Combine harvester Polesie: types and varieties

Combine harvesters "Polesie" are produced with different technical indicators, presented in the table.

| Technical indicators | Model of the Polesie combine harvester | |||||

| PALESSE GS16 | PALESSE GS14 | PALESSE GS12 | PALESSE GS10 | PALESSE GS812 | PALESSE GS575 | |

| Engine power, hp | 530 | 400 | 330 | 330 | 210 | 155 |

| Number of drums for grain threshing, pcs. | 2 | 2 | 2 | 1 | 1 | 1 |

| Width of threshing device, m | 1,7 | 1,5 | 1,2 | 1,2 | 1,2 | 1,2 |

| Straw walker type | rotary | key | key | key | key | key |

| Header working width (max), m | 9 | 9 | 7 | 7 | 4 | 5 |

Grain harvesters “Polesie” produced by the GomSelmash holding: 1 – PALESSE GS16;

2 – PALESSE GS14; 3 – PALESSE GS12; 4 – PALESSE GS10; 5 – PALESSE GS812; 6 – PALESSE GS05 Digital values in the machine model characterize the throughput of the threshing-separating device, kg per second.

Only the PALESSE GS812 model has a throughput of 8 kg/s.

Owner reviews about the Polesie-1218 and Polesie-812 combines

The Polesie combine harvesters (as well as the work of the dealer network) received mixed reviews from peasants in the CIS.

Pros. On the one hand, both combines demonstrate high productivity and good harvesting power reserves. Where combines from other manufacturers lag significantly behind, “choking”, “Polesie” continues to work at the same pace, without feeling the load. This is especially true for “KZS-1218” - the presence of an accelerator drum affects it.

In terms of fuel efficiency, they are in no way inferior to foreign analogues. Gomselmash combines demonstrate a throughput capacity of at least 3 thousand tons of grain per season, and this with minimal losses.

Everyone notes that thanks to comfortable working conditions (climate control, very good noise, vibration and dust insulation of the cabin), you can work effectively on a combine for longer than on old-style combines. Which has a positive effect not only on the operator’s health, but also on reducing harvesting time.

Minuses. When moving uphill and on side slopes, grain losses increase significantly. The large total length of the accelerator deck and drum, as well as the insufficient elevation angle of the straw walker, have an effect.

Grain often flies out from behind, here it is necessary to install seals between the lower sieve and the grain shaking board; and between the lower and upper sieve. There are often problems with starting the straw chopper (the tips do not work). The quality of painting leaves much to be desired: the paint on combines fades quite quickly and falls off in places. As a result, the three-year-old Polesie combines take on the same appearance as the 10-year-old Rostselmashevskie combines.

The header often becomes deformed, wears out, and begins to fall on one side; the sieves cling to each other. There are complaints about the work of Gomselmash dealers: they do not always have the necessary spare parts and consumables in stock. In some cases, you have to wait so long that the very relevance of the repair is lost.

Indicators of the advantages of Belarusian agricultural machinery

The line of these harvesting machines is designed for harvesting grains, as well as rapeseed, buckwheat, soybeans, corn and other crops. As production tests have shown, the effective system for cleaning the grain mass gave results at the level of the best in the world. Even specialists from American and Israeli agricultural machinery factories were forced to accept the results of comparative production tests.

| Cleaning quality indicators | Models of combine harvesters being tested in 2012 | ||||

| Acros 580 | Tucano 450 | John Deere W650 | New Holland CSX7080 | Palesse GS12 | |

| Real grain losses, % | 1,57 | 1,62 | 1,36 | 1,78 | 1,42 |

| Correspondence between actual and declared throughput, % | 88 | 83 | 92 | 91 | 88 |

The table shows that the main characteristics of the Polesie combine are at the level of leading manufacturers. An important factor that determines the choice of many farmers to give preference to Belarusian agricultural machinery is the price. For these machines it is an order of magnitude lower than that of equipment from non-CIS countries.

The GomSelmash holding provides long-term guarantees for all equipment produced by it. Spare parts and equipment, if retrofitting and repairs are necessary, are supplied as quickly as possible. Today, in some regions of Russia, service points have been created where maintenance and repairs can be performed. To reduce buyer costs, service can be ordered on the territory of your farms. Specialists will arrive on site and carry out a series of preventative maintenance according to the maintenance plan.

Repairs can be carried out similarly if units are damaged during operation. Major repairs are carried out only in service centers. As practice shows, today Polesie combines are in an advantageous position in comparison with other similar agricultural machines.

Application

The Polesie GS05 combine harvester is intended for separate, direct harvesting of cereal grains, cereal crops, as well as grass seeds located on flat fields with a slope of up to 8 degrees. The equipment performs high-quality cutting, threshing, separation, cleaning of crops, accumulates grain in a bunker and then unloads it. The non-grain part is also processed by a combine and formed into windrows. GS05 belongs to economy class equipment and is suitable for small agricultural enterprises that need a compact, inexpensive and maneuverable harvesting machine.

GS10 is used for direct, separate collection of cereal grain crops, as well as for harvesting the seeds of grass, cereals, and leguminous crops on flat fields with a slope of 8 degrees. The Polesye grain harvester belongs to the upper level of the middle class in terms of productivity. It easily cuts, cleans, threshes, separates, accumulates, and unloads grain, while the non-grain part is either placed in windrows or crushed and scattered across the field. GS10 is capable of processing crops of any yield.

GS12 works in a wide range of crop yields, and has proven itself in unfavorable harvesting conditions (difficult to thresh, clogged, wet, high-straw crops). All-wheel drive allows the combine to harvest crops on soils with low bearing capacity. The machine grinds soybeans, corn, rapeseed, legumes, sorghum, grass seeds, cereal crops, sunflowers for grain.

The GS14 combine is a powerful, high-performance self-propelled machine designed for harvesting large volumes of high-yielding grains and other threshing crops.

Model GS16 is a high-power combine harvester for large-scale harvesting of fields with maximum yield. Processes cereals, cereals, legumes and other threshed crops even in the most difficult working conditions (clogs, high humidity).

GS812 is a classic model of a middle-class combine, used on farms with low and medium yields. Ease of use is complemented by a comfortable cabin and on-board computer. The characteristics of the Polesie combine allow it to be used on land with low bearing capacity.

Geography of sales of Polesie combine harvesters

In 2020, interesting data were published on sales of Belarusian-made agricultural machinery to the CIS countries, and in particular Polesie combines:

- Russian Federation – 58 pcs.;

- Republic of Kazakhstan – 22 pcs.;

- Ukraine – 6 pcs.;

- Republic of Uzbekistan – 17 pcs.;

- Kyrgyzstan – 9 pcs.

Comparing data over the past five years, we can note positive sales dynamics. Every year there is a certain increase, which indicates the growing popularity of Polesie combines.

Tip # 1. Polesie combines are provided with service centers in many CIS republics, so they have an advantage in service compared to agricultural machinery from other manufacturers. It is easier and cheaper to carry out repairs with the involvement of specialists from the service department than to carry out repairs on your own.

Main buyer mistakes:

- Mistake #1. You purchase a combine harvester only with the widest header for a given model, but during operation it turns out that some fields have a side slope of more than 8°. The header becomes detached from the support shoes.

- Mistake #2: Some buyers use a food processor to harvest rice. But to equip agricultural machines, a tracked drive from the SK-5 Niva and Yenisei 1500 combines is used. In this case, there is a need to regrind the landing bushings. As a result, the manufacturer's warranty on the purchased equipment disappears.

Features of the devices of combine harvesters "Polesie" ("PALESSE")

Let's take a closer look at the design of grain harvesters.

Harvester headers "Polesie"

Headers for Polesie combines operate in a similar way to headers for Russian-made combines. They include a number of basic mechanisms:

- a reel that lifts laid grains, directing the stems to the cutting elements;

- mower that mows grain mass. The teeth perform reciprocating motion driven by a planetary gearbox;

- augers that collect the mown mass to the center of the header. They have a chain drive from V-belt variators;

- finger conveyor, which ensures the supply of mass to the inclined conveyor;

- an inclined conveyor that supplies grain mass for processing into a threshing and separating device.

The photo shows side cutters, a cutting device, augers, a finger conveyor and an inclined conveyor . The plant produces a series of headers with a working width from 4 to 9 m. All types of headers have support shoes that allow you to follow the field surface when harvesting. When moving between fields, it is recommended to disconnect the header from the combine, and then transport it in the form of a trailer, following the combine.

Header for the Palesse GS16 combine with a working width of 9 m in transport position. The photo shows auxiliary wheels; the header is mounted on them when moving the grain harvester between fields

Threshing device of combine harvesters "Polesie" ("PALESSE")

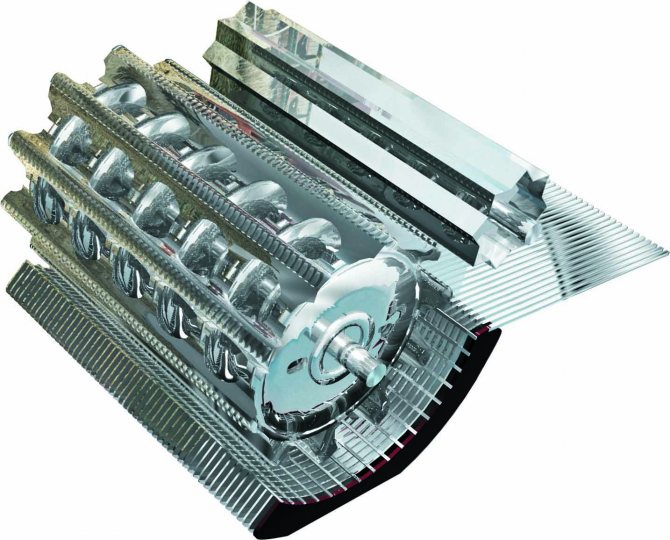

The Palesse GS16, Palesse GS14 and Palesse GS12 models use a double-drum threshing system. Drums of different diameters:

- the first beater drum with a diameter of 600 mm;

- the second drum has a diameter of 800 mm.

Sifting decks are located below, through which the grain is sifted down, and the straw with the remaining seeds is moved further to be shaken off. The rotation speed of the reels is such that the linear speed on the first reel is lower than on the second. Therefore, the incoming mass is stretched. Therefore, the main part of the grain spills on the second drum.

Beating drums of the threshing and separating device of Polesie combines with high throughput. In addition to the drums, cutting decks are shown, through which the threshed grain is sifted

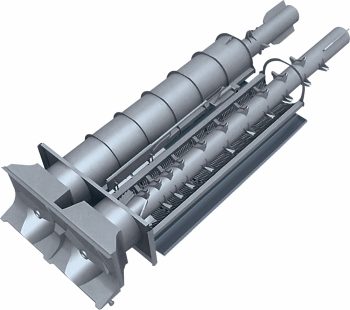

The PALESSE GS10, PALESSE GS812 and PALESSE GS575 low-capacity combines have one beater drum installed. Its diameter is 800 mm. The length of the drum corresponds to the width of the receiving chamber. Different models have different widths, which explains the different throughput.

Single-drum threshing device for Polesye combines. The beater drum and perforated decks are the main elements of the thresher

Separating devices of combine harvesters "Polesie" ("PALESSE")

The PALESSE GS16 model uses the principle of rotary separation. The cylinders, similar to beating drums, are wrapped around decks. The cylinders rotate towards each other. The grain mass with straw is thrown onto the decks under the influence of centrifugal force, and then falls back onto the beaters.

The beaters themselves are small blades directed at an angle of 5...7 ° towards the exit from the separator. Due to this, forward movement occurs. The remaining grain is sifted through the decks.

The use of the rotor principle makes it possible to achieve high cleaning efficiency of the mass. As practice shows, the energy intensity of this separation principle is higher, and at the same time a high degree of purification is observed. No more than 1% of the grain remains in the heap of straw.

Rotary separator of the PALESSE GS16 combine. There are two cylindrical beating rotors, they are wrapped with mesh decks

The remaining models of Polesie combines are equipped with traditional push-button straw walkers. Only the PALESSE GS812 and PALESSE GS575 models have four keys; the PALESSE GS14 has six keys, and the others have five. The settings and adjustments were developed for the first combine harvesters, implemented on American-made John Deere models, and then it was repeated many times on other similar combines. The difference is only in size, but the general principle is the same. Each key is driven by rotation of the crankshaft. Each knee is controlled by its own crank. Therefore, one goes up and the other goes down. The rotation frequency is high, with a relatively low amplitude. Therefore, the straw walker vibrates at a high frequency.

By this time, the straw is already noticeably crushed, but the particle size is several times larger than the grain size. Therefore, grains with a large mass fall down, and the straw goes out onto the fan. Then it is thrown out.

The PALESSE GS812 model can additionally be equipped with an automatic stacker. It is available upon special order from the buyer. Some livestock farms have developed a technology for increasing the nutritional value of straw by barothermochemical processing of straw (farms in Crimea), which is why they are the main customers of this option for combines.

Design and operating features

The Polissya KZS 812 series has a standard design, including a chassis, threshing system, loading hopper and cabin. The combine represents the category of grain harvesting machines with one drum, a straw walker and a beater. Due to ease of maintenance and technological reliability, such a scheme has received the greatest recognition in Russia.

The undercarriage is designed to withstand tough conditions. As an option, it is possible to install a caterpillar drive with reinforcement or twin wheels (KZS 812S). This modification is suitable for areas with wet and unstable soil.

The cleaning process in Polesie KZS 812 is carried out in several stages. The working parts of the combine are involved in the process:

- reaping part. The base for the model are Gomel headers of various widths. They are protected from mechanical damage by hydropneumatic accumulators. The reaping part of most versions is equipped with a relief copying mechanism, ensuring maximum productivity. A planetary gearbox is used to drive the reaping apparatus. The cutting apparatus contains stamp-welded fingers with lower and upper cutting edges and a system of alternating segments. This ensures a clean cut and ensures cleaning. Additionally, Polissya KZS 812 can be equipped with equipment with rapeseed reflectors and fingerless side dividers for harvesting rapeseed, a system for collecting corn (cob separator, stalk chopper, replaceable concave) and other units;

- inclined camera. The element ensures uniform supply of mass for stable threshing;

- threshing and separation system. The PALESSE GS812 thresher is equipped with an inertial drum, which improves the quality of harvesting crops with medium straw content. The latest versions of the combine are equipped with a Big Drum threshing apparatus, equipped with a modern high-inertia drum. The operator can set the concave clearance directly from the passenger compartment. When an element is clogged, an emergency concave release system is used to restore threshing stability. The presence of an autonomous pre-threshing device eliminates the possibility of overloading the thresher. Grain separation is carried out using a 4-key cascade-type straw walker with a large area. Due to the adjusted step difference, optimal separation of the residual mass occurs. A 3-cascade cleaning system with sieves with an area of 3.86 sq.m and electrically controlled cleaning fan guarantee high quality of the final product;

- large bunker with quick unloading.

The cabin of the Polesie KZS 812 combine harvester is large and is designed for 2 people. It has panoramic glazing and increased vibration and noise protection. The air conditioner allows the operator to work in comfortable conditions in any area. The combiner's working area is designed in accordance with the latest advances in ergonomics. The adjustable seat adapts to any operator configuration.

Monitoring the main systems and warning about problems are the responsibility of the on-board computer. When starting the engine, the system checks the integrity of the working mechanisms and their serviceability. In case of problems, information is instantly sent to the operator. The system is also responsible for selecting the optimal operating mode, taking into account the type of crop and external factors, adjusting the air cleaning force, the level of opening of the sieves, the speed of the threshing drum and other parameters. This ensures maximum quality of operation.

The cost of the new Polesie KZS 812 combine harvester produced by Bryanskselmash starts from 4.9 million rubles (modifications KZS-812-27 and KZS-812-22). A similar model produced by the Belarusian enterprise Gomselmash is available at a price starting from 3.6 million rubles (basic version KZS-812).

Price tags for used Polesie KZS 812 combines in good condition (2010-2013) are 1.7-2.5 million rubles

SIMILAR ARTICLESMORE FROM THE AUTHOR

Combine harvester RSM 161

Combine harvester RSM 101 Vector 410

John Deere W650 grain harvester

1 COMMENT

“Header for combine harvester KZS-812 “PALESSE GS812” The header is designed for harvesting cereal crops, and with the use of special devices also for harvesting rapeseed, leguminous and cereal crops. Specifications. Type Frontal, copying the field relief in the longitudinal and transverse directions at a given height. Design working width is 6m. Installation cutting height: - when copying the field relief - 55+15mm, 90+15mm, 120+15mm, 160+15mm, 195+15mm. -without copying the field relief - From 50 to 800mm, Transport speed, no more than 20 km/h, Overall dimensions of the header in transport position (on a trolley), no more: - length 10200mm, width 3000mm, height 2500mm, Weight of the header -1900mm The product is supplied in a basic configuration (including a set of spare parts), an instruction manual is required. The supplied product must be new, unused, not after repair, manufactured no earlier than 2020, with a warranty period of at least 12 months from the date of commissioning. The contract price includes delivery and unloading at the location specified by the customer.

Features of servicing combines "Polesie" ("PALESSE")

During the harvesting period, maintenance activities are required to ensure uninterrupted operation of the combines. Agricultural equipment manufacturers have developed special maintenance cards for their machines

| Types of maintenance during the cleaning period | Checking hydraulic systems | Checking V-belt variators | Engine check |

| ETO (daily maintenance) | + | – | + |

| TO1 (every 120 engine hours) | + | + | + |

| TO2 (every 240) | Mandatory complete oil change | Troubleshooting and replacement of belts | Checking the engine oil level, coolant level, timing belt adjustment |

To perform maintenance, all combines are equipped with tool sets, as well as auxiliary devices for lubrication and monitoring of main systems and assemblies.

Possible errors during operation:

- Mistake #1: Some farmers neglect daily maintenance. As a result, the combine is left without coolant in the cooling system, and the engine fails.

- Mistake #2: Trying to save on oil for hydraulic drives results in loss of efficiency when raising and lowering working parts. This leads to damage to the header. A sharp lowering of the header when moving between fields is especially dangerous.

V-belts are adjusted in a certain sequence:

- A ruler and a dynamometer are taken from the spare parts kit.

- The belt between the pulleys is pulled with a force of 100 N.

- The belt deflection is measured.

- The resulting value is compared with the tabular data.

- If necessary, the required deflection is set using tension rollers.