Combine "Don-1500" in the Volgograd region. Combine harvester "ACROS 595".

Combine harvester

- a complex grain harvesting machine (reaping-thresher), which performs sequentially in a continuous flow and simultaneously: cutting bread (that is, plants), feeding it to the threshing apparatus, threshing grain from the ears, separating it from the heap and other impurities, transporting clean grain to the bunker and mechanical unloading from it.

One of the most important agricultural machines, capable of performing several different operations at once. For example, a grain harvester cuts the ears, knocks the grains out of the ears, and cleans the grains with a stream of air. A complex machine performs the functions of three simple ones - a reaper, a thresher and a winnower.

Additional accessories are available for grain harvesters that allow them to harvest different crops.

History of the combine and combine construction

The birthplace of the modern combine harvester is the USA. In 1828, S. Lane filed the first patent for a complex combined harvesting machine that simultaneously cut bread, threshed it, and husked the grain. However, this machine was not built.

The first combine harvester was invented by E. Briggs and EG Carpenter in 1836. This combine was mounted like a 4-wheeled cart; The rotation of the threshing drum and the drive of the cutting apparatus were carried out by transmission from 2 rear wheels.

In the same 1836, somewhat later, two inventors N. Moore and J. Hascall received a patent for a machine that, according to the basic principles of work processes, was close to the design of a modern type combine. In 1854, this combine was operating in California and harvested 600 acres (about 240 hectares). Until 1867, work on the design and creation of combines was carried out mainly in the eastern states of the United States.

In 1868, A. R. Vlasenko[1] built a combine harvester in the Russian Empire.

Built in 1875 in California, a combine designed by D. C. Peterson found much greater use than the combines of other inventors.

Antique combine harvester (New South Wales, Australia)

In 1890, the factory production of combines was already carried out by 6 companies (including Holt (English) Russian), which produced combines for sale. Combines of this type, although they were very close in their basic design to modern machines, were sharply different from the latter in their design. All Californian combines were made mainly of wood and had a large cutting apparatus grip. The movement of the combine across the field was carried out mainly by horses and mules, of which up to 40 heads were required, the working parts were driven by gears, from running wheels, and from 1889 - from a special steam engine. All this led to excessive bulkiness of the combines and their weight sometimes reached 15 tons.

In the late 1880s, about 600 California-type combines were operating on the Pacific Coast of the United States. In the early 1890s, in order to replace living traction with mechanical ones, steam self-propelled vehicles began to be used as a motive force, from which they later moved on to tractor-trailers with an internal combustion engine.

The first Holt combine, with a 36-foot (11 m) cutting apparatus complete with a 120-horsepower self-propelled steam engine with a separate auxiliary steam engine on the combine frame, was released in 1905.

In 1907, the same Holt company installed an internal combustion engine on the combine. Production, sales and export of combines in the USA, units

| Years | Production | Sold in USA | Exported |

| 1914 | 30 | 30 | — |

| 1920 | 3627 | 2717 | 929 |

| 1923 | 4000 | n. d. | n. d. |

| 1924 | 5600 | n. d. | n. d. |

| 1925 | 5100 | n. d. | n. d. |

| 1926 | 11760 | 6277 | 4707 |

| 1927 | 18300 | 30 | n. d. |

| 1928 | ~27800 | 21000 | 6800 |

| 1929 | 36900 | n. d. | ~6800 |

| 1930 | 24400 | n. d. | n. d. |

| 1931 | 5801 | n. d. | n. d. |

| 1932 | 4000 | n. d. | n. d. |

| 1933 | 300 | n. d. | 405 |

| 1935 | 4000 | 6000 | 500 (1934) |

The use in subsequent years of more reliable materials, improved mechanisms and lightweight gasoline engines with high speeds significantly reduced the weight of the combine, reduced their cost and made them more accessible for use in agriculture. However, this perfect machine, despite its enormous advantages, became the property of only large US farms, while the acquisition and use of combines was not available to the mass of small farmers.

Only in 1926 did the relatively widespread introduction of combine harvesters begin in US agricultural production. The development of the US grain industry and high prices for bread coupled with the high cost of labor in agriculture influenced both the development of the production of combines and their implementation.

However, the heyday of combine harvester production in the United States lasted only a few years. At this time in the United States, only 14-15% of farms used combines. Farmers in Canada purchased 3,657 combine harvesters in 1928. In 1929 - 3295, in 1930-1614, and in 1931 - only 178. The global economic crisis greatly affected the export of wheat and the production of combine harvesters.

The production of combines, which reached 37 thousand per year in 1929, fell in 1933 to 300 units; Many companies have completely stopped producing combines. Attempts to introduce combines into small farms - mainly through the production of small combines with a working width of up to 1.5 m - caused only a slight increase in the production of combines.

According to data as of 1930, there were 60,803 combines in the USA, and by 1936 their number increased to 70 thousand. In 1930, less than 1% of US farms were covered by combines. There are even fewer combines in other countries: for example, by 1936 there were only 10,500 in Canada, and 24,800 in Argentina. In European countries, the number of combines was insignificant.

Combine harvester: How to choose?

The abundance of combine harvester models sometimes confuses even experienced farmers. Making an informed choice is not easy; many nuances must be taken into account. In order not to suffer serious losses as a result, it is important not only to be able to distinguish between types of machines and carefully study the needs of the agricultural enterprise, but also not to forget to follow the instructions.

The performance of a grain harvester is one of the main characteristics that people pay attention to. You should start choosing a combine harvester only after a thorough assessment of the yield of the fields and the set of crops in the crop rotation, because using a powerful, expensive combine harvester not at full capacity is extremely unprofitable.

First, let's look at the types of cars. All models on the market can be divided into three types:

- drum machines with a single or double drum threshing system and a straw walker. These include RSM 161 Rostselmash - six-key double-drum, DEUTZ-FAHR 6095 HTS and DEUTZ-FAHR C 9206 TS - six-key single-drum;

- rotary - with a rotary threshing system. For example, John Deere 9880 STS, TORUM 740 Rostselmash, Case IH Axial-Flow AF8240, etc.;

- hybrid with a drum thresher and a rotary straw separator. For example, LEXION750 CLAAS: tangential threshing drum plus rotary separation.

Rotary combines have higher productivity, while drum combines are more versatile.

Models with a rotary threshing system are most effective in fields with high yields. In this regard, such machines should not be chosen by agricultural producers in regions with yields not reaching 40 c/ha, because a low load on the rotor with grain mass will not allow the full declared potential of the machine to be revealed and will inevitably reduce the quality of threshing and increase grain crushing.

If the choice fell on a keyboard machine, before purchasing it is worth assessing not only the climatic conditions in the region, but also the harvesting conditions in a particular agricultural enterprise. So, if high humidity of the crop, weeds and other unfavorable circumstances are regularly observed in the fields of the farm, management should turn their attention to double-drum machines. This can be explained quite simply: two drums can handle the moistened mass more easily.

But hybrid combines with a double-drum threshing system and rotary separation are suitable for working in unfavorable conditions and on dry fields. And this is a very profitable compromise. However, they should not be used on heavily weeded fields due to the increased sensitivity of these machines to changes in humidity. Rotary combines are also not suitable for such fields. It is considered optimal to use keyboard machines on clogged fields.

Important options.

The market for combine harvesters is represented by many models. However, it is not enough to understand the variety of machines on the market; you need to pay attention to the various options offered by equipment manufacturers.

Often, when determining the complete set of a combine, the range drive of the drum is undeservedly forgotten. But it performs the extremely important function of adjusting the rotation speed of the MSU. Let us remember that on wheat the MSU rotation speed should be about 700-800 rpm, while on corn only 300 rpm is required. And without this option on keyboard machines, it is basically impossible to lower the drum speed when switching to another culture. As a result, when passing through corn or sunflower at such a rotation speed, the crushing and flattening of the grain will increase, and the agricultural producer will receive products of lower quality.

If a company works using resource-saving soil cultivation technologies and has a wide-cut header, it is worth installing a chaff spreader and an active straw spreader on the combine. This is necessary because the power of the basic straw spreader may not be sufficient when working with wide-cut headers. And this option will help to evenly distribute crop residues across the working width, especially with a high straw-to-grain ratio.

When the yield is above 40-50 c/ha, a large amount of chaff accumulates in the combine, which is important to distribute well. This is best done with a separate active chaff spreader, or a device that transfers the chaff mass to the straw spreader, where it is crushed and then distributed along with the straw over the entire working width.

An electromechanical sieve adjustment system installed at the factory will help increase labor productivity and optimize work.

To avoid problems during unloading, it is important to take into account the size of the unloading auger, which should be related to the width of the header according to the principle: the wider the header, the larger the auger.

Rice growers should pay special attention to additional options. For their specific work, reinforced augers are required, as well as an abrasion-resistant internal surface (auger, shaft, etc.) and all-wheel drive.

And a real find for those who plan to minimize the human factor and optimize the performance of the combine will be automatic configuration programs such as CEMOS systems for CLAAS or ISA for John Deere. The operator can choose what he wants to adjust in this combine: improve grain quality, reduce losses, etc. And the combine will automatically adjust itself for these tasks, subsequently providing the operator with information about the results of the changes made.

Combine harvesters in the USSR and Russia

The first combine harvester was brought to Russia by Holt (English)Russian. in 1913 at the Kyiv Agricultural Exhibition. It was a wooden structure on a single-belt crawler with a 14-foot (4.27 m) cutting arm and a gasoline engine to simultaneously operate the mechanisms and move the machine itself. The combine was tested at the Akimov machine testing station and gave relatively good performance indicators. But it did not find application in Russian agricultural conditions—the First World War began in 1914.

They return to the harvester again in the USSR. In connection with the organization of large-scale commodity production in grain state farms, the USSR in the period from 1929 to 1931 organized the massive import of combine harvesters from the USA. The first American combines at the Gigant state farm passed the tests brilliantly.

Trailed grain harvesters on the fields of the USSR, 1930s

Trailed grain harvester on the USSR stamp of January 1941 (TsFA [ITC "Mark"] No. 784). The plot of the stamp is based on a photograph in the magazine “Soviet Photo”, No. 3, 1939[2]

Simultaneously with imports, our own production is launched. At the beginning of 1930, the first-born of the Soviet combine harvester industry in Zaporozhye produced the first 10 Soviet Kommunar combines; by the end of the year, the total number of produced combines reached 347. In 1931, the Rostovsky combine began producing combines (the “Stalinets” combine); in 1932, the plant named after. Sheboldaev in Saratov (SKZ - "Sarcombine", now the Saratov Aviation Plant), which were of the same type and worked on the same principle, while at the same time the "Stalinets" had a larger working grip (6.1 m) and some design differences. The Kommunar and SKZ were equipped with a GAZ automobile-type gasoline engine, adapted for operation on NATI combines and called FORD-NATI, with a power of 28 hp. With. The Stalinets was equipped with a kerosene engine of STZ and KhTZ tractors with a power of 30 hp. With. Movement across the field was carried out using STZ, KhTZ and Stalinets tractors from the Chelyabinsk Tractor Plant. Combines worked with Stalinets tractors from ChTZ, 2 in a hitch.

All of them were not suitable for harvesting wet bread; therefore, in 1936, the Lyuberetsky plant named after Ukhtomsky began producing a northern combine designed by Soviet inventors Yu. Ya. Anvelt and M. I. Grigoriev - SKAG-5A (northern Anvelt-Grigoriev combine 5th model), which was adapted for harvesting wet bread in small areas.

Production of combines in the USSR and availability in MTS and state farms

| Years | Production | MTS | State farms NKSH |

| 1930 | 347 | — | — |

| 1931 | 3548 | 7 | 1741 |

| 1932 | 10010 | 109 | 6343 |

| 1933 | 8578 | 2244 | 11886 |

| 1934 | 8289 | 10531 | 13434 |

| 1935 | 20169 | 15207 | 15522 |

| 1936 | 42545 | 29861 | 29900 |

| 1937 | 44000 | 67683 | 33740 |

Combine harvester SK-5 "Niva"

Thanks to their own production, by 1935 grain state farms were harvesting 97.1% of the area with combines. During the harvesting campaign of 1937 in the USSR there were already about 120 thousand combines, which collected 39.2% of cereal grains, thereby ensuring a significant reduction in harvesting losses, which reached 25% when using lobogreki, even despite numerous limitations in operation and the presence of design flaws .

After the Great Patriotic War, major scientific research was carried out in the USSR, which significantly enriched the theory of the grain harvester. In particular, the role of the breaker beater and straw walker in the process of grain separation was studied in detail, which made it possible to significantly increase the operating efficiency of these units. Studies were carried out on the aerodynamic properties of a coarse heap, which made it possible to significantly improve the efficiency of grain cleaning. Based on these achievements, in the 60s, projects of high-performance (for those years) combine harvesters of the SK-5 and SK-6 types were developed.

The first self-propelled grain harvesters in the USSR were S-4, the production of which began in 1947. Self-propelled harvesters SK-3 appeared in 1956, SK-4 in 1962, and SKD-5 Sibiryak in 1969[3].

Since 1970, the SK-5 “Niva” combine harvester has been produced, and the Taganrog Combine Harvester Plant has produced the SK-6-II “Kolos” combine harvester.

Combine harvester

Combine harvester

A machine that mows and threshes bread, pours grain into a bunker, collects straw and chaff into a stacker or dumps it on the field. Grains, leguminous crops, oilseeds, grass seeds, lupine, corn for grain, etc. are harvested using the direct combining method (the bread is mowed and threshed at the same time) or using the separate, two-phase combining method (the stems are mowed with a header and placed in a windrow, and then the windrows are picked up and threshed). A distinction is made between self-propelled and trailed tractors. The working parts of a trailed tractor, towed by a tractor, are driven by an engine installed on the combine harvester or by the power take-off shaft of the tractor. The self-propelled gearbox moves from the engine, which powers all the working parts.

The first samples of protective gear were made in the USA at the end of the 19th century. Constructed almost entirely of wood, bulky and heavy, they required a team of 20–30 horses for transportation. In the 1st quarter of the 20th century. The gearboxes were significantly improved: wood was mainly replaced by metal, an internal combustion engine was used to drive the working parts, horse traction was replaced by a locomobile, and then by a tractor. As improvements were made, the production of steel parts increased: in 1914, 30 pieces were produced, in 1920 - over 3.5 thousand, in 1925 - over 11 thousand, in 1929 - almost 37 thousand pieces. Factories first mastered the production of trailed gear. In recent decades, their production abroad has sharply decreased. Mostly self-propelled gearboxes are manufactured. A mounted gearbox, mounted on a self-propelled chassis, has been developed. The first Russian grain harvesting plant, “Horse grain harvesting plant,” was built by agronomist A. R. Vlasenko in 1868. Plant harvesting machines were not produced in Tsarist Russia. In the USSR, the mass production of trailed attachments "Kommunar" with a grip of 4.6 m was organized in 1930. Soon the production of attachments with a grip of 6.1 m began. ,4 m. In 1947, the production of the trailed Z. K. S-6 and the first self-propelled - S-4 was mastered; in 1956 - the trailed Z. K. RSM-8 with a grip of 6 m and self-propelled - SK-Z. Since 1962, the industry has been producing self-propelled SK-4 combines with a throughput capacity of up to 4 kg/sec of harvested crops with a grain to straw weight ratio of 1:1.5. Since 1969, they have produced SKD-5 Sibiryak combines with a throughput capacity of 5 kg/sec, and since 1972 - SK-5 Niva with a throughput capacity of 5 kg/sec and SK-6-3 Kolos with a throughput capacity of 6 and 8 kg/sec at the same ratio of grain mass to straw mass. By the end of 1970, there were 623 thousand z. in agriculture in the USSR.

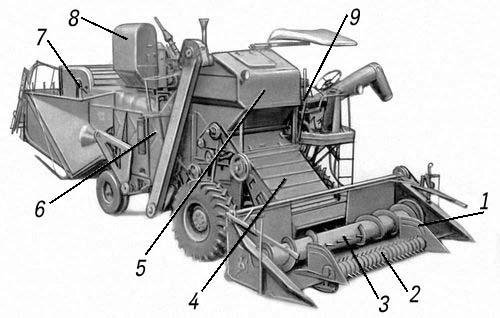

A combine harvester ( Fig. 1 ) consists of a header, a thresher, a stacker, a bunker, an engine, a cabin or platform with controls and a chassis; for separate harvesting, a pick-up is mounted on the header.

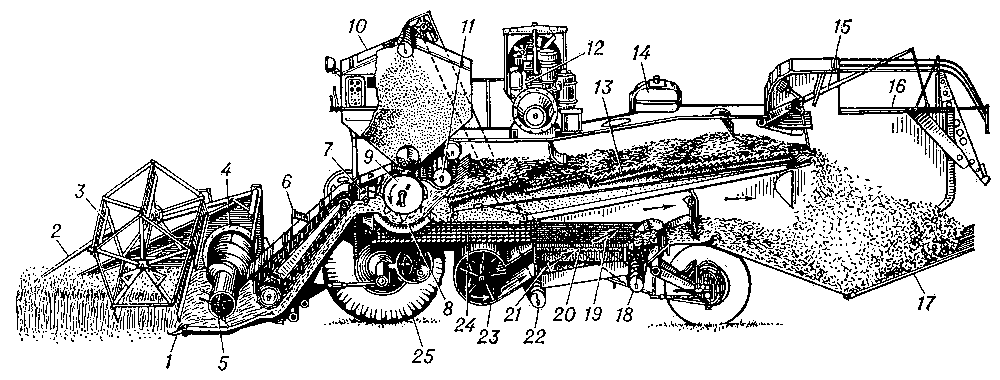

Technological process of the harvester. The cutting apparatus of the harvester of the harvester ( Fig. 2 ) cuts the stems, and the reel places them on the header platform. A double-sided auger conveyor rakes the stems to the middle of the platform, to a finger mechanism that feeds the stems to an inclined conveyor, which transfers them to the receiving chamber of the thresher; The receiving beater evenly feeds the stalks into the threshing apparatus. The rotating drum, in cooperation with the concave, threshes the bread. The main part of the threshed grain and small impurities spill through the gaps of the concave onto the transport board. The drum throws the straw with the remaining grain onto the bar grate. The beater fingers throw the straw onto the lattice straw walker, which releases the remaining grain and small impurities. The straw enters the stacker chamber, after which the combiner lowers the bottom using a special mechanism and the stack slides to the ground. The transport board delivers the mixture to the upper cleaning sieve. The fan forces a stream of air under the cleaning sieves. The upper cleaning sieve releases large and light impurities, which are directed by air flow into the accumulator chamber. The grain spills onto the lower cleaning sieve, which releases the remaining impurities. The cleaned grain is poured along a ramp into the casing of a screw conveyor, which delivers the grain to the hopper. During separate harvesting for threshing bread dried in windrows, a pick-up unit is attached to the header of the windrow by removing the reel, which throws the windrow onto an inclined conveyor that moves the picked stems into the receiving chamber of the threshing machine. Instead of a stacker on the windrow, you can attach a straw chopper, which feeds the chopped stems along with the chaff into a trailed dump cart. To control the harvester on the move and adjust its working parts, a hydraulic system is used, which raises and lowers the header, moves the reel and changes the number of its revolutions, as well as the speed of movement of the combine. Control mechanisms and control devices are located on the combiner platform. The threshing machine is equipped with a diesel engine connected by a V-belt drive to the receiving pulley of the drive wheel axle and the main counter-drive shaft of the thresher.

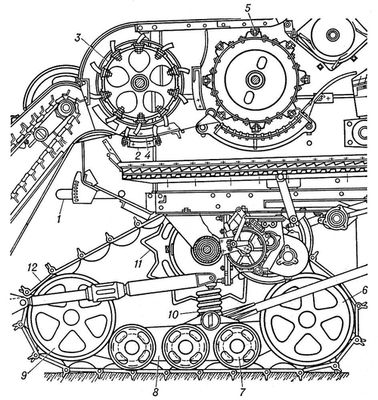

Based on this self-propelled vehicle, modifications have been created that are designed to operate in various soil and climatic zones, on soils of varying composition and moisture content. In addition, for harvesting the seeds of grass, corn for grain, buckwheat, millet, oilseeds, legumes and other crops, the industry produces devices mounted on the harvester. Self-propelled harvester, designed for harvesting rice and grain crops on soils of high humidity , instead of driving wheels, it is equipped with 2 caterpillar movers ( Fig. 3 ). Some rice mills for harvesting rice are equipped with a second pin-type threshing apparatus. The mass, threshed by the pin apparatus, enters the threshing apparatus for finishing.

For harvesting grain crops and rice in irrigated fields, harvesters with a high-mobility tracked undercarriage are used. For harvesting difficult-to-thresh grain crops and crops with easily damaged grain, a harvester with 2 threshing units is used, which increases throughput by 30% and reduces grain losses.

Lit.: Portnov M.N., Grain combines, 5th ed., M., 1966; Izakson H.I., Self-propelled combines SK-Z and SK-4, 3rd ed., M., 1963; Karpenko A. N., Zelenev A. A., Agricultural machines, 2nd ed., M., 1968.

A. N. Karpenko.

Rice. 1. Self-propelled grain harvester with pick-up: 1 - header; 2 - pick-up; 3 - screw conveyor; 4 - inclined conveyor; 5 — grain hopper; 6 - thresher; 7 — straw collector; 8 — engine; 9 - control platform.

Rice. 2. Design and technological diagram of the combine: 1 - cutting apparatus; 2 - dividers; 3 - reel; 4 — screw conveyor; 5 — finger mechanism; 6 — inclined conveyor; 7 — receiving beater; 8 — concave; 9 — threshing drum; 10 - bunker; 11 — impact beater; 12 — engine; 13 — straw walker; 14 — fuel tank; 15 — straw filler; 16—accumulator; 17 — folding bottom of the stacker; 18 — grain auger; 19 — upper cleaning sieve; 20 - lower cleaning sieve; 21 - pitched board; 22 — screw grain conveyor; 23 - fan; 24 — transport board; 25 - drive wheel.

Rice. 3. Threshing device and caterpillar drive of a combine harvester for harvesting rice on waterlogged soils: 1 - lever for adjusting the tooth frame; 2 - tooth frame; 3 - pin drum; 4 - grate; 5 — beater drum; 6 and 9 — guide wheels; 7 - skating rink; 8 — balancing trolley; 10 — shock absorber; 11 — drive sprocket; 12 — caterpillar belt.

Source: Great Soviet Encyclopedia on Gufo.me

Meanings in other dictionaries

- grain harvester - GRAIN HARVESTER, a machine for mowing and threshing grain crops, separating grain, cleaning it and collecting it in a bunker, collecting straw and chaff in a stacker or dumping them on the field. 3. Agricultural dictionary

- Blog

- Jerzy Lec

- Contacts

- Terms of use

© 2005—2020 Gufo.me

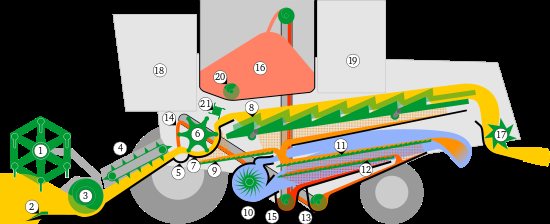

Structure of a grain harvester

Main parts of a combine harvester

- Reel

- Cutting apparatus

- Screw

- Feeder with conveyor

- Stone catcher

- Threshing drum

- Deca

- Straw walker

- Transport board

- Fan

- Chaff sieve

- Spike sieve

- Ear auger

- Return of spikelets

- Grain auger

- Grain hopper

- Straw chopper

- Control cabin

- Engine

- Unloading auger

- Impact beater

The stems, cut by the cutting device (2) with the help of a reel (1), are directed to the header platform, where the auger (3) transports the cut grain mass to the center of the header and, with fingers located in the central part, pushes it into the inclined chamber (4), where there is conveyor feeding the stems into the receiving chamber of the thresher. In the combine body in front of the threshing drum (6) there is a stone catcher (5), into which stones fall out of the grain mass. The threshing drum threshes the ears, the threshed grain, chaff and small impurities spill through the deck (7) onto the transport grid (9). The straw and the unthreshed ears remaining in it are thrown onto the keys of the straw walker (8), where, due to the vibration and reciprocating movement of the keys, as well as their special design, the grain is separated from the straw, which spills onto the sieve (11) (rattle). The fan (10) supplies air under the sieve to clean the grain from light impurities; heavier impurities are separated due to the vibration of the sieve. The straw goes through the straw walker into the chopper (17) or stacker (not shown in the diagram, installed instead of the chopper). Straw can also be laid out behind the combine into a windrow without chopping for subsequent collection using balers. The cleaned grain is poured into the chamber of the grain auger (15), which feeds the grain into the hopper (16). The unthreshed ears are conveyed through the grate onto a pallet, on which they are poured into the grain auger (13), which returns the ears to the threshing drum[3].

There are also so-called rotary harvesters. Unlike a classic combine, they have a longitudinal rotor installed instead of a threshing drum, beater and straw walker. This solution allows you to increase productivity and reduce grain losses, but it requires a more powerful engine and works worse at high humidity. It is most rational to use rotary combines in fields with high yields[4].

Along with a traditional header containing a cutting apparatus, grain harvesters can be equipped with stripper type headers. This allows you to significantly increase the productivity of the combine when harvesting spiked and panicle grain crops under certain conditions[5].

The grain combine is modified to work in different conditions and to harvest certain types of grain. Adaptation can be made through the use of special attachments or the release of a separate model. To work on soils with high humidity, in particular when harvesting rice, the combine uses a tracked chassis instead of a wheeled one. To increase productivity, reduce grain losses, as well as when working with difficult-to-thresh or easily damaged crops, double threshing devices are used, including with different types of first and second threshers. The main type of engine used in combine harvesters is diesel, which provides both propulsion and operation of internal systems. The working bodies are controlled using a hydraulic system[3].

Modern combines, along with the function of threshing grain crops, have a robust design, a slope leveling system, a large grain bin capacity, high-speed unloading and better productivity. The features of modern combines include an increased level of comfort for the combine pilot: a color monitor in the cockpit with the ability to communicate with individual combine systems, control of intensive cascade cleaning, control over the return, chopping and wide spreading of straw and chaff in several modes, control of precise fuel supply, low in-cab noise levels, powerful cooling system, full field view through transparent cab walls, plus high-precision yield sensor, moisture sensor, differential global positioning system (DGPS) yield mapping, desktop software and support services , SmartSteer™ laser system for guiding the combine on “autopilot”, parallel passage from row to row with an accuracy of 1-2 cm, solutions for an integrated control system (sensors and regulators)[6].

Lexion series grain harvesters

Class combines of this series are distinguished by high productivity and good transport speed.

In addition, these machines practically do not damage the soil during operation and have high maneuverability.

Combine harvester CLAAS LEXION-670

This effect is explained by the fact that many machines use the Terra Trac running system. This is a peculiar combination of tracked and wheeled travel. The drive wheels are equipped with rubber tracks, and the steered axle remains the same (wheel pair).

The main components and steering column are controlled by a hydraulic transmission. A total of 7 cars were produced in this series. The beginning was made with the 480 model. The series ended with the Lexion 780 grain combine.

It is worth noting that this machine was released for the 100th anniversary of the Class company. The Lexion 780 was not included in the official series, but thanks to dealers, the car can be seen in the fields of our country. Considering the exclusivity of this combine, here are its technical characteristics:

Compared to the first 480 model, the Lexion 780 has more power. Unlike all other cars in this series, the Lexion 780 is equipped with a Mercedes-Benz engine.

Forage harvester CLAAS Jaguar

The remaining combines are powered by a six-cylinder Caterpillar. This gave the machine additional power, which had a positive effect on the quality and speed of cleaning.

Notes

- Great achievements in technology, construction, medicine: Combine harvesters Archived copy of July 14, 2014 on the Wayback Machine

- Kochetkov N.

What the catalogs are silent about. - M.: ITC "Marka", 2006. - P. 13. - ↑ 123

Article “Combine harvester” in the Great Soviet Encyclopedia. - GRAIN HARVESTER - Large encyclopedic dictionary. Agriculture - Explanatory Dictionaries and Encyclopedias

- Stripping header "Slavyanka UAC" (Russian). Ukr.Agro-service. Retrieved May 26, 2020.

- The official dealer of New Holland combines in Russia is the Selmashservice Group of Companies selmashservice.ru Archived copy dated July 21, 2013 on the Wayback Machine

Sources

| Combine harvester at Wikimedia Commons |

- Agricultural Encyclopedia 1st ed. 1932—1935 M. OGIZ RSFSR

- Agricultural Encyclopedia 2nd edition. 1937-1940 M. - L. Selkhozgiz

| This article or section contains a list of sources or external references, but the sources of individual statements remain unclear due to a lack of footnotes. Claims that are not supported by sources may be questioned and removed. You can improve the article by providing more accurate citations to your sources. |

| Types of agricultural combines | |||

| |||