What carburetors are used on Chinese chainsaws

The most optimal carburetor designs for chainsaws were developed by the world's leading manufacturers - German Stihl, Japanese Walbro and others. These top developments are hard to beat. Therefore, most Chinese manufacturers copy the best models.

Today there is a large offer of Chinese carburetors for chainsaws on sale.

Some are nameless, from an unknown manufacturer and do not even have markings. They are simply offered for a specific chainsaw model. For example, a carburetor for a Stihl MS 361 chainsaw.

Others have brand names of well-known brands.

Still others have their own catchy names - in Russian transcription King Kong, Technopark, Rezet and others.

Features of the Chinese chainsaw carburetor

Their design and parameters differ depending on the power and model of chainsaw they are intended for. All of them are almost identical to the original carburetors in design, but not always in quality. Today, all Chinese products cannot be considered 100% rubbish. In turn, according to their quality, they can be divided into three groups:

- Poor quality. Unsuitable alloys are used which oxidize, crumble and break. There is no accuracy of fit, the calibrated holes do not correspond to the required values, which leads to excessive consumption or lack of fuel in the combustion chamber. Critical parts quickly fail. Plastic parts quickly become rough or, conversely, become softened by gasoline and stop working. The axles and wire rods are bent, the threads of the fasteners are torn off. Such products are the cheapest. They are made in semi-handicraft industries using adapted equipment. As a rule, they do not have a name or marking.

- Carburetors are of average quality. These are factory assembled products. They do not skimp on alloys; they have established continuous production with quality control. These are fully functional carburetors that can have a service life even longer than that of the entire chainsaw.

- High quality carburetors. First of all, these are products from global manufacturers whose facilities are located in China. Geographically, they can be considered Chinese, but they are made using the technologies of the company that owns the brand and values its reputation. For example, Japanese Walbro carburetors are produced in China.

In addition, among Chinese manufacturers there are those who rely on high quality. They invest heavily in powerful production facilities, register their own brand and work on its reputation.

Modifications

During the entire production of the chainsaw, Friendship 4 has not undergone any major design changes. Let's see what minor changes have occurred in the design of the chainsaw:

- 1950 - 1960. The first structural modification concerned a change in the mounting option for the handles; they began to be attached to the fan cover, and subsequently the fastening was moved to the clamp that connected the engine and gearbox.

- 1960 - 1980. At this time, a modification of the chainsaw called Druzhba - 4A, which had two main advantages: a contact magneto and the well-known KMP-100 carburetor, entered the assembly line and was produced for 20 years. At the end of the 80s, the modification of the Druzhba -4A chainsaw was discontinued.

- Late 1980s. Release of the Druzhba-4M Electron modification. Electronic ignition was used for the first time.

- 1990s. Equipping the chainsaw with a modern (at that time) carburetor KMP-100U. Changes in the saw set - the use of modern type chains.

Many people are confused and say that a number of other changes were made to the Druzhba 4 chainsaw, such as a removable starter, a detachable crankcase and a removable cylinder, but they are deeply mistaken. All these changes were made on the Ural chainsaw, the basis of which was Druzhba.

Adjusting the carburetor of a Chinese chainsaw with your own hands

Adjustment is not provided on all carburetors of Chinese chainsaws. Today there are many models of household chainsaws, including European brands, whose carburetors simply do not have adjusting screws. Or there is only one idle speed adjustment screw.

Such carburetors require adjustment only when the chainsaw at idle makes too few emissions (revolutions) and sometimes stalls. Below in the text we will discuss the algorithm for adjusting the idle speed of the carburetor on a Chinese chainsaw.

Required Tools

Adjustment requires a screwdriver that fits the slots of the adjustment screws. On different carburetors they are flat, cross-shaped, with an internal or external hexagon, an asterisk, etc.

An electronic tachometer will help with adjustment. If it is not there, adjustment is carried out by ear and by assessing the actual operation of the engine.

Carburetor adjustment algorithm

Before making adjustments, make sure it is necessary. All Chinese carburetors on each chainsaw undergo factory settings, which rarely go wrong. A new carburetor, or in rare cases an old one, may require adjustment.

The cause of deterioration in engine performance with symptoms similar to poor supply of the fuel mixture is, in most cases, the following:

- clogged air filter,

- exhaust windows and muffler clogged with carbon deposits,

- bad fuel.

If this is not the problem, then try adjusting the carburetor.

The engine must be warm. A cold engine and one warmed up to operating temperatures operate differently. Therefore, adjustment in cold conditions will be incorrect.

- Provide access to the adjusting screws. On some chainsaws, it is enough to remove the cover and air cleaner. On others you have to remove part of the body. On the third, the housing has holes for a screwdriver.

- The screws are marked on the carburetor or near the holes - T (or LA) L and H. The T (or LA) screw is designed to adjust the idle speed. Always located away from screws L and H, which are next to each other.

- If the chainsaw stalls when gas is supplied, the engine does not have enough fuel to develop speed. The amount of fuel is adjusted using screw H (main screw). Unscrew it 1/4 turn and give gas. If the engine begins to work better, unscrew it another 1/4 turn. (If worse, then tighten it 1/4 turn in the opposite direction).

- If the engine starts to idle, it means there is a lot of fuel, screw H is screwed back.

- The peak speed is controlled by ear or using a tachometer. The maximum speed for each chainsaw is indicated in the instructions. (10,000 – 12,500 rpm). In practice, 10,000 – 11,000 rpm in the “full throttle” position are normal values.

- By increasing the amount of fuel supplied with screw H, the quality of the fuel mixture is adjusted with screw L. It increases and decreases the amount of air in the mixture. If there is not enough air, the fuel will not burn out; as a result, the engine smokes, does not develop power and consumes excess fuel. Screw L also affects engine operation at low and medium speeds.

- After adjusting screw H, screw L is unscrewed 1/4 turn. If there is smoke in the exhaust and the engine moves from low to medium and high speeds with dips, screw L is unscrewed some more.

- Adjustment of screw L is stopped when the engine runs smoothly, moves smoothly from low to high speeds and does not smoke.

After adjusting the two main screws, it is most often necessary to adjust the idle speed with the third screw.

Idle speed adjustment

Idle speed adjustment sequence:

- The engine is started and warmed up for 5-7 minutes.

- The screw is unscrewed, increasing the speed until the chain begins to rotate.

- Then the screw is screwed back 1/4 turn.

Chainsaw doesn't cut well

- In this situation, the problem is most likely a dull saw chain of the tool. It needs to be replaced with a new one or sharpened.

- Check the supply of lubricant to the saw bar; if it is missing, diagnose the lubrication system and eliminate malfunctions.

The tire pulls to the side

- It is necessary to inspect the tire and, if increased wear is detected, replace it with a new one.

- The teeth of the chain on one side are much higher than the teeth on the other side; it is necessary to sharpen the chain correctly and adjust the cutting depth.

The driven tire sprocket rotates with jamming

The problem is that debris has gotten into the sprocket bearing, you need to wash the tire in gasoline and check again; if such actions do not help, then the cause is wear of the bearings and the tire needs to be replaced.

The chain spins at idle

The main reasons why the chain may spin at idle are incorrect idle speed adjustment on the carburetor and a broken spring in the clutch mechanism of the tool. You must first inspect the clutch for faults and eliminate them if any, and then, if necessary, adjust the idle speed on the carburetor.

Chinese chainsaw carburetor repair

Carburetors cost 500-1000 rubles. It doesn't always make sense to repair. A repair kit with a set of gaskets and a diaphragm costs not much less than the cheapest carburetor, 300-350 rubles. A frequent breakdown of Chinese carburetors is the failure of the injector valve, and such a part is not sold in repair kits. Therefore, it is easier to buy a new carburetor.

But there are breakdowns that can be relatively easily fixed on your own:

Loss of seal between parts of the carburetor body or between the carburetor and the engine. Sometimes it is enough to tighten the fastening screws. In other cases, you can remove the carburetor, replace the gaskets, or use a suitable sealant along with them.

Obvious mechanical problems - deformation of the wire rod from the throttle, sticking of the axes on which the throttle and air dampers rotate - are also easy to fix. The thrusts are straightened. The axle landing sites are lubricated with a drop of oil and free rotation is developed by hand.

Carburetor cleaning

The carburetor air filter needs to be cleaned periodically. They come in different types. From some it is enough to knock out dust and dirt by knocking on wood. Others are washed with soapy water. Still others require disassembly. The fourth ones are almost impossible to clean; they need to be replaced with a new one.

The features of the air filter for each chainsaw and maintenance rules are described in the instruction manual for each specific model.

If there is a filter in the gas tank, nothing can become clogged in the carburetor. If there is still a suspicion that the tiny holes in the jet are clogged, the carburetor is disassembled. The parts are laid out on a clean cloth, remembering which one comes from where. The holes are purged with a pump or compressor. The body and parts are washed in kerosene or gasoline.

There is no need to bring the condition of the filters to such a deplorable state. This greatly affects the performance and life of the chainsaw engine.

Gasoline does not flow into the carburetor: what to do

The fuel line from the gas tank is short and uncomplicated. Three problems may arise in this area:

- The gasoline supply hose is pinched. The break is found, the hose is straightened or replaced if the round shape is not restored.

- The filter at the bottom of the gas tank, which is installed on some models of chainsaws, is clogged. It is removed with a thin wire hook, inspected and cleaned. The gas tank is flushed with gasoline.

- The breather has failed. When fuel is sucked in, a vacuum is created in the gas tank, and fuel flows poorly or does not flow at all. This part cannot be repaired. Most often, the breather is located in a hard-to-reach place, at the outlet of the fuel line from the gas tank. It is replaced with a new one.

Sometimes, instead of repairing the breather, a hole with a diameter of 0.2-0.5 mm is made in the gas tank cap. The downside is that gasoline may leak through the hole during operation, and after operation the chainsaw can only be placed on its side, with the gas tank cap facing up.

How are things going with repair kits?

The repair kit can be purchased at the same retail outlets where carburetors are sold. They are sold in two configurations:

- rubber-plastic parts (gaskets, diaphragm)

- the same thing, plus a cross with a needle valve.

It is difficult to find other spare parts separately.

First launch and further maintenance

The Champion 240 chainsaw arrives in stores already assembled, with the exception of the saw part, which must be installed independently. If you follow the assembly instructions, you can complete this task yourself.

When starting the engine for the first time, the fuel tank must be filled in a ratio of 1:25 oil to gasoline. For further use, the saw must be filled with a mixture of 1:50.

When using it in the future, it is necessary to periodically check the chain tension. As a rule, this action is performed at each refueling and before starting work. Automatic fuel supply and emergency chain stop systems also require regular checks for serviceability. It is prohibited to use the saw if any of the systems fails.

The toothed stop is sold complete with the Champion chainsaw; you must install it yourself. The stop improves grip on the tree trunk when cutting.

To do this, you need to unscrew the fastening nuts and remove the protective casing, then put the chain on the saw bar so that the cutting edges are directed in the direction of movement of the chain. Install the bar, put the chain on the drive sprocket and install the metal toothed stop. Finally, it is necessary to adjust the chain tension.

Champion 240 carburetor

Pros and cons of Chinese carburetors

Chinese carburetors can be of low, medium and high quality. Low quality products have the advantage of extremely low prices. The best option in terms of price-quality ratio is, as a rule, in the middle price segment.

An original European-assembled Stihl carburetor or a purely Japanese Walbro carburetor are excellent in quality. But their cost is sometimes equal to the price of an entire Chinese chainsaw. Therefore, it is better to confidently navigate the wide variety of Chinese carburetors with which our market is flooded, and make an appropriate choice.

The heart of an internal combustion engine is the carburetor. Just like in the human body - if there are interruptions in its work, the instrument will cease to function normally.

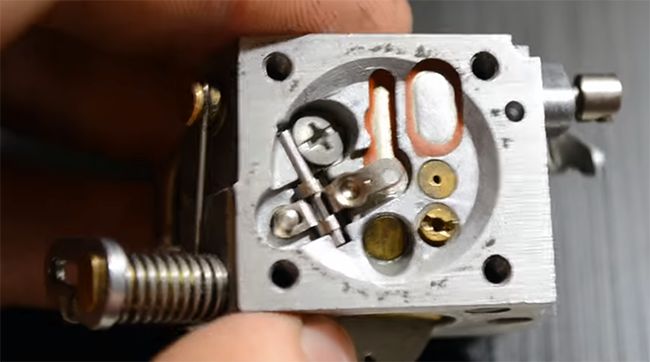

STIHL 180 chainsaw carburetor disassembled

Today we will tell you how to adjust the carburetor of any Chinese chainsaw. Let's look at the design of the carburetor and the main malfunctions.

Chainsaws Comfort

In recent years, the previously unknown Comfort brand has been gaining popularity in the post-Soviet space. Messages have repeatedly appeared online that the company is of American origin, however, this information has not been confirmed. The information about the Chinese registration of the brand looks more plausible, which is confirmed by the markings on some parts of Comfort chainsaws.

Like all young companies, the manufacturer is trying to create a good reputation for itself, and therefore carefully monitors the quality of its products. In their reviews, owners of Comfort chainsaws talk about their high performance and reliability. Chainsaws from this company are successfully used in the construction and repair of houses, sheds, garages, and other residential and commercial buildings. Comfort chain saws can also be used for landscaping, garden pruning, harvesting and sawing firewood.

Features of Comfort chainsaws

- Good balance of the body is combined with a modern design;

- Reliable, unpretentious engine;

- Easy to maintain and operate;

- Protection against vibration and bounce;

- Low price, with high reliability of the unit;

- Ergonomic handles and convenient placement of control tools.

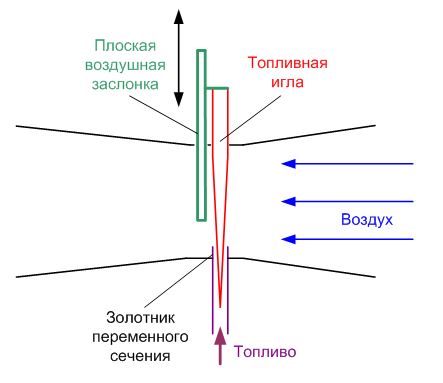

Consider the design of a gasoline carburetor

This unit is designed to form a mixture of gasoline and oxygen, which is then supplied to the cylinders for ignition.

Engine designers have determined the mixture parameters at which your tool will produce maximum power with minimum fuel consumption.

Accordingly, it is necessary to mix air and gasoline in certain proportions, and save a portion of the prepared mixture before feeding it into the intake manifold of the engine. This is what the carburetor does.

A needle connected to a float meters the amount of fuel entering the carburetor chamber. The air damper supplies a certain volume of air. The quality of the mixture depends on the coordinated operation of the entire mechanism.

To set operating parameters, as well as if adjustments are necessary (for example, when working in the mountains or when refueling with low-quality gasoline), adjustments are provided.

Unlike modern car engines, a chainsaw is a more primitive unit. Otherwise, its cost would be too high.

Practical tips for setting up a Champion chainsaw carburetor

Therefore, there is no correction for the formation of the fuel mixture, like many other electronic systems used in modern internal combustion engines. These functions are assigned to the owner of the chainsaw.

We rose 100 meters above sea level, the mass fraction of oxygen in the air changed - we enrich the mixture. We changed the gasoline supplier (unfortunately, in our realities this is a pressing issue), and again it is necessary to update the settings.

Service centers will give you the correct settings, but for money and in bench conditions. But in real life, you need to be able to perform this procedure yourself. No one will help you with repairs in the forest. Here are all the details on how to repair a chainsaw yourself.

Basic carburetor malfunctions

Let's look at common faults that you can fix yourself.

Stalls at idle or runs intermittently

When you press the throttle, it doesn't immediately pick up the revs and even stalls. The reason in most cases lies in the clogging of the mesh protecting the fuel supply channel.

It needs to be carefully pulled out, for example with a needle, and cleaned; if it is leaky, it will have to be replaced.

Next you need to check the injectors and jet.

Location of the nozzle, jet and valve in the chainsaw carburetor

The injector and jet can be purged with a regular bicycle pump. The jet must first be unscrewed with a regular screwdriver and checked for light. A clean hole with smooth edges should be visible.

The tool does not start due to fuel overflow

It happens that the tool does not want to start due to fuel overflow. In this case, it is necessary to clean the needle and rocker arm. Sometimes, dirt gets under the rocker and prevents the channel from completely closing, which leads to overflow.

We clean the needle and rocker from dirt

To do this, you need to unscrew the nearby screw and lift the needle with the rocker arm. The photo shows the wear of the rocker arm. This can happen from ingress of abrasive and vibration during operation. Over time, the idle speed may disappear, and the damaged rocker arm will have to be replaced.

Homemade chainsaws Friendship

Another reason for the great popularity of the Druzhba chainsaw is the wide range of possible DIY projects using this tool. In Soviet times, it was used wherever possible. Let's look at the most common models of homemade devices with impressive modifications.

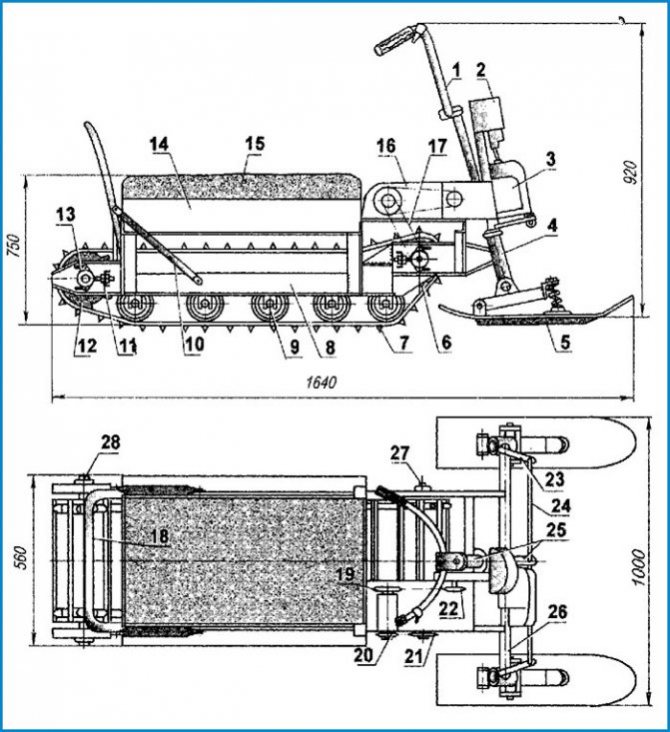

Snowmobile

The popularity of the Friendship chainsaw in the development of a snowmobile is due to the simplicity of the design and disassembly of the device.

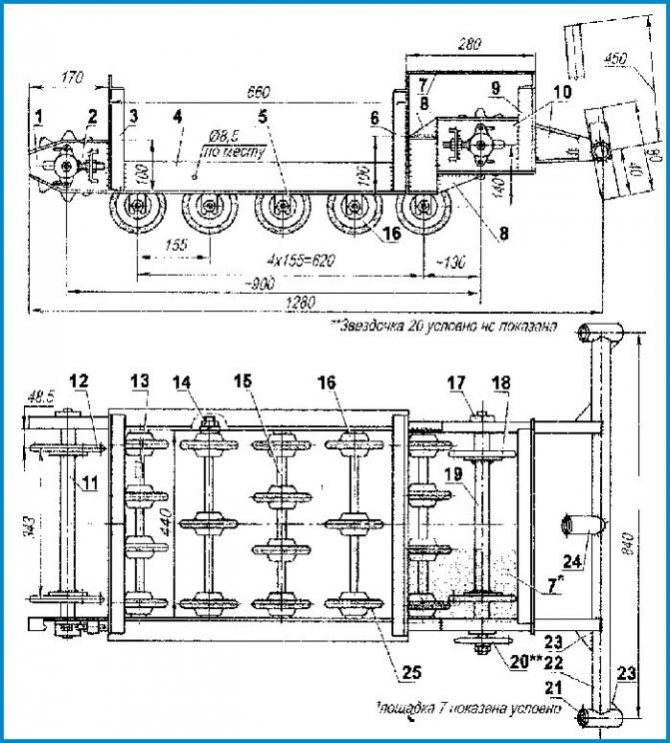

The general drawing of the snowmobile is shown in the following photo:

The main thing in the manufacture of a snowmobile is the creation of a drawing in which the transmission, engine and skis should be connected.

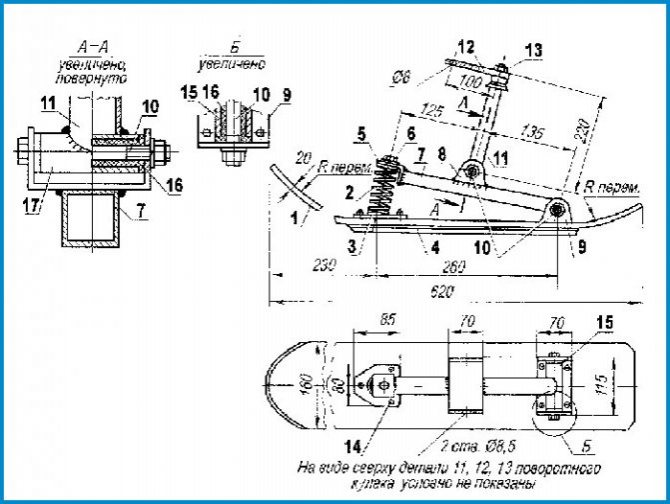

The rack manufacturing diagram is shown in this photo:

And here is a drawing of the tracks:

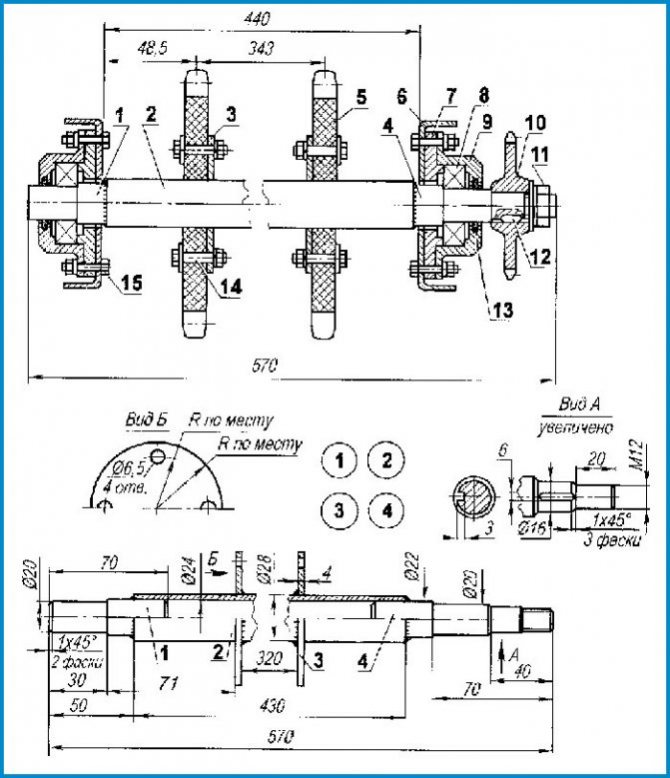

The drive shaft can be made according to the following scheme:

As a steering element, you can take the steering wheel from a regular scooter or bicycle, but there is no braking system provided here; you just need to release the throttle, because you won’t develop high speeds on it.

If you have any questions, watch the video collection

How to adjust the carburetor of a Stihl chainsaw.

Features of launching Chinese chainsaws using the Hunter chainsaw as an example. A detailed story and demonstration of carburetor repair, as well as its adjustment.

In a chainsaw, a lot depends on the carburetor: stable operation regardless of speed, power of the tool, efficiency of use, fuel consumption. In addition to the fact that the carburetor needs to be monitored, it must also be properly adjusted for the chainsaw to function properly. Setting up a carburetor on a chainsaw, like on any other machine, is a very complex matter, and it requires a thoughtful approach and following instructions. But if you strictly follow all the necessary instructions, then almost anyone can adjust the carburetor, and it must be done at the first sign that the chainsaw is not working properly.

How to install a saw made in China?

The design of the carburetor on Chinese chainsaws is no different. The installation procedure and principle are also the same and are performed in the same order. The only difficulty that may arise during work. This determines the purpose of the adjusting screws. Typically the T screw is at the top and the H and L screw are located at the bottom of the carburetor body. There may be one extra screw there.

Figure 3. Location of control mechanisms

Usually their goal is determined experimentally, slightly changing the position and monitoring the result. Once the purpose of the elements is clearly defined, further configuration is straightforward and can be done in the usual way.

Adjusting the chainsaw carburetor is an important and necessary procedure that must be performed periodically to restore normal operation of the tool. This process does not create any fundamental difficulties, but requires the user to be careful, attentive and follow safety rules. Chainsaws are usually not removed because you need to keep an eye on their position. Therefore, it is important to always remember the possibility of triggering it and exercise the necessary caution.

READ How to Adjust the Carburetor on a Stihl 180 Saw

The adjustment should be made smoothly, with slight changes in the position of the screws, so as not to cause too sudden changes in the mode of rotation of the shaft. The result depends on the care and diligence of the user, and a properly adjusted carburetor will extend the life of the tool.

Carburetor chainsaw . This is the element that is responsible for mixing the air-fuel mixture. Not only the stability of the engine, but also the speed of the entire chainsaw depends on the condition and serviceability of this important unit. In this regard, every owner of gardening equipment should study the design of the carburetor, as well as become familiar with the rules for its maintenance and repair.

When is it necessary to adjust the carburetor?

There are several signs that help you understand that you need to adjust the carburetor on your chainsaw, these signs are listed below:

- The factory settings of the chainsaw were changed due to the loosening of the carburetor adjusting bolt;

- The UPT housing cover is damaged;

- The engine starts poorly or does not start at all;

- the chainsaw does not hold idle speed or operates unstable at idle speed;

- the chainsaw exhaust is too thick;

- excessive fuel consumption;

- spark plugs quickly turn black or become covered with a white coating;

- the chainsaw does not achieve the stated power characteristics;

- the chainsaw engine stalls as it gains speed;

- the chainsaw vibrates strongly at idle;

Of course, these reasons can be caused by other problems with your chainsaw, and in order to eliminate unnecessary problems, you need to take a number of measures. If dirt gets into the fuel system, the engine may also jump at idle, and in this case you just need to flush it. If your piston group is worn out, then power is lost, but in this case, when idling, a characteristic knock will be heard - you need to change the piston group.

Also, you will need to adjust the carburetor if you start using a different fuel, or use a chainsaw in other atmospheric conditions.

Adjustment tools

To adjust the carburetor, you will need Phillips or slotted screwdrivers of varying lengths or thicknesses. The size depends on the design of this unit and the characteristics of the engine assembly. It should be noted that some manufacturers produce carburetors designed for use with special tools.

In particular, installation of Husqvarna carburetors and other imported tools may require a special screwdriver. It is advisable to clarify this issue even when purchasing a chainsaw, so that you can purchase the necessary additional equipment in advance.

In addition, washed gasoline or acetone will be needed to flush and clean the device. They are used to clean the external surfaces of the carburetor. All internal channels are washed with kerosene, diesel fuel or white alcohol. Before washing the carburetor, remove all rubber or plastic parts that may come into contact with aggressive chemicals.

READ Carburetor Adjustment for Poulan 2250 Chainsaw

Wrenches or ring wrenches are used to disassemble the carburetor. Washing of internal channels is carried out in specially designated baths; sometimes plastic syringes are used for this.

Carburetor parts, preparation for tuning and safety precautions

Before adjusting the carburetor, you should definitely make sure that the air and fuel filters are clean. Also, make sure that there is no air leaking into the engine from the side, otherwise you will not be able to adjust the carburetor correctly.

Almost any carburetor in a chainsaw is adjusted using three screws:

- The main jet bolt, which is usually indicated by the letter "H", is used to set the maximum engine speed;

- The idle jet bolt, which is designated “L”, and is used to set low speed or idle speed;

- Idle speed adjustment bolt, which is designated differently: “S,” “LA,” “T”

Of course, you may find carburetors with fewer screws. Such carburetors, as a rule, are specially designed to protect their products from incorrect settings.

Specifications

The chainsaw today is morally outdated, after all, half a century has passed, so you should treat its characteristics with understanding.

On a note. Friendship 4, although a rarity, to this day a large number of copies are in working order and are in demand among the population of the country and neighboring countries! This is due to the fact that very reliable chainsaws were released in the 60s.

Let's return to the technical characteristics of the Friendship 4 chainsaw:

- weight: 12 kg (it is distributed as evenly as possible throughout the entire body, for comfortable operation of the operator);

- tire: length 45 cm;

- chain pitch: 0.325 inch;

- fuel type: AI-92 gasoline + oil for 2T engines.

- fuel tank capacity: 550 ml.;

- oil tank capacity: 260 ml.;

- chain lubrication: only the Druzhba 4A chainsaw had automatic chain lubrication;

Engine characteristics:

- make and model: MP-1 (single-cylinder, carburetor, two-stroke, air-cooled);

- working volume: 94 cubic meters cm.;

- power: 4 hp (2.94 kW);

- maximum crankshaft speed: 5200 rpm;

- Lubrication system: gasoline with oil;

- connection system with saw set: flange connection fixed with a clamp.

The flange connection made it possible to replace a failed unit without any problems, and also provided the ability to rotate the saw set to an arbitrary angle.

Carburetor adjustment in case of changing operating conditions

In this case, you do not need to identify the breakdown, and the carburetor is adjusted so that the chainsaw can work in new conditions. First, start the chainsaw and let the engine warm up for 10 minutes. After this, you need to determine the position of the idle screw so that the speed is maximum. To do this, turn the screw very slowly and smoothly, first in one direction, then in the other, and so on until the desired position of the screw is found. After this, turn this screw a quarter turn counterclockwise (hereinafter referred to as FC).

Then continue adjusting the idle speed using screw “S”:

- If the chain, after manipulating the first screw, is motionless, then you need to smoothly rotate the screw “S” clockwise (hereinafter POCHS) until it begins to move, and then tighten the screw “S” a quarter turn in the opposite direction;

- If the chain moves, then you need to rotate the screw “S” of the frequency control until the chain stops, and then tighten the screw “S” a quarter turn in the same direction.

After this adjustment, the engines should run smoothly and engine acceleration should be normal. Normal engine acceleration is when, when you press the fuel button, the speed reaches maximum values without dips. If the engine does not run smoothly or accelerates very poorly, then you need to tighten the screw “L” by 1/8. After this, you need to again adjust the “S” screw as described above. These manipulations must be repeated until the engine begins to operate smoothly and acceleration is normal.

After this you need to check the "H" bolt setting. To check it you need to accelerate the engine to maximum speed. Be sure to take breaks and do not hold maximum speed without load for very long. Watch the exhaust and the sound of the engine. If there is a lot of bluish smoke coming from the muffler and the engine is very loud, it means your carburetor is making a very rich mixture. In this case, you need to turn the “H” bolt a quarter of the way. Then check the engine operation again and repeat the adjustment if necessary.

When the chainsaw makes a squealing sound, the engine gets very hot, the exhaust is accompanied by a crackling sound and/or misfires are heard, that is, detonation is occurring - the mixture is too lean, and the maximum engine speed is higher than it should be. This leads to overheating of the power unit, burnout of the piston, rapid wear of the cylinder and burnout of the spark plug. In this case, you need to turn “H” 1/4 turn.

To complete the adjustment, check the saw at idle speed. With a correctly adjusted UPT, it should work like this:

- 1. The chain is stationary.

- 2. The engine sounds almost like a four-stroke.

- 3. Pressing the accelerator leads to a rapid increase in maximum speed.

If these conditions are not fully met, you should use “S” (“LA”, “T”) as indicated above, or repeat the setting from the very beginning.

This is how an approximate adjustment is made. For accuracy you need a tachometer. We do the same thing, only we turn the adjusting bolts, focusing on the readings of this device. This will allow you to accurately and, most likely, adjust the carburetor the first time, achieving, depending on the model of the tool for working with wood, an idle speed setting of 2800–3300 rpm or higher and a maximum speed of 11000–15000 rpm. Which ones should be set should be looked at in the technical documentation (operating instructions) for the saw.

Adjusting a partially or completely misaligned carburetor

After maintenance, such as disassembly and washing, or previous unsuccessful attempts to adjust, this unit may become completely out of alignment. So much so that the chain saw will not start at all. In this case, it is necessary to configure the engine power system in 2 stages, conventionally called:

- basic – with the engine not running;

- final - performed on a warm engine.

At the first stage, slowly screw in the adjusting screws “L” and “H” until they stop. In this case, you do not need to make a lot of effort and try to tighten them. Then we turn both screws back - for many models of saws by 1 turn. And for some - by 1.5 turns. There may be other settings. This must be clarified in the technical documentation for the chainsaw. For a number of models, the hint is printed directly on the cover of their case near the adjusting screws.

This will perform the recommended factory base carburetor setting. In this case, we do not touch the screw “S” (“LA”, “T”) under any circumstances, unless, of course, it has already been turned. When it is already twisted, you will have to work with it. Slowly screw in the “S” of the PRChS until it stops.

Let's move on to the final stage. We are trying to start the engine. If there were no manipulations with the “S” (“LA”, “T”) adjustment and “L” and “H” were set exactly as recommended, then it should start.

If “S” had to be turned on for the reasons stated above, then the engine most likely will not start right away. After each attempt, it will be necessary to tighten this screw 1/4 turn and try to start the engine again. It has to make money eventually.

Then warm up the engine for 10 minutes. If, after starting it or during the warming up process, the motor operates unstably or the chain begins to move, then you need to slowly and carefully rotate “S” (“LA”, “T”) of the frequency control unit. As soon as the engine starts running steadily and/or the chain stops, we immediately stop adjusting. If the engine stalls, then tighten this screw 1/8–1/4 (look in the technical documentation) of the POCHS turn.

During the warming up process, the idle speed may begin to increase, then, again, it will be necessary to “S” (“LA”, “T”) to begin to slowly turn up the frequency control until they become normal by ear. With the engine already warm, we continue adjusting the power system unit, as described in the previous chapter.

Characteristics

Over the 60 years of production, the design of the Druzhba chainsaw and its characteristics have changed insignificantly.

The general parameters are:

- weight when fully equipped - 12.5 kg;

- dimensions - 865x460x500 mm;

- saw bar length - 450 mm;

- The fuel tank capacity is designed for 1.5 liters of fuel liquid;

- spark plug - any with a diameter of 17 mm.

The main difference between the modifications is power. It is indicated by the number in horsepower at the end of the model names.

Friendship 2

The technical characteristics of this model are as follows:

- engine power - 2.2 kW;

- saw starting type - manual;

- lack of a rotary gearbox.

What makes Druzhba 2 different from the first model is the presence of a device for braking the chain, which made it safer: the tool cannot accidentally injure the worker or the people around him. The material from which the case is made is reliable and can withstand any temperature changes.

Friendship 4

This model received a gold medal at the World Technology Exhibition in Brussels in 1958.

The technical characteristics of the chainsaw are as follows:

- power - 2.94 kW;

- engine oil tank volume - 150 ml;

- total shaft rotation speed - 5000-5400 rpm;

A gas-powered saw can cut through a trunk with a diameter of up to 50 cm in 1 minute.

Friendship 4M electron

The Druzhba 4M electron chainsaw is distinguished by the fact that this model is equipped with an electronic non-contact ignition system, which significantly increases the reliability of the engine.

The technical characteristics of 4M are as follows:

- power - 3 kW;

- fuel consumption - 720 g/kW h;

- the distance between the spark plug electrodes is within 0.6-0.7 mm.

The inner walls of the aluminum cylinder liner are plated with chrome to increase wear resistance. The model is equipped with rubber shock absorbers that reduce the transmission of engine vibration to the handles. The Druzhba-4M model uses a KMP-100U carburetor, and with the Druzhba 4A modification, the use of forced chain lubrication began due to the installation of an oil pump. This made it possible to significantly increase the service life of the chain and guide bar.

Adjusting the carburetor after running in the chainsaw

After running in the chainsaw, it is necessary to adjust the carburetor. In this case, you will definitely need a tachometer and technical documentation from the chainsaw you are using. The fact is that when running in a chainsaw engine, slightly different carburetor settings are used, which are configured to prepare a slightly richer mixture, in contrast to that. which is used in constant work. Running in the engine occurs in a gentle mode and therefore after it you need to reconfigure the chainsaw engine.

We strongly recommend that you mark the bolt positions before adjusting the carburetor. Using the marks, in case of an unsuccessful attempt, you can return them to their original place and start setting up again. Adjustment should begin with the “H” bolt. After you have set the maximum speed, check the idle. If they are different from normal, then first set them with “L” and then “S”. But turn the screws based on the tachometer readings.

Running in the new Druzhba saw

For refueling, special oil for two-stroke engines and AI-92, AI-95 gasoline are used. Prepare a fuel mixture at the rate of oil/gasoline 1:15. Running in the chainsaw should be carried out in accordance with the operating instructions for the Druzhba saw, in two stages. At the first stage of running-in at idle, at least four tanks of fuel must be used up. After this, you can start working without overloading the tool.

At the second stage, the saw must work for 25 hours in gentle mode. Only after this can you remove the retaining ring and begin full operation.

Chain tensioning and lubrication

The performance of the saw and its service life largely depend on proper chain tension and lubrication.

- Place the chain on the bar.

- Install the tire onto the gearbox.

- Tighten the mounting bolts, then loosen them.

- In this position, the chain should sag by 7-10mm.

- Tighten the mounting bolts.

The Druzhba 4 chainsaw has an automatic chain lubrication system. Pour oil into the reservoir and check that the oil is spraying evenly while idling.

It is also important to know how to replace the sprocket. This process consists of the following stages:

- Dismantling the chainsaw headset, unscrewing the nuts of the tire cover. Removing the bar and chain.

- Removing the air filter.

- Unscrew the spark plug using a universal wrench and replace it with a piston stopper.

- Using a clutch puller, which is mounted in a universal wrench, the clutch is removed.

- Replacing the sprocket.

- Reassemble in reverse order.

Carburetor adjustment

Often the Friendship chainsaw starts and stalls, does not start at all, or consumes too much gasoline. One of the reasons for increased fuel consumption and uneven engine operation is an incorrectly adjusted carburetor. Its adjustment does not require special skills and can be done at home.

Before you start disassembling the carburetor, make sure that the spark plugs are not filled with fuel mixture - this happens quite often in units of this type

Then you should pay attention to the gas valve and bend it a little inward. This operation reduces the amount of fuel supplied

If the engine still runs unevenly, proceed to adjusting the carburetor:

- Tighten the fuel screw until it stops.

- Unscrew it back three full turns.

- Turn the propeller all the way in.

- Loosen the propeller two turns.

- Check the seals for leaks.

Maintenance

Daily maintenance is carried out before and after work: the functionality of the Druzhba chainsaw is checked and it is cleaned of contaminants. Routine inspections are carried out in case of malfunctions, minor malfunctions, to adjust the chainsaw carburetor, sharpen the chain, etc.

Main components of the Druzhba chainsaw

After completion of active work, it is necessary to mothball the unit. Clean it from dirt, dry it, lubricate the working parts to prevent corrosion from forming, cover it and put it in a dry place.

Reactivation of the Druzhba chainsaw

Thoroughly clean the outer surfaces of the housing from factory grease.

Pay special attention to the starter. Unscrew the spark plug, wash it in gasoline, wipe it with a clean cloth, dry it and put it back in place. Wipe the ignition wire with a clean cloth.