ZIL-164

ZIL-164 on Wikimedia Commons

Total information

| Manufacturer | ZIL |

| Years of production | 1957—1964 |

| Assembly | ZIL (Moscow, USSR) |

| Class | Cargo |

| Other designations | Zakhar (nickname) |

Design

| Platform | ZIS-150 |

| Wheel formula | 4 × 2 |

Engines

| Manufacturer: | ZIL |

| Brand: | ZIL-164 |

| Type: | Petrol |

| Volume: | 5555 cm3 |

| Maximum power: | 97 l. s., at 2600 rpm |

| Maximum torque: | 324 Nm, at 1200 rpm |

| Configuration: | in-line, 6-cylinder. |

| Cylinders: | 6 |

| Valves: | 12 |

| Max. speed: | 75 km/h km/h |

| Cylinder diameter: | 101.6 mm |

| Piston stroke: | 114.3 mm |

| Compression ratio: | 6,2 |

| Supply system: | carburetor |

| Cooling: | liquid |

| Valve mechanism: | SV |

| Cylinder block material: | cast iron |

| Cylinder head material: | aluminum |

| Clock (number of clock cycles): | 4 |

| Cylinder operating order: | 1-5-3-6-2-4 |

| Recommended fuel: | A-66 |

Transmission

| manual 5-speed | |

| Manufacturer: | ZIL |

| Model: | 164 |

| Type: | mechanical |

| Number of steps: | 5 |

| Gear ratios: | |

| 1st gear: | 6,24 |

| 2nd gear: | 3,32 |

| 3rd gear: | 1,9 |

| 4th gear: | 1,0 |

| 5th gear: | 0,81 |

| Reverse gear: | 6,7 |

| Switching: | floor lever |

The main gear is double, the gear ratio is 7.63.

Characteristics

Mass-dimensional

| Length | 6700 mm |

| Width | 2470 mm |

| Height | 2180 mm |

| Clearance | 265 mm |

| Wheelbase | 4000 mm |

| Rear track | 1740 mm |

| Front track | 1700 mm |

| Weight | 4100 kg |

Dynamic

| Max. speed | 75 km/h |

On the market

| Predecessor Predecessor ZIS-150 | Successor Successor ZIL-130 |

| Related | ZIL-157 |

| Similar models | GAZ-51 |

Other

| Load capacity | 4000 kg |

| Fuel consumption | 27 l |

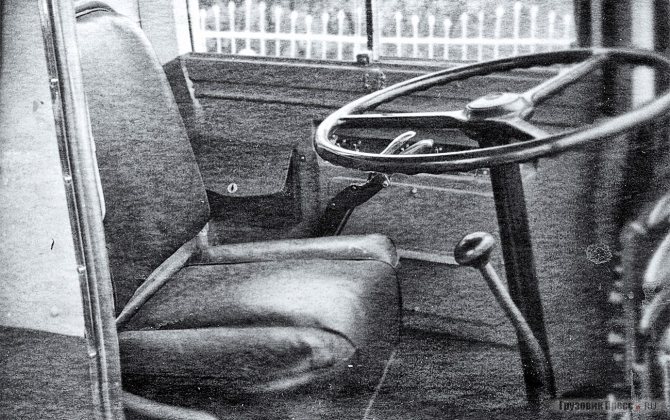

ZIL-164, cabin.

Cabin interior.

A fire truck based on ZIL-164 at a parade in Barnaul, 2020.

ZIL-164

- Soviet truck produced by the Likhachev Plant. Created on the basis of the ZIS-150 by modernizing its individual components and assemblies. Produced from October 1957 to December 1964 (from December 1961 - ZIL-164A).

History of creation

Predecessor defects

The Winter War of 1939-1940 showed that the Red Army did not have efficient and reliable all-terrain vehicles. The ZIS-22 half-track tractors in service demonstrated a whole “bouquet” of shortcomings. The rubber-fabric caterpillar tracks used on them quickly stretched, often fell off when turning and broke. If the chains driving the drive wheels broke, the car was left with virtually no brakes (the front brakes did not hold, and the most effective hand brake acted on the driveshaft) - this was especially dangerous on descents. The car maneuvered very poorly: it was especially difficult to get out of a rut if necessary - the front non-driving steered wheels simply skidded. Due to large mechanical losses in the tracked drive, the engine power was not enough - the main driving modes were 1st and 2nd gears. It was rarely possible to get into 3rd gear, and 4th was practically never used.

But the most unpleasant thing was that the car did not demonstrate the cross-country capability expected of it in snow and soft soils. Snow and dirt piled into the crawler and increased the resistance to movement. At the same time, the drive wheels began to slip inside the icy caterpillar tracks. This defect was further aggravated by the differentials located between the front and rear drive wheels in each of the tracked bogies (they were installed for fear of power circulation inside the tracked circuit) - as a result, as soon as one of the four drive wheels skidded, the car stopped. This was fully demonstrated at the show, which was held at the end of January 1940 at the experimental field of NATI in the presence of the head of the GABTU of the Red Army, commander of the 2nd rank D. G. Pavlov. The show included all-wheel drive vehicles ZIS-K-1 (6×6), ZIS-K-2 (4×4), half-track GAZ-60, NATI-VZ and ZIS-22. They all got stuck in the snow.

After such a fiasco, NATI designers, under the leadership of the creator of the ZIS-22, G. A. Sonkin, thoroughly redesigned the car - first of all, introducing forced engagement of the drive wheels with the caterpillar track.

ZIS-22-N

In the spring of 1940, a prototype ZIS-22-N

("new"). It also had two drive wheels on board with a differential between them, but its drive wheels, instead of dual pneumatic tires, received a pair of solid weights (rubber bands), between which sprockets were installed for forced engagement with the track. The weak rubber-cord track was replaced with a metal one with imported Johnson rubber-metal joints. Each track received two outer rubber shoes. The propulsion frame was strengthened and its rigidity increased. As a result of these improvements, the curb weight of the vehicle increased by 545 kg and amounted to 5205 kg. Almost the entire increase in weight came from the tracked vehicles, which now weighed 1973 kg - 38% of the weight of the entire vehicle.

ZIS-22-50

On the next sample of the vehicle, designated ZIS-22-50

, the design of the tracked propulsion unit was significantly simplified - only one drive wheel (front) was left in each tracked vehicle. This made it possible not only to abandon the side differentials in the trolley, but also to simplify the tension of the tracks - the eccentric supports of the supporting rollers were eliminated and the tension was carried out due to the longitudinal movement of the idler, which the rear (former driving) wheel has now become. In addition, the drive wheels were equipped with shoe brakes operating (together with the front brakes) from the pedals. At the same time, at the exit from the gearbox, the central disc brake (from the ZIS-6) with manual control was retained. The safety and reliability of the machine increased, but the weight of the trolleys also increased with them - they now weighed 2070 kg. In addition, the capacity of gas tanks was increased by 160 liters. Instead of the ZIS-5 engine (73 hp), a more powerful ZIS-16 engine (85-88 hp) was installed on the car, thanks to which it became possible to reduce the gear ratio in the chain drive (from the rear axle to the drive wheels) 10.6% - now it was 1.6. To eliminate engine overheating, an enlarged radiator was installed on the car, borrowed from the ZIS-6. All this made it possible to increase the maximum speed of the car to 38 km/h, but the curb weight reached 5845 kg (without load).

ZIS-22-52

In order to reduce weight on the next version of the machine, designated ZIS-22-52

, the metal caterpillar tracks were replaced with lighter ones, each of which consisted of two rubber-fabric belts connected to each other by forged linings (tracks), located at intervals of 100 mm. The teeth of the drive wheel engaged with these linings, and the tapes were kept from slipping off by stamped plates, which were attached to the tapes from the inside. On the outside, rubber shoes, vulcanized to steel bases, were attached to the tapes. To move on ice, 5 spurs were installed on the caterpillar. The total width of such a double track was 400 mm. In this case, the average specific pressure on the ground was 0.433 kg/cm². The ZIS-22-52 was built in two copies and was tested in Kubinka in September 1940 and February-March 1941 together with the Krauss-Maffei half-track tractor. Based on the results of tests of the ZIS-22-52, it was recommended to strengthen the tracked vehicles (especially the road wheels), reduce the weight and prevent the tracks from falling off. However, in general, the ZIS-22-52 was recognized as meeting the requirements of the Red Army. It was decided to introduce the ZIS-22-52 into production at the Moscow ZIS automobile plant with the production of 2000 cars in 1941.

ZIS-22M - aka ZIS-42

When the ZIS-22-52 design was introduced at the factory, the vehicle received the factory designation ZIS-22M. The following changes were made to its design: the width of the tracks was increased from 400 to 414 mm, the linings connecting them were strengthened and began to be precision forged. We increased the strength of stamped tiles and introduced stiffening ribs into them. To reduce the likelihood of the tracks falling off when turning, the distance between the plates was reduced to 35 mm. To increase cross-country ability on snow and soft soils, the axles of the drive and guide wheels were lowered - at the same time, the length of the supporting surface increased to 2100 mm (with the mover immersed by 100 mm), but maneuverability deteriorated somewhat. The scarce and insufficiently reliable ZIS-16 engine was replaced with the serial ZIS-5 with a power of 73 hp. With.

Considering the large number of design changes that have accumulated compared to the original ZIS-22, the ZIS-22M was relabeled as the ZIS-42. By the summer of 1941, three vehicles had been produced as standards for the series. One of them received a shortened base in order to improve maneuverability (however, the experiment was unsuccessful). In July 1941, these vehicles underwent field tests, which were considered successful. The car was being prepared for production, but plans for its production were thwarted in October 1941, when the evacuation of the plant began[1].

The "truth" about the engine

The main problem in the construction of prototypes of the ZIS-129 was the creation of a high-power engine, which allowed the bus with a gross weight of about 14 tons to reach a maximum speed of 70 km/h. Unsuccessful experience in operating the ZIS-154 with a two-stroke diesel engine, which was characterized by increased noise and smoke, led to an erroneous statement about the unacceptability of diesel engines for city buses, so the use of the YaAZ-206 engine, which was equipped with the ZIS-127, was completely excluded. “A modern bus requires an engine with a power of approximately 180 hp. With. But the automotive industry does not produce such an engine. It is no coincidence that the experimental ZIL-129 buses at the I. A. Likhachev plant have 180 hp engines. With. they did it with great difficulty,” wrote Moskovskaya Pravda already in March 1957.

A V-shaped 7-liter carburetor engine ZIS-E129 with a power of 180 hp was developed especially for the ZIS-129. pp., placed transversely in the rear overhang. The power plant was equipped with a hydromechanical transmission, which included a pair of single-plate wet clutches with cermet linings and automatic control, a 3-speed torque converter, a reduction gearbox with a ratio of 1.35 and a 2-speed synchronized manual gearbox with manual shifting. At the same time, the final drive ratio was increased from 3.64 to 6.86. ZIS-129 with a total weight of 13.5 tons had a maximum speed of 70 km/h.

Description of design

Tests of the prototype ZIS-42, April 27, 1942.

The half-track ZIS-42 differed from the basic ZIS-5V by the presence of a tracked undercarriage with two oscillating bogies instead of rear drive wheels. The frame of each crawler bogie consisted of stamped sidewalls, rigidly connected by a support hub and cross members. At the ends of the cart, between the sidewalls, there was a drive wheel in front and a guide wheel (sloth) in the back. A system of four rollers, covered with a casing, was balanced between them. The entire propulsion unit was suspended balanced on the axle shafts of the rear axle. ZIS-42 had a pan and a casing on the front axle. To protect the movers from impacts when driving over rough terrain, four limit rollers were installed on special brackets on the underside of the platform.

The caterpillar track (total width 414 mm) consisted of two rubber-fabric belts, each 21 mm thick and 178 mm wide, connected by metal pads. The teeth of the drive wheel engaged with these linings, and the tapes were kept from slipping off by stamped plates, which were attached to the tapes from the inside. On the outside, rubber shoes, vulcanized to steel bases, were attached to the tapes.

When driving in deep snow and swamps, skis mounted on the front wheels were used.

The modernized car (ZIS-42M) had an engine of the ZIS-5M type (76 hp)[2];[3]. The radiator and headlights were covered with a grille to protect against damage.

Specifications

- Load capacity: when driving without a trailer - 2250 kg

- when driving with a trailer - 1500 kg

- when driving on virgin snow - 1750 kg

- with overload - 4750 kg

- in the cabin - 2

- length - 6097 mm length with skis on front wheels - 6745 mm

- height along the awning (with load) - 2900 (2944) mm

- from the axis of the front wheels to the swing axis of the crawler bogie - 3810 mm

- front wheels - 1546 mm

- full - 414 mm

- under the front axle - 318 mm

- caterpillar propulsion on hard ground - 0.299 (0.304) kg/cm²

- on the highway with a trailer - 390 km

- estimated - 35.9 (41.8) km/h

- maximum lift on the ground with a trailer - 17°

Technical characteristics of the ZIL-158 city bus

Length, mm 9030 Width, mm along the skin 2396 overall 2500 Height without load, mm 3000 Base, mm 4858 Overhang, mm front 1470 rear 2702 Track, mm front wheels 2126 rear wheels 1806 Empty weight, kg 6500 Control fuel consumption, l/100 km 37 Engine power, hp at 2800 rpm 109 Number of cylinders 6 Cylinder diameter/piston stroke, mm 101.6/114.3 Displacement, l 5.55 Compression ratio 6.2 Cylinder operating order 1-5-3-6-2-4 Weight power unit, kg 555 Wheel tires 10/20 I-145 (or 11/20 V-195A)

P. ZELENKEVICH, Modeler-Constructor, No. 6'2001

Vehicles based on ZIS-42

Fire truck on the ZIS-42 chassis ZIS-42M (model), State Polytechnic Museum (Moscow)

Based on the ZIS-22M and ZIS-42, two experimental models of self-propelled guns were created, which did not go into production:

- ZIS-41 is a semi-armored tractor for the 122 mm M-30 howitzer and a self-propelled gun with a 57 mm ZIS-2 cannon (the vehicle was created on the basis of the ZIS-22M in the design bureau of artillery plant No. 92 in Gorky and has been tested since November 1941 )[4].

- ZIS-43 is a semi-armored self-propelled gun with an anti-aircraft automatic 37-mm 61-K cannon (created at the Moscow ZIS plant on the basis of the serial ZIS-42, tested since November 1942)[5].

- ZIS-BM-82M

is a self-propelled mortar, which was an 82-mm battalion mortar on the ZIS-42 chassis. In November 1942, one ZIS-BM-82M was manufactured, which was sent to the front for testing in a combat situation, but the operation of the vehicle revealed insufficient chassis strength and after the ZIS-42 failed, the experiment was stopped[6]

It should be noted that the coincidence in the designation is accidental - unlike the anti-aircraft ZIS-43, the ZIS-41 was created not at the Moscow Automobile Plant named after Stalin, but at the design bureau of artillery plant No. 92 in Gorky, which also bore the name of Stalin[4 ] (its products are ZIS-2, ZIS-3 artillery guns and others).

Modifications

In 1959, the standard model ZIL-111, the photo of which is presented above, went through the first stage of modernization and received the name 111A.

The car was equipped with the first special air conditioner in the Union, and the rear window was also significantly reduced. This decision made it possible to strengthen security measures and improve the comfort of movement. In 1960, the 111B phaeton was produced in a small series. It was a huge car with seven seats, equipped with an awning that folded and unfolded hydraulically. The design of the roof resembled the analogues used on ZIS vehicles.

The modified version 111G has become the most significant in the direction of radical implementations and transformations. The car received double front headlights, chrome arrow-shaped moldings on the sides and an updated nickel-plated radiator grille. ZIL-111 (photo of the interior below) was decorated inside completely differently, a new semi-hidden air conditioner appeared. As a result, the vehicle became 200 kilograms more massive and 50 millimeters longer.

Later, ceremonial phaetons (ZIL-111D) were designed based on the 111G model. The first copy rolled off the assembly line in 1963. Only seven units of this type were produced. The total number of open-type limousines based on the technology in question was about 120. Thus, the problem with domestic luxury cars was solved.

Notes

- Prochko E.

Artillery tractors of the Red Army // Armored collection: magazine. - 2005. - No. 2. - Matveenko V.I.

History of the design and production of off-road trucks in the USSR in the period from the late 20s to the mid-40s of the XX century: Dis. ...cand. history Sci. - St. Petersburg, 2004. - 278 p. - Polikarpov N.

ZIS-5 truck. - M.: LLC Publishing House "Tseykhgauz", 2007. - 48 p. — 2000 copies. — ISBN 5-9771-0021-3. - ↑ 1 2 Kirindas A.

Half-track all-terrain vehicles of the Red Army. - M.: Publishing house, 2004. - 48 p. — 3000 copies. — ISBN 5-94038-056-5. - Kolomiets M.V.

Armor on wheels. History of the Soviet armored car 1925–1945. - M.: Yauza, KM Strategy, Eksmo, 2007. - 384 p. - (Soviet tanks). — 3000 copies. — ISBN 978-5-699-21870-7. - Doctor of Technical Sciences B. M. Fitterman (NAMI). Wheels or tracks? // magazine "Automotive Industry", No. 2, 1989. pp. 33-35

“King of off-road” - the legendary ZIL-157

Representatives of the older generation remember that in the 50s and 60s there were a lot of trucks on the roads, almost more than cars. As a child, I loved to stand and watch them. But for some reason I liked the ZIL-164 most of all. I don’t know how he won my heart. Maybe because of its forms, which by the end of the 60s were already very outdated. The truck looked archaic, but that was precisely what had its special charm. I liked its rounded fascia, large bulbous wing ears mounted on the headlight brackets. And there was something else about him...

Here is an excerpt from a conversation between Lev Shugurov and the famous automotive engineer Valery Nikolaevich Belyaev: “But why is it so good, Valernikolaich: the steering wheel is heavy, the ventilation is rubbish, and there is no heater - it’s always cold in the cabin in winter?”

“He, you know, is not only sternly noble in appearance, but throughout his entire structure he is the same.” You, of course, know the building of the Central Telegraph - it was built by Ivan Ivanovich Rerberg, a descendant of a Danish shipbuilder. It has everything, like in “ZIS-one and a half hundred”: asceticism and rationalism, unusualness and traditionality, its own inconveniences and its own advantages.

This truck had a very interesting modification that outlived its ancestor by 30 years. It was the famous ZIL-157 truck, which had unique cross-country ability and was called by drivers the king of off-road conditions. I always liked his appearance. Flat fenders, an elongated buffer behind which the winch was hidden, nice and elegant wheels with 12.00x18-inch tires - all this gave the car an extremely rational and spartan look, as befits an off-road truck.

In 1991, fate brought me directly together with this wonderful truck. I was offered to take part in the conversion of the ZIL-157. Instead of the original engine, a V-shaped six-cylinder diesel engine YaMZ-KAZ-642 (modification of KamAZ) with a clutch and a KamAZ gearbox was installed on it. It was a modification of the ZIL-157KG with a shielded electrical system. Not only the ignition system was shielded, but also other circuits containing contacts (water temperature and oil pressure sensors). The V-shaped six-cylinder diesel engine has become quite good instead of the original in-line gasoline “six”, only the starter traction relay turned out to be located very close to the frame side member. There were no special problems with the gearbox either; we only had to slightly modify the driveshaft. True, the pneumatic booster for the clutch drive was not installed, and the force on the clutch pedal was incredible. The diesel engine, although it was one and a half times more powerful than the original engine, was noticeably noisier and less balanced. And I yearned for my native lower-valve “six”... I would like to tell you more about this engine, as well as the design of this truck in general.

Production of the ZIL-157 began in 1958. Its main difference from its ten-year-old predecessor, the ZiS-151, was the presence of single-pitch wheels with a centralized tire pressure regulation system (TPR). The ZiS-151, like the Studebaker on which it was modeled, had conventional dual-pitch wheels at the rear and single-pitch wheels at the front, which had a negative impact on cross-country ability. Designers have long proposed using single-pitch wheels for off-road vehicles. This was done on the GAZ-63. But the advantages of this scheme were especially evident when using the SRD. For the first time, such a solution was used on a large floating vehicle ZiS-485 (BAV).

At one time, the famous automobile designer Vitaly Andreevich Grachev addressed Marshal Zhukov with a letter in which he described the advantages of the SRD and advocated for its speedy introduction into army military equipment. The marshal got acquainted with the arguments of supporters and opponents of the new system and ordered comparative tests of various types of all-terrain vehicles. They were appointed for the summer of 1954. This is how one of the participants describes this event (taken from Yu.G. Alekseev’s book “People and Automobiles,” 1990): “About thirty years have passed since then... Maybe I forgot. We chose a place not far from the “minka”, but it looked like it was in the tundra or somewhere among the Polesie swamps. Right from the dirt road there are bumps and swamps for about a kilometer and a half. Everyone gathered at eight o'clock. On the side of the road they lined up a ZIS-151 - double-slope: without pumping, BTR-152 - single-slope without pumping, BTR-152V - with pumping, ZIS-1211 and GAZ-63 - single-slope without pumping. Another prototype of the ZIS and Grachev’s floating vehicle - both single-slope and with pumping. Maybe there were others, I can’t say for sure. Grachev, our officers, people from factories, from the Automotive Industry were present.

At exactly nine o'clock a ZIS-110 braked near us. Zhukov came out. He gave the command: “Begin!” An officer sat in the cab of each car next to the driver. Controllers. The cars slid down the country embankment and moved through the swamp. The first, after about a hundred meters, was “one hundred and fifty-one.” Then, a couple of minutes later, the “sixty-third” sat down... In general, after a little while in our swamp it became like on the Kursk Bulge - a dozen and a half cars got stuck like flies in jam. From a distance I see officers in their cabins. worried. They wave their hands - they stimulate drivers. But where is it? Everyone is sitting tight. And the single-slope “zisok” with pumping, the BTR-V and the Grachevskaya amphibian, have released all the pressure - and are crawling quietly. We made a circle and got out onto the road. Zhukov watched everything in silence. And when the three cars returned, I wanted to take a ride through the swamp myself. They gave him a leather jacket. He threw it over his jacket, climbed into the BTR-V and waved his hand. The driver carefully took him around the parked “all-terrain vehicles” and drove him straight to the ZIS.

“There are maneuvers in the Belarusian district in October,” says Zhukov. — So that I have ten of these vehicles at my maneuvers.

“What are you talking about, Georgy Konstantinovich,” the auto industry people answer him, “We only have two prototypes.” We won’t have time to do another eight in three months...

“I don’t know anything,” the marshal interrupted them. “If there are no cars, I’ll cancel the military orders.” He got into the back seat of the ZIS and drove away.

Of course, ten armored personnel carriers came out on time for maneuvers and performed excellently. At the same time, the issue was irrevocably resolved in favor of single-pitch wheels. Since then, all military off-road vehicles have been equipped with such wheels. And most of them also include systems for centralized tire pressure regulation, which over the course of several years was not only mastered in mass production and operation, but also significantly improved compared to the first prototypes.

Yes, thanks to the SRD, the truck really had unique cross-country ability. What else was interesting about this car?

Let's start with the engine. This in-line, six-cylinder lower valve engine was a modernized version of the ZiS-120 engine, which was installed after the war on ZiS-150 trucks. In turn, this was a development of the ZiS-5 engine, which, as is known, came from the American GM. The American origin is evidenced by the dimensions: cylinder diameter 101.6 mm, piston stroke 114.3 mm (4 and 4.5 inches, respectively). This engine had many modifications, differing in compression ratio, valve timing, cylinder heads (cast iron or aluminum), and carburetors. The ZIL-157 was equipped only with two-chamber carburetors, providing more power. The engine design was quite traditional for those years. The cooling system is closed type (without expansion tank), thermostat in the cylinder head. Lubrication system with a floating oil receiver and coarse and fine oil filters (they were located nearby). The inline lower-valve “six” was distinguished by smooth and silent operation. Once, when I was a child, I stood next to a running truck engine on the side where the exhaust noise was less audible, and I was surprised by the almost complete absence of noise and vibration. It seemed that only the fan and the fluttering belts gave away his work...

In the mid-70s, the engine was modernized. The cylinder diameter was reduced from 101.6 to 100 mm, which made it possible to use piston rings from the ZIL-130. Piston pins, a thermostat, and a rev limiter were also used from this engine. The K-88AZh carburetor was also a modification of the 130th carburetor.

The lubrication system received a centrifugal full-flow oil filter. It should be noted here that the first centrifuge for oil purification appeared in 1958 on the UralZiS-355M, the engine of which had a similar design, since it also came from the ZiS-5. The upgraded ZIL-157D engines were also installed on some modifications of the ZIL-130, intended for operation without a trailer.

Transmission. Until 1961, the ZIL-157, like the ZIL-164, was equipped with a double-disc clutch and a five-speed gearbox without synchronizers, with an overdrive fifth gear. Then we switched to a simpler single-plate clutch and a ZIL-130 type gearbox with synchronizers in the four highest gears and a direct fifth gear. To compensate for this change in the gear ratio, the ZIL-164 reduced the final drive gear ratio. And on the ZIL-157 the same effect was achieved by reducing the gear ratios of the transfer case. The main gears used from the GAZ-51 with a gear ratio of 6.67 were retained. Although the designs of the axle shaft housings and the axle shafts themselves differed from similar units of the GAZ-51.

The steering mechanism is a worm-roller, with a gear ratio of 23.5. There was no amplifier. This steering mechanism was also used on LAZ buses. Brakes. ZIL-157 had a pneumatic brake drive. Initially, the compressor was cooled with air. Then a water-cooled compressor was used. And the disc parking brake was replaced by a drum one. Just like on the base ZIL-164. After all these changes, in 1961 the base truck received the index 164A. And the ZIL-157 became the ZIL-157K.

The electrical equipment of the ZIL 157 was very simple: a DC generator, a three-element relay regulator, and a foot-operated starter. A special pedal was used to turn it on. The turn signal breaker had only two terminals. The ignition switch is extremely simple, with two positions (on - off). The headlight switch is a foot switch. There were two 6-volt batteries connected in series. They were designated 3-ST-84. An alternating current generator has already begun to be installed on the ZIL-157D engine. Cars with this engine received an index of 157KD.

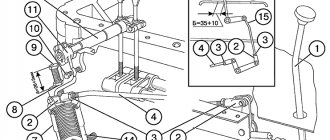

The interior of the ZIL-157 cabin differed from the interior of the ZIL-164. Firstly, there were additional levers for turning on the front axle, controlling the transfer case, and turning on the winch. Secondly, there were two pressure gauges. In addition to monitoring the pressure in the brake system, there was also a pressure control in the DRM. Under the instrument panel there were valves for supplying air to the wheels.

As we can see, the truck was very simple in its design. There wasn't even power steering. But it was precisely his simplicity, asceticism and rationality that captivated him. The simplest lower-valve engine had good low-end thrust. In combination with single-pitch wheels with 18-inch low-pressure tires with SRD, this provided the truck with excellent cross-country ability. They say that the military insisted on maintaining its production after the ZIL-164 was discontinued in the mid-60s. Perhaps his simple and graceful appearance played an important role here. Spartan, stern and noble features perfectly matched the image of a military truck. Serial production of the truck at the Ural branch of ZiL continued until 1992. But then for another two years it was assembled at car repair plants. Thus, he outlived his ancestor ZIL-164 by 30 years. And if I haven’t seen a ZIL-164 on the roads for about thirty years, then the ZIL-157 still occasionally comes across, causing a storm of emotions with its simple noble appearance.

But the YaMZ-KAZ-642 diesel never took root on that ZIL-157 and was subsequently removed. I think there is something iconic about this...

author: Mikhail Danilov

This is interesting:

Removing the front drive axle from the vehicle

ZiS 151

Year of manufacture - according to chassis number ZIL 157