Truck spare parts for Mercedes

The importance of timely replacement of Mercedes truck spare parts

The condition of any vehicle directly depends on the timely replacement of parts and assemblies that have reached the end of the lifespan set by the manufacturer.

This statement is especially important for trucks, which during their operation, as a rule, operate under strict time schedules and various climatic conditions. Therefore, Mercedes truck spare parts occupy one of the leading positions in the general product catalog. Based on the possibility of partially replacing most parts and assemblies of a vehicle, to restore their functionality, you can often use a conventional repair kit, which, naturally, will lead to minimizing economic costs. The qualifications of our specialists allow us to competently recommend specific Mercedes truck spare parts so that the purchase is as effective as possible and meets the required level of repair.

Big Mercedes

At the next auto show 1938 in Frankfurt, the company presents a completely updated executive Mercedes-Benz 770 (W150).

Mercedes-Benz 770 (W150)

The W150 model was endowed with a number of progressive solutions. The engine power has been increased. The fuel tank capacity has been expanded to 195 liters. The interior has become more spacious, resulting in an increase in the size of the car and its weight. The armored version became especially powerful.

The massive car corresponded to the spirit of the Nazi elite. Hitler liked it and the concern was immediately instructed to produce a special batch for the Nazi leadership.

Correct selection of Mercedes truck spare parts

Despite the fact that Mercedes-Benz trucks are distinguished by high reliability and durability of all components and parts, their service life is not endless. In this regard, the competent selection of Mercedes truck spare parts is the most relevant. After all, we are talking not only about the spent financial resources, but also time costs. Therefore, the need to turn to qualified specialists in this case is objectively determined by the real state of affairs.

When choosing a specific component option, it is important, first of all, to decide which Mercedes truck parts to use when performing repair work. We are talking about originals and substitutes. Today, the market situation is such that many parts and assemblies are supplied to manufacturing plants from third-party manufacturers, who undertake to abandon individual labeling. And the situation often arises that analogues can surpass the originals in their technical parameters.

Only specialists in this field can know all these nuances. Therefore, to save time and money, it is recommended to contact trusted suppliers who are well versed in all the nuances and market trends. As a leader in the truck spare parts market, we offer our potential clients the benefit of our experience and knowledge, which is guaranteed to be positively assessed in the near future.

Mercedes

The history of the name is closely connected with the name of Emil Jellinek. In the 90s, already a fairly rich man and serving as consul in Nice, he met Daimler and Maybach. A passionate fan of cars, Emil began ordering cars from Daimler MG for resale to wealthy racing fans, later becoming a sales representative for the company.

Emil Jellinek

He himself participated under an assumed name in racing series. The entrepreneur chose the Spanish name of his daughter from his first marriage as his pseudonym - “Mercedes” (Mercédès). This name gradually became famous in car enthusiast circles.

In 1900, the businessman ordered the development of a new, more powerful model, concluding an agreement for the supply of two large batches of cars.

The designer Maybach managed to fulfill a profitable order in the shortest possible time. Jellinek insisted that the car be named after his daughter. The name Mercedes was registered as a trademark of the company in September 1902. Thus began the history of the brand, which has become synonymous with the most reliable and best car of our time.

The Mercedes 35PS created by Maybach had a four-cylinder engine with a power of 35 hp, a classic layout of components and an elegant appearance. Subsequently, DMG released a more advanced design.

It was created by another designer of the company - Ferdinand Porsche, the future author of high-speed cars. In 1924, he designed a real masterpiece in the form of the Mercedes-24.100.140 PS, with a power of up to 140 “horses”.

Mercedes-24.100.140 PS

By the time of the merger, the DMG company produced 148 thousand cars.

What about in Russia?

Mercedes has been present in Russia for a long time, since tsarist times.

In 1994, a Mercedes-Benz representative office was opened. Since 2010, a joint venture between KAMAZ and Daimler has been operating in Naberezhnye Chelny to produce trucks.

In 2013, the Mercedes company organized with Russian partners the production of light-duty Sprinter Classic trucks in Nizhny Novgorod. The production of diesel engines for them has been established in Yaroslavl.

Mercedes-Benz Sprinter Classic

New Generation

Since the mid-50s, the company's management began developing new series of its products. The main directions were the convenience of passengers, their safety, Italian style in external design, and adherence to Mercedes traditions in the development of the front end of the car.

The result was the emergence of the subsequently popular W111 (220) sedans, as well as the 4-cylinder 190 (W110) and 190D.

Mercedes-Benz 190 (W110)

The German concern produced over 337 thousand cars of this type.

Photo report from the Mercedes-Benz Trucks Vostok plant in Naberezhnye Chelny

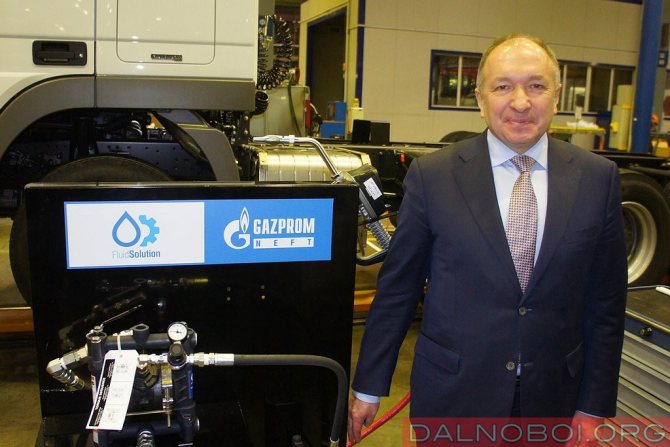

is increasing the localization of production in Naberezhnye Chelny. In December, an automated line for filling oils into Russian-assembled Mercedes-Benz trucks was launched.

The official opening ceremony of the new project was attended by General Director of MBTV LLC Karsten Botmann, General Director Alexander Trukhan, Production Director of the MBTV plant Axel Benz and other business representatives.

It is appropriate to remember that Mercedes-Benz Trucks Vostok LLC is the general importer and exclusive distributor in Russia of Mercedes-Benz, Freightliner and Western Star trucks and special equipment. In the five years after its creation in Russia in 2009, about 15 thousand units were sold through 56 official dealerships and authorized service centers in the largest cities of Russia. technology. Among the G7 members, the share reached 14%.

The project of MBTV LLC to assemble German trucks in Russia started 5 years ago, and production itself was launched in 2011. During this time, in Naberezhnye Chelny, with the help of 200 employees, about 7.5 thousand heavy-duty commercial vehicles of all models were manufactured: Actros, Axor, Atego and Unimog, including a railway locomobile certified by Russian Railways. In total, more than 30 different modifications of trucks with a chrome star on the hood are produced here. At the presentation, a Mercedes-Benz Actros with a Russian VIN code and serial number 7414 was exhibited.

The Russian history of the Chelny enterprise began with the assembly of standard cars, and now orders are dominated by equipment assembled for carriers, taking into account their specific requests. At the initial stage, all 100% of components were obtained from Germany, and as the assembly process stabilized, they came to localization. Each of these processes takes one and a half to two years. Tires and fuel filters have already been localized, and experts estimate the total level of localization at 20-25%. Through partnership with KAMAZ, this figure is planned to be increased by several more points in the near future.

Created in November 2007, it has five production sites in Russia, Italy and Serbia. The total annual production of high-quality oils, lubricants and technical fluids is 490 thousand tons. The company occupies 14% of the Russian lubricants market. The management system of the company and its production assets meets the requirements of international standards ISO 9001, ISO 14001, ISO 16949 and OHSAS 18001.

The company supplies branded products to the conveyors of Gorky Auto, AK Derways and LLC MBTV. Industrial products from the manufacturer are ordered by MMK, Evraz, Sibur, Severstal, Gazprom and other consumers in more than 45 countries, including the countries of Eastern and Northern Europe, the CIS, the Baltics, Central Asia and the Dominican Republic. The assortment includes 470 product names for all market sectors (over 1000 product items). Of these, only nine will be supplied to Naberezhnye Chelny.

According to Carsten Botmann, the choice in favor of Gazpromneft - Lubricants was made deliberately. Not every company specializing in the field of fuels and lubricants can offer an uninterrupted daily supply of different types of lubricants to the conveyor, but their business partner could. The filling complex installed in the production workshop allows for the supply and automated accounting of over 3000 liters of oils and technical fluids per day. This allows us to guarantee the refueling of 300 automobile chassis per work shift, and the actual assembly rate does not exceed 10 units. cargo equipment.

Experts have been preparing the joint project between MBTV and Gazpromneft - Lubricants for two long years. Everyone understood that no one needed haste in such an important matter, and therefore all stages were carried out according to European standards. All oils and technical fluids of nine types, supplied by the partner represented by Gazpromneft - Lubricants to the Mercedes-Benz Trucks Vostok conveyor, are produced at the parent company’s own enterprises. They meet the highest international requirements for product quality and can even be used in modern highly loaded engines of the Euro-6 environmental class.

In relation to Naberezhnye Chelny, this is a prospect: as soon as MBTV begins to produce equipment of this level, the business partner will make adjustments to the supply range. Especially for the current project, Gazpromneft - Lubricants has developed a unique service. It includes the purchase, storage and delivery of branded products to the point of consumption and is characterized by the maximum level of process automation, simplicity and high data transfer speed. Based on such information, employees make accurate production and logistics decisions. All these factors taken together make it possible to ensure a continuous supply of the required amount of oils and technical fluids to the assembly line, which is extremely important for optimizing conveyor production.

General Director Alexander Trukhan commented on the new project with the Russian manufacturer of heavy trucks Mercedes-Benz: “Cooperation with automakers is one of the most important and promising areas of our company’s work. Among the key principles of interaction is an individual approach to the partner and the requirements of his business. A striking example of this is the unique technical and logistics solutions that we developed as part of the project to launch an automated conveyor oil filling service at the Mercedes-Benz Trucks Vostok production facility. We highly value the trust of the world’s largest automaker and are confident that the quality of our lubricants and services will continue to be highly valued in the Russian and international markets.”

In turn, in the opening remarks, General Director of MBTV LLC Karsten Bo. Cooperation with her to provide oils and technical fluids to the assembly production of Mercedes-Benz Trucks Vostok LLC allows us to increase the share of localization and achieve the required indicators within the planned time frame.” Carsten Bothmann also added: “The launch of a unique refueling complex on our conveyor fully complies with the high quality standards of the Mercedes-Benz brand and ensures a modern level of automation and logistics of production processes.”

Alexander TROKHACHEV, photo by the author