General parameters of LBU-50 drilling rigs

The drilling machine is equipped with a mechanical drive. The equipment is mainly used for wells:

- used in the construction of a wide variety of objects;

- having a technical purpose;

- geological developments;

- designed for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool experiences enormous pressure from a special device;

- during drilling, the rotator can be tilted away from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing columns;

- The machine allows you to drill holes using the cable-percussion method, while simultaneously using a winch.

A minor disadvantage of drilling equipment is that it is driven by a motor from the transport base.

The LBU 50 drilling rig has the following serial models: 05, 07, 08, 10, 20.

The following can be used as optimal mobile bases:

- ZIL-131;

- URAL;

- KamAZ.

Photo of the LBU-50 drilling rig on a KamAZ chassis

With the drilling system you can do the following:

- make holes with augers up to 500 mm in size;

- form pits up to 850 mm;

- make wells using the rotary impact method with a diameter of 550 mm;

- drill holes using the flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

How auger well drilling is performed

Drilling a well with an auger

Auger drilling is very often used to create water wells. The process of such drilling consists of crushing and sampling the soil. An auger is used as a tool for drilling wells. The hard rock is destroyed during the work with a special cutter and then removed using an auger to the ground surface. The article discusses the issues of do-it-yourself drilling.

Types of well drilling

You can drill a water well on a personal plot or summer cottage using one of the following types:

The listed drilling technologies differ from each other in the methods of rock destruction and methods of extracting soil structures from the shaft. In each case, certain equipment is used, which affects the quality differently, which determines the final price of the work. Each method of the process can be seen in the video. This article discusses in more detail the issues of drilling wells using the auger method, and the features that an auger well pump has.

What is auger drilling

The essence of the process is to destroy the rock with a chisel, followed by its delivery to the surface using an auger screw that rotates at high frequency. This method is used in the presence of rock of low hardness and without flushing the well. Features of the process:

- When auger drilling, a high speed of work is ensured without grinding and abrasion of the rock that has already been separated from the bottom.

- The face is cleaned continuously, simultaneously with the destruction of the rock.

- When separated from the face, the rock is fed to a screw auger, which rotates at high speed. The centrifugal forces that arise press it against the walls, and a constantly moving screw belt lifts the rock upward. In this case, part of the rock is rubbed into the walls using the flange of the tape.

- With this process, the face is well cleaned of destroyed rock. This ensures high drilling speeds up to category IV rocks in terms of drillability.

- High mechanical speed is ensured when passing through weak cemented deposits of small pebbles and crushed stone. This is due to the fact that the latter are not destroyed, but are brought to the surface entirely.

- The auger conveyor does not work well in viscous clays that stick to the augers and prevent the transportation of drilled rock.

- The bit and augers are cooled due to their rapid penetration into soft rocks with constantly changing temperatures.

- Auger drilling can be done to depths from 1.5 to 80 meters.

- This process is used for drilling exploratory and engineering-geological wells, during hydrogeological studies in combination with other methods.

Advantages of auger drilling in soft rocks:

- High deepening speed.

- Rock transportation is carried out without lifting the tool, continuously.

- Drilling can be done without flushing.

Disadvantages of the process:

- Relatively shallow drilling depth.

- Rotating a heavy screw column requires more power.

The design of the auger drilling tool includes:

- Bit.

- Auger drill collar.

- Column of augers.

Well drilling tool

Advice: To increase the service life of the bit, it must be reinforced with carbide cutters. The diameter of the bit must be 15-20 mm larger than the diameter of the auger for free rotation of the auger column in the well, due to the fact that a slurry crust forms on its walls.

The most popular are two- and three-blade chisels. The body of a three-bladed bit is made of steel casting with serrated blades inclined along a helix. Carbide octagonal cutters reinforce the blades.

Machines for screw installations

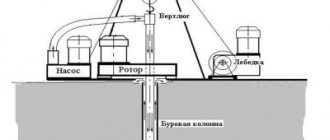

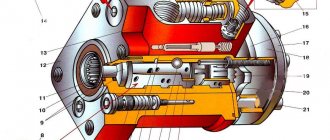

The rotation of the working tool on the screw installation is carried out by special machines. Thus, auger drilling of wells using machines of the LBU 50 type is provided by a movable rotator, which eliminates the use of spindle and rotor type devices. This is necessary to provide high torque and carry out translational axial movement of the screws. To ensure high speed, machines must be powerful, highly productive and have sufficient mobility.

To do this, they are often installed on the chassis of tractors or cars, as shown in the photo.

Well drilling rig

Auger drilling of wells using CO 2 type machines is carried out with a mounted working body. The CO 2 installation is installed on an E-1252 type excavator. On it:

- Using a hinged device, a stand is attached to which a hinged working element is movably connected, including a carriage with an electric drive.

- A telescopic auger drill string with a drilling tool and a cleaner is installed on the shaft of the device.

- The column consists of two telescopic sections; auger blades are mounted on the bottom.

- The reamer or auger with a drill bit is pinned to the bottom section of the column.

The purpose of the drill bit, which has the shape of a three-blade bit that rotates, is to destroy the soil in the bottom and feed it to the drill string auger. For different soils, a set of crowns is included with the installation.

Tip: To hold the drill string when switching telescopic rods, you need to use an interception lever from two levers.

With this device you can drill to a depth of up to 70 meters, and the use of an expansion tool allows you to increase its diameter to two meters.

Screw pumps for wells

Auger pumps for wells are widely used, operating on the same principle as drilling installations - supplying water to the surface using an auger.

Screw pump for wells

A downhole auger pump, unlike others, can pump liquids containing abrasive particles and aggressive chemical elements. Work equally well in vertical and horizontal positions. They are distinguished by their reliability and simplicity of design, the price of the units is acceptable for use on any site.

Screw submersible pumps for wells have several important features:

- Convenient design. The attached instructions allow you to operate the device without any problems and, if necessary, carry out repairs.

- During repairs, the pump can be easily dismantled; all wear parts can be easily replaced with new ones.

- The design of the product is carefully worked out. There is no possibility of deposits on the suction body, and the suction pipe can be rotated 90 degrees.

- There is no vibration, which leads to increased service life.

The Russian company Geomash has earned credibility and popularity thanks to its reliable instruments for drilling wells. The head office of the plant is based in Moscow, and production lines are in the Kursk region.

The drilling machine is equipped with a mechanical drive. The equipment is mainly used for wells:

- used in the construction of a wide variety of objects;

- having a technical purpose;

- geological developments;

- designed for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool experiences enormous pressure from a special device;

- during drilling, the rotator can be tilted away from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing columns;

- The machine allows you to drill holes using the cable-percussion method, while simultaneously using a winch.

A minor disadvantage of drilling equipment is that it is driven by a motor from the transport base.

The LBU 50 drilling rig has the following serial models: 05, 07, 08, 10, 20.

The following can be used as optimal mobile bases:

- ZIL-131;

- URAL;

- KamAZ.

Photo of the LBU-50 drilling rig on a KamAZ chassis

With the drilling system you can do the following:

- make holes with augers up to 500 mm in size;

- form pits up to 850 mm;

- make wells using the rotary impact method with a diameter of 550 mm;

- drill holes using the flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

Design features

The machine is equipped with a mechanical drive device and a rotator, and the feed structure is driven by a mast, which is the guiding force.

The mast has a transport and working position. They are changed by hydraulic cylinders. The mast is also equipped with a single string rig, which is located at the top.

To provide mobile drilling rigs with stability and balance, the machine is equipped with hydraulic jacks.

The drilling device has powerful headlights, thanks to which it remains operational in the dark. The entire system is controlled using reliable remote controls, which are located on the mast structure and on the frame. It is also important to create comfortable working conditions for the installation driver. For these purposes, the structure is equipped with a convenient removable platform.

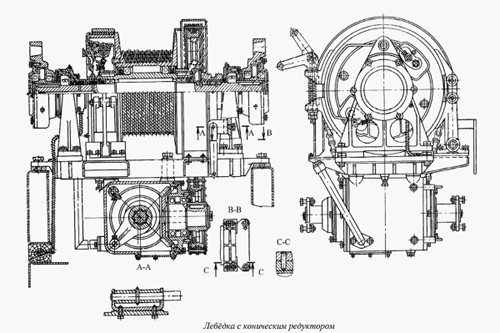

Drawing of the LBU-50 drilling rig winch

Basic equipment

In the basic version, the installation is equipped with the following equipment:

| Device | Unit measurements | Data |

| Drills with augers | mm | 135, 180, 230, 300, 330, 350, 400, 500 |

| Equal augers | mm | 200, 320, 470 |

| Augers with removable chisel | mm | 300 |

| Augers with sliding chisel | mm | 350 |

| Breaking Projectiles | mm | 121 |

| Set for shock-rope work: | ||

| — blow.-driving glass | mm | 89 |

| - impact-driving cartridge | mm | 108 |

| - casing system | mm | 127 |

| Dry working kit | ||

| Column device | model | SKS-127 |

| Blowing kit | ||

| Device for flushing work | ||

| Devices for continuous technology | ||

| Boers | mm | 650, 850 |

| Sliding augers | mm | 650, 850 |

| Pneumatic plunge hammers | mm | 550 |

Additional equipment for forming well systems

The installation is designed, if necessary, to work with the following equipment:

| Tool | Model |

| Pump | NB-50 |

| Compressors | PK-50 |

| Generators for welding | 500 |

| Two hydraulic jacks | |

| Winch | |

| Balance | |

| Desktop | |

| Casing table |

Modifications

The technology for forming wells has several modifications:

| Equipment | 20 and 05 | 07 | 08 | 10 |

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump | — | + | — | — |

| Compressor | — | — | + | — |

| Generator | — | + | Optional | + |

| Front jacks | — | + | + | + |

| Rear jacks | + | + | + | + |

| Additional rear jacks | — | + | + | + |

| Loading platform | + | + | + | + |

| Driver's platform | — | + | + | + |

| Swivel | — | + | + | — |

| Clamping table | — | + | Optional | — |

| Desktop | — | Optional | + | + |

| The basis | ZIL, URAL, KAMAZ | KamAZ | KamAZ | KamAZ |

Photo of modification LBU-50-08

Technical characteristics of the LBU-50 drilling rig are presented in the table:

| Characteristics | Unit measurements | Indicators |

| Drive power | kW | 95-165 (depending on the chassis) |

| Innings | m | 3,25-3,9* |

| Top feed | kgf | 12000 |

| Bottom feed | kgf | 4000 |

| Frequency spindle | rpm | 14-101, 14-220* |

| Torque | kgm | 2000 |

| Load capacity of winch device | kgf | 2500 |

| Well depth | m | 16-200 (depending on drilling method) |

| Diameter of formed holes | mm | 190.5-850 (depending on drilling method) |

* - depends on the installation model

LBU-50

The LBU 50 multi-purpose drilling rig with a mechanical drive of a movable rotator is designed for drilling wells for various purposes when performing construction work, technical, hydrogeological and water supply wells, during engineering surveys and geological exploration work.

The LBU-50 drive is carried out from the transport base engine through the power take-off (PTO).

LBU-50 is mounted on the chassis of various trucks, including AMUR (ZIL-131), URAL, KamAZ.

A movable rotator with a mechanical drive in combination with a powerful hydraulic feed mechanism makes it possible to create a significant axial load on the rock cutting tool from the first meters of drilling.

The design of the LBU 50 rotator makes it possible to move it away from the well axis to perform tripping operations, installing casing strings and implementing cable-percussion drilling technology using a drawworks.

SPECIFICATIONS:

| Feed stroke, m | 3,25 — 3,9* |

| Feed force, kgf | |

| - up | 12 000 |

| - down | 4 000 |

| Spindle speed, rpm | 14 — 101; 14 — 220* |

| Torque, kgm | 2 000 |

| Winch load capacity, kgf | 2 500 |

| Conditional drilling depth, m | |

| — augers | 60 |

| - auger drill | 25 |

| - auger drill sliding along the rods | 16 |

| - with flushing | 200 |

| — with purging | 100** |

| Drilling diameter, max., mm | |

| — augers | 500 |

| - auger drill | 1 050 |

| — with flushing (final) | 190,5 |

| — with purging (final) | 190,5 |

| — down-the-hole hammers | up to 550 |

* - depending on the modification ** - limited by the parameters of the compressor

MODIFICATIONS LBU 50

| Execution | LBU-50 | LBU-50-07 | LBU-50-08 | LBU-50-10 |

| LBU-50-20 | ||||

| LBU-50-05 | ||||

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump NB-50 | — | + | — | — |

| Compressor PK-5.25 , 2 pcs. | — | — | + | — |

| Welding generator GSV-500 | — | + | +* | + |

| Front jack, 2 pcs. | — | + | + | + |

| Rear jack, 2 pcs. | + | + | + | + |

| Rear jack (additional), 2 pcs. | — | + | + | + |

| Cargo platform with guard, 2 pcs. | +** | + | + | + |

| Driller's site | — | + | + | + |

| Oil seal swivel | — | + | + | — |

| Clamping table | — | + | +* | — |

| Work desk | — | +* | + | + |

| Elevator for TBSU pipes with a diameter of 63.5 mm | — | +* | +* | — |

| Elevator for TBSU pipes with a diameter of 85 mm | — | + | + | — |

| Elevator, shock-absorbing for TBSU pipes with a diameter of 63.5 mm | — | — | +* | — |

| Thread releaser | — | +* | +* | — |

| Dust suppression device | — | — | +* | — |

| Transport base of installation | AMUR (ZIL-131) | KamAZ-43118 | KamAZ-43114 | |

* - completed at customer's request. ** - on the URAL-4320, KamAZ-43114 chassis. It is not installed on the AMUR (ZIL-131) chassis.

As an alternative technique, you can familiarize yourself with the installations UBGM-1T, MBU-20, GBU-20.