the cow in principle, which is an inevitable consequence of overexposure to glasses on the teats.

The operating principle of all milking machines is as follows: rarefied air from a vacuum wire enters the pulsator through a special hose, after which it then moves into the inter-wall space. This completes one stroke of sucking. However, in the chamber under the teats at the teat cup, the vacuum is constantly exposed.

To produce cow's milk use:

- push-pull devices based on the compression-sucking principle;

- three-stroke with an additional rest period.

When compressed, air from the atmosphere enters the chambers between the walls of the milking cups, which leads to compression of the teats. During the sucking stroke, the pressure in the chambers stabilizes and milk comes out of the nipple.

Also, due to high pressure and vacuum, blood, lymph and various gases enter the udder, which causes the nipples to become significantly larger. This is a rather painful process that can lead to pathological changes in cells. That is why the third step was introduced - rest - to reduce the negative impact on tissue. Detailed machine milking of cows is presented in the video at the end of the article.

Milking cows - which technology to choose?

Milking is carried out manually or by machine. Nowadays, modern housewives use the manual milking method to a very limited extent, since it is the most labor-intensive and costly. But you cannot do without it, for example, if the udder is saggy or asymmetrical, and the nipples are too short. It is also not recommended to use a milking machine if there is uneven development of the milking and low or high (more than 3.5 liters per minute) intensity of milk production per minute.

The apparatus for milking cows is very convenient to use in farms where there are several heads of livestock: this allows you to significantly save on the process time. Cup- and bath-shaped udders with conical or cylindrical teats are ideal for machine milking. The optimal length of the nipple should be from 5 cm to 9 cm, diameter - from 2 cm to 3.2 cm.

In addition, the container should allow the animal to accumulate and retain milk for 10-12 hours. The machine method, compared to the manual method, has its advantages: firstly, the amount of milk per milk yield increases due to the complete emptying of the udder, and secondly, sanitary and hygienic conditions are more strictly observed.

- Preparing the udder for milking

Before milking a cow, it is imperative to prepare the udder with massaging movements. Thanks to this, milking time is significantly reduced from 7 to 5 minutes, and the amount of milk delivered increases by 16%. Massage promotes blood circulation and improves the delivery of nutrients, which has a beneficial effect on the process of milk formation.

In addition, preparatory and final massages protect the cow from diseases, including mastitis, help timely fertilization, and activate the activity of the ovaries. In nulliparous heifers, the sac begins to be massaged three to four months before calving and stops 25-30 days before. Regular massage and the friendly attitude of the owners teach first-calf heifers and adult animals to stand calmly when the owner gives milk.

- How to milk a cow by hand?

When milking by hand, you need to be careful, try to get clean milk and not damage the cow. First of all, remember - milk the cow with dry, clean hands, without tugging or pulling on the nipples.

Let's take a step-by-step look at how to milk by hand:

- We clean the udder and nipples using a damp individual towel or disposable napkin. It takes 20-30 seconds to prepare.

- We massage and stimulate the tips of the nipples, while simultaneously squeezing the first streams of milk into a separate container. In this way, you can determine whether the animal is suffering from mastitis (bloody discharge, clots). In case of illness, you should immediately call a veterinarian.

- The animal must be milked with your fist. The thumb and forefinger pinch the nipple at the base, preventing the milk from returning back.

- Then we sequentially squeeze the middle, index and little fingers, thanks to which the milk comes out.

- After this, we unclench our fist, but do not tear our hand away: milk flows into the nipple again. Again we squeeze our fingers one by one.

- After finishing, wash, disinfect and wipe dry the udder.

If the animal has short nipples and the fingers are constantly wet, then it is better to milk her by pulling the nipple with the thumb and forefinger. Experienced milkmaids can make up to a hundred such movements in one minute. The intervals between milkings significantly affect the composition and quantity of milk, especially the fat content. Systematic udder massage helps produce richer milk.

- How to use a milking machine correctly?

The technology of milking cows with a machine includes the same massage and manual expression of the first streams of milk. Naturally, do not forget to wipe with a clean towel before doing this. Immediately put on the milking machine, avoiding the entry of air. The milking process should not last more than 6-7 minutes. In this case, the pulsation frequency is 45-60 cycles per minute, and the vacuum in the manifold is 37-41 kPa.

We constantly monitor the behavior of the cow and the operation of the milking machine. As soon as we notice a decrease in the flow of milk in the hose, we pull the collector down a little and then back up. Such actions should facilitate the outflow of milk and ensure complete milking of the milk. Before removing the device, turn off the vacuum and fill the manifold with air. Important, the milking machine must not be torn off! The tips of the teats should be dry and pink after machine milking.

Preparing the milking machine for operation

A milking machine is a special technical device that comes into direct contact with the animal and products. Therefore, it requires special care and preliminary preparation before each milking.

Effective milking of cows is only possible if the milk extraction unit is in good working order and is configured correctly by the operator. Therefore, before starting work, it is necessary to accurately diagnose it for problems and various malfunctions. Correct operation means ensuring the correct pulsation frequency and vacuum pressure. How to achieve these settings is usually described in the milking machine user manual.

Before starting work, you need to check that the hoses with other parts fit tightly, the nipple rubber is intact, and there is a gasket between the edge of the can and the lid. You also need to make sure that there are no mechanical damages on the can, because air can leak through dents, which will cause all the equipment for milking cows to fail.

It should be borne in mind that the liners on the glasses break most quickly. They wear out, so it is advisable for the machine operator to always have a few extra sets in stock.

Comment! During operation, the milking machine should not make any extraneous noise - grinding or knocking. The presence of such a sound is a clear signal of a malfunction in the installation.

Almost all milking machines require regular lubrication of rubbing parts. You can read more about this in the user manual, where the manufacturer himself provides recommendations for operating the device.

The process of basic preparation of the installation for automated milking of a cow is as follows:

- Before putting on, the milking cups are heated; to do this, they need to be held in water with a temperature of 40-50 for several seconds;

- upon completion of milking, all accessible parts of the device are also washed - first with warm water, and then with a special washing solution;

- the internal parts of the device that are in direct contact with dairy products are also washed after each use. This is done using a vacuum, when instead of milk, detergent and disinfectant are passed through the entire apparatus.

A clean device is stored in the position and conditions specified by the manufacturer. Operation in accordance with the rules is the key to quality milking.

A little history

Vintage photo - milking a cow by hand

Early attempts at milking cows involved a variety of methods. Around 380 BC, the Egyptians, along with traditional hand milking, attached a straw of wheat to the teat of cows. The milking machine was first used in 1851, although the attempt was not entirely successful.

To stimulate further invention, the Royal Agricultural Society of England offered a reward for the presentation of a safe milking machine. At the end of the 19th century, a machine with a vacuum pump driven by a steam engine was developed in Scotland. This unit, along with the introduction of the double teat cup, led to automated milking of animals. Since the beginning of the 20th century, the principle of machine milking has taken root in the dairy industry.

How to properly milk a cow with a milking machine

When using automatic devices, you must follow the following rules for machine milking of cows:

- Before starting the process, you need to inspect the animal's udder for any problems - diseases or damage. It is also advisable to regularly conduct tests to ensure that milk meets sanitary and epidemiological standards.

- If several cows are served by one milking machine at once, then it is necessary to draw up a special calendar and the order of their processing. A certain sequence must be followed. First of all, those cows that have recently calved are milked, then the young and healthy ones are milked, and the old and “problem” cows are the last to be milked.

- Before placing glasses on the cow's teats, 2-3 streams are manually milked from each udder. All milk must be collected in a special container. Leaving it on the floor is strictly prohibited, as this can lead to an outbreak of diseases and the rapid spread of harmful bacteria. A person who works with a cow must be able to visually assess the quality of milk - check for the presence of clots, inclusions or any other deviations in color and texture.

- To prevent the cow from developing mastitis and to keep the milk clean, the teats are washed and then wiped dry with each milking. To do this, it is advisable to use disposable paper towels or an individual fabric cloth after the milking machine, which is washed after each use.

- After turning off the unit, you need to wait until the vacuum drops inside the glasses. There is no need to forcefully pull on the cow's udder to remove the equipment. This can cause mastitis.

Attention! To prevent cows from transmitting diseases to each other, it is necessary to strictly adhere to the rules of the procedure, hygiene standards and thoroughly wash the unit after each use.

Types of milking machines

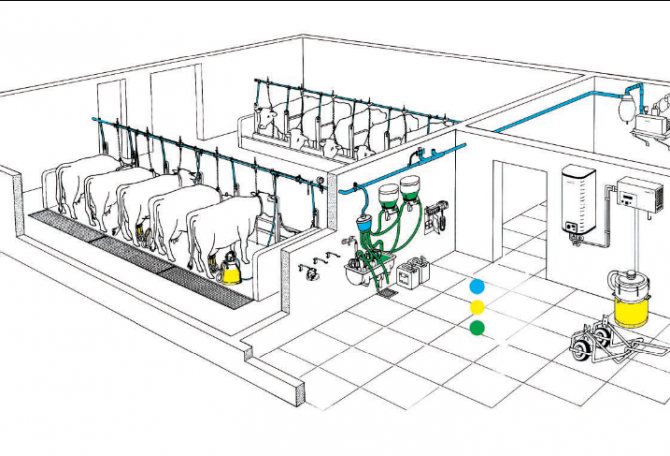

Milking machine diagram

With the advent of milking machines, the work of farmers and ordinary cow owners has significantly improved. The device allows you to save time and effort, so necessary for farming. There are several types of milking machines, the type of which depends on the scale of application.

Portable milking machines

Portable milking machines are ideal for small numbers of livestock (up to 20 heads). The portable machine provides an efficient and convenient way to milk animals. An oil-free, electrically driven vacuum pump creates the vacuum needed for automated milking. Each machine comes with a vacuum regulator and pressure gauge to ensure and maintain the proper level of pressure during the milking process. Pulsation in the cluster is created using a pneumatic pulsator installed in the apparatus. It meets all requirements for reliability, durability and precision. The pulsation speed is set using an adjusting key. The coefficient is chosen by the user himself.

Portable milking machine

The milk is collected in a durable stainless steel bucket for further transportation. Options available with both one and two buckets. The complete milking machine kit includes the necessary fastenings for easy installation and pumping tubes. All parts are securely mounted on a lightweight yet stable trolley that is easy to transport and requires minimal maintenance.

Portable milking machine mounted on a cart with two milk containers

Milking system

The milking system is installed on farms where animals are kept in their stalls and is designed for 20-100 heads. Milking is carried out using a portable machine that provides pulsation and vacuum. The block is connected to the milking station. Typically, one station is installed for every two heads. The product enters a receiving vessel with liquid level control and is then pumped into a cooling tank. The system is easily scalable.

Automatic milking systems are installed on large farms and are designed for more than 100 heads.

Automatic milking system

How to accustom a cow to a milking machine

Preparation for automatic milking of cows occurs in several stages:

- Prepare the udder and room.

- The cow is gradually adapted to the noise from the apparatus.

Preparation of the animal's udder includes treatment before and after the procedure, and also protects in every possible way from the formation of mechanical damage.

Comment! It is worth paying attention to the preparation of the room for milking and the psychological state of the animal.

Experts recommend:

- Always collect milk at the same time;

- carry out the procedure in the same place (then the cow itself will enter its box out of habit), adaptation takes an average of 5-7 days;

- the first days in the box, the cow is milked by hand until she gets used to the environment, and then they begin to accustom her to the milking machine;

- accustom the animal to noise - cows are very timid and can experience stress from any excess noise; loud sounds from the milking machine can completely stop lactation.

Advice! It is advisable to purchase a milking machine that has a muffler. If this is not possible, the device must be operated continuously so that the animal becomes completely accustomed to it.

Experts are confident that it is not at all difficult to accustom an animal to machine milking. The owner must be patient and understanding with the cow, and not show aggression or use physical force. This way he will achieve success in a short period of time.

Types of milking machines

All installations differ in technical capabilities, milking methods and mobility. Taking them into account, groups with certain criteria are distinguished:

- Method of obtaining milk. On large farms, it is collected from each cow through pipelines into one tank. Farmers use devices from which the product enters a separate small container.

- Number of cows connected for milking. On a small farm, it is enough to perform the procedure with two animals at the same time. This is not profitable for large farms; they choose units designed for a large group.

- Motor type. Oily ones are quiet and don’t like low temperatures, but the animals feel calmer. Dry engines operate loudly, do not tolerate high humidity, but are unpretentious in operation.

The most important feature that characterizes the milking machine is the principle on which it works. There are two-stroke and three-stroke units. The difference can be understood if you understand how a calf suckles a cow. This happens in three steps: he squeezes the nipple, swallows the milk, and rests. This is exactly the principle of manual milking.

Relatively recently, only two strokes were available for milking machines: sucking and squeezing, constantly maintaining a vacuum. The moment of rest was ignored. To ensure unhindered flow of milk, the collector had a small hole for air suction. Similar devices continue to exist, but are used exclusively in the CIS countries.

Modern three-stroke machines take into account natural milking conditions and are supplemented with a rest phase. At this time, a portion of air is admitted under the cow's nipples, the pressure under the glasses is almost equal to atmospheric pressure. Blood circulation is restored, which contributes to better milk production.

Important! You should not transfer cows from three-stroke to two-stroke machines: productivity is immediately lost and mastitis appears. It is prohibited to equip the units with parts from other brands, or to use different devices on the same installation.