How to make a grain crusher with your own hands step by step

As a loading tank, I used a washing machine tank, to which I welded a piece of pipe measuring 40*60. In order for the grain supply to be somehow regulated, it is necessary to slightly trim the wall from the pipe and insert a damper. To secure the electric motor, you need to cut a hole in the sheet. We also make a hole for the motor shaft. We do the same for loading grain, but in such a way that the hole is as close to the center as possible.

I made the knives from strips from a combine header. The flange must be machined to the same height as the drum, and after that the knives must be welded. There should be 8 of them, 4 pieces for each row. The distance between them is 1 cm. Each knife is sharpened at an angle of 45˚. The lower knives are sharpened in such a way that the grain is thrown upward. When the drum rotates, the grain falls into the sieve.

The grain loading hopper is welded to the sheet, where holes are pre-cut. To weld the drum, you need to thoroughly clean the sheet. We attach the engine with bolts. The pressed-on flange is also bolted to the motor shaft. The drum can be welded to the sheet using a semi-automatic machine. The stitches should not be very large. The knives should also be level with the drum. The drum must be closed with a sieve. I took the outer diameter of the drum as a basis. This unit can last for many years. The only thing that needs to be changed from time to time is the sieve, which can get worn out. Knives can also wear out.

Instructions

When all the parts and tools have been purchased, you can begin to decide how to make the grain crusher grind grain. To do this, you must strictly follow the instructions:

- The prepared knives must be sharpened with sandpaper yourself and holes drilled with a diameter corresponding to the size of the shaft.

- Secure the shaft with a washer.

- Attach the blades, sliding them onto the shaft, and secure with a clamping nut;

- Make a funnel for the processed grain. For this purpose, the machine must have an enlarged drain, which is cut out to the required diameter using a chisel and hammer. A piece of pipe is inserted into the resulting hole, from where the ground grain will be poured into the container.

When remodeling a washing machine, be sure to install a sieve in the unit’s tank at an angle of 15 degrees, which will prevent feed from slipping into the cracks. This is the most difficult stage when rebuilding a washing machine, requiring maximum effort, so it is done in stages:

- You need to cut the sieve in accordance with the dimensions of the container: length and width.

- Find out how far the blades rise during rotation and mark the location.

- Draw lines a short distance from the mark.

- Secure the sieve with bolts and nuts.

- The resulting gaps between the part and the walls of the apparatus are sealed with sealant.

To process vegetables, the sieve must be removed and have different cells. In this regard, you need to figure out how to make it yourself.

A ring should be rolled out of a metal sheet and the edges should be secured with fasteners. Bend the bottom of the ring up to later attach it to the walls of the machine. A converted washing machine should be equipped with a damper to control the feed flow.

Both engines that a homemade grain crusher has move in opposite directions. For ease of use, the washing machine must have a lid in which you need to cut a hole into which to insert a funnel or a container with a wide neck to prevent loss of raw materials.

The grain crusher produces a volume of product depending on the size of the tank. If a small model is used, the capacity will accordingly be small.

To understand how to make a grain crusher, you should watch the video.

Examination

When the do-it-yourself grain crusher from a washing machine engine is ready, you need to test the machine before you start using it. The timer equipped with the washing machine should be set to the maximum possible number of revolutions. The knives will rotate in place of the activator. Only after this do we turn on the structure we remade with our own hands.

You should pay attention to how the machine works: is there any unnecessary sounds, is the engine heating up, how the knives turn. The grain can be filled in if the tests are successful. Then the homemade structure is covered with a lid and plugged into the network.

After commissioning, the nuances should be taken into account so that the forage is chopped efficiently. Firstly, a homemade grain crusher must be installed on a barrel or some kind of container. Secondly, the blades of the knives wear out during use, so they can be easily replaced. When to do this, the quality of grain grinding will tell you. Thirdly, the grain crusher must not be left unattended during operation. It is worth making sure that foreign objects do not get into it, leading to damage. This home-made design is indispensable at home, as it helps in case of lack of funds to purchase factory-made products, and most importantly, it is not inferior to them in terms of its performance characteristics.

Grinder grinder

A hand saw with a rotating blade is an indispensable thing for the home and in general for the household. Farmers have figured out how to significantly expand the functionality of this power tool. A grinder makes an excellent homemade grain crusher. No drawings are needed to make this design. It's done like this.

Read also: Gas convector with an open combustion chamber

Take a sheet of durable plywood. This will be the basis of the entire structure to which the remaining parts will be attached. You can use a piece of laminate. Two holes are cut in the plywood, the saw body is inserted into one, and a grain receiving hopper is inserted into the other.

The body of the angle grinder is secured with a metal bracket and bolts. Instead of a cutting disc, a knife is made of metal with a double-edged sharpening. This will be a grain crusher.

To the bottom of the plywood sheet, you need to attach a mesh of the appropriate size using bolts. Such meshes can be purchased ready-made or made by yourself. For example, use a saucepan with holes drilled in the bottom or an old colander.

You can use a 5 liter plastic bottle as a grain bin. A budget do-it-yourself grain crusher is ready for work.

Drawing and design conditions of the DCU

It is hardly advisable to give specific dimensions of certain working units of a homemade grain crusher. The fact is that a particular person may have a completely different model of washing machine, which has its own individual parameters and structure.

In this case, the most important thing is the understanding of the conditional design , as well as the operating principle of the entire device.

A do-it-yourself grain crusher from a washing machine and its drawings are quite conventional, based on the example of a specific model. However, by looking at them, you can understand the approximate progress of further work and the structure of the main components:

Scheme of a homemade grain grinder Let's look at the example of the Oka washing machine, which we will convert into a grain crusher. We don't have to disassemble it; we just need to unscrew the plastic part of the activator from the device. We will need the rest of the structure later.

None In place of the unscrewed activator there will be an additional engine, as well as cutting elements - knives, which must be made double-edged.

[custom_ads_shortcode2]

Grain crusher from a washing machine

At home, a grain crusher can be made from an old washing machine. This will be a more advanced model than the previous version.

At its core, the washing machine is already a ready-made feed cutter and grass cutter; you just need to slightly modify the design.

It is worth noting that it is recommended to use old washing machines as a basis. They are usually cylindrical in shape and the motor is located at the bottom.

In order for the grain crusher to work properly, the “washer” must be equipped with an additional engine. It is installed in the upper part, directly under the top cover.

Install the motor on metal corners or plates. As in the previous case, you will need to make a metal knife with a double-edged sharpening; the cutting edge should not reach the walls a little.

The second knife is installed on the base engine, which is located below. In order for a homemade grain crusher to work with maximum efficiency, the cutting knives must rotate in opposite directions.

A hole is cut in the top lid for pouring grain. It is recommended to design a small funnel so that the work can be carried out with minimal losses and greater convenience. As a funnel, you can use any plastic container with a wide neck or make a small box out of tin.

Considering that the upper motor will operate in an aggressive environment, it is necessary to supplement it with a dustproof casing. You can make it yourself from an empty paint can. Near the lower motor, a hole is cut in the side wall to allow the crushed grain to exit.

The operating principle of this design is simple and intuitive. By and large, the product resembles a large coffee grinder. Due to the large cutting plane and versatile rotation, the feed cutter effectively crushes any type of grain crops.

It makes no sense to provide specific drawings, because the model of the washing machine used as a basis may vary. The main thing is to understand the general principle of operation of the device. It is worth noting that this is the kind of do-it-yourself grain crusher that is most often used at home.

Structure of a grain crusher

Grain crushers are mainly used for farms, but ordinary summer residents and people who regularly live in villages often resort to using grain crushers. Some of them, wanting to save money on its purchase, managed to use an ordinary washing machine for this purpose with minor modifications.

A grain crusher is a technical unit with which you can make feed for feeding livestock at home. It is made by crushing and grinding various grains to a fine consistency.

[custom_ads_shortcode1]

Grain crusher from a vacuum cleaner

At home, you can make a grain crusher from an old vacuum cleaner. Actually, the vacuum cleaner itself is not needed, you only need an electric motor. As a base, you can take a sheet of durable plywood with a hole cut in the center. The engine working shaft will come out through the hole.

Read also: Voltage regulation circuit on a thyristor

To make a knife, you can use a metal plate about 200 mm wide and 1.5 millimeters thick. A vegetable cutting disc works well. The knife is secured to the motor shaft using nuts.

As a working chamber, you can use a ready-made metal sieve, but it is better to make it yourself. If you plan to grind not only grain, but also vegetables for your home, then the mesh should be removable, with different cell diameters . Such interchangeability is not provided for in purchased products.

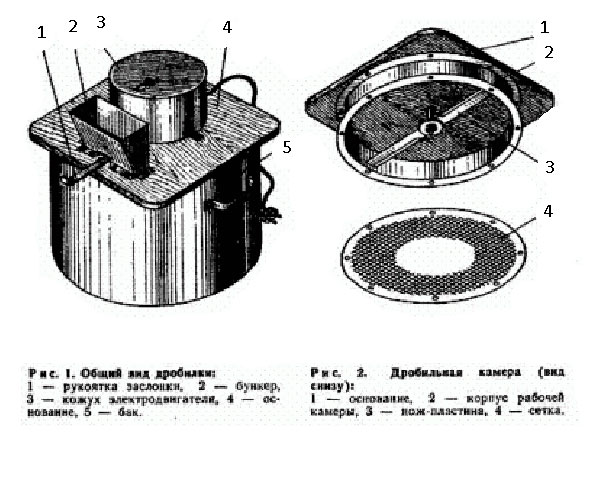

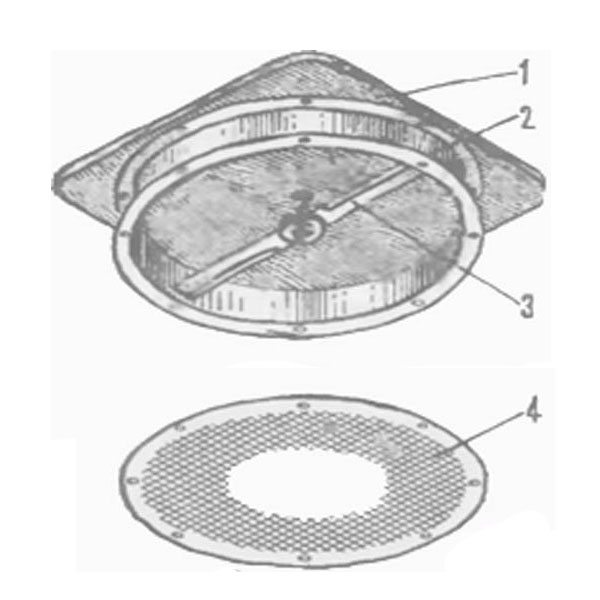

To make a sieve with your own hands, you will need a thin sheet of metal, about 700 mm long. The workpiece is rolled into a ring, the edges are bolted or riveted. The lower edge is bent outward; the width of the folded part should not exceed 15 mm. The bend is necessary to secure the mesh.

A receiving hopper for finished products is installed under the sieve. Any container that has the volume you need is suitable here. This could be a basin or an ordinary tin bucket. To feed grain into the working chamber, you can construct a tin box. To control the supply of raw materials, it is recommended to add a movable damper to the box.

From the information above, we can conclude that a grain crusher, regardless of materials, works on the same principle. To make a high-performance feed cutter for your home with your own hands, you just need to show a little imagination. The required elements you will need:

- Electric motor. At home, a motor with a power of 1.5 - 2 kW, with a rotation speed of about 150 rpm, will be sufficient. Even if you don’t have old household appliances that can be disassembled, you can buy such an engine at any flea market. It makes no sense to use more powerful motors; electricity consumption will increase, and accordingly the economic benefits of operating a home-made unit will disappear.

- Cutting plane. Can be made from any durable metal sheet in minutes. You can use ready-made discs from vegetable cutters and blenders.

- Sieve. The diameter of the cells depends on the fineness of the grind. You can purchase a finished product or make your own design with interchangeable meshes.

Even if you buy all the necessary parts, the cost of a homemade feed cutter will be much lower than the price of any store-bought model. At the same time, the performance of a homemade unit will be no worse.

Grain crusher: drawings, diagrams, dimensions, photos and videos of a homemade grain crusher. A grain crusher is an indispensable thing in the household; it is used for grinding grains of cereal crops - corn, wheat, barley, oats, for preparing dirt or feed for poultry and animals.

Households usually do not require a powerful mill; a small grain crusher is quite sufficient, which we will manufacture in this article.

There are quite a few types of grain crushers; we will look at the simplest version of a homemade grain crusher that you can make with your own hands.

To make a crusher you will need:

- Electric motor with a power of about 1 kW.

- Sheet metal 3 mm thick.

- Hardened steel for a knife.

- Bolts, nuts, washers, screws - M8.

- A metal barrel or container of suitable size.

- Grinder with cutting wheel.

- Electric drill.

- Grinding machine.

- Welding machine.

- Locksmith's tool.

Video: Homemade feed crusher

For more information about the grain crusher with your own hands, watch the video: It is known that the processed and crushed product is much better absorbed in the animal’s body, which has a positive effect on its reproductive functions and productivity, which is expressed in milk production and egg laying.

Thus, we can say that the grain crusher is an indispensable assistant for any farmer who maintains large or medium-sized livestock and poultry. Frequent purchases of ready-made feed can significantly hit the budget, but making feed yourself will allow you to save quite a lot of money.

This link will tell you how to make a cultivator with your own hands.

The operating principle of all grain crushers is similar to the operation of a conventional household coffee grinder, only on a more global scale. The unit is first plugged into a regular power supply, after which the engine is started. This is very important, because the engine must first warm up before you can start working.

Next, raw materials for processing are poured into a special tank (hopper), after which it enters the crushing chamber, where the grinding process itself takes place. Grinding occurs using special knives located in this chamber. Then, the raw materials are sifted through a sieve of a certain diameter (usually there are several of them in a set).

It is the diameter of this sieve that will determine the fraction, i.e., the degree of grinding of grain or other crops.

By the way, depending on the characteristics of a particular grain crusher, it can process a wide variety of raw materials:

- rye;

- barley;

- legumes;

- corn;

- cake;

- husk, etc.

Some units are equipped with a special disc grater that allows you to grind various root vegetables, fruits and herbs. In general, the design of a grain crusher is quite simple, so it is quite possible to make it at home.

There are quite a few detailed methods with drawings describing this process on the Internet. The method of converting from a washing machine deserves special attention , because its device is already somewhat reminiscent of the notorious coffee grinder.

You will find all the information about the AID-2 milking machine in this article.

[custom_ads_shortcode2]

Homemade grain crusher: diagram.

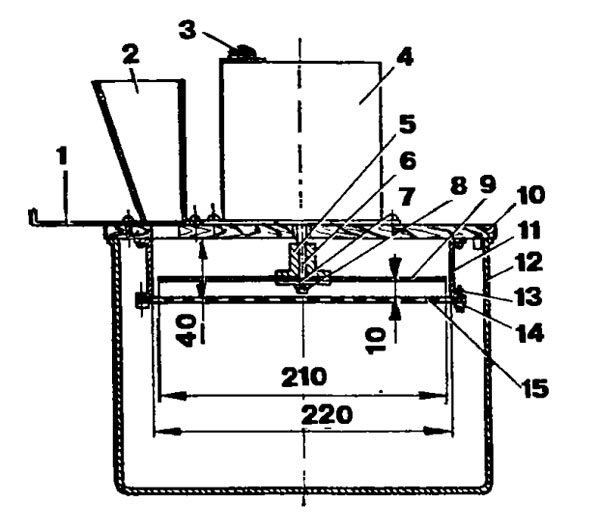

The grain crusher consists of the following units:

- Gate valve for regulating the flow of grain into the working chamber.

- Grain bunker.

- Electric motor on/off button.

- Electric motor.

- Sleeve.

- Axis.

- Washer.

- Screw.

- Screw.

- Base.

- Working chamber housing.

- Container for crushed grain.

- Bolt.

- Screw.

- Metal mesh (sieve).

Read also: Pipe thread parameters table

Diagram of the crusher working chamber.

Types of grain crushers

Grain crushers are equally used both on large farms and on private farmsteads, and differ in the size of grain grinding. For fine, medium and coarse grinding, dry crushing devices are used, and if very fine grinding is needed, then a grain grinder using a wet method is needed.

Read also: DIY wood sawing machine drawings

Grain crushers have a number of advantages:

- Compactness allows you to move the device,

- The device operates from a regular electrical network,

- Large selection of models,

- Easy to make at home,

- The necessary spare parts for grain crushers can be found in every home.

A roller grain grinder grinds the product between two rolls that rotate in opposite directions. Rotary ones differ in that the knives are attached to the main rotary shaft. In hammer crushers, the main working unit includes a drum, a sieve and decks. Crushing occurs under the influence of impacts in a hammer-shaped drum. In jaw crushers, raw materials for processing enter from above and are crushed between two jaw plates. And in a cone device, crushing is carried out in a constantly rotating cone head.

One of the most popular models, which is used in many grain shops, as well as on farms and private farmsteads, is the Shmel grain crusher.

It is easy to use and accessible. The standard package includes such spare parts for grain crushers as lingums, devices for drawing in grain, a sieve with a mesh of four millimeters and a sieve with a mesh of six millimeters, as well as a power cable.

The bumblebee can produce up to two tons of crushed grain per hour, and the drum section is designed to produce more than 200 tons of grain between maintenance.

Making a homemade grain crusher.

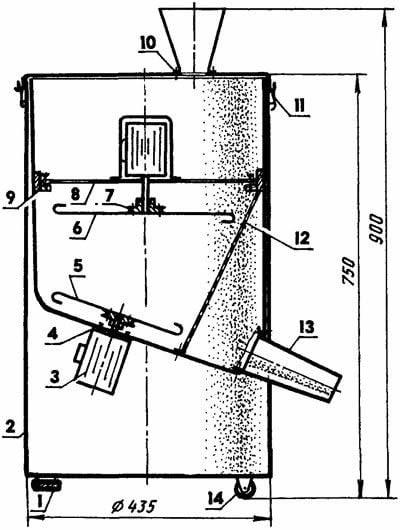

For the grain crusher, you can use a water pump engine with a power of about 1.5 kW 3000 rpm.

The engine is installed on a base, a metal sheet with a thickness of at least 3 mm. You need to drill a hole in the sheet with a diameter slightly larger than the diameter of the motor shaft. We fasten the engine to the plate with bolts.

The working chamber can be made from 3 mm sheet metal, cut out a strip 40 mm thick and bend a ring with a diameter of 300 mm from it. The ring is welded to the base.

To attach the knife to the motor shaft, you will need a coupling; you can order the coupling to be turned by any turner.

A grain crusher blade can be made from a lawn mower blade or a circular saw blade. The length of the knife should be accordingly 10 - 20 mm less than the diameter of the working chamber. The knife is attached to the coupling with M 8 bolts, the coupling is placed on the motor shaft.

We close the bottom of the working chamber with a sieve; the sieve can be made from a metal mesh with a hole size of 3 - 3.5 mm. We attach the sieve to the working chamber with studs and nuts; if you need to change the grind size, just change the sieve to another one with holes of the required diameter.

Installation of a bunker for filling grain. You can use any cone-shaped container for the hopper; to do this, you need to make a small hole with a diameter of about 30 mm in the upper plate of the working chamber, weld the hopper onto it and make a valve to regulate the flow of grain from the hopper to the chamber.

We install the grain crusher on a metal barrel or other suitable container.

Making a knife for equipment

A do-it-yourself grain grinder must be made using a knife, which must rotate at high speed, due to which the grain will be ground; this element must be performed separately. To do this, you will need to use a steel plate, which should have dimensions of 15 × 200 millimeters, while the thickness should be 1.5 m. It is preferable to choose the strongest materials. In addition, you can use car holders or other parts that can be borrowed from household appliances. The knife should be sharpened in the form of a blade; for this, both edges must be processed towards the axis of rotation. When making a homemade grinder with your own hands, you can experiment with the shape, giving the blade the appearance of a propeller or bevelling the corners. Using sandpaper, you can adjust the plate horizontally and vertically. Afterwards, in the central part of the working surface of the knife, you need to make holes with a diameter suitable for the shaft of the vacuum cleaner motor. The knife must be fastened to a threaded tail using a bushing, two washers and a nut.

The operating principle of a homemade grain crusher.

We close the valve in the bunker and pour grain into it, turn on the electric motor and gradually open the valve. The grain will gradually begin to spill into the working chamber and be crushed by a rotating knife.

When the grain is crushed, it will begin to spill into the lower holes of the sieve of the working chamber and end up in the barrel. Depending on the diameter of the sieve holes, you will get either a coarse grind or a fine grind, until the grain is crushed to such an extent that it begins to fall into the holes, it will remain in the drum and be crushed with a knife.

The valve on the hopper is needed to regulate the grain supply; if the engine begins to lose speed, then it is necessary to reduce the grain supply by closing the valve, thereby reducing the size of the inlet hole.

The working knife gradually wears out during operation, so it needs to be changed periodically.

When pouring grain into the hopper, you need to ensure that stones and metal objects that can damage the knife and damage the engine do not fall into the crusher along with the grain.

I recommend watching a video that shows a homemade grain crusher in action.

Video grain crusher device.

Structure of a grain crusher

This device is designed for grinding grain. As a result of the operation of the grain crusher, the grains are cleared of the shell. If this is not done, the stomachs of many animals, even bison, will not be able to digest such grain. Once this treatment is done, the food will be better digested by the animals, helping to increase their productivity.

In addition, the grain is crushed in the grain crusher and passed through a sieve. In addition, you can add the necessary additives to the food for livestock; the chopper will prepare a homogeneous mixture that the livestock on the farm will eat with pleasure.

The device of a grain crusher.

[custom_ads_shortcode2]

Which grain crusher is better - hammer or rotary?

This question is asked by many beginning farmers. To answer this, you will need to carefully understand the design differences between both types of units.

The work of a rotary chopper is to move the cutting blade. It is designed to crush the mass that is fed into the receiving hopper. The hammer unit crushes raw materials using hammers that are attached to a solid base.

Products obtained using a hammer machine are considered to be of higher quality. This can be achieved due to the high amplitude of movement of the hammers, which can crush even the most distant grains of grain. At the same time, an impact crusher consumes much less electricity and has higher productivity.

Read also: What is a diode measured in?

To give a final answer to the question posed above, you should decide on the tasks of the crusher. If the farm has a large number of adult livestock and poultry, then it is best to purchase an impact crusher. However, if a farmer raises small poultry and a large number of young livestock for trade, then the optimal choice will be in favor of a hammer chopper.