Big X is a technique for those who have set a goal - to be the best in everything! The highest quality of harvested feed, unprecedented productivity, clean harvesting in different conditions, incredible cross-country ability, intelligent capabilities for adapting to the moisture content of the mass and for saving fuel, compactness and comfort of the machine, ease of operation and minimal costs. Could there be a more profitable investment?

Strong arguments!

- Grass pick-up EasyFlow:

- The world's first constant pick-up for forage harvesters

- Adapted X-Disc mower: sets the trend

- EasyCollect corn head: it couldn't be simpler

- AutoScan sensor: always the optimal length

- Direct feed flow

- Pre-press rollers: Pre-press ensures even higher quality

- Chopping drums: 3 for all occasions

- Corn-Conditioner grain grinder: crushes every grain

- Chopping quality: from 2.5 to 31 mm

- Fuel consumption: the wider the header, the lower the consumption

- Driver's cab: Comfort in servicing equipment ensures high productivity

- Service: More time chopping, less time waiting

BiG X - The most powerful shredder in the world

New comfortable spacious cabin

New joystick for superior control comfort

New MAN engines up to 1,078 hp.

VariStream suspended crop flow, optional Biogas drum with 40 knives, Super Biogas drum with 48 knives

What power do you need?

The highest level of powerful and economical MAN engines with the latest technology: with common rail injection, the BiG X in all power classes impresses with smooth running, low fuel consumption, maximum efficiency and minimal maintenance. . The innovative KRONE-Power-Management system allows switching from Eco Power to X Power or vice versa. This way you can use less or more engine power as needed.

V -shaped 8-cylinder engine with a volume of 16.16 l

BiG X 700

Engine power according to ECE R120: 570 kW / 775 hp.

X Power continuous shredding performance: 492 kW / 669 hp.

Continuous chopping mode Eco Power: 374 kW / 509 hp.

V -shaped 12-cylinder engine with a volume of 24.24 liters

BiG X 850

Engine power according to ECE R120: 625 kW / 850 hp.

Long-term shredding performance X Power: 607 kW / 825 hp.

Eco Power continuous chopping mode: 469 kW / 638 hp.

BiG X 1100

Engine power according to ECE R120: 793 kW / 1,078 hp

Performance of long-term grinding mode X Power: 760 kW /1.034 hp. Eco Power continuous chopping mode: 469 kW / 638 hp.

Eco Power – X Power Eco Power is used where you can get by with less machine power. If you need more power, on BiG X 700, 850 and 1100, switch to X Power using the key. This switching can also be done automatically (optional) depending on the engine load. With this device, you have the opportunity to choose, namely, to reduce diesel fuel consumption and preserve the environment.

Reliable and convenient:

Six feed rollers with an 820 mm distance between the front roller with metal detector and the shear plate mean not only better pre-pressing, but also increased safety against foreign metal objects. Thanks to the patented KRONE AutoScan system, the hydraulic drive allows manual or automatic adjustment of the chopping length at different stages of ripening.

Will cope with any task:

The huge space between the six feed rollers guarantees the highest throughput. With a compaction force of over 4.6 tons, six rollers provide the best chopping quality and low fuel consumption per ton of harvested material. VariStream: High loading rate at

less diesel fuel consumption

If maximum productivity with the best grinding quality is required, the technology must also be suitable. This is based on numerous innovative elements, such as six hydraulic press rollers, a large chopping drum with no less than 48 knives and the VariStream crop flow control system, awarded in 2009. With sprung bottoms under the chopping drum and behind the accelerator drum, the VariStream system ensures trouble-free, clogging-free operation even when the harvested crop is unevenly supplied. The shredder loads better and requires less diesel per ton of material collected.

Main classification of forage harvesters

Forage harvesters are classified according to two principles. According to the principle of autonomous operation (trailer, mounted, self-propelled), and the principle of arrangement of knives (drum, disk).

The structure of a self-propelled combine includes a chassis - a chassis and an engine. This ensures independent movement on the field. The productivity of such combines is higher, since they cover a larger area of the cultivated area. Self-propelled forage harvesters are used to work with large areas.

Mounted and trailed combine harvesters. They are attached to the driving mechanism (tractor). What makes them distinctive is the principle of fastening. Trailed combine harvesters are typically located at the rear. Mounted ones are located on the side of the driving mechanism. The harvesting area of such combines is smaller than that of self-propelled ones. Performance is lower. They are used in medium and small areas.

Forage harvesters also differ in the design of the chopping apparatus. Drum type involves the presence of a drum with knives and a sharpening device. This allows you to simultaneously chop forage and sharpen knives.

A disk shredding machine consists of a disk working body with knives mounted on it, located at an angle, a rotation drive and a shear plate. The working body consists of two parts with internal and external disks. Fast grinding reduces energy costs.

For any task – a chopping drum!

You can choose: Drum for coarse grinding, standard grinding, "Biogas" or "Super-biogas". With a diameter of 660 mm, a width of 800 mm and V-shaped knives, KRONE drums are attractive for their highest chopping quality, constant collection flow and low power requirement. Due to the high cutting frequency with 40 or 48 knives, using Biogas drums, even with short chopping lengths, greater throughput can be achieved.

Drum with 20 knives:

This "coarse chop drum" is used in many countries where long chop lengths are required.

Drum with 28 knives:

This drum is standard equipment on all BiG Xs, is suitable for universal use and, with half a set of blades, is best suited for grass harvesting.

Drum with 40 knives:

Thanks to its high throughput and low diesel fuel consumption, this Biogas drum, equipped with 40 knives, will pay for itself in no time. In addition, the proportion of excess length in the crushed mass is significantly reduced, which increases efficiency in the fermenter of a biogas plant. As a result of improved gas yield, area utilization per m3 of biogas is reduced.

Drum with 48 knives:

The new Super Biogas drum with 48 knives is designed specifically for the requirements of modern gas installations. With a cutting frequency 20% higher than 40-knife drums and a theoretical chopping length of only 2 to 12 mm, this Biogas drum can chop even finer. The gas output and throughput of the biogas plant become even greater. With equal grinding lengths, diesel fuel consumption per ton of harvested crop is reduced.

Grain crusher

Corn Conditioner

Two systems for your success

Excellent crimping with large 250 mm diameter rollers

New: High-performance disc chopper for BiG X 1100 with 2.5 times larger working surface, included as an accessory

Quick and easy installation and dismantling of the grain chopper

Comfortable adjustment of the distance between the rollers, day and night

High feed digestibility

This is a requirement of practice. To do this, each grain must be crushed, even with long grinding lengths. Thanks to the large diameter of the roller and the larger friction surface, KRONE grain crushers are attractive for their higher productivity with lower energy consumption and provide the best harvested crop mass.

The Corn Conditioner KRONE grain crusher will crush every grain:

Standard gear rollers: 250mm diameter rollers have a larger friction surface than smaller rollers, can handle larger roller spacings, are more efficient with less diesel consumption, and handle long chops better. The roller speed differential is 20% and optionally 30% or 40% for straw grain silage. The new disc grain crusher with a large working friction surface operates without any difference in rotation speed and is designed for the high throughput of the BiG X 1100. Installation and dismantling of the grain crusher takes only a few minutes.

The rollers of a standard grain crusher have 123, 144 or 166 teeth. Thanks to the large roller diameters of 250 mm, high-quality feed is prepared while maintaining high productivity.

Disc rollers

The grain crusher, thanks to the V-shaped gaps, has a friction surface 2.5 times larger than a standard grinder. This allows you to increase throughput with the best quality of grain processing. Disc rollers operate at the same rotation speed. This allows you to reduce the required power by 10%.

Forage harvester mechanisms

The main mechanisms affecting productivity and energy consumption include: · Headers or supports; · Feeding, transporting and grinding devices; · Breakdown protection system; · Devices for adding mineral additives; · Engines; · Control transfer mechanisms; · Hydraulic equipment; · Electrical equipment; · Chassis for self-propelled forage harvesters.

Modern harvesters are also equipped with stone recognition devices. This prevents them from getting into the cutting mechanisms, dulling the knives and breaking the moving mechanisms.

There are a large number of models of forage harvesters from domestic and foreign manufacturers on the modern market.

EasyCollect

To increase economic effect

Up to 10.50 m working width – exclusively from KRONE

Better chopping quality, lower mass fraction

excess length due to longitudinal feed Simple design and lower energy consumption.

Unique width – high power ratings:

With a working width of up to 10.50 m, the BiG X can be equipped with the world's widest row-independent attachment for maize chopping.

Endless rotating collectors transport the cuttings to the center, where they are drawn in linearly at right angles. Ideal for the best chopping quality with a small proportion of excess length.

Brilliantly simple - simply brilliant:

EasyCollect impresses with its simple modular design with endless rotating collectors. The result: significant weight savings, lower maintenance costs and long service life.

Reliable selection:

EasyCollect works in any situation. Even individual rows of maize are picked up cleanly by EasyCollect, transported to the center and directed to the chopping unit. The orderly and longitudinal feeding of the plants ensures the best chopping quality.

Same stubble height:

The EasyCollect lateral remote sensors ensure that the stubble height of the cultivated area is always the same. Using remote sensors, EasyCollect adapts to the set working depth not only in the transverse direction, but also longitudinally in the direction of travel.

Easy Floy – a pick-up without complex rake controls

More performance, smoother running, less wear

Infinitely variable rotation speed

Highest level of comfort thanks to automatic speed adjustment in relation to driving speed

Two working widths:

With a working width of 3.00 m or 3.80 m , six rows of tines and a tine spacing of 55 mm, these control-free KRONE pick-ups leave nothing behind on the soil surface even with faster work and large swathing volumes. The pendulum frame of the BiG X feeding apparatus is responsible for lateral copying of the soil and

clean work of the picker. The robust design of EasyFlow has proven its worth even in the most difficult operating conditions and allows for optimal load distribution on the high-performance BiG X forage harvesters. Protection is provided by friction clutches.

EasyFlow – exclusively from KRONE

EasyFlow 300 and 380: pick-ups without rake control.

KRONE EasyFlow operates without guide rollers or pulleys, has 58% fewer moving parts than traditional pick-ups and is also smoother than conventional pick-ups. Therefore, less wear is reflected in lower maintenance and service costs. With approximately 30% higher rotation speed, EasyFlow picks up cleanly and achieves more.

It's easier without control:

The highlight of this pick-up is the special design of the galvanized scraper. It provides a continuous flow of green material when dipping the teeth.

Perfect coherence for greater productivity:

Depending on the thickness of the roll and the working pace, you have the opportunity to smoothly change the rotation speed without getting up from the driver’s seat. With automatic adjustment, the speed of movement is adjusted without the assistance of the operator. One or two gauge wheels and the pendulum frame of the feed apparatus of the forage harvester are responsible for better copying of the soil contour.

Comfort makes working conditions easier:

During the reversing process, the cross feed auger and the large press roller are raised automatically. Foreign objects detected by the metal detector can be easily removed. As soon as the forage harvester continues to move, the clamp and auger automatically return to their working position. The gauge wheels are moved to transport position using a hydraulic system.

How we are the first in the world to robotize forage harvesters

Recently, my colleague told how we robotize combine harvesters and what we have learned this season. Harvesting of forage crops begins and we are actively mastering forage harvesting equipment. A forage harvester is a technically more complex and powerful machine. In conjunction with it there are several vehicles for harvesting (tractors with trailers, trucks, silage trucks). Only experienced machine operators with several years of experience behind them are allowed to operate such equipment.

Operating a combine while harvesting feed corn is similar to driving in a car in thick fog, only instead of fog, there is a tall green wall of plants along the entire route from which a boar, a pole or a person can jump out. After grinding a person (the story is in my last article), the combine operators turn gray and can no longer work. In addition, in this “green fog” you must be able to avoid crashing into a silo truck driving nearby, monitor the accuracy of loading the silo with a trunk up to 7 meters long, from which 50-60 kg of silage per second flies out, and fill the van evenly so that it does not drove half empty back and forth.

In fact, one combine operator works for three, monitors the corn harvesting process (one workplace), drives the equipment (second workplace), and loads the silo truck (third workplace). As a result, something suffers. If you drive poorly, you can break expensive equipment (the minimum price of a forage harvester is 16 million rubles, there are models for 50 million), so the quality of harvesting and loading usually deteriorates.

We automate most of the work, now I’ll tell you what difficulties we overcome and what we do.

No visibility

The height of ripe corn is on average 2-2.5 meters, the height of the combine is 2.5 meters, the machine operator is most often at a level slightly higher than a person standing on the ground and sees only plants in front of him, he essentially no longer sees further than his nose, and so on throughout the entire working day, and this is a 12-hour shift, few can withstand such strain on the eyes and maintain the pace of assembly, and pigs or a pole may jump out on the way!

There are combines, for example KRONE, with a telescopic cabin that rises to a height of up to 3 meters, or Acros RSM-142 with a height of 4 meters, but this is rather an exception to the rule.

Therefore, only experienced combine operators who have worked for 3-4 seasons can operate such a combine.

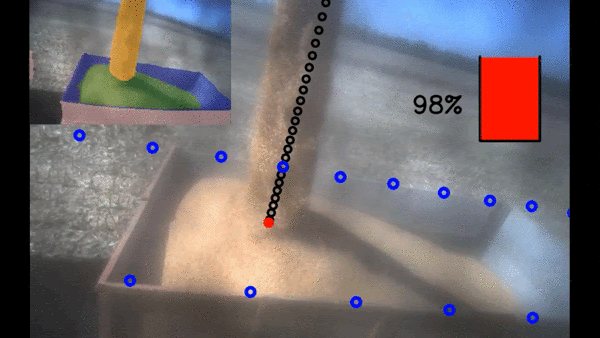

Losses during operation

Unlike grain harvesters, a forage harvester cannot store the crop in a bunker, but immediately releases it through an unloading trunk into a vehicle driving nearby. As I said, the silage ejection speed can reach 50 kg per second, depending on the model of the combine, the length of the trunk is 5-7 meters. I drove a little sideways away from the car or slowed down and lost half a ton of silage in 10 seconds. On average, up to 7-10% of the harvest remains on the field. Nobody collects the lost silage anymore; losses on fuel and lubricants will be much greater. The video shows how the silage spills out if you move the trunk a little.

Uniform filling of the van

In a team with one combine there are up to 7 cars, one car is filled in about 20 minutes. In a day they can make over 10 trips to the silo. It all depends on the length of the delivery arm. If the field is near the pit, then the arm is short and more trips can be made for unloading; if further, there are fewer trips and here it becomes very important to properly fill the van (silage truck) so that it does not carry air. I brought half of the trailer, but I think I lost it on fuel; the combine operator must guide the trunk as correctly as possible in order to evenly fill the silo truck.

What can we automate in forage harvesters?

As mentioned above, only experienced combine operators are allowed to operate such combines.

Almost all effective machine operators trained under the USSR, after which the technological secrets of this civilization were lost. Specifically, training has weakened, and the “young” people who come in naturally work worse. This is normal for almost all working professions, but here our robot is in great demand primarily because of this effect. Second, our robot sees the edge, obstacles on the field, and sees other equipment. The work of the combine operator is simplified as much as possible; now he can monitor the technical condition of the combine and the calibration of the corn fraction that is most suitable for this type of livestock.

Also, our robot can completely and evenly, and most importantly accurately, fill the silo tank, this reduces losses on fuel and lubricants and reduces harvesting losses to zero.

The norm is considered to be a loss of 7% of the harvest during harvesting, if they are reduced to zero, then since silage is made mainly not for sale, but for feeding our livestock, we can reduce the sowing of corn by 7% and give it to wheat, which is more profitable. Let's say, if 1000 hectares are allocated for corn, of which 70 hectares are allocated for wheat, then even according to minimal estimates, with a harvest of 30 centners per 1 hectare, we will collect 210 tons, and this is approximately 1.5 million rubles in direct profit. At the same time, due to more complete assembly, fuel consumption is reduced by reducing the number of trips from the silo to the field.

How we train neural networks to analyze corn harvesting scenes

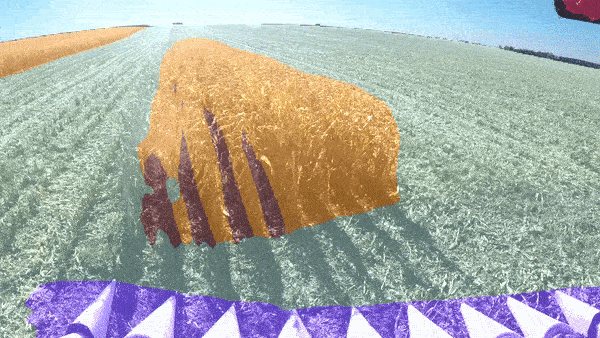

Corn is harvested using special attachments for row crops. For this case, an operating mode is provided in which the combine tries to hold the header in the middle of the row spacing. Having received a frame (scene) segmentation map and knowing the position of the header, you can find the so-called vanishing point and calculate the deviation of the header tooth from the required position.

Unlike wheat, where we monitor the edge of the harvested field and drive the harvester along the edge, here the task of the neural network is to see the row spacing between the plants. The neural network perfectly sees the rows between the corn, unlike a person, the camera is located above the crop, and at the same time it does not get tired.

Images come to us in video stream format, or as separate images. The data is processed and stored in Cognitive Agro Data Factory. In addition to raw data from the camera, there are also target marked frames, which, if necessary, can be added to the training dataset.

To more accurately select possible harvesting scenes, it is necessary to correctly compose the training dataset. In addition to real images obtained from the camera during the harvesting process, an approach is used to generate synthetic images using an augmentation procedure based on natural images.

The network accepts a 3-channel RGB image as input. Further, in the process of training the neural network, brightness/color distortions in HSV space, local distortions of channels in HSL space are applied to the input tensor - the procedure for adding artificial shadows, geometric distortions and adding noise. Selection of augmentation parameters is a non-trivial procedure that requires a detailed analysis of scenes obtained in real conditions.

The trained network is capable of producing segmentation maps that define the row space.

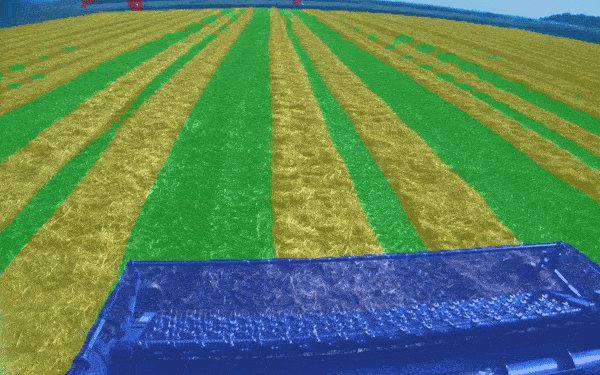

Hay cleaning

In addition to silage, forage harvesters are also used to collect haylage using a pick-up attachment. The harvesting process is similar to corn, the only difference is that the combine goes along the windrow. The windrow may not differ in color from the total mass and the combine operator may often run idle.

For example, in the video above you can see that the windrow is practically indistinguishable from grass and how precisely the combine operator needs to drive the machine along the windrow and at the same time constantly monitor the process of loading the haylage into the truck. The work is very intense; by the end of a 12-hour shift, combine operators simply collapse; they can only handle a full shift if they have at least 3-4 seasons of experience.

If the combine operator is inexperienced, then idle work is a waste of fuel and lubricants. A forage harvester, unlike a grain harvester, spends only 10% of fuel and lubricants on the movement of the combine itself, the remaining 90% goes to cutting, chopping, pulling, throwing silage or haylage. Therefore, it is very important to work with a fully loaded combine.

The neural network does a great job with windrows, an example of how the network sees windrows.

Here our system can help the combine operator in driving the combine along the windrow, also our robot can completely and evenly, and most importantly accurately fill the silo tank, this reduces losses on fuel and lubricants and reduces harvesting losses to zero, the combine operator becomes the operator of the combine, and takes on all the work yourself on autopilot.

We are now developing feed corn, sunflower, and haylage. At the end of the season, if you are interested, we will tell you how our robots coped with forage harvesters.

PS If your agronomist is not on Habré, but he is interested, then you can find contacts here: promo.cognitivepilot.com and discuss in detail which combine harvester requires which specific set of equipment, approximately how much it costs, and how you can quickly see and test it.

X-Disc- Straight cut header

High throughput, lower energy consumption

Worldwide proven EasyCut disc mower technology from KRONE

Highest reliability thanks to KRONE SafeCut

Mowing and chopping in one working pass:

The KRONE X-Disc is the specialist for the 900 mm diameter BiG X grain feed auger and is therefore universally applicable. The XDisc is even more productive and can easily ensure forage harvesting without loss and will convince anyone to pick up even long, bulky forage with its clean mowing. With the help of a huge

X-Disc: with it you will achieve success

Grain fodder plays an increasingly important role in the preparation of animal feed and the production of bioenergy. With the 6.20 m wide X-Disc, mowing and chopping are carried out simultaneously. With clearly high performance, the X-Disc 6200 has the ability to harvest crops without loss and with the highest cutting quality.

- Reliable running at 40 km/h:

For transport, the XDisc is quickly and easily mounted on a specially designed trolley. The integrated braking system will ensure your safety.

2. SafeCut Inside – exclusive from KRONE:

Unique protection of mowing discs and drive mechanisms from foreign objects. Short-term overload breaks the hollow pin in the drive shaft with threaded teeth. The knife disk rotates upward along the shaft thread and no longer rotates. Collisions with adjacent mowing discs and subsequent damage are therefore excluded.

3. Clean mowing, safe and comfortable:

The extremely reliable welded cutter bar, equipped with large spur gear drives, has a very convincing smooth running character. Quick release locks save time when changing blades. Thanks to the large overlap of the blade paths, the XDisc can cut crops cleanly.

4. High throughput:

The high-performance feed auger with an impressive 900 mm diameter works even in dense and tall crops. It has a pendulum linkage and the ability to reverse. The auger turns are equipped with removable protective strips made of high-strength Hardox steel.