Skid steer attachments

ISTK company is a reliable supplier of Japanese attachments. We have a wide range of multi-function devices for Komatsu brand skid steers. The catalog contains both popular series of spare parts and components from global manufacturers, as well as new items.

As an official distributor, the company offers its customers original products in a wide variety of models at manufacturer prices. After-sales service of specialized equipment and attachments for mini loaders is available, with guaranteed provision of the client with the necessary branded parts. Related additional services are also provided: from installation of products to training of mechanics and operators in the use of devices.

The provision of services and the supply of attachments for mini loaders is carried out on the territory of several federal districts of Russia: from Central to Volga. Flexible payment terms and the possibility of individual deliveries of custom-made products are provided.

The following product items are presented to the attention of buyers:

- hydraulic drills,

- buckets,

- brushes,

- hydraulic hammers,

- other devices.

You can get acquainted with the whole variety of products by studying the catalog in more detail. You can order attachments for mini loaders and consult the contact numbers of the ISTC sales department.

Modernize and expand the functionality of your special equipment on favorable terms! By purchasing attachments for mini loaders, business owners save significantly due to the absence of the need to spend on purchasing new machine models.

Comfort and habits

For most mini-loaders, or more precisely for compact loaders of the classic type (Bobcat, Russian ANT, etc.), the boom is located in front on two beams, respectively, the entrance to the cabin is directly through the working equipment - from the side of the bucket or blade.

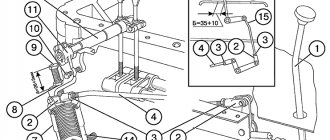

“The attachments are lifted on two boom beams, one on each side - left and right,” explains Svetlana Petrova. “For this reason, entry into the cabin is not possible from the side, but only from the front, through the attachment.” But there is another, more convenient location. For example, JCB has a monobeam boom - that is, it has only one lifting beam, which is located on the right. Accordingly, the entrance to the cabin is on the left. This nuance must also be taken into account when choosing a car.

Since in agriculture a mini-loader is operated in close proximity to farm workers and animals, the visibility factor is critical for machines of this class, notes Svetlana Petrova. “The placement of the boom on the right significantly increases all-round visibility, which is 270 degrees (instead of 160 for analogues on the market).”

Loaders with the transmission located at the bottom also have better visibility - the operator sits higher, notes Dmitry Ivanov. Whereas in classic skid steers, the operator's view is limited by the lower landing point and the boom structure that rises above him.

“We shouldn’t forget about the presence of an air conditioner with a good filtration system, since mini-loaders spend almost 90% of their time indoors,” notes Alexander Stovbun. “This is very important when working in aggressive environments of poultry houses and barns, as well as dusty areas of grain storage facilities.”

Svetlana Petrova reminds that equipment operating in such conditions must be equipped with a spark arrester, which is also important when working with flammable hay and straw.

Bobcat recommends paying attention to protecting important components from damage: the bottom, engine, chassis and all hydraulics. In addition, work productivity will be improved by equipping the loader with an electric attachment lock to simplify and speed up the change of working parts.

Control in the cabin of mini loaders is most often carried out using levers, as in conventional bulldozers and excavators. For people of the “old school”, this does not present any difficulties.

However, new models and designs are increasingly appearing where control is carried out using servo joysticks (for example, for JCB: the left one controls the transmission, the right one controls the boom). And for many operators, machines with completely classic controls (like a conventional loader) seem more comfortable: using a steering column and a monojoystick. For example, in Weidemann or Italian Venieri. According to Dmitry Ivanov, this arrangement is much more convenient and simpler, especially for machine operators who have not previously dealt with a fully lever control system.

In some cars, the gas pedal is supplemented with a “manual gas”, which, according to experts, allows you to quickly regulate engine speed, and this provides significant savings in diesel fuel (up to 30% compared to models without a pedal).

For example, in Venieri mini-loaders, the “manual throttle” option allows the operator to regulate engine speed, and accordingly, the hydraulic flow to the attachment, regardless of the speed of movement of the machine itself.

Dmitry Ivanov points out that this makes it possible to more efficiently operate the machine with brushes, mowers and buckets with belt conveyors for distributing litter.

Electrically driven models of mini loaders have also appeared on the market. These machines are not only characterized by the absence of soot pollution and CO2 emissions, but also by lower noise levels. This allows you to work in areas with a critical attitude to loud sounds and CO2 levels, including poultry houses. For example, from Wacker Neuson (Weidemann 5055e loaders, etc.).

Mini loader - definition, history, application.

A mini loader (English: skid loader, skid steer loader) is a machine with a rigid frame and lifting arms (“paws”) that are attached to the rear of the cab and are used for attaching and manipulating a wide range of attachments. Thanks to a large selection of attachments, mini loaders are quite versatile machines designed to replace manual labor as much as possible. Like other types of forklifts, it is capable of pushing materials, carrying them in a bucket, or loading them into an onboard vehicle.

Mini loaders can be tracked or wheeled. A tracked loader has greater cross-country ability and, as a rule, greater lifting capacity, and can also extend the bucket further. A wheeled mini loader is a machine with four wheels, and the left and right groups of wheels are independent, which allows you to control the rotation of the machine like caterpillars. Thanks to this design feature, the wheeled mini loader is also known as a skid steer loader. This design allows the loader to make turns and turns on the spot, which makes this class of machines especially maneuverable and indispensable in confined spaces.

Unlike a front loader, the manipulators in these machines are mounted behind the operator’s back and run along the entire side. Because the driver is in close proximity to moving hands, early skid steers were not as safe as front loaders, especially while the operator was getting in and out of the cab. Modern mini loaders have a fully enclosed cabin and other features to ensure maximum operator safety.

A mini loader can sometimes be used instead of a large excavator to dig a hole or pit from the inside. To do this, first make an earthen ramp leading to the upper edge of the pit. Next, the mini loader uses a ramp to push the earth out. During the digging process, the ramp is made steeper and longer. This digging method is used when the height does not allow the use of excavators, for example, when you need to dig a hole under a canopy.

A regular mini loader bucket can be replaced with one of a variety of specialized buckets or other attachments that are powered by the hydraulic system of the mini loader itself. Some examples of attachments: backhoe, hydraulic breaker, pallet fork, brooms and brushes, auger, mowing attachment, snow removal attachments, trencher, plow, concrete mixer, saw.

The mini loader prototype was invented by the Keller brothers in Minnesota (USA) in 1957.

This loader was invented by the brothers to help the farmer automate the process of removing manure from the chicken coop, and was a three-wheel front loader with a front drive wheel. This light and compact machine could turn around its length and still perform the same tasks as a conventional front loader. Then in 1958, the Melroe Manufacturing company bought the rights to this loader from the brothers, also hiring them to work for them to further improve their invention. As a result, in the same year, the M-200 model appeared - a mini loader with two front independent drive wheels and one rear wheel, with a 12.9 hp engine. and a load capacity of 340.19 kg. Two years later, the rear wheel was replaced with an axle, and the M-440, the first four-wheel skid steer, was introduced. He quickly became a Melroe Bobcat. "Bobcat" is sometimes used as a term for a skid steer. This model was equipped with a 15.5 hp engine. and had a load capacity of 498.95 kg. The development of the loader continued until the mid-60s and the result was the M-600 model. Now many world manufacturers produce their own versions of mini loaders, such as: John Deere, Case, JLG, JCB, New Holland, Gehl, Mustang, ASV, Caterpillar and others. Category: Mini loaders

View the built-in online gallery at: https://www.dashdemir.com/index.php/katalog-tekhniki/jcb/mini-pogruzchiki/item/82-mini-pogruzchiki-na-maloj-platforme#sigProIdf812077bba

Description:

Mini loaders with a small platform SSL135, SSL155, SSL175, SSL190, have small overall dimensions, a stable wheelbase, are very compact, powerful, reliable and maneuverable, while simultaneously having a lifting height of up to 2.6 meters and a load capacity of up to 900 kg. Most often it is used during work in confined spaces: small warehouses, docks, workshops, narrow city streets. The small size of the equipment does not in any way affect the comfortable, spacious cabin with a large viewing angle, which is increased by the JCB loader's all-round skid steer. It is equipped with control levers and an instrument control panel, a comfortable and ergonomic driver's seat. All models are equipped with powerful, reliable and extremely efficient JCB Dieselmax engines. The unusual shape of the cars facilitates access to the cabin and ensures safety for drivers while driving. . The movement speed of these loaders is low - 10 km/h, but it is quite sufficient for equipment of this class and purpose. A wide range of selection of attachments can significantly increase the scope of application of mini loaders with a small platform. A quick-release equipment holder is included as standard, allowing you to quickly change a wide range of optional equipment, providing installation versatility. Rollover/Falling Object Protective Systems (ROPS/FOPS) with seat belt as standard to protect the operator in the workplace. The forklift parking brake cannot be released until the operator is in a safe seated position. A self-leveling system can be installed for pallet handling. Small skid steer loaders are workhorses that can handle many everyday jobs with full efficiency.

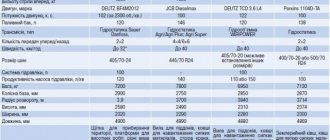

Specifications:

| Name | : | SSL135 | : | SSL155 | : | SSL175 | : | SSL190 |

| Boom design | : | Radial | : | Radial | : | Vertical | : | Vertical |

| Load capacity, kg | : | 612 | : | 703 | : | 794 | : | 862 |

| Total weight, kg | : | 2752 | : | 2844 | : | 3011 | : | 3127 |

| Engine model , | : | 404D-22 (2.2) | : | 404D-22T (2.2) | : | 404D-22T (2.2) | : | 404D-22T (2.2) |

| Engine type, number of cylinders | : | diesel (4) | : | diesel (4) | : | diesel (4) | : | diesel (4) |

| Wheel drive | : | 4WD | : | 4WD | : | 4WD | : | 4WD |

| Engine power, kW (hp) | : | 35,7 (47,5) | : | 44,7 (59,9) | : | 44,7 (59,9) | : | 44,7 (59,9) |

| Max torque, Nm(kgcm) | : | 143 | : | 189 | : | 189 | : | 189 |

| Transmission | : | hydraulic two-speed | : | hydraulic two-speed | : | hydraulic two-speed | : | hydraulic two-speed |

| Speed, km/h | : | 12 / 18,5 | : | 12 / 18,5 | : | 12 / 18,5 | : | 12 / 18,5 |

| Wheelbase, mm | : | 1070 | : | 1070 | : | 1070 | : | 1070 |

| Ground clearance, mm | : | 210 | : | 210 | : | 210 | : | 210 |

| Fuel tank, l | : | 98 | : | 98 | : | 98 | : | 98 |

| Hydraulic system, l. | : | 42 | : | 42 | : | 42 | : | 42 |

| Pump capacity, l/min | : | 70 | : | 100/ 70 | : | 100/ 70 | : | 100/ 70 |

| Max lifting height, m | : | 3 | : | 3 | : | 3 | : | 3 |

| Loading height, m | : | 2,84 | : | 2,84 | : | 2,84 | : | 2,84 |

| Unloading height, m | : | 2,26 | : | 2,26 | : | 2,26 | : | 2,26 |

| Turning radius, mm | : | 1650 | : | 1650 | : | 1650 | : | 1650 |

| Tires | : | 10 x 16.5 | : | 10 x 16.5 | : | 10 x 16.5 | : | 10 x 16.5 |

| Type of working body | : | Forks/Bucket | : | Forks/Bucket | : | Forks/Bucket | : | Forks/Bucket |

| Standard fork size, mm | : | 1000x100x50 | : | 1067x100x50 | : | 1067x100x50 | : | 1067x100x50 |

| Bucket, cubic meter | : | 0,4 | : | 0,44 | : | 0,44 | : | 0,44 |

| Tipping load, kg | : | 1356 | : | 1406 | : | 1587 | : | 1723 |

| Lifting force, kg | : | 1440 | : | 1770 | : | 1570 | : | 1570 |

| Bucket breakout force, kg | : | 1820 | : | 1820 | : | 2140 | : | 2140 |

| Dimensions, m | : | 3.49x1.52x1.98 | : | 3.49x1.60x1.98 | : | 3.53x1.60x1.98 | : | 3.56x1.69x1.98 |

File name: mini-pogruzchik-JCB-SSL135.pdf

1336 193 2.66MB

File name: mini-pogruzchik-JCB-SSL155.pdf

1336 202 5.38MB

File name: mini-pogruzchik-JCB-SSL175.pdf

1336 204 2.66MB

File name: mini-pogruzchik-JCB-SSL190.pdf

1336 214 5.38MB