Over the past few years, there has been talk about free provision of land in the Far East. Any citizen of the country can receive this land for free. But another question arises: what to do on these hectares? How to get real income from them? In the article we will tell you about a mini grain harvester and its advantages when harvesting crops from fields.

It makes sense to look back a little, when predecessors created not only large agricultural machinery, but used the simplest and most efficient machines. Here, the accumulated experience must be used to get the expected result. The development of grain harvesting equipment began with small-sized devices. The first attempts to make a machine for mowing and threshing grain were made in the middle of the 19th century. Then the calculation was made on muscular horsepower.

Mounted mower for direct cutting of grass and bread

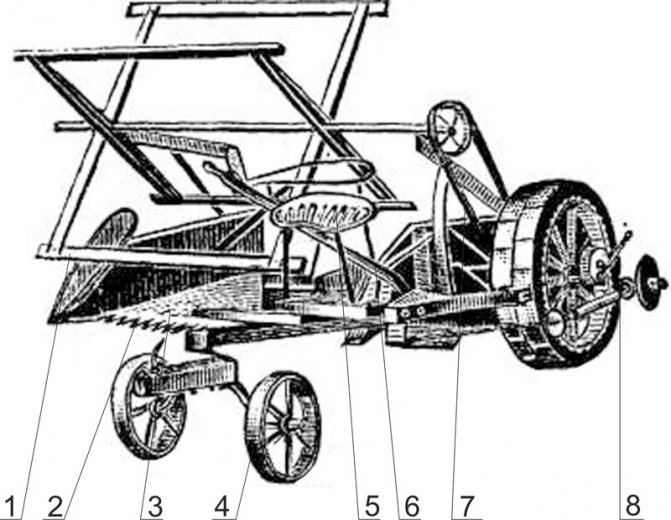

Bread harvesting begins with mowing. Horse-drawn mowers (Fig. 1) appeared almost simultaneously in Germany, Russia, and France. They implement the basic principles of cutting that are still used today. The mower has movable blades and shear plates. The movable knife makes reciprocating movements. The stem is clamped between the knife and the plate and then cut. Subsequently, it falls outside the knife plates.

General view of the horse-drawn mower: 1 – seat; 2 – platform; 3 – wheel; 4 – increasing gearbox; 5 – crank; 6 – folding mower blade; 7 – movable knife; 8 – fixed shear plate on the folding blade; 9 – locks the mower blade in the transport position.

To ensure high speed of the blades on the mower blade, a two-stage gearbox is used, in which the rotation speed increases six times. The crank converts rotational motion into reciprocating motion. It is transmitted by traction to the block of movable knives.

In many countries, horse-drawn mowers are still produced today; if you have horses on your farm, you can purchase a similar horse-drawn mower. On average, such a mower can mow at least 10 hectares of grain per day. Usually two people work, one mows, and the other puts the hay into a windrow with a rake.

Horse reaper (lobogreka)

In many countries (countries of Asia and Latin America) they still use horse-drawn reapers, which in Russia are traditionally called lobogreyki (there is no time to remove sweat from the forehead while working). These horse-drawn and then tractor-trailers were used everywhere. Two people worked. The first, sitting on a spring-loaded seat, controlled the horse, turned on the mower and reel. The second worker was located on the platform. Its task is to direct the beveled bread into the windrow.

Horse loaf warmer; 1 – reel; 2 – mower; 3 – platform; 4 – support wheels of the reaper; 5 – seat; 6 – mower control lever; 7 – grain catcher; 8 – gearbox with crank converter.

In the loboheater, sieves were installed on the platform, through which the crumbled grain was directed into the grain catcher. After each pass (usually about 100 m), the grain catcher was cleaned, up to 50 kg of grain accumulated in it.

In a day, such a horse-drawn mower mowed up to 20...30 hectares of grain. Several mini-brigades worked simultaneously on one field. In the USSR, before the appearance of the first combines (1957), the main grain harvest was harvested with precisely such harvesters. When developing virgin and fallow lands (1953...1959), similar machines were used; they were attached to a tractor with 2-3 reapers.

The concept of creating miniature equipment for farmers

Russia and other CIS countries inherited large agricultural enterprises from the USSR. Even modern farms are trying to model the style of work and the implementation of basic agricultural operations according to the principles developed since the early 30s of the last century.

Real farming does not expect to attract large numbers of people to work. On the contrary, they try to perform the work individually, concentrating several operations in one hand. Therefore, they try to equip agricultural machines with multifunctional mounted trailed units. For example, the John Deere X 700 minitractor has more than 50 mounted and trailed units. Depending on the production tasks, the farmer purchases the necessary equipment and uses it to obtain maximum profit.

Farm area sizes

The size of farm areas in some countries is shown in the table.

| Average farm area in countries, ha | Direction of agricultural activity | |

| Crop production | Livestock | |

| Germany | 180…320 | 15…30 |

| France | 210…430 | 20…40 |

| Spain | 130…260 | 15…25 |

| Italy | 120…220 | 10…20 |

| USA | 520…750 | 60…90 |

| Australia | 1000…3000 | 250…450 |

| Japan | 45…70 | 5…12 |

It turns out that not much land is concentrated in the hands of one user. It can be serviced without the involvement of powerful and highly productive agricultural machines. There are not many millionaires among farmers around the world, although their fortune is estimated at several million dollars, they can really only be obtained by selling their land and equipment. But it is these farmers who produce the main agricultural products that feed the population.

Energy saturation of agricultural production

The energy intensity of farming is one of the most important indicators of production. Energy saturation refers to the specific power per 1 hectare of arable land. As a result of the analysis of indicators, a table was compiled.

| Average energy intensity of one hectare of arable land in countries, kW/ha | Direction of agricultural activity | |

| Crop production | Livestock | |

| Germany | 3,5…4,8 | 12,0…18,5 |

| France | 2,4…3,8 | 8,4…9,0 |

| Spain | 0,8…1,9 | 5,2…6,0 |

| Italy | 0,7…2,2 | 4,8…5,5 |

| USA | 7,5…8,8 | 12,8…20,5 |

| Australia | 0,6…1,5 | 3,2…4,0 |

| Japan | 8,5…10,0 | 15,5…18,8 |

The higher energy saturation in livestock farming is explained simply; they use machines to prepare feed for feeding; they use not only roughage grinders, but also devices for producing hot water and steam.

The warmer the climate in a particular country, the less power is required to service the available area. The intensity of work is also lower; the lack of energy from tractors and agricultural machinery is compensated by the excess solar energy per hectare.

Basic requirements for small-sized agricultural machinery for grain harvesting

Based on the observations outlined above, the basic requirements have been formulated that it is advisable to take into account when choosing equipment for small areas of grain crops:

- low cost of cars. Everyone understands that expensive equipment will require large loan payments, eating up all the profit received;

- low specific fuel consumption per unit area. The lower the fuel consumption, the higher the labor efficiency, since the cost of purchasing fuel is reduced;

- small overall dimensions will allow you to leave smaller turning lanes, which saves crop area;

- simplicity of design. It is known that modern farmers do many jobs with their own hands and save on everything.;

- simple operating techniques will allow you to independently operate agricultural machines and not involve additional hired workers with high qualifications;

- Convenient transportation and compactness will reduce the cost of delivering equipment to hangars for storage during the winter. There are few requirements. The main thing is to make the equipment as miniature as possible.

Tip #1. Some people are so keen on miniaturization that they buy machines that can barely cope with the tasks at hand. Here you need not to get carried away by the very small dimensions and costs.

The principle that the miser pays twice works most noticeably here. Some try to purchase equipment with a reserve of power and other indicators. As a result, they are forced to incur additional costs for maintaining the purchased equipment.

Optimizing the composition of agricultural machinery for your farm is a task that will have to be solved constantly. You will have to not only purchase, but also sell those cars that are not satisfactory in terms of their parameters. Leasing can help here. The cars are used, payments are made for them, but at any time you can terminate the contract and rent another car with different characteristics.

Buy a used grain harvester

We have used grain harvesters of various modifications for sale. We can also deliver to order at the customer's request.

For consultations and orders, call: 8. The call is free.

To order, call ☎ 8 800 222 31 35. The call is free!

Brands of potato harvesters

The main brands sold by our company

Potato harvester ANNA (ANNA) Z644

Widely used in agriculture for harvesting from fields. This technique separates potatoes from soil, tops and various growths during digging.

Potato harvester BOLKO Z643

The working row spacing is 62.5 – 75 cm. By changing the attachment, you can convert the combine harvester to collect beets, carrots and even onions. The productivity of the Z-643 combine can vary depending on the change of attachment and soil moisture. This potato harvester is perfect for small and medium-sized farms, as well as for private use.

John Deere potato harvester

A productive and reliable combine harvester for harvesting potatoes and other vegetables. Can be used in any climate zone.

Combine harvesters - main types

Combine harvesters differ in size and capabilities and are divided into 3 main types:

Self-propelled grain harvesters

The name itself speaks for itself; it is a full-fledged combine harvester with an internal combustion engine, on a wheeled or tracked platform.

Trailed combine harvesters

This type of combine harvester operates through a hydraulic drive or cardan shaft, connecting to any type of tractor (wheeled with a traction level above the second or crawler).

Mini grain harvesters

Used in private households or on small agricultural lands. Such combines are connected to a mini tractor. You can buy a mini grain harvester

Miniature harvesters for farming

Combine harvester "Zarya"

The Chinese Zarya grain harvester is periodically supplied to the Russian market. Despite its small size, this is a pretty good machine that helps you harvest grain on your own land.

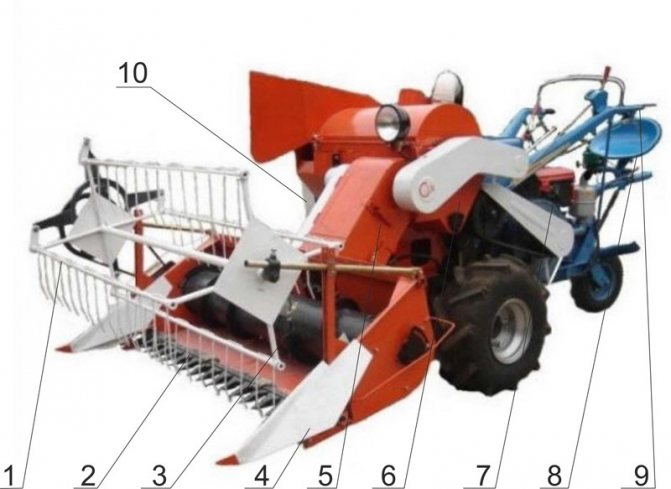

Miniature grain harvester Zarya: 1 – reel; 2 – mower; 3 – header auger; 4 – cut-off device; 5 – inclined conveyor; 6 – threshing drum; 7 – engine; 8 – combine operator seat; 9 – control handles; 10 – grain bag.

This small machine, weighing only 500 kg, has all the same units as a large grain combine:

- mechanically driven reel;

- mower with a working width of 1100 mm

- auger feeder moving the beveled bread to the conveyor;

- an inclined conveyor that supplies the grain mass for threshing;

- a threshing and separating device consisting of a threshing drum and an air separator;

- 8 hp liquid-cooled diesel engine;

- fabric bin for collecting grain with a volume of 800 l.

Work on a grain field is carried out according to the standard scheme for a conventional combine: mowing, transporting, threshing, separating, storing grain and throwing out straw. During tests in Novosibirsk in 2014, a satisfactory result was obtained in terms of the quality of barley harvesting. Grain losses turned out to be at the level of 2.2% of the total mass of the mown grain mass.

Disadvantages of the car:

- The presented photo shows that the combine operator on this combine is located on an open seat. There is no protection from the environment.

- When working on tall grains, winding of the stems on the drum is observed;

- Engine power is often insufficient when working on steep fields.

Attractiveness to the buyer: the price attracts buyers. This tiny car is sold on the secondary market for less than 100,000 rubles. A new combine costs a little over 400,000 rubles. The demand is constant. The table shows the number of Zarya grain combines sold in the CIS republics.

| CIS State | Sales of Zarya combines by year | ||

| 2013 | 2014 | 2015 | |

| Kyrgyzstan | 23 | 96 | 115 |

| Kazakhstan | 264 | 275 | 300 |

| Tajikistan | 65 | 77 | 72 |

| Uzbekistan | 36 | 56 | 62 |

| Ukraine | 235 | 365 | 470 |

| Russia | 32 | 64 | 68 |

At a low price, the combine threshes over 30 tons of grain every day. It is served by small vehicles. At the bottom of the fabric hopper, the knot is loosened, and the grain is poured by gravity into the back of a car or small cargo scooter.

contents .. 1 2 3 ..1 Combine P110-01.

Description and operation 1.1 Purpose of the P110-01 miner

The P110-01 tunneling miner is a selective-action miner with an arrow-shaped executive body (IO), designed for mechanization of breaking and loading of rock mass when carrying out workings of arched, trapezoidal and rectangular cross-sectional shapes from 9 to 30 m2 in penetration with an inclination angle of ±12° through coal, rock (f<=6) and mixed face with a maximum rock strength under uniaxial compression = 120 MPa (f-8) and abrasiveness up to 18 mg in mines hazardous for gas and dust, except for formations that are dangerous due to sudden outbursts, while the content of rocks with BZ = 100-120 MPa should not exceed 30% of the face area with a total undercut of rocks of no more than 85%. The diagram of the minimum and maximum sections of excavations produced by a combine harvester from one installation, the radii of rotation of the combine for different sections of excavations is shown in accordance with Figure 33.

It is permissible to use a combine for working in mines that are dangerous due to sudden outbursts of coal and rock, taking measures to combat sudden outbursts in accordance with the current instructions.

Climatic design of the combine: Location category 5 according to GOST 15150-69.

The combine must be used in mine workings with a water cut of no more than 2 m3/h.

The combine meets the requirements of GOST 28599-90 for tunneling miners with a swept-type executive body of the third standard size, “Safety Rules in Coal Mines” and “Safety Standards for Face Mining Machines, Complexes and Assemblies.”

1.2

Technical characteristics of the P110-01 combine

The characteristics of the combine and its components are given in Table 1. Table 1

* Weight of the combine without taking into account components, replacement equipment, liquid fillers, dust collection and irrigation systems, mounted and trailed equipment, spare parts, tools and accessories. 1.2.1 The design of the combine provides the ability to operate with a built-in internal irrigation system with water supply under the cutter.

1.2.2 Control of the combine - from a portable remote control via a wireless communication channel or from a portable remote control via a two-wire communication channel (main mode) or from a local control panel (adjustment mode).

1.2.3 Main distinctive features of the combine:

— double-motor drive (2×110 kW) of the executive body, which allows obtaining approximately the same torque at two speeds of rotation of the bits (30 and 60 rpm);

— sequential start of the executive body engines with a delay of 2-3 s;

— use of hydraulic clamps in the frame of the executive body to compensate for wear of the gearbox guides when telescoping it;

— spaced suspension supports of the executive body, increasing the strength and rigidity of the structure;

-support feeder with replaceable extensions, allowing you to increase the loading front from 2400 mm to 4000 mm;

-two-motor symmetrical electric drive of the conveyor (2×15 kW) with an open chute and a replaceable lifting and rotating section;

— unified hydraulic drives of the feeder and running trolleys;

-small construction height (1600mm), allowing additional auxiliary equipment to be placed above the combine, if necessary (monorail with devices for lifting the top of the support, loader, etc.);

— gearless oil station with a three-section gear pump;

— two crawler speeds:

1) working 1.3 m/min;

2) shunting - 5 m/min.

1.3 Composition of the P110-01 combine

1.3.1 The combine harvester (Figure 1 2П110.00.00.000НРЭ1) consists of main parts, the name, designation and quantity of which are given in Table 2.

table 2

1.3.2 The combine harvester package also includes:

— single set of spare parts, tools and accessories (according to the spare parts list);

— a set of operational documentation according to the list of operational documents.

contents .. 1 2 3 ..