| K-744 | |

| Project, g | 1995 |

| Purpose | Soil cultivation: plowing, harrowing, cultivation, no-moldboard technology, peeling and planting. Sowing, application of mineral fertilizers and plant protection products from pests. Transport operations for the transportation of goods by trailers of various purposes and carrying capacity. Carrying out snow removal measures. |

| Propulsion type | Wheels; caterpillars (optional) |

| Location | |

| Cabin: | average |

| Engine: | front |

| Engine | |

| Engine make | Domestic engines: K-744R1 “Standard”, engine. YaMZ, 300 l. s., TK-5 K-744R1 “Standard”, engine. TMZ, 300 l. s., TK-5 K-744R1 “PROM”, engine. YaMZ, 300 l. s., TK-5 K-744R2 “Standard”, engine. TMZ, 350 l. s., TK-5/6 K-744R3 “Standard”, engine. TMZ, 390 l. s., TK-8 K-744R4 “Standard”, engine. TMZ, 420 l. s., TK-8 Foreign engines: K-744R1 “Premium”, engine. Cummins, 306 l. s., TK-5/6 K-744R2 “Premium”, engine. Mercedes, 354 l. s., TK-5/6 K-744R3 “Premium”, engine. Mercedes, 401 l. village, TK-8 K-744R4 “Premium”, engine. Mercedes, 428 l. village, TK-8 |

| Transmission | |

| Transmission type | transmission control system "CommandPost" |

| Equipment | |

| Hydraulic equipment | Hydraulic system of working equipment with axial piston pump ISO Category IV N three-point hitch with quick hitch system, drawbar and hydraulic hook |

| The lineup | |

| Basic model | K-700 |

| Subsequent model | K-9000 |

| K-744 on Wikimedia Commons | |

K-744 is the 5th generation of Kirovets tractors with the CommandPost transmission control system.

In the K-744

series-P includes four models of general-purpose agricultural tractors and one industrial tractor of 5...8 traction classes with power from 300 to 428 hp. With. Each model can be equipped with a domestic or foreign engine. All tractors are equipped with a working equipment hydraulic system with an axial piston pump with a maximum capacity of 180 l/min. The basic equipment of all tractors includes a three-point hitch of category IV N according to ISO with a quick hitch system, a tow bar and a hydraulic hook. At the customer's request, the tractor can be retrofitted with optional equipment that expands its production capabilities.

Story

| 1924 The production of American Fordson tractors is localized in Krasny Putilovets. The first Russian tractor was released - Fordson-Putilovets . The Russian industrial tractor industry has been launched. |

| 1934-1940 The plant mass-produced the more powerful Universal-1 and Universal-2 tractors . In total, almost 150,000 Universal and Fordson-Putilovets tractors have been produced since 1924. |

| 1962 The first generation of agricultural tractors "Kirovets" : models |

| 1964 Kirovets tractors was launched . On September 14, 1964, the first production K-700 rolled off the main tractor conveyor of the plant; more than 1,200 vehicles were produced during the year. |

| 1975 Second generation of agricultural tractors "Kirovets" : the first serial K-701 (300 hp) was assembled, the 100,000th serial K-700 was produced. |

| 1979 The first generation of industrial tractors "Kirovets" : design documentation was developed and the first serial tractors K-703 (235 hp) were assembled as a basis for the manufacture of a complex of forestry machines. |

| 1980 The first samples of the world's most powerful wheeled agricultural tractors have been assembled 8 traction class K-710 “Ilyich” (500 hp), and the 200,000th production tractor rolled off the plant’s assembly line. |

| 1985 Third generation of agricultural tractors "Kirovets" : the first production tractor K-701M (335/350 hp) was assembled, the 300,000th tractor was produced. |

| 1989 Second generation of industrial tractors "Kirovets" : production of road construction machines based on the industrial tractor K-702 (235/250 hp) began |

| 1995 The fourth generation of agricultural tractors "Kirovets" : the first models K-734 (250 hp) and K-744 (350 hp) were released for export. The 460,000th serial tractor was produced. 1996 The first 744A models with engines were released. 250 hp for delivery to the German market. |

| year 2000 Fifth generation of agricultural tractors "Kirovets" : the first batches of models of the new K-744R tractors (letter “P” - i.e. for Russia) were released for the domestic market. |

| 2002 Implemented since February 1, 2001 complete transition from production |

| 2007 Third generation of industrial tractors "Kirovets" : design documentation was developed and prototypes of the K-3060 front loader model with a lifting capacity of 6 tons were produced. |

| 2008 Sixth generation of agricultural tractors "Kirovets" : design documentation was developed and prototypes of the K-9000 models (354-516 hp) were produced. |

| 2010 Design documentation was developed and prototype models of the K-3080 front loader with a lifting capacity of 8 tons and the K-708 universal tractor module with an overall width of 2.5 m were produced. |

| 2014 The Kirovets K-702 series of loaders and universal road machines was updated. A dump truck based on the K-708 was released. A deep modernization of the Kirovets of the K-744R series was carried out. |

| 2016 The K-744R became the first plant model in 25 years to be sent to the North American continent. [1]. |

Tractor k 744

The Kirovets models from the K-744 line, which began production in 1995 and underwent extensive modernization in the early 2000s, were the result of a radical change in the outdated K-700 and K-701 tractor models. They have incorporated all the latest improvements in technology and equipment, interior and exterior elements, maintaining undeniable leadership among Russian equipment of this type in the power range of over 300 hp.

Purpose

The K-744 belongs to the high 5th traction class and at the same time has extensive capabilities for working with various trailed tools and all kinds of attachments. This “comprehensiveness” of the machine expands the boundaries of its application to the status of a multifunctional draft unit and allows it to solve a wide range of problems:

- The main purpose is agricultural work of all types.

- Transporting heavy loads over short and long distances.

- Work at fishing and rock mining sites.

- Issues of construction, road and utility services.

The value of the model lies in the fact that in climates of different latitudes it can be freely used year-round, and for the most difficult tasks of transportation, towing, etc.

INTERESTING! Only one K-744 tractor can completely cultivate (prepare and sow) areas of up to 5 thousand hectares per season, ensuring the minimum cost of each hectare of crops.

Advantages and disadvantages

At the moment, domestic tractors of the Kirovets K-744 brand are one of the most popular and most powerful tractor equipment purchased in Russia, which is explained by the unique combination of many useful properties in one unit:

- Equipped with powerful and at the same time economical turbodiesels produced by well-known companies with 6 or 8 cylinders, developing power up to 428 hp. and torque up to 2000 N*m (TMZ, YaMZ, Cummins, Mercedes-Benz).

- Continuous operation without refilling for up to 14 hours thanks to the large gas tank.

- The ability to change gears without interrupting the power flow under load.

- Increasing, if necessary, traction capabilities by installing an additional set of dual wheels and ballast weights.

- High driving characteristics due to all-wheel drive and the presence of elements that increase driving efficiency:

- self-locking differential;

- planetary type wheel reducer;

- sprung front axle.

- Increased maneuverability, which is ensured by a very small turning radius for such colossal equipment due to the action of the articulated frame of the machine.

- Convenience, comfort and safety of the operator in an ergonomic cabin with modern equipment.

- Can be combined with any trailed and mounted equipment.

- Relatively affordable in comparison with similar foreign equipment.

ATTENTION! Some disadvantage of the K-744 series tractors is the problem of the standard hydraulic system, equipped with an NSh pump, which produces significant energy losses. To eliminate this problem, machines are equipped with oil flow regulators - electronic with remote control or manual.

Photo of the Kirovets K-744 tractor

Modifications

The line of agricultural tractors consists of eight modifications in two versions and one industrial tractor in the line of industrial equipment[4][5]:

Agricultural modifications:

Domestic engines:

- K-744R1 “Standard”, engine. YaMZ (Yaroslavl), 300 l. s., TK-5; engine TMZ (Tutaev), 300 l. With. TK-5

- K-744R2 “Standard”, engine. TMZ (Tutaev), 350 l. village, TK-5/6

- K-744R3 “Standard”, engine. TMZ, 390 l. village, TK-8

- K-744R4 “Standard”, engine. TMZ, 420 l. village, TK-8

Foreign engines:

- K-744R1 “Premium”, engine. Cummins, 306 l. s., TK-5/6 (temporarily out of production)

- K-744R2 “Premium”, engine. Mercedes, 354 l. village, TK-5/6

- K-744R3 “Premium”, engine. Mercedes, 401 l. village, TK-8

- K-744R4 “Premium”, engine. Mercedes, 428 l. village, TK-8

Industrial modifications:

- K-744R1 “PROM”, engine. YaMZ, 300 l. village, TK-5

Additional equipment (options) for Kirovets tractors of the K-744R series:

- Wheel doubling kits

- Wide profile tire set

- Track kit

- Power take-off (PTO)

- Attachment Positioning System (EHR)

- Protection kit for cultivation of fallow lands

- Four types of towbars (TSU): pendulum towbar (PDU); hydraulic hook; drawbar; trailer hitch

- Removable hydraulic blade

- Precision farming system

Tractor "Kirovets" K-744R1: technical characteristics

The St. Petersburg Tractor Plant offers the K-744R1 user improved key indicators that became available after modernization this year.

Today, the buyer can choose one of four available tractor modifications. The main series is equipped with domestic YaMZ and TMZ engines, known for their ease of maintenance and reliability. Power units have a power of 300 hp. up to 420 hp Large-sized Kirovets K-744Р1 tractors are also equipped with German Mercedes and Cummins engines. These models have power from 306 to 428 hp. Obviously, the user chooses between reliability and low cost of repair in the event of a breakdown.

The power of the hydraulic system has been increased by increasing the pump output to 180 l/min. The hydraulic distribution mechanism of a five-section design with separately controlled elements made it possible to integrate with all modern machines and implements.

The proprietary transmission with non-stop gear shifting is time-tested and has proven its reliability in any situation. The rear linkage system is a three-point, high-power one. Its performance has been proven through testing and real-world operation.

The large-capacity fuel tank was specially designed for seasonal use of the tractor without the need for refueling. To increase the productivity of the K-744R1 tractor during agricultural work, the manufacturer has provided a wheel doubling system. This increases traction and flotation while reducing ground pressure.

Notes

- “Kirovtsy” are returning to Canada Archived copy dated November 17, 2016 on the Wayback Machine // Official website of JSC “Petersburg Tractor Plant”, May 27, 2016

- Alexander Karlin agreed to assemble the latest generation tractors in Altai

- Results of the work of the Altai industry for the first half of 2016 // Official website of the Altai Territory, June 16, 2016

- Kirovets K-744R series, Official website of the plant, 2016

- Tractors “Kirovets” series K −744R, Presentation, 2012

Description and purpose

Kirovets K-744 is a high-performance machine, on the assembly line since 1995. Since 2002, the Kirov Plant began to produce only this model, but in several versions. In this regard, the previous machines K-700, K-701 and K-703 were removed from the assembly line for obvious reasons. At the moment, the K-744 has four modifications. The tractor received its last major update in 2014. The modernized vehicle is distinguished by higher traction characteristics, a modern cabin manufactured in accordance with comfort and safety requirements, as well as multifunctional hydrostatic steering equipment. The Kirovets K-744 model is widely used mainly in agriculture. This tractor is aimed at a mass audience. It is often purchased by large logging companies, as well as utilities, builders and private entrepreneurs. In farming, this device is in demand in operations such as plowing soil in various ways, towing trailers, loading and unloading. In the construction and public utilities sector, the equipment is used as a loader and in repair and installation work. In road construction, the tractor mainly transports heavy loads, including concrete structures, since the machine has a high load capacity. The machine is perfectly adapted to harsh weather conditions. Thus, in agriculture, this is one of the few machines that is capable of completely cultivating an area of up to 5 thousand hectares in a short time.

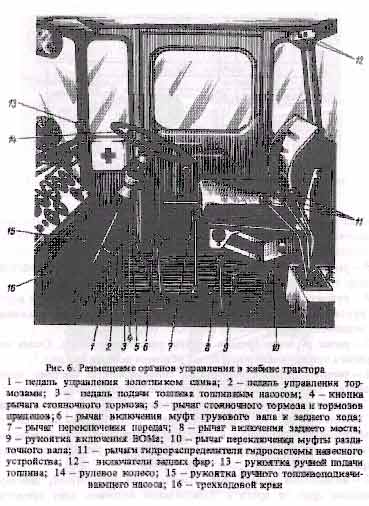

Controls for tractors Kirovets k 701, k 700A, k 700, k 744.

Tractor controls k700, k700A, k701, k744.

In the cockpit (

2 — brake control pedal; 3 — pedal for supplying fuel with a fuel pump; 4 — button on the parking brake lever; 5 - lever for parking brake and trailer brakes.

The parking brake is tightened by successively pumping the lever toward you.

until complete braking. Release of the brake - by moving the lever all the way forward with the button recessed. Autonomous braking of trailers while the tractor K700, K700A, K701 is moving is carried out by moving the same lever from the extreme forward position towards itself with a pre-recessed button; 6 — lever B for engaging the cargo shaft and reverse clutches.

The diagram of the lever positions when turning on various modes, as well as reverse gear, is shown in Fig.

7. A plate with a diagram of the location of the levers is located on the instrument panel; 7 — gear shift lever C.

The diagram of the lever positions is shown in ;

8 — rear axle engagement lever.

When moving the lever forward (along the tractor's path), the axle is turned on, back - the axle is turned off;

9 — handle for turning on the power take-off mechanism.

When moving the handle clockwise, the power take-off mechanism is turned on, and counterclockwise, it is turned off;

10 - lever A for shifting the transfer shaft clutch.

The diagram of the lever positions when turning on various modes is shown in;

11- levers of the hydraulic distributor of the hydraulic system of the attachment.

They have four fixed positions forward along the tractor, respectively: “Lifting”, “Neutral”, “Forced Lowering” and “Floating”.

From the “Lifting” and “Forced Lowering” positions, they automatically return to the “Neutral” position when removed from a fixed position manually or when the hydraulic cylinder’s working stroke ends; 12 — rear headlight switches.

There are two switches that operate independently of each other and allow you to turn on one middle, two outer or all three headlights at the same time;

13 — manual fuel supply handle.

When you move the handle towards you, the fuel supply increases, the fuel supply control pedal follows the handle;

when operating the pedal, the manual fuel supply handle does not follow it, but fixes the set fuel supply, limiting the pedal travel; 14 — steering wheel; 15 — handle of the manual fuel priming pump; 16 - three-way valve.

Faucet handle (

) has three positions: I - the left tank is on; II - neutral - both tanks are turned off; III - the right tank is turned on. The lever for disabling the diesel engine from the transmission () is located on the pump drive gearbox. When the lever is in the forward (along the direction of the tractor) position, the diesel engine has no gear to the transmission; when it is in the rear position, the diesel engine has a gear to the transmission. The towing switch lever () is located on the gearbox on the right side near the filter. The lower fixed position of the lever corresponds to normal operation (diesel drive), the upper one corresponds to towing (wheel drive).