Purpose and scope of application of the Don 1500 combine

The Don 1500 combine is used for harvesting all types of grain crops, and is also used to collect seeds of annual and perennial grasses. The best performance indicators are observed when operating on fields with a slight slope (no more than 8 °), as well as on large crop areas.

The manufacturer has provided for the possibility of using wide-cut headers of 6000 mm, 7000 mm and 8600 mm, which is significantly larger than other domestic machines for similar purposes. Only two models were developed, which were produced sequentially at the Rostselmash association: Don 1500A and Don 1500B. The latter took into account the shortcomings of the first model.

During the Soviet period, the combine was equipped with a six-cylinder diesel engine with turbocharging from the Kharkov Motor SMD; since 1996, an eight-cylinder diesel engine YaMZ-238 (Yaroslavl Motor Plant) with a power of 235 hp began to be used as a power unit.

General view of the Don 1500 combine from the front. Visible are a wide-cut header, a cabin with a driver's platform located on the front and side parts of the body

Distinctive features of this self-propelled agricultural machine are:

- quite significant weight and overall dimensions, which determines the wide grip when harvesting crops;

- high productivity of devices for mowing and threshing grain and seed plants;

- successful design of drums and sifting decks with an optimal ratio of parameters, which ensures reliable separation of grains with minimal losses when threshing the grain mass;

- the use of hydraulic boosters made it possible to create easy control of a complex and heavy machine when performing various manipulations with attachments;

- many adjustments are made quite simply, which allows you to configure the operation of the equipment in optimal modes;

- the presence of a wide and comfortable platform with guards facilitates access to units located at high altitudes;

- high-arched low-pressure wheels have high cross-country ability, which will allow you to move steadily both through chernozem and soils with a high sand content (non-chernozem gray sandy loam), this expands the range of use of the combine in the Russian Federation and other CIS countries;

- The visibility from the cabin is quite large, which allows the driver to control the progress of the grain harvesting and threshing processes.

Frontal view of the Don 1500 combine harvester. The photo shows the header, cabin, huge grain bin and stacker

The DON 1500 combine is a machine designed for harvesting grain crops. Its configuration is based on a powerful 4-stroke diesel engine YaMZ-238AK with a forced liquid cooling system. The engine is not equipped with turbocharging, which greatly simplifies its independent repair. The large fuel tank ensures long-term operation of the model without stopping. The video will tell you more about the capabilities of the Don 1500 machine.

The combine design includes a PowerStream header. The width of its grip can be adjusted in positions 6/7/9 m. The rotation speed of the cutting knives is 946 cuts per minute. The reel rotates at speeds from 15 to 49 rpm.

Threshing is provided by a drum with a diameter of 80 cm. Its rotation frequency can be adjusted in the range from 445 to 900 rpm.

The Don combine is equipped with a reliable 5-key straw walker, 4.1 m long. The total separation area is 6.15 m2. A 6-blade fan is responsible for cleaning the grain. Its rotation speed can be adjusted in the range from 380 to 1000 rpm.

Factory model parameters include:

- power – 235 l. With.;

- fuel tank capacity – 540 l;

- Fuel consumption when operating under medium loads is 165 g/l. s./h.;

- grain tank capacity – 6 m3;

- weight including header - 12.59 tons.

This Don combine can be used under any conditions. Its header is equipped with a special copying device and stone catchers. Thanks to this feature, the machine can be operated even in very difficult areas.

Features of the Don1200 model

The Don 1200 combine is similar in its modification to the basic configuration of the unit, which can be seen even in the photo, without considering the main parameters. The Don combine under consideration has differences in the design of the header, chassis and power transmission. Model 1200 is equipped with a hydraulic leveling system. Unlike the Don 1500A combine, the volume of the bunker tank is reduced here, which is four and a half cubic meters.

The combine harvester is constructed of a cabin, a hydraulic automatic system for leveling the position relative to the landscape, a header, a thresher, a motor unit, a grain tank, electronics and electrical equipment. The Don combine can be used for operation on steep slopes, and you can choose a transport or working position.

Specifications

| The name of indicators | Units | Numerical values |

| Overall dimensions of the combine: | ||

| length | mm | 12200 |

| width (with smallest header) | mm | 6100 |

| height | mm | 3980 |

| Weight | kg | 13400 |

| Grain tank volume | l | 6000 |

| Grain unloading speed by screw conveyor | kg/min | 2500 |

| Number of straw walker keys | PC. | 5 |

| Total straw walker length | m | 4,1 |

This model can work with headers of different widths and configurations. It performs equally well in different conditions. The model shows stability in sloped areas.

The machine is capable of operating in direct and separate combining modes. Its design includes a mechanism for harvesting the non-grain part of crops and collecting stems into windrows.

To separate grain from stalks, the Don combine is equipped with a threshing and separating system. It reduces crushing and collapse of grain. The improved design of the thresher makes it possible to use it at a high feed rate of grain mass.

Model parameters include:

- power – 280 l. With.;

- fuel tank capacity – 516 l;

- Fuel consumption when operating under medium loads is 180 g/l. s./h.;

- grain tank capacity – 6 l3;

- weight including header – 14 tons.

The sufficiently large weight allows this Don combine to show high stability on sloped areas. High-quality spare parts make the machine as reliable as possible when working under high loads.

| Characteristics | Indicators | Unit measurements |

| engine's type | SMD-31A | |

| Speed (transport, maximum) | 22 | km/h |

| Speed (operating, maximum) | 10 | km/h |

| Performance | 14000 | kg/h |

| Drum rotation speed | from 512 to 954 | rpm |

| Drum diameter | 0,8 | m |

| Drum length | 1,484 | m |

| Header grip | 6.7 or 8.6 | m |

| Weight (weight with six-meter header and stacker) | 13 | T |

| Grain tank volume | 6 | m3 |

| Ground | from 6 to 8 | kg |

| Thresher width | 1,5 | m |

| Height | 4 | m |

| Width | 8,05 | m |

| Length (with divider and stacker) | 11 | m |

Forage harvester Don

The RSM 100 Don 680M forage harvester is an ideal option for both small and medium-sized livestock farms where the number of livestock does not exceed five hundred. But the Don silage combine is often used for large enterprises. Using this type of equipment, you can provide daily feed to livestock, without delays or downtime. In addition, it can be noted that thanks to the design features of the technological path, the Don combine allows the mulched mass to move along a clear path, reducing transportation time.

Main modifications

Don-1500A

This model is the original one. All the characteristics and features listed above apply specifically to it.

Don-1500B

This variation was a consequence of the refinement of the previous model.

In particular, the following was done:

- Many copies began to be equipped with a more modern engine - the YaMZ-238 AK, without turbocharging, with a V-shaped arrangement of cylinders.

- Instead of one stone catcher hatch, there were two.

- The size of the crankshaft crank has been increased while its rotation speed has been reduced.

- The upper sieve has become larger.

- The parameters of the drum pulley have changed, and its speed range has increased.

- The unloading auger has become larger.

- A reverse has appeared in the drive mechanism of the header.

- The cutting mechanism has shortened open fingers.

- A special deck has appeared that eliminates sticking when wet grain is removed.

The cleaning area has increased by one third, which immediately increases productivity by one fifth.

| Characteristics | Don-1500A | Don-1500B | Unit measurements |

| engine's type | SMD-31A | YaMZ-238 | |

| Straw walker crank radius | 6 | 8 | cm |

| Crankshaft speed | 157 | 195 | rpm |

| Engine power (operating) | 165,6 | 178 | kW |

| Rotational speed (nominal) | 2000 | 2000 | rpm |

| Number of engine cylinders | 6 | 8 | PC. |

| Cylinder diameter | 12 | 13 | cm |

| Piston stroke | 14 | 14 | cm |

| Working volume | 9,5 | 14,86 | l |

| Fuel consumption (specific) | 224-234 | 220 | g/kWh |

| Performance | 14000 | 16800 | kg/s |

| Drum rotation speed | from 512 to 954 | from 450 to 900 | rpm |

| Diameter of inclined unloading auger | 25 | 30 | cm |

Modifications and features

The first copies of Don 1500 appeared in 1986. All subsequent versions were the result of modernization of the debut model.

Harvester modifications:

- Don 1500A is the first option, considered the standard model. The equipment was equipped with 2 large wheels in the front and 2 small ones in the rear. The design of the combine used an SMD-31A unit with a very inconvenient location, and the reaping part had the ability to copy the terrain;

- Don 1500B is a modernized version of the classic model. The previous engine was replaced here with a more powerful YaMZ-238 AK engine. Other innovations included: a wider speed range, an enlarged unloading auger, a reverse drive mechanism for the header, a deck to eliminate sticking when collecting wet grain, an enlarged crankshaft crank, a second stone catcher hatch, and an enlarged upper sieve. Another important addition was a picker, which made it possible to separate the harvested crop. Don 1500B completely replaced the debut version in 1994;

- Don 1500N – version for work in non-black earth areas;

- Don 1500R – modification for harvesting rice. The half-track combine moved confidently through weak and wet soil and had a smaller header width.

Read also: Description of black duck breeds

Features of Don 1500B:

- a threshing drum with one of the largest diameters in the world;

- reliability;

- ability to work with headers of various sizes;

- low-pressure tires with high lugs, allowing you to work on any type of soil;

- high-speed release system to prevent clogging;

- large volume bunker;

- low cost and availability of spare parts. The combine can be repaired even in the field. In terms of maintenance and operation, the model will cost much less than its foreign counterparts;

- Ease of Management.

Disadvantages of Don 1500B:

- the engine is located too close to the cabin, so the hot air heats up the cabin too much, which affects the level of comfort;

- lower level of convenience, functionality and reliability in comparison with foreign competitors.

Grain harvester RSM-10B “Don”-1500B

The design of this machine is equipped with a powerful 4-stroke diesel engine YaMZ-238AK. The engine is equipped with a direct fuel injection system. There is no turbocharging included.

The main feature of the model is its atypical gearbox. It does not change speeds, but allows you to configure the machine to work in specific conditions. The first gear switches the combine harvester into travel mode with an empty hopper. The second is needed to configure the machine for harvesting in fields with a slope of 0–4 degrees. Third gear is necessary to be able to collect grain on land with a slope of 4–8 degrees.

The chassis of the model includes a driving and driven axle. Torque from the motor to the drive wheel gearboxes is transmitted through the axle shafts. The latter are connected to the gearboxes using bushings.

Combine parameters include:

- power – 235 l. With.;

- fuel tank capacity – 540 l;

- Fuel consumption when operating under medium loads is 165 g/l. s./h.;

- grain tank capacity – 6 m3;

- weight including header - 13.44 tons.

The Don combine is equipped with a spacious cabin with high-quality sound insulation and a large viewing radius. The steering column is located in the center of the cab, and the operating gear shift levers are located to the right of the operator.

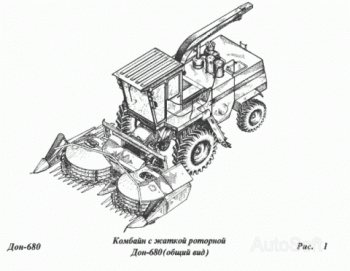

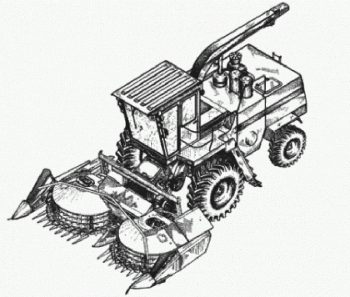

Combine headers are available in several versions. They are produced with a working width from 6 to 8.6 m. There are also small batches where rotary mowing working parts are used. Such headers are equipped with combines used for harvesting seeds from perennial grasses.

Combine "Don 1500" with a rotary header. The photo shows the features of the rotor design with centrifugal-type knives. There are no counter-cutting plates; mowing is carried out due to the high translational speed of the knife moving rotationally around an axis and translationally due to the movement of the entire machine

For harvesting corn, headers from SK-5 Niva combines are used. The linkage system is being reworked, and additional replaceable sprockets are being installed for the chain drive of the mechanisms. The performance when harvesting corn is slightly worse than when using the SK-5, but there is no need to purchase or rent an additional agricultural machine.

Some farms in the Rostov region and Krasnodar region use the experience of rice farmers in Uzbekistan. The Don 1500 combine harvester is mounted on a half-track mover. This transformation makes it possible to harvest rice.

It is known that in rice fields, soil moisture remains quite high even after the rice ripens. Harvesting can be done by direct combining. Setting it up on crawler tracks allows you to move a heavy machine over soft ground.

Harvester "Don 1500" on a half-track. The photograph shows special caterpillar supports used for movement in rice-growing conditions

On a grain harvester, the wide header is mounted on special shoes when mowing bread. They rest on the ground and guarantee a stable cutting height for all plants. An obvious advantage in the work, but it turns out that this complicates the preparatory work on field leveling for the use of the Don 1500 combine.

Possible errors when using a combine harvester for grain harvesting:

- Mistake # 1. Using a combine on fields with large slopes leads to the fact that the wide header comes off the surface on one side. Mowing occurs at the height of the ear - this leads to grain losses.

- Mistake #2. Using a combine harvester in fields where preliminary grading has not been carried out or the quality of harrowing is low. As a result, the edges of the header are also torn off on one side. The likelihood of mowing at high altitudes increases. The likelihood of the agricultural machine overturning increases.

Not all fields of one farmer may be ideal for using the Don 1500 combine. Some may have a large slope that will not allow you to take full advantage of the machine. But they find a way out here too.

- The grain mass is mowed into windrows, then, without allowing this mass to dry out, the mowed grain is collected using a roll pick-up and taken to the edge of the field. Here the combine is placed permanently. The grain mass itself is fed to the header picker.

- The grain mass enters the lifting conveyor, and then the threshing separating device moves.

- Threshing and separation are carried out inside the combine.

- As a result, the straw is collected in a transport trailer, and a fan throws it there in crushed form.

- The grain is fed into a bunker, where it accumulates, and then it is fed by an auger into the body of a vehicle, which transports it to the grain warehouse.

When organizing work like this, many machines are used. It is necessary to rhythmically perform several operations, simultaneously organizing the movement of vehicles. This type of work experience was carried out for the first time in the foothill zone of the Stavropol Territory. Subsequently, the results of the work of grain harvesting units using several agricultural machines were compared. The table shows the main results of the work.

| Indicators of wheat harvesting on inaccessible areas | Type of combine used (separate combine) | ||

| SK-5 "Niva" | "Don 1500" | JOHN DEERE | |

| Specific fuel consumption per ton of grain, kg/t | 14,3 | 18,4 | 16,2 |

| Number of units of agricultural machinery involved, pcs. | 1 | 3 | 2 |

| Cleaning productivity, t/hour | 6,2 | 12,4 | 9,2 |

| Given costs per 1 ton during harvesting, rub./t | 480 | 620 | 545 |

From the presented data it is clear that the real costs are when using the SK-5 Niva combine, but labor productivity is higher when using the Don 1500. Therefore, if the number of days for harvesting is limited by weather conditions, then in order to preserve the harvest and its timely harvesting, it is necessary to organize harvesting and transport links, where the main unit is used as a stationary device for threshing the grain mass, and the rest contribute to the timely mowing and delivery of the grain mass for processing .

Organizing harvesting and transport links is creative work. A wide variety of machine combinations are possible. The main thing is to determine your priorities and then calculate options for their implementation. It can be profitable to mow with one machine and process with another. It all depends on the specific circumstances.

Organization of the harvesting and transport link for separate grain harvesting. It can be seen that rhythmic work is possible if a number of conditions are met, for example, approximately equal productivity of the agricultural machines used

Engine

Six cylinders lined up inside a four-stroke turbocharged engine are cooled by water from a tubular radiator. The air is purified passing through two stages of purification. The engine is located next to the cabin, near the threshing mechanism.

Power is taken from both sides of the crankshaft, which rotates clockwise. The drives of the working mechanisms are powered from the rear, and the hydraulic pump for the chassis drive is supplied from the front.

Brake system

The unit is equipped with a mechanical parking brake, controlled by a lever with a button that snaps into place a pawl lock. To stop the car, you need to pull the lever towards you until the third or fourth click. The brake is released by moving the lever up and simultaneously pressing the button.

There are also separate hydraulic disc brakes for each wheel. They are mounted on onboard planetary spur gearboxes and are controlled by pedals, the height of which is adjusted by a hydraulic brake cylinder fork.

This system is used for a smoother turn on soft and wet ground. Separate braking is not recommended on hard roads.

Hydraulics

This system consists of three: the chassis control drive, the steering drive and the hydraulic system of the working mechanisms. The latter has a minimum of piping and includes distributors with spools controlled mechanically or hydraulically. With its help, in particular, they control the header, reel, auger rotation, stacker, chopper, air duct cleaning, and scrolling of the threshing mechanism.

Scheme of the Don-1500 combine

Steering

The steering column operates from a hydraulic volumetric drive. The steering wheel can be adjusted to the height of the combine operator, changing the height by up to 11.5 centimeters. A collet type clamp is used for this. It is also possible to change the tilt of the steering wheel from 5 to 30 degrees - a pedal is used for this.

Chassis

The drive axle is separate-aggregate. It is controlled hydraulically, which allows you to continuously change the speed of movement (in any of the speed ranges). Thanks to this, the combine has good maneuverability. The hydraulic motor is mounted on the shaft of the gearbox (mechanical, three-way, with four modes when moving forward and one when moving backward).

The driven axle is also hydraulically operated. The clutch is dry type, single-disc, with a diaphragm spring. The tires have treads that provide excellent cross-country ability and self-cleaning.

Diagram of chain drives of the Don-1500 combine

An inclined chamber is suspended from the thresher, to which, in turn, the header is attached on hinges with springs. It includes cutting and balancing mechanisms, as well as a drive mechanism, dividers, a reel (attached to the header by four bipods) and an auger.

In the front part of the header there are shoes for following the terrain. During operation, they can be placed in one of four positions. The harvester is transported on a special trolley.

Cutting mechanism - can be with open or double fingers. The reel with quick release pins, controlled by two synchronous hydraulic cylinders, is equipped with two eccentrics (located on the sides). The reel rake angle is adjusted automatically. The balancing mechanism consists of two suspensions (adjustable and non-adjustable), a lever, a removable pin, a spring block and an adapter. The auger has an increased size - 59 centimeters.

This “Don” combine is considered a successor to the one discussed above. After certain modifications and bug fixes, in this version it was possible to achieve improved power indicators and 5 times increased productivity with the same fuel consumption. Thanks to this, the Don 1500B combine harvester from Rostselmash is included in the list of the most powerful among the equipment of this specialization. In 2004, it was continued in the Don 141 combine, which is in the same power class.

Advantages

- equipped with a non-turbocharged 8-cylinder 4-stroke diesel engine “YaMZ”-238;

- doubled number of compartments for stone catcher;

- large-sized crankshaft, which reduced its rotation speed

- the area of the cleaning sieves is expanded by a third compared to the 1500th grade;

- wide range of grinding unit speeds;

- large auger for unloading;

- precision knife mechanism that uses open short fingers;

- addition of a special deck to the combine design, which eliminates the sticking of seeds and allows you to work with wet materials;

- ergonomic cabin from where the header and other working components are adjusted.

Purchasing a combine harvester for farming needs

The Don 1500 combine is convenient and quite productive in operation. But it cannot be recommended for all farms. The main conditions under which its choice will be justified:

- the presence of large areas of arable land (more than 1000 hectares);

- all crops have a slope of no more than 4...5 °;

- grain yield is consistently above 20 c/ha;

- ripening occurs simultaneously, the gap between achieving milky-wax ripeness and consumer ripeness is no more than 15 days.

Advantages of the Don 2600 combine

Model Don 2600 is a combine harvester, which today has become one of the main grain harvesting units in Russia. Thanks to innovative developments, when harvesting cereal crops, minimal damage to the grains is observed. To increase the scope of application, it is enough to use auxiliary devices. The machine is equipped with a two-stage wind-sieve cleaning system. Users have the opportunity to order many additional options and components for efficient operation of the unit.