Question: I use a Neva MB-2 walk-behind tractor with a Subaru engine. Starts well, spark plug is new. You start to apply load - press the lever on the handle, and the engine starts to stall, it doesn’t seem to pull. I plowed half of the garden normally, but I can’t plow the other half, I could barely get it into the garage, I can barely pull myself together, I don’t sneeze, I don’t puff, but it keeps stalling.

Answer: Check how easily the rod moves from the lever on the crankcase to the carburetor throttle valve. On these engines it is simple - everything is visible. There is only one craving there. When the engine is not running, it should move completely freely, without the slightest jamming. And come back with a spring. Second, try replacing gasoline with something else. Even from a completely different gas station.

Question: Please tell me which drive belt is best to install on the Neva MB-2 walk-behind tractor with a Honda engine. And is it possible to install a non-factory one? I read somewhere that they installed a front-wheel drive alternator belt. Will it fit?

Answer: Select according to your parameters. The size of the original belt on MB is 1180. Profile A.

Question: I use a Neva MB-2s 7.5 pro walk-behind tractor with a Robin Subaru ex21 engine (7 hp). I bought it last year, assembled it and put it in the garage for the winter, but didn’t start it. Yesterday I decided to try it and it didn’t work, I filled it with gas, there was compression, there was a spark, the spark plug was flooded, but it still wouldn’t start. Today I changed the gasoline to a fresher one, there is no use, the compression and spark are gone, the spark plug is flooded. What could happen at zero? Is the factory Japanese spark plug bad?

Answer: Did you happen to forget to fill the engine with oil? Apparently your oil level is insufficient, which is why the ignition interlock sensor has tripped. Oil is not poured according to the dipstick, but in the amount indicated in the operating instructions. The normal oil level is when it reaches the top thread of the filler neck thread. It should even drip when you unscrew the plug with the dipstick. The walk-behind tractor must naturally stand strictly horizontally relative to the surface.

Question: Tell me, what checks and adjustments need to be done after the Neva MB2 walk-behind tractor has not been in operation for a long time?

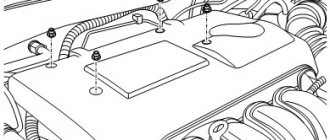

Answer: - check the oil level in the engine crankcase by unscrewing the plug (after waiting for some time to allow the oil to drain, if the engine was previously uneven). — check if fuel is flowing by opening the fuel supply valve. — check the gasoline in the carburetor by unscrewing the settling glass under the carburetor. — check the spark plug as standard for an auto-moto (dry, wet, sooty, gap, etc.). — Check the air filter for contamination. — check whether the air damper opens and closes with the start lever (in the same place as the fuel valve). — check whether the on-off switch closes. ignition — check the throttle cable - does it move freely? Are there any bends or pinches, is there any rust inside? - check the stroke of the throttle cable with your hand using the throttle handle (the starting stroke may be adjusted incorrectly - try to open it as much as possible for starting, there is a larger or smaller drawing near the handle). - check the fastening of the cable near the carburetor - is the body of the cable tightened with a clamping bracket, is it not overtightened, the cable itself (thin steel wire) is clamped with a cross screw (for me) in the through nut, you can manually temporarily tighten the throttle handle near the carburetor to start, check for Are there springs there that return everything to “0”. - do not fill the tank completely with fuel at the first start - let it be a little, or remove the filler cap. - start with the starter smoothly, but firmly, pull the handle - when you feel a catch - only then a jerk.

Question: help with this problem - the Neva MB-2 walk-behind tractor, the Honda GC-190 engine started working only at high speeds, as I understand it, the gas regulator does not work.

Answer: The regulator, it never fails on its own, it’s too primitive, there’s nothing to break. There must always be an external reason. The following cases are possible: Subaru engine. The regulator does not work - the engine rotates at only one speed, does not respond to control of the handle, and reduces speed under load. The reason is that the roller coming out of the engine (on which there is a long lever) has “dried up” in its hole. Cured by disconnecting the long rod from the carburetor and turning it by hand several dozen times from extreme to extreme position until it began to work freely. The engine is similar to a Honda. The regulator does not work the same way, with the same symptoms. I remove the carburetor - the throttle axis does not rotate. Fine dust got on the axle and it jammed. I removed the damper, pulled out the axle, washed it, blew it out, and put it back together.

Question: Tell me why the spring on the clutch cable of the Neva MB-2s 7.5 pro walk-behind tractor with a Subaru engine stretched. Is everyone like this? or marriage. Maybe because the belt has stretched? By the way, can you tell me what size belt it is? and how quickly can it stretch? I didn't notice right away about the belt stretching. and then they tried to tension the cable and the spring burst (they re-attached it to the coils, since it was stretched) Or maybe the belt was simply stretched to the limit? And that’s why speed 2 didn’t work when plowing? (pulleys are set to low speed).

Answer: Belt A1180. Don't buy cheap ones. There is a bitter experience. They stretch, overheat, twist, and eventually break.

Question: I am using a Neva MB-2s 6.5 walk-behind tractor with a Subaru EX 21 engine. During operation, I replaced the oil in the engine (it was black) and in the gearbox. I managed to plow the garden a little. Then I decided to mow the area with a rotary mower. Everything was fine at first, however, at a certain moment I noticed that black soot was coming from the exhaust pipe and the engine began to rev unevenly. He stopped and turned off the engine, but when turned off, it did not stop working immediately, but detonated and fired for some time. I thought maybe the fuel was of poor quality. I restarted it and started mowing again, but the black smoke still continued to flow. The engine ran for about another minute and suddenly white smoke began to pour out of it and the walk-behind tractor began to stall and choke. I turned it off immediately. I took off the rotary mower and rolled it in neutral to the house and left it to cool. About an hour and a half later I started it again. At low speeds it works fine and maintains speed evenly. it doesn’t smoke, but as soon as you add a little gas (without load), at first it starts to vibrate more strongly, then it starts to smoke again and the speed jumps. Tell the wizard how to fix or get rid of this problem?

Answer: First, an air filter (you can start it without it for testing), a spark plug, then flushing and blowing the carburetor. If you changed the oil, then it is possible: 1. overfilled - place the MB2 on a level surface so that the engine base is horizontal, wait a little and check the oil level on the dipstick. 2. It is quite possible to tilt to the sides when working on uneven surfaces - then the oil will “throw around”. 3. check the engine idle speed adjustment, on level ground after warming up. i.e., releasing the “gas” and gaining it is at the end of the cable that is clamped near the carburetor. I have it adjusted so that the idle speed does not turn off the engine, otherwise you never know. That is, by resetting the “gas” to “0” it won’t stall.

Question: A completely new walk-behind tractor Neva MB-2s 7.5 pro with a Subaru engine; when milling, the cutters hardly spin (under difficult conditions) and the sound is unpleasant. I think the fault is in the belt (probably stretched). The belt looks like new, can it be tensioned? There is no room to adjust the clutch handle anymore. Could there be another malfunction?

Answer: I had the same thing, if it’s urgent and temporary, then you can shift the motor platform relative to the frame to the following holes, i.e. those that are closer to you, if you look at the walk-behind tractor from the front. But most likely you will also need to adjust the motor itself along the platform, and this is very difficult, because a tubular one cannot be reached there with a regular key or head, and in order to slip the tubular one in, you need to pull the motor with the platform off the MB-2 frame.

Question: I spent a long time choosing from motor cultivators, but I bought a Neva MB-2s 6.5 walk-behind tractor with a Subaru EX-17D engine. Please tell me, before starting operation, do I need to change the factory oil to a new one?

Answer: The factory fills the engines with oil that is not the worst - don’t drain it, work on it. Regarding idling, I would not recommend it. All Robin engines undergo exhaust control at the factory, which includes starting and running for some time. That is, as if to begin with, the engine has already turned a little. Then the oil is drained and onto the packaging. The engines for Neva MB-2 walk-behind tractors arrive at the manufacturing plant without oil; after installing them on the walk-behind tractor, they are filled with oil, started and placed on the stand. For the first period of operation of the walk-behind tractor: I think that it would be best to start the engine, warm it up a little and start working. But it’s best not to work at full throttle and not to overload the walk-behind tractor - don’t install additional cutters, don’t cultivate virgin soil in second gear. And don’t forget to change the oil with fresh one no later than after 20 hours (This is for Subaru).

Question: Can you tell me how to cut the beds for planting potatoes? Motoblock Neva MB-2. Honda engine. Quick in the field. In operation for one year. Can I use a hiller, or is there a special plow?

Answer: Most likely it won’t work with a plow. The walk-behind tractor with its right wheel follows the cut furrow, but what if the potatoes are already laid out there? I don’t know how, where, but here we cut furrows with a hiller. You can then fill them up with the same hiller, but this must be done as carefully as possible - you need to guide the wheels along the ridges so as not to fall into the furrows with potatoes and crush them. Usually, not very large areas are cut with a hiller and covered with a rake.

Question: During maintenance of the Neva MB-2b 6.5 pro walk-behind tractor, I visually do not see any oil in the gearbox through the plug (breather). I read in the instructions that it should be 2.2 liters. I thought I could see through this plug (similar to the engine). But, as I already wrote, it is invisible. Question: is this how it should be?

Answer: The plug is on the side of the gearbox. Visually, the oil was also not visible. I felt it with a wire and it’s there. I rolled the unit on its side. Added oil. Transmission oil. The passport must contain the brand of oil. I understand that when pouring oil into the filler breather, oil should flow out of the control breather when the level becomes normal. The walk-behind tractor must, of course, be horizontal.

Question: Is it possible to fill the Neva MB-2b 5.5 motor-block with semi-synthetic 10w30 oil purchased from auto parts?

Answer: Of course, it is possible if it corresponds to the API category - SF, SG, SH, SJ and higher. The instructions for the engine should contain recommendations for the use of oils depending on the ambient temperature. 10w30 - all-season.

Question: Yesterday I tilled the ground with cutters. Neva MB-2k 7.5 with a Honda engine, the gear shifting was very frustrating, sometimes you have to apply gas to get it into gear (which can be done, I don’t really want to drag it into the city). Tell me approximately how to mill correctly (how much to open the throttle and what gear)?

Answer: don't give it too much gas. There are no synchronizers in the box. And for normal inclusion you need to move the pulley a little and stick the gear in. In the instructions at this point there is. The gears in the gearbox can fly off from the throttle - it is generally forbidden to shift while moving.

Question: While operating the Neva MB-2k 7.5 walk-behind tractor with a Brigss&Stratton engine, a malfunction occurred. Doesn't pull when plowing. A friend looked and said that the belt was not tensioned. Adjustment on the handle did not bring the desired effect. I moved the platform with the engine forward to the outermost holes. It doesn't idle as it should. I would like to adjust it to the maximum before plowing. In connection with this, the questions are: Did I do the right thing so far by moving forward? Are there any other ways to adjust (other than using the handle and shifting the platform). Which of the three positions is best to put the belt on the drive pulley and which of the two positions on the large one? (As I understand it, traction also depends on this).

Answer: There are two streams for the speed of the walk-behind tractor. Third power take-off shaft for attachments. The clutch is adjustable only on the handle. Most likely the cable spring is stretched. Alternatively, buy a new cable. Yes, you understand correctly when the speed increases, the traction disappears.

Question: Please recommend an engine for the Neva MB-2b 6.5 pro walk-behind tractor, except for the unnamed Chinese ones, otherwise they have a power indicated on the body that does not correspond to reality. Did you like the Brigss&Stratton engines, how are they reliable and fuel consumption?

Answer: Today I just put into operation my walk-behind tractor with a Brigg Stratton engine. The reality lived up to my wishes, I am very pleased. I won’t say anything about reliability and consumption yet, but when I was choosing, the advantage in comparison with the subarik was that they talk about unpretentiousness to fuel (of course, everything is relative, but still).

___________________________________________________________________________

Important

“If you want to connect a new printer to your computer and you don’t have a 12-year-old child at hand, then most likely you will suffer all weekend” (c) Scott McNeil, President of SUN Microsystems

It's time to plow. I rolled out my Meccanica Benassi MF 223 walk-behind tractor, checked the oil, filled it with gas, and tried to start it. Children gathered nearby and watched. The last time I started the walk-behind tractor was a year ago, only a few times and I already forgot how to do it. I read the section of the instructions for the Subaru Robin EX17 “Starting the engine” and follow it:

Installed. "2. ..."

But the engine won't start.

I read the instructions again and try to start it:

"1. Set the engine switch to position "I" (ON). See figure..." Checked, installed. "2. ..."

The engine will not start.

What's the matter? It should start. A year ago it started 2-3 times.

I read the instructions, fortunately, they are small, only a dozen pages in small handwriting. And it says “If you do not intend to use the engine for more than 1 month, drain the fuel in order to prevent the formation of tar in the fuel system and on carburetor parts.” And I,..., a year ago I didn’t drain the fuel and now... But better late than never. I unscrewed the special screw at the bottom of the carburetor and drained the gasoline. Since it began to smell strongly of gasoline, I drove the children away. Filled with fresh gasoline. I'm trying to start it. I already know the “Starting the Engine” section by heart:

"1. Set the engine switch to position "I" (ON). See figure..." Checked, installed. "2. ..."

But the engine won't start. What is it?

I read in the instructions about the fuel sump, which needs to be checked regularly. I found it, unscrewed it, and it was clean.

Maybe I’m weakened from winter physical inactivity and tugging weakly? I began to pull more energetically, but the engine would not start, and my back began to hurt.

A year ago everything worked without problems, I flew only 2 hours. Wintered in a cold room, but under a canopy, almost no traces of rust. Everything should work. But the engine won't start. Taking it to service is problematic. Service in Kyiv. The walk-behind tractor will not fit into my car. Ordering a gazelle 2 times to take it away and bring it back is expensive. You need to remove the engine. I really don't want to take it apart.

This is Monica Bellucci Meccanica Benassi - the most reliable walk-behind tractor. It costs so much that it’s scary to remember (and with each jerk of the starter it gets worse) and it’s a shame to say. Engine Subaru Robin EX17 - written Made in It was not made by our guys - it must work. But it won't start. The children periodically ask to come closer, but it stinks of gasoline, and I don’t allow it.

I have never had to repair gasoline engines. I am studying the “Troubleshooting” section of the instructions. They write there that you need to check the spark at the spark plug. To do this, you need to unscrew the spark plug, but it sits deep, and you can’t unscrew it with a regular socket wrench. The lids on both sides get in the way. I really don’t want to take it apart!

I took off the trigger cover, but still couldn’t get to the spark plug. I took off the cover on the other side of the spark plug, the timing belt appeared under it, but I still couldn’t get to the spark plug. You need a 21 socket wrench, but not an ordinary one, but an extended one. I remembered that the gas generator included something similar. Eureka! Key for the candle! I unscrewed the spark plug. The instructions say that the distance between the electrodes in the spark plugs should be 0.6-0.7 mm, but mine is more than 1 mm. I corrected it, screwed in the spark plug, and screwed the caps back on. I try to start it, but it won't start.

I unscrew the spark plug and there are no traces of gasoline visible. Either there is no gas supply, or this is how it should be. I put the spark plug to the body, I start it - there is no spark. This means the power supply is not working. What's the matter? I carefully study the electrical wiring. Eureka! That's the problem! The contact that goes from the switch to the body does not fit well to it.

Corrected. I try to start it, but it won't start.

What to do? It seems like a primitive device, cannot be compared with the MIG-25 PDS. And everything should work. It’s not like I, a giant of thought,… won’t be able to start it. What am I doing wrong? I really don’t want to take it apart! But if I don’t start it, I’ll have to remove the engine and take it to Kyiv for service. I really don’t want to take it apart! And time goes by.

The former young technician, “the one who sits inside me” (c), says: “It’s interesting to see what’s inside.” But the former aircraft mechanic, “the one who sits in me” (c), says: “In order for the technology not to let the technology down, the technician needs to meddle less with the equipment.” And the former typewriter repair mechanic, “the one who sits in me” (c), says: “After assembly, you will still have extra parts. The guys at the service center, which you still have to take to, will swear a lot. Surely the fault will be found quickly, and then they will correct your work.” And the former mechanical engineer, “the one who sits in me” (c), says: “Well, what do you care about the Japanese. If what they put together doesn't work..." And a former graduate of the Department of Production Organization, “the one who sits in me” (c), says: “You have already spent 3 hours. And the effect? How much more are you going to spend?”

The children ask to come over again. Gasoline hardly stinks, and I allow it. My 9-year-old son comes up, points to the steering wheel and asks: “Why is it turned off?” I look at the steering wheel, and there is a second button for turning on the power of the electric motor, which I forgot about, and it is disabled! “@#%&%#@*@%#%#@*@*@%#%@#%&%#@*@%#%#@*@!” - thought Stirlitz. I turn it on. The engine started with one jerk.

The fact is that the walk-behind tractor comes with 2 manuals: for the Subaru Robin EX17 engine and for the Meccanica Benassi MF 223 walk-behind tractor. In the instructions for the Subaru Robin EX17 they write “Install the engine switch...”, which is located on the engine. And it is clear that there is not a word about the second switch. But the instructions for the Meccanica Benassi MF 223 walk-behind tractor say nothing about starting the engine. Last year I was studying all the switches on the steering wheel and this switch turned on, but today I didn’t look there. And my little one has had a lot of electric toys, and he knows what “On” and “Off” mean.

04/29/2013

© Vitaly Vorobiev

A mini-tractor is considered a functional device. It is indispensable for farming. Attachable special equipment makes it possible to carry out cultivating the territory, mowing grass, removing snow, transporting goods, planting and harvesting crops. Often a situation arises when the walk-behind tractor does not start. The owner must establish the cause of the failure and eliminate the damage.

Possible reasons

Does the walk-behind tractor start and stall? Why is this happening? There may be several reasons why a motorcycle does not start when starting. These include:

- damage to the carburetor (in units with a gasoline engine);

- defective ignition and glow devices;

- low level of basic lubricant.

When unusual changes occur in the unit and its operation becomes unstable, the carburetor is checked first. In this essential unit, the formation of the fuel-air mixture (FA) and its dosage for supply to the cylinders of the internal combustion engine (ICE) take place. And if the jets become clogged

, there is an obstruction in the fuel system, due to which the carburetor loses its ability to guarantee engine starting. In order to eliminate the defect, the fuel line is repaired, which involves a partial analysis of the carburetor, flushing the pump, and purging the nozzles through the fuel fitting.

If the Neva walk-behind tractor does not start, the reasons may also be different. Sometimes the problem is hidden in a malfunction of the spark plugs, which play an important role in starting a carburetor internal combustion engine, or the glow plugs, which ensure the start of a diesel engine. If the igniter devices become wet, which happens due to fuel assemblies being thrown into them, the spark begins to disappear in them. In the absence of sparking, the fuel-air mixture is not ignited and, therefore, the engine cannot be started.

This problem can be solved in various ways:

- carry out minor repairs and replace non-working spark plugs with new ones;

- “burn” the flooded candles and use a flame to clean them of traces of fuel.

The equipment does not start due to a defect in the glow plugs. In a diesel engine, fuel is ignited by contact with hot air, which is heated in the cylinder when compressed by the piston. This occurs without complications if the unit is already heated and the operating temperature in it is maintained by the heated walls of the cylinder. However, in cool weather, the engine is heated using incandescent devices, and if they break, it will not be possible to start the walk-behind tractor.

If, upon inspection of a carburetor engine or diesel engine, no defective spark plugs were identified, but difficulties persist, and are also accompanied by popping noises in the muffler, it is necessary to check the functionality of absolutely all devices responsible for the flammability of fuel. A defect in them may also be a reason that the walk-behind tractor does not start. It is more correct to carry out diagnostics in a service center, where specialists will find the cause of the damage and carry out professional restoration.

Motor vehicles will not start even if there is a lack of lubricant in the engine. Certain modifications are equipped with special control sensors, which, if there is a lack of lubrication, prevent the engine from starting. Particular attention should be paid to those machine variants that do not have such meters. Sooner or later, the degree of the lubricant mixture will reach its limit value, and if it is not compensated to the norm, this will soon lead to wear of the elements and, as a result, to a major overhaul of the engine.

Walk-behind tractor ignition system: how to set the ignition yourself

One of the main components in the design of a walk-behind tractor is the ignition system. It is responsible for the formation of the spark required to instantly ignite the fuel mixture. The ignition system of a modern walk-behind tractor has a fairly simple design, which allows you to configure or repair the unit yourself. However, for this you need to follow the correct procedure, otherwise there will be a high risk of damage to system parts.

Untimely adjustment of this unit will lead to accelerated wear of other, no less important mechanisms of the agricultural machine.

In order to be able to independently adjust the ignition system on a diesel walk-behind tractor and its gasoline counterpart, you need to study the design diagrams of this unit. A properly configured walk-behind tractor ignition system is capable of creating a spark in the right place and at the right moment. In this case, the magneto cover is responsible for distributing the resulting spark, and its lower part is responsible for interrupting the spark.

In order for the ignition system to work exactly according to this principle, it must be adjusted. The performed ignition adjustment will speed up the start of the walk-behind tractor engine and make it smoother, which will lead to slower wear of the piston group and other important elements of the engine of an agricultural machine.

This is one of the typical malfunctions of the ignition system of a walk-behind tractor. The most common reasons for this are the formation of carbon deposits on the spark plug or its breakdown. In this case, you should unscrew the spark plug and carefully inspect its side and central electrodes.

If the spark plug is covered with soot formed as a result of flooding the part with the fuel mixture, then cleaning the spark plug alone will not be enough - you will need to check the pipes of the fuel system of the walk-behind tractor for leaks. Examples of cases of a spark plug heavily contaminated with fuel are clearly visible in the photo. If the spark is lost, then in any case you will need to thoroughly clean the spark plug.

To do this, it is best to heat it over a gas burner, and then scrape off the dried fuel from the surface. After cleaning the part, put a tip on its upper part and bring it to the motor block motor housing. The spark plug must be held so that its electrode is approximately 1 millimeter from the engine housing.

If the spark plug is fully operational, a spark will form in its lower part, which will jump out and hit the motor housing. A blade should be placed between them, and if it fits tightly between the two electrodes, then the gap has optimal dimensions. If the blade is loose, you will need to tap the back of the central electrode with any hard object. As a result of this, it will move, after which you need to try to start the walk-behind tractor engine again.

Another important element of the walk-behind tractor ignition system is the magneto. If a unit malfunctions, it can also be carefully inspected for operability.

Checking the magneto of a walk-behind tractor is quite simple. To do this, you need to clean the spark plug from the carbon deposits that have accumulated on its surface and make sure that it is in good working order. Then a cap with a working drive is put on the spark plug. Next, the lower part of the spark plug must be brought to the magneto housing, and begin to rotate the flywheel located in the motor with your fingers.

If a spark does not appear in the magneto on the walk-behind tractor, it means that the element has failed. In this case, it will be necessary to replace the magneto of the ignition system of the walk-behind tractor in order to prevent wear and tear on other mechanisms of the unit.

The ignition coil should be checked and, if necessary, repaired according to the same principle as the magneto of a walk-behind tractor. Signs that the ignition coil of a walk-behind tractor has failed are indicated by the following factors:. In any of these cases, you will need to carefully inspect the ignition coil of the walk-behind tractor.

To do this, it is best to completely dismantle it. To do this, first unscrew the mounting bolts and remove the top cover of the ignition system housing. Then you will need to disconnect the high-voltage wire and, carefully prying the coil, remove it from the housing. After this, you need to carefully inspect the part for signs of melting - if black spots are visible on the coil, then, most likely, the current it creates did not reach the spark plug, as a result of which the ignition coil itself succumbed to voltage.

Farmers whose walk-behind tractors have contactless ignition are especially often faced with this problem. The reason that the current did not reach the spark plug was poor contacts on the high-voltage wire. In this case, repairing the walk-behind tractor ignition comes down to stripping the wires or completely replacing them. In walk-behind tractors where an electronic ignition system is installed, in the event of a breakdown, the wire is automatically turned off due to the presence of a special fuse. In agricultural machines with other types of ignition systems, it is necessary to disconnect the wire manually if it breaks.

In order to avoid the need to repair the ignition system of a walk-behind tractor, you need to follow a number of simple rules. Compliance with them will extend the life of the unit and save time and money for the equipment owner. By adhering to these simple rules, the owner of a walk-behind tractor will increase the working life of the ignition system and other important parts and mechanisms of his unit.

Setting up and repairing the unit is performed in the same order for each of the listed agricultural units. The ignition system in a walk-behind tractor is one of the most important elements of an agricultural machine, the function of which is to generate the spark required to ignite the fuel mixture. From time to time, the owners of the unit have to repair the ignition of the walk-behind tractor.

This may be due to improper operation or simple wear and tear of the main elements of the unit. In any case, the faster the malfunction can be eliminated, the less other parts and mechanisms of the walk-behind tractor will suffer from the breakdown. If, in order to start the walk-behind tractor, you need to pull the starter cable for a very long time, or you notice that the unit’s engine starts with some delay, then most likely you will need to adjust the ignition system of your agricultural machine.

The operating instructions for the unit will help you do this correctly. If it is not there, then the ignition adjustment should be performed in the following order:. Installing the ignition of a walk-behind tractor performed in this way takes no more than 20 minutes. By completing this simple procedure in a timely manner, you will protect the remaining mechanisms of the walk-behind tractor from increased load and excessive wear. Quite often, the spark plug suffers from oversaturation of the fuel mixture with engine oil, which gets onto the surface of the part, preventing it from forming a spark.

This kind of procedure is carried out in a similar way, both on a diesel walk-behind tractor and on a unit with a gasoline engine. The main thing when working is to carefully remove carbon deposits at the top of the part so as not to break the expensive part. The magneto on the walk-behind tractor plays the same role as the ignition coil of the unit and serves to generate a spark.

To check the magneto of a walk-behind tractor, you must adhere to the following algorithm of actions:. By following all the listed tips for setting up the ignition system of a walk-behind tractor and checking the serviceability of its main components, you will be able to carry out repairs yourself, saving on visiting a specialist. This article will discuss the design, repair and maintenance of the OKA walk-behind tractor.

This motorized device has been produced for a year at the Kaluga Motor Plant under the name Motoblock MB. Its purpose is to carry out all types of agricultural work on small and medium-sized plots of land with different types of soil. Functional attachments, presented in the assortment by the manufacturer KaDvi, significantly expand the capabilities of the walk-behind tractor.

When purchasing any Oka model, the first thing you need to do is read the operating instructions for the motorized device, which contains the following sections: It is necessary to start the engine correctly, according to the algorithm specified in the instructions.

If certain actions are not followed, there is a high risk of engine failure. We invite you to watch a short video on how to start the Oka walk-behind tractor: The walk-behind gearbox transmits torque from the engine to the wheel drive. Its design is as follows:. It is best to use a collapsible chain gearbox, which consists of a collapsible housing with bolted connections. Unlike a non-separable gearbox, such a mechanism can be easily repaired and will last for many years.

A gear reducer can be installed on more powerful equipment; a worm gearbox is rarely practiced in walk-behind tractors. Carburetors are gas distribution devices inherent in gasoline engines. The function of the carburetor is as follows:. Before starting field work, it is necessary to break in the engine to avoid damage to moving parts and mechanisms.

Proper running-in of the Oka walk-behind tractor engine begins immediately after the first start and lasts more than 30 hours. Tillage should also be carried out in a gentle manner - in several passes with a depth of no more than 10 cm in one pass. After the break-in period of hours worked in a gentle mode, it is necessary to completely drain the used oil and fill it with fresh oil into the engine crankcase. The first replacement is made after running in the walk-behind tractor. After every 25 operating hours, the oil level in the gearbox is checked and fluid is added if necessary.

Scheduled inspections must be carried out after the first and engine hours; it is recommended to completely change the oils, both in the engine crankcase, gearbox, and transmission. The instructions included with the Oka walk-behind tractor contain a table that lists all possible problems, but we will focus on the most common ones:

We suggest watching a video on how to change the bearing and replace the oil seal on the gearbox of an Oka walk-behind tractor:. In order to perform the replacement, it is necessary to determine what size drive belt is required for the Oka walk-behind tractor.

The following drive belts are available for sale:. The new belt should not sag, nor should it be under strong tension. Correct tension is when the belt bends slightly when pressed with your hand.

One way to upgrade is to install headlights. Making light on an Oka walk-behind tractor is not that difficult; you just need to find and connect a generator of the required power to the unit. The connection algorithm is as follows:. The more powerful the generator, the brighter the light will be; many people prefer to install automobile electric generators on this agricultural equipment.

We invite you to watch a video on how to install the light on the Oka walk-behind tractor yourself: Installation, repair, maintenance of OKA walk-behind tractor.

Operating Instructions Link to main publication. The ignition system of a walk-behind tractor is an important element of an agricultural unit. Its task is to form a spark to ignite the fuel.

Preparing the walk-behind tractor for start-up

Difficulties with starting the engine can appear not only in used walk-behind tractors and cultivators, but also in new ones just purchased at the shopping center. For this reason, before starting a mini-tractor for the first time, you should read its instructions, then carefully examine all connections and, of course, check the oil level in the internal combustion engine.

You should study the annotation compiled by the manufacturer in order to find out what operating speed the engine has: four-stroke or two-stroke. This is important to understand, since modifications with a two-stroke engine (like the Mole cultivator) require a special combustible mixture, consisting of a mixture of fuel and oil in a special proportion.

Due to the mismatch of fuel, the special equipment will make noise, and the spark plugs and fuel line may also be damaged, which can lead to fuel pump failure, and this is a direct path to expensive repairs at a service station. Determine whether the fuel is suitable for the motorcycle

, you can by the smoke that appears. If the quality of the fuel is poor, it will have a white tone, as happens when the car is tilted too much.

Fuel quality is also important for a diesel walk-behind tractor. It does not start in winter - or it starts, but soon freezes - if summer diesel fuel is poured into its engine, since at low temperatures it begins to thicken and clog the fuel line.

The start-up of motor vehicles both in the summer and in the winter must be carried out in the established order. For example, to start a Krot brand motor cultivator, the following procedure is carried out:

- open the gas tap;

- set the suction motor to the “Choke” state;

- turn off the ignition and turn the engine several times with a manual starter;

- start the motor again and move the motor to the “Run” state.

Conditions often appear

when the power device starts easily, but freezes after a couple of seconds. In this case, you should check the permeability of the sump. If the reason is that the tap is clogged, then it is cleaned with gasoline.

Start a motorcycle with a diesel engine

it will be a little more difficult. Starting a diesel engine begins with “de-airing” the fuel path, that is, by ridding it of air accumulations. For this:

- open the fuel supply valve;

- untwist the connections of the outlet channel until fuel appears;

- twist the connections and blow through all the nozzles.

If after the operations the motor does not function properly, and the special equipment begins to smoke, then the reason is the old lubricant, and it must be completely changed. The unit does not start due to insufficient volume of oil fluid, so do not forget to control this parameter.

Starting a motor cultivator after winter

or prolonged downtime also has its own nuances. In order to bring the unit into working position, perform the following manipulations:

- open the gas tap;

- check whether the power is turned on;

- check the presence of lubricant;

- let the gas reach about half way.

Before putting the motorcycle into operation, all connections are checked, including transmission sections, clutch, starting mechanisms, and, if necessary, they are adjusted.

Failures, their causes and solutions

There may be several reasons why the walk-behind tractor does not start:

- The wire is broken;

- Insufficient fuel level;

- The fuel is not digested;

- Spark plug problems.

If you plan to find the cause of the breakdown yourself and fix it, follow these steps:

- Check the wires from the power button to the spark plug;

- The spark plug must be removed. The contact can be cleaned with sandpaper and at the same time checking the distance between the contacts;

- Secure the candle in place;

- Blow out the fuel supply system;

- If necessary, clean the fuel filter. It can become clogged, making it difficult to supply fuel to the combustion chamber.

A few more ways to “revive” your walk-behind tractor:

- If the starter cord comes out very easily, it may be due to a worn cylinder seal or gasket between the carburetor and an improperly installed filter.

- If the unit starts spinning but immediately stops, the cause may be poor permeability of the sump. Check the faucet and clean it. The fuel may also contain water, so the fuel must be completely changed.

- If you hear characteristic noises and flames coming out of the muffler, you need to check the flywheel key. It may be damaged or deformed. This needs to be replaced.

- If you notice that your walk-behind tractor is intermittently shutting down with a pop-up window, you should check the spark plug. If it is wet, replace it with a new one or clean it. To do this, rinse, think and burn.

Always choose only high-quality fuel and oil for your equipment. Otherwise, you may run into problems before the machine even breaks down. Finding a replacement for a damaged section for a Neva walk-behind tractor is not a problem, but it will cost money.

Source

Technological progress does not affect Bosch and agriculture. For anyone who works with the earth, there is a huge variety of equipment on sale that greatly simplifies the work and protects human health.

Walk-behind tractors are universal machines that can cope with any task - from plowing the land to planting and harvesting. There are a huge number of types on sale, divided by manufacturer, price category, and engine type.

READ Motoblock Agat Working With a Plow Video

In this article we will look at a situation where the Nevsky walk-behind tractor does not start for some reason. Over time, you will be able to determine the cause of the failure and quickly resolve it.

Starting a gasoline and diesel unit

The equipment is equipped with gasoline or diesel engines. Starting a diesel walk-behind tractor

and a gasoline device has differences. For this reason, it is necessary to analyze the factors due to which the unit does not start for each specific type of engine.

Before purchasing a walk-behind tractor

, preparing special equipment. It is necessary to make sure that absolutely all elements are present and to make sure that the mechanisms are securely fastened.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the walk-behind tractor systems. Storing in a cool and humid area will cause the following problems:

- oxidation of contacts;

- violation of wiring insulation;

- watering of fuel and oil;

- clogged carburetor jets.

Before launching a new walk-behind tractor

They control absolutely all connections, clutch cable, reverse and gas. Do not turn on the device if there are clamps or twisting of the harness threads.

During the first start-up, be sure to check the oil level in the crankcase. Lack of lubrication will damage the piston group. The crankshaft spins up to 1400 revolutions per minute at idle. It only takes a couple of seconds to create a scuff mark on the cylinder plane.

Old oil can cause the engine to not run. At the same time, the walk-behind tractor emits white exhaust gases. This begs for an absolute oil change.

It should be taken into account that the mini-tractor does not start easily if there is not enough oil. Keep an eye on this setting before

How to start a carburetor and diesel walk-behind tractor. In some modifications, protection is determined by a low level. The device blocks startup and the unit freezes.

It should be remembered that any type of engine requires a specific brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is kept in strict balance.

Design of the ignition system on a walk-behind tractor

Probably every person who is somehow connected with agriculture has encountered the fact that a walk-behind tractor starts up and immediately stalls. The video shows a problem due to which the engine did not want to run when the air damper was open. Now let's figure out what happens if the walk-behind tractor starts up poorly and stalls almost immediately. The most likely reason for this lies in the air filter, which is either dirty or has simply expired.

Ignition maintenance on a walk-behind tractor: causes of engine failure, spark plugs. If there is no spark, then the ignition coil has failed.

Mechanism repair

Starting a diesel engine after purchase can be difficult. The problem is that air gets into the fuel supply system. If cranking for a long time (with the starter) fails to start, it is necessary to release the air plugs. To do this, open the supply valve and unscrew the connections along the channels. The final point of purging is the injectors.

To start the internal combustion engine

, several conditions must be met. Let's list them in order:

- preparation of the mixture;

- delivery of fuel to the cylinder;

- ignition of the mixture;

- release of gases.

Fulfillment of the mentioned conditions ensures the start of any engine.

Ignition of walk-behind tractors

The start of any internal combustion engine is directly related to the ignition system. If it fails, the motor will not work. In order not to seek help from specialists and in order to save money, the owner of a walk-behind tractor must learn to set the ignition on his own. It is this that ensures timely ignition of the combustible mixture in the cylinder. This occurs at the moment of maximum compression of the piston, when the compression reaches its greatest density. At this time, the magneto supplies a spark through the spark plug into the combustion chamber, and the mixture ignites. If the walk-behind tractor's ignition system is faulty, the engine will not start. Sources of problems can be:. The engine may malfunction and shut down intermittently due to dirt accumulated on the spark plug cap.

Difficulty starting

Difficulties during startup indicate a malfunction of components and elements. The success of repair work depends on the accuracy of the diagnostics. If deficiencies are found, they repair the diesel walk-behind tractor. Service and minor repairs can be carried out on your own. You will need a set of keys, a locksmith mechanism and skillful hands.

At the fuel preparation stage, the following incidents are likely:

- a lightweight filter does not let air in;

- the hole in the tank lid is boarded up;

- the fuel supply channel is clogged;

- The carburetor broke down.

After a series of unsuccessful launches

It is advisable to unscrew the spark plug. The working part can be filled with fuel. In this case, we dry the element, then pump the cylinder through the hole. We twist the candle and start it again.

If the candle is dry, it means that fuel is not entering the combustion chamber. Let us perform several operations one by one to restore the supply system:

- drain old gasoline;

- wash the tank;

- clean the special filter from dirt;

- clean the fuel supply hose;

- clean the carburetor jets;

- fill the tank with the cleanest fuel;

- open the tap;

- Clean the breathing channel in the tire.

Ignition system malfunctions

The engine will not start if it breaks down

in the ignition system. Why is this happening? Sources of interruption may be the generator, high-voltage cable, cap and spark plug. An external inspection is necessary to check the cleanliness of the ignition system elements. Dirt and moisture serve as a prerequisite for high force breakdown on the body. A lack of spark occurs when the cap does not make proper contact with the main electrode of the spark plug.

A weak spark indicates poor spark plug performance. The gap and type of electrodes should be checked. The gap is usually checked with a feeler gauge. As a rule, the figure is 0.8 millimeters. If necessary, remove fumes from metal elements and insulators. It is recommended to change the spark plug.

The condition of the piston category elements affects the readiness of the engine as a whole. They operate in difficult circumstances. Under loading, the rubbing surfaces heat up. The cylinder, valve and rings are responsible for a significant indicator - compression. A low compression ratio in the cylinder will indicate replacement of elements.

It is also necessary to check the intake and exhaust valves. They should be close to the saddles. The muffler is the last point on the gas path. Over time, combustion products are deposited in the walls of the muffler, and the engine freezes. For a standard passage of exhaust gases, it is necessary to clean the walls of carbon deposits from time to time.

Buy gasoline for walk-behind tractors at gas stations. The operating period of the machines directly depends on the properties of the fuel. There is no need to start the walk-behind tractor on bad fuel.

In this topic, we will analyze the malfunctions of walk-behind tractors and cultivators of all brands. Neva, Zubr, etc., and their elimination and repair. Most problems are typical for all types of walk-behind tractors, their engines and other components.

There is no spark on the walk-behind tractor - let’s look into the problem

Another common reason that a walk-behind tractor will not start is due to a problem with the unit’s ignition system. Faults may be hidden in the cap, magneto, spark plug or high-voltage wire of an agricultural machine.

When inspecting the ignition system, first of all you need to carefully check each part for blockages. If the spark is lost, the reason for this is often moisture or dirt getting on the elements of the ignition system. Also, often an agricultural machine does not start due to the inability to form a spark - the reason for this is poor contact between the central electrode and the spark plug cap.

If you do not find dirt or moisture in the ignition system, and the walk-behind tractor does not start, then be sure to check the integrity of the electrodes and the gap between them.

As a rule, a special probe is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove carbon deposits from the insulator and metal elements of the ignition system. If the unit does not start, and none of the above procedures helped, then you will need to replace the spark plug of the walk-behind tractor. The cost of replacement parts is low, but when purchasing, we advise you to give preference to more expensive spark plugs - they will last many times longer than their cheaper counterparts. All of the methods listed are suitable for repairing motoblocks Krot, Neva MB-1 and MB-2, as well as Cascade, Zubr, Agro and Salyut.

Engine power has dropped

It often happens that a previously serviceable walk-behind tractor, which has served for several years, suddenly loses power.

— If the power has dropped after long-term storage

, perhaps the walk-behind tractor was stored with a wet carburetor and fuel system, which led to deposits. In this case, you can start the engine and let it run, often after these actions the power is restored. If you have the skills, you can disassemble and clean it; if you don’t have the skills, it’s better to contact the service.

— The carburetor may be clogged

. Clean

— Fuel hose is clogged

. Need to blow it out.

— Possible loss of performance of the crankcase cuff

. Remove the casing and gearbox cover and inspect the cuff.

— Carbon deposits on the cylinder, muffler

. Clean.

— The air filter is clogged

. Clean.

— No compression

. Change piston rings, cylinder, piston.

Engine won't start

- If the engine is tilted

, must be placed horizontally.

— Fuel may not be supplied to the carburetor

. The fuel system needs to be disassembled and purged with air.

— The filter may be clogged

. The filter needs to be replaced or cleaned.

— The outlet hole in the gas tank cap may be clogged

. Needs cleaning.

- Perhaps it's the candle

. You need to check the connection of the wires, the engine stop buttons, remove the spark plug and clean it. Replace if necessary.

— Possible magneto failure

. Replace.

Why the walk-behind tractor does not start - we understand the reasons

Before the start of the season, it is necessary to prepare both gasoline and diesel walk-behind tractors. To do this, the owner of the device must make sure that the design of the device has all the necessary parts for operation, and each of them “sits” tightly in its usual place.

Often, many walk-behind tractors equipped with a Subaru engine or engines of other well-known brands refuse to work after a long winter period of inactivity. At the same time, improper storage conditions for an agricultural machine also affect it - if it was parked in a cold, damp room, it is likely that it will not start before spring work begins. This is due to a number of problems:

- Oxidation of contacts in electrical wiring;

- Violation of the integrity of the wiring insulation;

- Watering oil and fuel;

- Debris accumulation in carburetor injectors.

Before starting the walk-behind tractor, its owner must carefully check all the connections that are provided in the design of the device. It is necessary to check the movement of the gas cables, reverse gear and traction - it should be soft. If during inspection you find clamps or twisted cables, you will not be able to start the walk-behind tractor.

Before starting the walk-behind tractor for the first time, check the oil level inside the crankcase. If there is no oil, it will seriously damage the piston group. Judge for yourself: at a crankshaft speed of 1400 rpm, a second is enough to form several burrs on the surface of the cylinder.

Oil left over for the winter is one of the main reasons for unstable engine operation. To verify that an off-road tractor is bad for this reason, it is quite simple - after starting, white smoke will come out of the vehicle's exhaust pipe for a few seconds, after which the unit will lag. Do not forget that both a diesel engine and a gasoline walk-behind tractor start poorly due to lack of oil. Some unit models are equipped with low level protection; Owners of other cars must independently control the amount of oil inside the tank.

READ What kind of oil to pour into the gearbox of a walk-behind tractor

Another important factor is the gasoline you use to fuel your walk-behind tractor. If you regularly fill up with the wrong brand of fuel recommended by your vehicle's manufacturer, this may also prevent your vehicle from starting.

The starter squeals, the cord comes out

It may squeal if there is a lot of grease on the balls. You need to clean the balls and the places in the ratchet where they are inserted.

The cultivator made several pops, the speed began to “float”

Most likely, the power system cannot cope, or the fuel level in the tank is low, the float axis may be skewed and debris may have gotten under the needle valve, you need to remove everything and check the air filter and jets.

The material will be updated, we are waiting for comments with questions, stories about identifying a particular malfunction and ways to eliminate it. Also, see the answers to questions about a particular walk-behind tractor model on its description page.

Why won't the walk-behind tractor start?

First of all, you need to check the availability of all the necessary spare parts and components, especially if the walk-behind tractor is new or, conversely, has not been used for a long time. Before starting, carefully check all fasteners, connections and cables and their movement. Make sure there is oil in the crankcase and sufficient fuel level in the tank. Do not start the walk-behind tractor if the movement of the cables is difficult - this may indicate twisting of the harness threads. After a winter holiday, the most common reasons for the failure to start the walk-behind tractor are oxidized contacts, damaged wiring insulation, and deterioration in the quality of fuel and oil during inactivity.

Also, common reasons that the walk-behind tractor does not start well include:

- breakdown and/or clogging of the carburetor and its components;

- malfunctions in the ignition system (the most common breakdown);

- low level of lubrication or its complete absence in the gearbox;

- problems with the cylinder.