Modern technology for working in the fields is designed to minimize manual labor, which helps to increase productivity. There are industrial grain combines for large areas, but they are not suitable for compact areas. The agricultural equipment market offers farmers the Zarya mini grain harvester, which is quite powerful and productive. It is worth noting that this special equipment is practically indistinguishable from large-sized developments, while having smaller dimensions and weight. The presented equipment is cost-effective for compact fields.

Compact combines for harvesting grain crops

The harvesting procedure will be carried out several times faster if specialized equipment is used to resolve this issue. This minimizes the amount of manual labor. Manufacturers of modern equipment of this type are constantly expanding the existing list of equipment, so you can easily select a unit to achieve various goals in agriculture. One of these machines is a mini-harvester designed for harvesting grain.

Mini grain harvester: small equipment for the farmer

A mini grain harvester is a necessary type of agricultural equipment, thanks to which you can harvest and process crops. Thanks to this type of unit, it becomes much simpler and easier to carry out all activities, because previously it was hard manual labor. In the modern market of agricultural machinery, such combines are presented in a wide range. Each manufacturer, when producing equipment, tries to introduce all the elements necessary for successful operation.

Mini grain harvesters

Modern mini grain harvesters are distinguished by their versatility and extreme ease of operation. The small dimensions and minimal weight characteristics of such a unit facilitate its transportation and make storage as simple as possible. Such machines are unpretentious in maintenance and very economical to operate. In addition, compact grain harvesting equipment is very economical due to its low weight.

Purpose

Combine harvesters are capable of performing a whole range of options in a stream, including harvesting grain crops. By using such equipment, farmers carry out a whole range of work, which consists of cutting off ears of wheat, cleaning individual crops from heaps and other impurities, as well as subsequent threshing of grain in a threshing apparatus.

Compact equipment for harvesting and caring for crops is used by small agricultural enterprises whose production volume is not yet too large. Mini-harvesters can easily cope with cleaning and cutting grain crops.

Purchasing compact grain harvesting equipment frees you from the need to buy a thresher, winnower and reaper. As a result, we can talk about significant savings in money. It should also be noted here that optionally, additional attachments can be installed on mini grain harvesters, which allows you to expand the functional potential of the machine. As a result, through the use of mini-harvesters, sheaves are also knitted, and the issue regarding sowing seeds is also resolved.

Features of operation

With very compact dimensions, mini-harvesters are lightweight, resulting in minimal pressure on the ground during operation.

For this reason, overall yield tends to increase. The machine can be equipped with one seat for the operator or have a full-fledged cabin. As an alternative, a special visor is installed to protect the driver from direct sunlight. Mini grain harvesters are equipped with a small-displacement diesel engine, which allows significant fuel savings during operation. The power plant is aggregated by a gearbox, which in most cases has three forward speeds and one reverse. The clutch is not released by the pedal, but by a lever. If necessary, the operator is given the opportunity to adjust the height of the cutting device or even the entire header. This need arises when harvesting in hilly areas.

At the final stage of harvesting, the cleaned grain is poured into a bag or a special bunker. Subsequently, the crop is unloaded into a pre-prepared place. Straw is discharged separately.

Good maneuverability allows the use of mini-harvesters for grain harvesting in areas with difficult terrain. And thanks to high maintainability and extreme design simplicity, troubleshooting can be carried out even at the immediate place of work.

Choosing the right combine

The technical characteristics of mini-harvesters can vary markedly, so before purchasing you need to clearly determine the operating conditions and the set of necessary functions of the harvesting equipment.

Base. Most compact combines are mounted on a wheelbase, but they are also found on tracks.

Performance. It is necessary to take into account the width of the header, engine power, and speed of operations. It is advisable to find out how many unharvested ears remain, how many of them spill past the receiver, and how well the grain is threshed and cleaned. It is advisable to immediately calculate the area of land that will need to be cultivated and estimate the time required for work.

Model and manufacturer. It is up to the buyer to decide whether to opt for an advertised brand of mini grain harvesters or to choose a new player in the agricultural machinery market. But reviews from those who have already assessed the capabilities of the unit they like can provide a lot of useful information.

Availability of additional options. Some models are suitable for planting work, others are also designed for harvesting rapeseed or forage crops.

Method of storing grain. Choosing a model with a compartment-hopper or a bagging function depends on whether the grain will be poured into storage or immediately sent for processing in small batches.

Engine power and diesel fuel consumption. All “kids” have low-power diesel engines. There are both very economical and extremely expensive models to operate.

Review of popular manufacturers

Among the manufacturers of specialized agricultural equipment there are both domestic representatives and foreign companies. There is a wide range of Chinese equipment on the market. Many models are made to order.

The compact combine harvester Zarya 4L 0.5 is used for harvesting wheat in a small area. Design features and high maneuverability allow the machine to be operated in areas with difficult terrain. The unit combines many functions, including cutting, threshing and cleaning crops. Additionally, this machine is used for harvesting and compressing rice.

Small weight indicators allow minimizing fuel consumption. During one working hour, the mini-harvester will consume only 400 grams of fuel. The model has three forward speeds and one reverse speed.

Technical characteristics of the mini-harvester Zarya 4l 0.5 (MZK 800):

| Characteristics | Indicators |

| Dimensions, mm: | |

| - length | 3400 |

| - width | 2400 |

| - height | 1300 |

| Header working width, mm | 1100 |

| Total weight, kg | 500 |

| Engine power, hp | 8 |

| Fuel consumption, l/h | 0,4 |

| Productivity, m2/hour | 600 |

| Wheel diameter, mm | 210 |

| Place for unloading cut crops | bag |

Video review of the Zarya 4L 0.5 mini-harvester:

Farmer

Farmer mini-harvesters are equipped with one drum. Through their use, nine different grain crops and grasses are harvested. The model is equipped with a powerful 85-horsepower engine, which, paired with a manual transmission, consumes a minimal amount of fuel. The maximum speed of the combine can reach 20 km/h. In working condition, this figure is 10 km/h.

The multifunctional control lever greatly simplifies the work process. There is a good overview from the cab, as a result of which we can talk about the maximum simplicity of operating the combine.

Technical characteristics of the Farmer K-01 combine:

| Characteristics | Indicators |

| Total weight, kg | 4600 |

| Dimensions, mm: | |

| - length | 8500 |

| - width | 2900 |

| - height | 3300 |

| Header working width, mm | 2350 |

| Threshing drum diameter, mm | 500-860 |

| Engine power, l/s | 85 |

| Plant cutting height, mm | 50-800 |

| Speed characteristics, km/h: | |

| — operating speed | 10 |

| — maximum speed | 20 |

Claas

The small-sized Class Consul combine is equipped with a 106-centimeter threshing unit. With a relatively small engine power potential, such combines are equipped with a fairly large threshing unit. This point can be called the main feature of the model.

All combines presented in this model range are distinguished by the presence of a hydrostatic drive and a large-capacity grain tank. If necessary, the height of the unloading auger can be adjusted, which allows you to unload the crop into pre-prepared bags.

Technical characteristics of the Klaas Consul mini-harvester:

| Characteristics | Indicators |

| Engine model | Perkins 4,236 |

| Number of cylinders | 4 |

| Engine volume, l | 3,8 |

| Engine power, l/s | 68 |

| Header working width, mm | 3010 |

| Width of alternative header, mm | 2600-3000 |

| Number of gears | 3 |

| Operating speed, km/h | 1,6-20,4 |

Photo of the small-sized combine harvester Caas Consul

DongFeng

DongFeng is one of the most famous Chinese manufacturers of compact combine harvesters. Visually, the 1548 model has virtually no differences from standard-sized harvesting machines. At the same time, the machine is focused on cultivating small plots of land. The harvesting width of the header in this case is kept at 2 m, as a result of which the harvesting speed can be 0.53 ha/hour.

Using DongFeng mini-harvesters, grain crops are cut and then threshed. As a result, straw is separated from grain raw materials. As options, additional equipment can be installed on such machines, presented in the form of a seeder or a device for binding sheaves.

Characteristics of the DongFeng 1548 mini-harvester:

| Characteristics | Indicators |

| Total weight, kg | 2175 |

| Dimensions, mm: | |

| - length | 5100 |

| - width | 1900 |

| - height | 2400 |

| Engine power, l/s | 53 |

| Header working width, mm | 2000 |

| Bunker capacity, m3 | 0,8 |

| Productivity, m2/h | 2600-5300 |

| Place for unloading cut crops | dump truck or bag |

Photo of DongFeng 1548 mini-harvester

Description of grain harvesters and combines for wheat

Mini grain harvesters are an excellent solution for collecting grain in small agricultural areas. The main advantage of this technique remains ease of use. The unit is also easy to repair and transport.

The characteristics of the Polesie forage harvester are presented here.

Every farmer can easily assemble and disassemble the combine; it is not heavy and can work on hilly soils. In terms of the functions they perform, mini-harvesters can be compared with their large-sized counterparts. Some models can bind grain into sheaves.

Among other things, the equipment in question allows you to mow, cultivate the soil, transport various loads, and carry out alluvial work. Among the available arsenal of models, there is one difference - engine power, design dimensions, cost, performance, manufacturer, switching speed and grain tank volume.

You will find types of trailed grain harvesters here.

How does a mini-harvester work? After he cuts the crop stems, they are captured using the blades of the threshing apparatus. Inside it, the grain crops are cleaned and separated from the spikelets. The grille of the device allows you to winnow the grain with an air supply. Thus, it is possible to get rid of the chaff and heap. Clean and threshed grain enters the bunker. Waste in the form of straw and chaff is accumulated in the stacker or dumped in the field.

Available models of mini grain harvesters can be classified according to the type of traction into the following types:

- Self-propelled . This type of technology is the most in demand. Starts working when you start your own engine.

- Mounted. It is used with small tractors by installing it on a self-propelled chassis. An example is the attachments for the MTZ tractor.

- Trailed . Its functioning comes from its own engine. It can also be driven from the tractor power take-off shaft.

The cost of the Challenger tractor can be found here.

The two types under consideration can be divided into motorized and non-motorized designs. According to the method of threshing equipment, equipment can be divided into:

- Bilnye. Equipped with one or two drums. Threshing is carried out by striking the ears and dragging them between such parts as the concave and the drum.

- Axial rotary . Using whips, it is possible to separate the stems from the grains.

- Pin-punch. Equipped with two drums. The ear passes through the concave pins. The result of this work is a strong sound from impacts.

We also recommend that you read in more detail about the segment mower for tractors in this material.

Taking into account the class of the straw heap separator, the presented equipment can be of a key or rotary type. The first type is used only in domestically produced combines. Its operation occurs when the keys hit the falling grains against each other. The second version of the model allows you to clear the grain from the stem by wiping it.

Find out what the Terrion tractor looks like from this article.

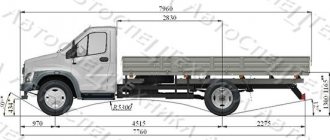

Features of the Zarya mini-harvester

The universal mini-harvester Zarya, due to its small size and weight, exerts minimal pressure on the ground, which has a beneficial effect on the work process. The machine does not sag and practically does not create ruts in loose soil. All combines of this type are equipped with a powerful and economical diesel engine. In mini-harvesters, the location of the main working parts is in the same projection as in the large versions. At the front there is a unit for cutting and harvesting the crop, in the center there is a small conveyor belt and a threshing machine. The finished grain is discharged to the side. This arrangement allows the equipment to be used in conjunction with other machines, for example a small truck such as the GAZ 3302. Compared to the large-scale version, the mini-harvester has the following features:

Purpose and operating features

The mini-harvester is designed for harvesting grain. It can be used to harvest all types of crops. The main advantage of these compact machines is their multi-purpose use .

Small farms are usually financially constrained; a mini harvester can replace three agricultural machines at once: a reaper, a winnower and a thresher.

Among the operating features, one can note minimal damage to the soil. Due to its low weight, the equipment does not damage the soil structure, so the field will regularly produce a good harvest.

The maneuverability of the mini-harvester allows it to be used in difficult conditions. If the field is located at an angle or has a complex geometry, in these cases a standard-sized combine cannot fully realize its capabilities and, accordingly, cope with grain harvesting work efficiently. And the use of more compact equipment allows you to harvest the crop with minimal losses.

In addition, it is worth noting the accessibility to the main components and mechanisms of the machine. This makes repairs and maintenance easier. And finally, the last advantage is low consumption of fuels and lubricants.

Manufacturers and prices of agricultural machinery for grain harvesting

Currently, many Russian farmers use the KZS 812 Polesie mini-harvester to perform agricultural work. In many technical parameters, this unit is capable of competing with the Akros 530 or 580 model from Rostselmash. In many respects, these two models are very similar. The engine power of these models is 330 hp. However, the Belarusian Polesie unit weighs a little more. This is explained by the fact that it has high fuel consumption. For the Russian Akros 530, the consumption is 5 liters, and for the Polesie combine - 6 liters.

Review of some models and manufacturers

On the domestic market you can find mini-combines for grain harvesting, both domestic and foreign. They differ not only in appearance, but also in size, consumption, functionality, operating principle of the threshing unit, etc.

We present to your attention an overview of some popular models of mini combine harvesters. to menu

The domestic mini-harvester “Zarya” is widely popular among small farmers. Ideal for cleaning work in small areas and areas with difficult terrain.

Mini harvester "Zarya"

The machine allows you to connect attachments designed for harvesting sunflowers, corn, rice and soybeans. In the basic configuration, it copes well with the collection, milking and cleaning of wheat, barley, oats and other grains.

Zarya runs on diesel fuel. The engine has a power of 8 horsepower and consumes 400 grams of diesel fuel per hour. Protection against overheating is provided by a water cooling system.

During the grain collection process, the speed of movement across the field is 11 km/h, which allows you to harvest 600 square meters within an hour.

The mini-harvester is equipped with a four-speed gearbox (three speeds for forward movement and one for reverse). In addition, the device is equipped with a hydraulic drive for the header to adjust its position. Header width – 1100 mm.

The disadvantages of this model include winding the stems onto the header auger, which often has to be cleaned manually. This significantly slows down and complicates the work process. to menu

Mini grain harvester MZK 800

John Deere

The homeland of John Deere combines is the USA. Today, equipment of this brand is produced in many European countries.

Despite its European origin, John Deere equipment is fully adapted to the climatic conditions of all Russian regions.

In its basic configuration, the mini-harvester is designed exclusively for grain harvesting. However, with the help of additional attachments, it can be repurposed to perform other tasks: sowing, mowing, etc.

John Deere feels great on fields with difficult terrain. Can perform work on slopes up to 22%. In addition, this combine is characterized by minimal consumption and high productivity.

When designing these mini-harvesters, much attention was paid to the comfort of the combiner. His workplace is equipped with maximum comfort. All control drives are located in the operator's cabin.

The big disadvantage of John Deere equipment for domestic farmers is its high cost. Therefore, many people choose more affordable models. to menu

Mini-harvesters from Chinese manufacturers

The peculiarity of all Chinese technology is its low price when completely copying devices from well-known brands. Mini-harvesters are no exception. In addition, for wholesale orders, Chinese manufacturers give the customer the opportunity to independently choose the basic package.

Purchase of the Zarya combine

This equipment is registered with the local traffic police as a special car, so you may need a separate category of driver’s license to drive it. At the moment, the sale of Zarya mini-harvesters is carried out through the official representative office of the manufacturer, as well as through private individuals. The main manufacturer of new equipment is located in China. The updated Chinese version is practically no different from the old domestic one. Representative centers for Zarya mini-harvesters and other agricultural machinery are located in almost all major cities of Russia. The modern mini grain harvester Zarya 4l 0 5 and other modifications are remembered by many owners for their ease of operation and unpretentiousness in maintenance. The low weight of the equipment allows it to be conveniently operated in small areas. The diesel engine has the necessary efficiency and power, so the mini-harvester is able to work with any type of plant. The owners note the following positive qualities of the equipment:

- engine efficiency;

- ease of repair;

- variety of spare parts on sale;

- interchangeability of parts;

- good performance;

The mini-harvester is perfect for working with grain on plantations up to 10 hectares. Despite positive reviews, the equipment has several disadvantages, namely: the lack of a good suspension for the operator’s seat, an unreliable hydraulic system and a lot of engine noise. Some owners deliberately modify new equipment, in particular, eliminate factory shortcomings, and overhaul the fastenings of attachments to install domestic Soviet-style systems, which are much more reliable.

Cost of purchase and maintenance

Types of combines

Depending on the tasks facing the potential buyer of the combine, you can choose the type of grain harvesting unit:

- Small. The simplest, most often auxiliary option. There is no operator's cabin provided. The low power of the motor corresponds to the volume of work for which the unit is designed.

- Average. Compact and undemanding, it features an open operator compartment. Noticeably more productive, used as a full-fledged grain harvesting equipment.

- Big. It differs from a regular combine only in size. The closed cabin makes the operator's work more comfortable, and the wide header is able to cope with a good harvest.

A number of models are not limited to the functions of a combine - they include equipment for tillage or can replace a seeder.

For very simple tasks, there are combine harvesters that are not equipped with their own base. They are used in combination with a tractor.

- Mounted. Can be sold separately, but is often included with the main unit. If the manufacturers are different, then the need for modification cannot be ruled out.

- Trailed. Easier to combine with appliances of different brands.

Combine harvester "Zarya" MZK-800: features and technical specifications

The Zarya brand is traditionally considered Russian, since it was recreated on the basis of developments. Although the entire production cycle is located in China today, the original features of these agricultural machines have been preserved. The basic configuration of the Zarya equipment allows you to combine in one device the functions of cutting the stems of cereals, their milking and separation. With the use of appropriate adapters, they can easily be converted into forage harvesting machines used for harvesting corn, rice and sunflowers.

Features of Zarya mini-harvesters

Such technical means are practically no different from full-fledged combines, although they are lighter and more compact.

At the front there are nodes for cutting and harvesting the stem and grain mass. In the central part there is a thresher and a block for cleaning grains. This design is ideal for small farms where purchasing and maintaining a traditional full-size combine harvester is unprofitable. The main advantages of these agricultural machines are:

- environmental friendliness - due to minimized size and weight parameters, mini harvesters from the Zarya brand do not create pressure on the soil, and therefore contribute to the preservation and restoration of its natural fertility;

- versatility for different types of soil - these units do not overload even in loose and wet soils. As a result of driving across the field, the typical ruts and dusting of the top layer, from which water and wind erosion begins, are not created;

- equipped with powerful diesel systems that are fuel efficient. For full operation, the Zarya mini-harvester will require only 400-500 ml of diesel fuel;

- high cleaning speed;

- adaptability to low-growing crops;

- maneuverability;

- suitability for repair.

Small-sized combine harvester "Zarya" MZK-800

One of the drum self-propelled mini harvesters from the Zarya model line, known under the Zarya label 4l 0.5. Equipped with a productive and small-displacement engine with a power of 8 hp. This ensures the low resource consumption of this unit, which is only 400 ml per hour of operation. This model is designed to overcome all uneven terrain. Thanks to the auxiliary equipment, it can be used as a rice harvester.

Design and principle of operation of the Zarya MZK-800 mini-harvester

MZK-800 is characterized by a classic arrangement of components and working parts. In the front part of the body there are blades with a thresher, the grip of which is only 1.1 m. In the inner part, the grain goes through the stages of milking, cleaning from heaps and straw. The winnowed grains end up in a special bag, replacing the bunker of conventional combines.

The operator's seat is located in the rear part of the body. There is no usual cabin with a roof, although it is possible to pull up an awning, which will solve the problem of unfavorable atmospheric conditions while mowing wheat or barley. The technological process of the Zarya combine is controlled in a sitting position.

- supporting frame made of thick-walled profile;

- high transport speed;

- reliable 4-cylinder diesel R 180 with hydrocooling system;

- a manual gearbox that allows you to change the operating speed in one of 4 modes. 3 of them are for moving forward;

- hydrostatic transmission;

- hydraulically controlled header position;

- winnowing seeds with a fan;

- relatively inexpensive and interchangeable spare parts;

- prostate in management, storage and maintenance;

- a wide range of attachments and auxiliary equipment - additional lighting, storage bin, roof for the body, unloading hose, soil ripper.

A significant disadvantage of this type of equipment is the imperfection of the header design. it quickly becomes clogged with spikelets and needs manual cleaning.

Technical characteristics of the mini grain harvester “Zarya” 4l 0.5:

- Power – 8 hp;

- Engine speed – 2.3 thousand rpm;

- Beating drum diameter – 50 cm;

- Adjustable knife height – 5..80 cm;

- Capture by the reaping part – up to 1300 mm;

- Productivity – up to 1500 m 2 /h;

- Rubber/metal wheels – 0.21/0.25 m in diameter;

- Performance indicators 1/2/3/reverse speed – 1.9/2.78/10.95/2.58 km/h;

- Losses – less than 3%;

- Dimensions – 2400 x 1400 x 1300 mm;

- Weight – 0.5 t.

The best forage harvesters of 2020

The state and level of development of livestock farming are directly dependent on feed production, on the volume and quality of harvested feed. The magazine "My Siberia" has prepared a review of the technical features and characteristics of modern forage harvesters from the world's leading manufacturers, necessary to create a strong forage base.

According to the Ministry of Agriculture of the Russian Federation, feed costs on average for agricultural organizations in Russia account for more than 36% of the structure of material costs. In dairy farming, the share of costs for feed production is more than 27%, in meat farming – about 39%. At the same time, one of the key and most expensive processes of feed production is the harvesting of forage crops, which requires farms to be provided with high-performance and reliable machines that allow the introduction of modern feed procurement technologies.

Every year, the world's leading manufacturers of agricultural machinery launch new models of modern forage harvesters on the market, the manufacturers of which compete in the areas of increasing the productivity and sustainability of the technological process of the machines, reducing the loss of nutritional value of feed during harvesting, improving the working conditions of the operator, and reducing the harmful impact on the environment. Thus, agricultural producers are faced with the task of effectively selecting and using these machines, which is impossible without knowledge of their design and technological processes, and the ability to optimally select them depending on operating conditions and the needs of the farm.

CLAAS

Like other agricultural machinery from this world-famous brand, CLAAS forage harvesters guarantee reliability and durability. Today, the company produces more than ten brands of forage harvesters of the JAGUAR series. There are currently two model ranges of these combines on the Russian market - the JAGUAR 800 and JAGUAR 900 series, which were significantly updated in 2020.

JAGUAR 850 forage harvesters are most effective for use on farms with large volumes of forage harvesting and on fields with a yield of 45-60 t/ha. This machine features an energy-rich 428 hp engine. and a working width of 4.2 m. This provides the machine with a high operating speed of 11.1 km/h and increased productivity per hour of main time of 4.66 hectares. The specific fuel consumption of the JAGUAR 850 combine is 14.8 kg/ha.

The design of the combine determines one of its most important properties - the direct movement of waste plant material from the rollers to the guide gate, with consistently high quality of chopping with maximum compactness of the cutting devices. The transition of plant feed from one combine unit to another is completely straightforward. In addition, the machine can be equipped with a re-chopper for grinding mature grain mass, which is driven at any time to re-grind feed residues with large grains, such as corn. For the convenience of unloading processed feed into the bodies of any type of transport, the unloading silo pipe of the combine can be rotated to any angle.

The chopping of silage or grass mass occurs in a chopping drum, inside of which cutting knives are located. This device is distinguished by carefully economical energy consumption, which is achieved thanks to the originally positioned knives, which allow you to perform not an ordinary straight cut, but a pulling shearing cut along an oblique path, which is gentle on machine parts. The placement of knives has the following features: the knives are arranged in pairs, in identical planes, and in pairs they form a V-shape. Adjustment and sharpening of knives is carried out automatically, without disassembling the device, by controlling this process directly from the operator’s cab.

To facilitate work with a variety of plant materials, the JAGUAR 850 combine is equipped with regulatory and protective systems that operate directly at the entrance of the cut mass into the machine. This is a COMFORT CUT regulator for the length of crushed pieces, which also simultaneously changes the feed speed, as well as a ROCK STOP protective device, which blocks access to the working parts of the combine for large and medium-sized stones. The metal detector built into the front feed roller responds to any body, even small ones, capable of magnetization. By instantly stopping the feeding apparatus is protected from damage. Thanks to the indication of the location of detection in the electronic system, the operator can quickly determine where to look for a metal object and quickly remove it.

KRONE

The Big X line of forage harvesters from Krone is a machine for those who aim to obtain first-class quality of harvested feed combined with high productivity, clean harvesting in different conditions, incredible maneuverability, intelligent capabilities for adaptation to crop moisture and for fuel economy, compactness of the machine , comfort and ease of use. The most powerful forage harvester Krone Big X 1100 with a power of 1,078 hp. is not only the flagship of the Krone combine harvester range, but also the most powerful forage harvester in the world.

The heart of the car is a powerful MAN engine with twelve cylinders and a displacement of 24 liters. The transverse engine arrangement provides both the best access and direct power transmission and optimal weight distribution of the entire machine. The hydrostatic drive gives the machine properties that are not possible with conventional chassis drives. For road driving, there is a continuously variable speed range from 0 to 40 km/h with automatic adjustment, which reduces fuel consumption and noise emissions. For field work, a stepless speed control range from 0 to 25 km/h is available. Here the engine operates at full power and high shredding quality is at the forefront.

Six feed rollers provide a long feed stroke with constant high pressure on the Big X 1100. This way the harvested crop is crushed easily and accurately. The patented KRONE AutoScan system allows manual or automatic adjustment of the chopping length at different stages of ripening. The blade drums operate at a stable rotation speed, continuously chopping the crop because one blade is always in contact with the shear plate.

The universal MaxFlow chopping drum is available with a choice of 20, 28 or 36 knives, making it adaptable to any operating conditions. The new arrangement of the knives under the knife holder provides increased space for greater throughput and for impressive smooth running even with long chopping lengths. The knife mounting strip provides additional protection against wear of the drum body. In addition, Krone offers a special “Super Biogas” drum with 48 knives for short chopping lengths especially for the Big X 1100. The crusher rollers with a diameter of 250 mm ensure the crushing of each grain. The distance between the rollers is infinitely adjustable from the cab using two electric motors in the range from 0.5 to 10 mm.

The ejection accelerator creates a constant, dense flow of feed. There is also a StreamControl spreading range adjustment device, which allows you to adjust the spreading distance of the harvested crop from the driver's cab via a rotating section in the rear wall of the thrower. If the spreading length is set to “short”, the crop material will not have much contact with the thrower. This fuel-saving feature is recommended during normal chopping operation when a vehicle and trailer is driving alongside the forage harvester. With a "medium/long" spreading distance, the plant material has more or complete contact with the thrower; This function is selected by the driver, for example, when chopping, when there is a trailer behind the forage harvester.

NEW HOLLAND

New Holland FR series forage harvesters have been in mass production since 2007. These are the largest field forage choppers, with the widest feed rollers and chopping drum in the global industry, designed for mowing and chopping silage crops while simultaneously loading into vehicles, as well as picking up the forage mass from the windrow.

The senior model of the line – FR850 – is equipped with a 20.1-liter engine producing 824 hp. New standard ECO mode settings and intelligent engine management help reduce fuel consumption in the field. According to the manufacturer, savings can reach 21% compared to previous models. PowerCruise maximizes productivity by constantly monitoring actual operating power and adapts machine speed to changing field conditions.

The combine is equipped with a chopping drum with an optimized cutter head. It has two cutting modes - for grass and corn, which are very easy to switch. For better grinding of biomass, combines are equipped with two rows of knives of 20 pieces each. The stock feed system is equipped with a HydroLoc transmission and the cutting length is variable. Thanks to the blade-type fan, air flows across the entire width of the sieve frame, which allows for a high degree of crop cleaning and prevents grain from accumulating near the drum. The two-position Variflow system allows the operator to set the blower to a specific distance from the chopper drum. When the combine harvester is working with grass, the supercharger moves closer to the drum by 20 cm.

A blade auger is installed as standard on the combine header, which transfers the crop to the feed rollers. This helps to carry out operations even in dense crops or particularly long grass stems that may break. The advanced header height adjustment system ensures uniform picking across the entire strip, regardless of the degree of surface unevenness. Autofloat automatically adjusts the header hydraulically to maintain a constant height and prevent it from sinking into the ground.

Feed rollers with a width of 860 mm ensure a continuous supply of material to the cutting head. The volume of crop entering the cutting head is increased by eliminating costly wastage through dropout. Because the crop is evenly distributed along the entire length of the rollers, cutting efficiency is improved as the crop is fed into the cutting head at an even density, resulting in the most efficient crop conversion rate.

Sharp blades provide clean, precise cuts for maximum productivity while reducing power and fuel consumption. Using patented Adjust-O-Matic technology, you can easily sharpen knives and adjust shearbars without leaving the cab. During the sharpening cycle, the direction of rotation of the cutter head is reversed and the built-in whetstone delivers a precise, razor-sharp edge to each knife, significantly increasing knife life and reducing shear bar wear.

Features of harvesting forage crops require precise coordination of the actions of both the combine and the simultaneously loaded cargo vehicle. The New Holland FR 850 operator has 360-degree visibility in every direction, allowing him to perform precise harvesting and unloading of crops. The spacious cab features a wide IntelliView IV color touchscreen monitor and an ergonomic armrest for control of all key operating parameters. And the IntelliFill system fills the trailer body itself, so the operator can focus on picking that requires attention.

GOMSELMASH

The KVK-800 “PALESSE FS80” forage harvester is one of the most powerful combines for harvesting feed from the Belarusian manufacturer of agricultural equipment “Gomselmash”. This machine is designed for mowing corn at any stage of grain ripeness, as well as other high-stemmed forage crops for silage, while simultaneously chopping and loading the forage mass into vehicles. It can also be used for mowing and collecting windrows of natural or seeded grass, also with chopping into silage and haylage and loading into vehicles.

The KBK-800 is distinguished by modern design solutions, a reliable and economical engine, and high-tech components - all this is designed for stable operation of the combine in the most difficult conditions with high quality chopping. The high degree of hydraulics of the machine ensures technological reliability, and making operational adjustments of the working parts from the cab reduces wasted time.

The combine is equipped with a modern 450 hp engine. At the same time, depending on market conditions and customer preferences, power units from various manufacturers can be used. These engines develop optimal power with minimal fuel consumption, operate reliably in intensive mode, ensuring maximum harvester performance. The grinding apparatus is driven directly from the engine crankshaft without intermediate gears by an exceptionally durable main drive belt. This guarantees not only the highest possible torque transmission efficiency, but also a reduction in specific fuel consumption.

Forty knives arranged in four rows on the chopping drum are set at an angle to the shear bar. This ensures a clean, bevel cut that saves energy. Due to sharp angles of inclination, the knives shift the mass from the edges to the center of the drum, reducing friction of the mass against the walls of the technological path and reducing the load on the bearings. The direct-flow scheme for conveying the mass provides the shortest path from the feeder rollers to the exit from the silo with an increasing flow rate. This scheme determines high throughput with minimal fuel consumption. When harvesting corn with waxy ripe grains, the grain grinder is switched on. With its toothed rollers, it intensively crushes the grain, increasing the quality of the silage produced. An emission accelerator helps maintain a high work pace. The powerful flow of crushed mass fills vehicle bodies extremely tightly, ensuring maximum utilization of their volume and reducing the number of trips. The combine can be equipped with a system for dosed application of preservatives, reducing the time required to lay silage and increasing its quality.

Smooth adjustment of the cutting length of the stems is carried out from the operator’s cabin by turning the regulator on the control panel in two ranges: 6-9 and 13-20. If you plan to work with larger grinding, then this option provides the ability to work with twenty rather than forty knives on the drum. Thanks to the automatic sharpening of knives and the feeding device protection system, which is included in the standard equipment of the combine, durability is ensured and the chopping drum knives are prevented from being damaged by foreign objects. If the metal detector and stone detector sensors are triggered, the feeder roller drive will be automatically turned off and the mass supply will stop.

The KVK-800 combine harvester is equipped with a pick-up with gauge wheels. The field relief is copied accurately and without damaging the plant root system. The design of the pick-up ensures the shortest path of the mass to the feeder, increasing the stability of the pick-up. The picking device is located compactly under the auger, so when the feeder rollers are reversed, the mass is removed directly onto the field.

The adapters with which the combine works create all the necessary conditions for high productivity and high-quality grinding. A rotary-type header feeds corn or sunflower stalks only with the lower part exactly in the direction of the longitudinal axis of the feeding apparatus. This allows you to completely avoid losses of cobs, leaving behind the machine a perfectly harvested field. And the use of grass headers in PALESSE FS80 combines with a system for copying the field topography and setting the cutting height guarantees an equally even cut.

The spacious Comfort Max cabin provides an excellent panoramic view of the entire work area when working with any of the adapters, reliable protection from heat, vibration, noise and dust. The work chair and steering column, thanks to the adjustment system, ideally adapt to an operator of any height and build.

ROSTSELMASH

Rostselmash is one of the world's leading manufacturers of agricultural machinery. The company's product line includes more than 150 models and modifications of 24 types of equipment, including forage harvesters.

Compress the standing crop or pick up the crop from the windrows quickly and without loss, qualitatively chop the leaves and stems, break the grain, add and thoroughly mix the preservative in the volume of the mass and carefully unload the future silage or haylage into transport, and all this with minimal costs, without downtime and with maximum comfort for the operator and driver of the vehicle. This is how a good forage harvester should work, and this is how the RSM 1401 works. Powerful, fast, economical and smart.

The decision to develop this innovative machine was made under the influence of the active development of livestock farming in Russia and the growing need for highly productive equipment for the preparation of feed. The result is a forage harvester with maximum productivity, high efficiency, excellent chopping quality and ease of operation. The RSM 1401 performs mowing or picking up dried mass from windrows, chopping and loading silage crops into a vehicle, including corn in the waxy ripeness phase of the grain, sunflower and other coarse crops, perennial and annual grasses and mixtures, sorghum.

Up to 170 t/h of corn for silage with a fuel consumption of 0.7-1.0 l/t, about 80 t/h for selecting windrows for silage, about 100 t/h of cereal legume mixture for direct combining with a fuel consumption of less than 0, 5 l/t is harvested by RSM 1401. Using only one such machine, you can fill a silage pit with a capacity of about 6,000 tons in 5 days and easily provide fresh green feed to a cattle herd of several thousand heads. And on a farm with large areas, it is necessary to ensure the procurement of feed within strict agrotechnical deadlines.

Thanks to the thoughtful arrangement of parts of the technological path, the movement of plant mass along it occurs along an optimal trajectory throughout the entire processing process. Thanks to this, the best indicators of the energy intensity of the machine are achieved and, as a result, conditions are created for saving fuel. Each subsequent technological operation is performed at a higher linear speed than the previous one. This ensures the fulfillment of one of the main conditions for the stable flow of the technological process, and therefore the production of high-quality silage, grain haylage or haylage.

The combine is equipped with a 4-roller feeding apparatus. Four speed modes for feeding plant material allow you to adjust the cutting length from 4 to 17 mm. The stone and metal detector starts automatically. The distance between the front upper and lower rollers in the lower position is 24 mm, which increases the detection efficiency of the detector (operation threshold from 1,500 rpm). The hydromechanical reverse of the feeder rollers simplifies the removal of foreign objects caught in the mechanism.

The grinding apparatus with a drum with a diameter of 630 mm can operate at a rotation speed of up to 1,200 rpm. Such parameters made it possible to minimize the load on the feeding apparatus and increase productivity at short cutting lengths. The automatic sharpening device allows you not only to sharpen knives, but also to establish a gap between them and the shear bar. These engineering solutions have increased the productivity of the combine and ensured fuel savings.

Powerful Mercedes engines of 500 hp. ensure maximum use of the machine's capabilities, being content with a small amount of fuel, which allows optimizing the cost of preparing feed under various operating conditions.

The strong frame and feeder are capable of “carrying” wide-cut implements - corn (stream and continuous cut) and grass (segment-finger and rotary) headers with a working width of up to 6 m and pick-ups up to 3.5 m. Confident pick-up of stems by the feeder at speed 1 m/s and acceleration up to 4.3 m/s, pre-pressing, cutting and acceleration up to 37/s, grain breaking and acceleration up to 42 m/s, injection of preservatives, acceleration and ejection at a speed of 57 m/s (in transport from any side height - height to the visor hinge 6 m).

The Adviser III on-board computer system provides the operator with all the necessary information - warns, helps, reminds. Information requiring special attention is duplicated in voice mode. You can seriously expand the “cognitive” abilities and efficiency of using the machine in particular and the farm fleet in general by installing the Agrotronic™ remote monitoring system. This system allows machine operators and engineers to improve settings “on the fly”, plan supplies of consumables and spare parts, logisticians to optimize the operation of the machine fleet, agronomists to assess the condition of soils based on yield data and, based on this information, rationally plan future work to restore fertility and etc.

Evgeniy Zagvozdin

Review of mini combine harvester models

The production of such models is carried out not only by foreign, but also by some domestic manufacturers. When choosing a mini grain harvester, it is important to carefully study its characteristics, as well as the ability to connect additional attachments.

It’s worth mentioning the Zarya MZK-800 mini-harvester. This model is produced and is one of the best for cultivating fields with an area of no more than 6 hectares . This is due to the fact that, due to its light weight, it does not sink into the ground, as a result of which rutting does not occur when passing through wet or loose soil. The unit has low fuel consumption and increased maneuverability. Thanks to the ability to connect attachments, a mini-harvester can even be used to make a machine for harvesting various types of crops such as barley, corn, and sunflower.

Video

This video will tell you about the best models of mini grain harvesters.

A mini grain harvester is a necessary piece of equipment in agriculture. This unit, like a rotary mower for MTZ, can be used not only in large enterprises, but also in households. When choosing a combine harvester, you should pay attention to factors such as engine power, productivity and fuel consumption. Find out how to properly use a gasoline backpack sprayer by following the link provided.

Features of operating mini-reapers

Even taking into account that such models are small in size, they do an excellent job of cultivating fields with subsequent separation of ears and threshing them. As a result, such units are capable of simultaneously replacing 3 different devices. When installing trailed equipment, they will also knit sheaves of hay. Most models are equipped with classic gearboxes that have 3 gears intended for forward movement, as well as 1 for reverse. They are switched by a special lever. It is also possible to adjust the height at which the ears are cut.

Advantages of mini-harvesters

Based on all of the above, the following advantages of this technique can be identified:

- Ease of transportation of the unit.

- Low cost models.

- Possibility of use for small areas or in the presence of complex terrain, which is ensured by its small size and high maneuverability.

- Low fuel consumption.

- Easy to use mini-harvester.

- There are no complex components, which allows you to carry out repair work while in the field.

Areas of use

Where there is no point in using large grain harvesting machines - when the volume of grain grown is small or access to the field is difficult - mini-harvesters become a convenient replacement. They are often used as auxiliary ones.

If the farmer’s main specialization is livestock farming, for which he wants to grow feed himself, and he allocates a small plot of land for fodder grain crops. Another example: a large agricultural complex has land with complex terrain, divided into several small fields. Access and operation are difficult for large equipment.

Small grain harvesters cope with obstacles by maneuvering freely in confined spaces.

Is it worth making a mini-harvester with your own hands?

Due to the fact that most manufacturers do not immediately indicate the final price, they make it possible to select the desired functions of the model by pre-order. Due to this, it is possible to obtain equipment that will best meet the customer’s requirements. The minimum price tag for it starts from 100 thousand rubles. But to make a mini-harvester with your own hands, you will need to spend a significant amount of time and the availability of the necessary components. But in the end, the design may be significantly worse in quality, but it will be more expensive.

Modern mini grain harvesters are small equipment designed to cultivate fields with an area of up to 6-7 hectares.

Thanks to the ability in many models to connect additional attachments to them, their range of use is expanding. This makes them maneuverable multifunctional devices capable of working in small or complex areas.

Advantages of small combines

The combine harvester simultaneously performs the functions of a reaper, a thresher and a winnower. He reaps, that is, cuts the ears, threshes them, knocking out the grain, and then cleans the grains with an air stream, winnowing them. Then the combine automatically removes the straw, and the grain is packed into bags or collected in a compartment-hopper.

A conventional combine is a large grain harvesting equipment designed for large fields, collective farms or owned by agricultural holdings. But if the landowner wants to sow crops in a small area, the usual technique becomes inconvenient or too expensive.

For mini grain harvesters, the working width of the header does not exceed three meters (for conventional ones it starts from 5). The overall dimensions are also modest. They are easier to control, they can easily turn around in small areas, outperforming large combines in cross-country ability. They do not require much space, they are noticeably cheaper, and their diesel fuel consumption is very low. At the same time, the “kids” perform all the necessary work, from reaping to collecting cleaned grain.

Features of the device and technical characteristics of the Zarya MZK-800 mini-harvester

On private farms you can find small-sized agricultural equipment - the Zarya mini-harvester. It is used for harvesting grain vegetation from small plots of land, up to 10 hectares. The model is structurally no different from its larger analogues; it has a similar device, but at the same time it is relatively light weight and smaller in size.

Operating a mini-harvesting machine is considered much more profitable for small farmers, because it is characterized by:

- economical fuel consumption;

- minimum pressure on the soil;

- high maneuverability in difficult areas;

- maximum performance;

- versatility;

- simple technical care and maintenance;

- affordable price.

Equipment from China

Chinese-made grain harvesting equipment was originally created for the domestic market. Local peasants cultivate everything, including the tiniest patches of land available on their plots. There may be no need to purchase large expensive equipment, but its smaller version sometimes becomes a real salvation.

As a result, Chinese mini grain harvesters combine simplicity, reliability, compact size and an attractive price. This makes them strong rivals to their more well-known counterparts from other countries.

Device features and technical description

The modern Zarya combine is produced in China. The design of the model is based on domestic technologies and developments, therefore small-scale agricultural equipment has the Russian Zarya brand.

In Russia and the CIS countries, the TM Zarya MZK-800 mini grain harvester is widely used, the direct purpose of which is to process low- and medium-sized crops. When attaching special header adapters, it harvests not only wheat and rye, but rice, sunflower, and corn. The basic configuration combines the functions of stem trimming, milking and separation in one transport unit.

The location of the assembly units is as follows:

- in front there is a mechanism for cutting stem vegetation and harvesting;

- in the center there is a conveyor and a threshing device;

- on the side there is a discharge of finished grains.

Thanks to this design, the machine works effectively with small-sized trucks like GAZ-3302.

A cabin is not installed on the Zarya combine harvester. The steering, working parts and driver's seat are attached to the equipment. If desired, a flexible awning is mounted on top to protect the driver from rain, snow and sun.

The configuration of the Zarya MZK-800 combine depends on customer requirements and operating conditions. As standard, grain harvesting equipment is equipped with an engine with a thrust of 50-150 hp. With.

Power plant parameters:

- Type - diesel.

- Number of cylinders - 4.

- Working capacity - 3.8 l.

Main performance indicators of the MZK-800 model:

- highest speed – 20 km/h;

- threshing drum diameter - 500 mm;

- cutting height of industrial crops - 50-800 mm;

- processing width - 2350 mm;

- fuel consumption - 0.4 l/h;

- productivity - 600 m²/h;

- overall dimensions - 8500x2900x3300 mm;

- vehicle weight - 4600 kg;

- operating temperature - up to +55°C.

The following are used as auxiliary equipment:

- diode lighting devices;

- receiving and assembly bunker;

- soil loosening agent;

- a soft roof or awning with risers and an auger for unloading.

Motor control is carried out by a mechanical 4-level (3 forward and 1 reverse) gearbox with hard gear shifting, clutch release is manual. The power unit is powered by a hydraulic pump, the front mechanism is powered by 3 hydraulic cylinders. The suspension is located on frame cushions.

Price and analogues

The Zarya combine is sold through existing factory representatives or private owners in Russia. The cost of equipment depends on the installation of the complete set, the location of the dealership center and the delivery method. The price of a new car is 150-350 thousand rubles. The standard purchase kit includes additional knives and consumables.

Among the harvesting analogues, German Claas, Chinese DongFeng and American John Deere are distinguished. Due to the installation of a luxury cabin, mini harvesters are much more expensive.

Reviews and how much the equipment costs

In Russia, the price of a mini-grain combine depends on the configuration and location of the dealership center. There are models that do not even have a driver’s seat as standard, so their cost is limited to 200-300 thousand rubles. Original foreign (Japanese, German, American) cars with a full-fledged cabin and higher power are expensive. Many models are exact copies of world brands, their prices are cheaper.

Farmers and private owners cultivating fields of 5-10 hectares can afford to rent mini-equipment. Rental price: 100 rubles per 1 sq.m. processed.

Stepan, 50 years old, Krasnodar region

I bought 2 mini-harvesters: the first was a Japanese Yanmar for rice, the second was a domestic Zarya for wheat and corn. There is no difference in the work: both have high productivity, comfort and convenience during the cleaning process at any time of the day. The advantage of a domestic machine is the availability of parts on the market and low cost. It is difficult to find spare parts for the Japanese. I order online.

Vadim, 38 years old, Vologda

I rent a small John Deere combine harvester from a city auto company. I pay about 200 rubles per hundred square meters for hiring a driver and a car. The guys on the unit work quickly and productively, completing the job in one shift. I tried it myself. Nice tractor. The view is wide from all sides. The seat is soft with control levers. Large grain tank. Threshes almost everything without loss. The disadvantage is the high price.