Flat cutters for a walk-behind tractor: advantages and disadvantages of using the device

Flat cutters can be safely called a kind of hybrid of a harrow and a knife. They are mounted parallel to the ground or at a slight angle. As a result, the device sinks into the soil to a shallow depth and cuts off the roots of weeds, thereby turning the soil itself, promoting better preservation of moisture and nutrients.

In addition to the above positive aspects, flat cutters:

- improve soil condition;

- destroy crusts and lumps formed after heavy rain;

- repel pests;

- prepare the soil for long-distance planting;

- perform inter-row cultivation of crops;

- saturate the top layer with oxygen.

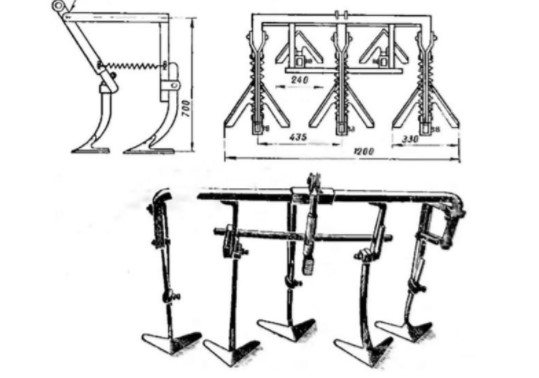

Naturally, in some cases, owners purchase flat-cutters with a ripper for a walk-behind tractor, which not only perform the mentioned tasks, but also remove excess load from a person, are easy to operate, do not require lifting, and are characterized by excellent productivity. Such devices often have a fairly affordable price, but some craftsmen manage to create flat-cutting rippers for walk-behind tractors with their own hands.

Do-it-yourself flat cutter for a walk-behind tractor: a simple manufacturing method

If the walk-behind tractor has quite impressive characteristics, it is advisable to make several flat cutters and place them on the device. Thus, you will get an even more productive unit that will not only save time, but also energy.

For excellent maneuverability of the created flat cutter, you need to take care of the appropriate wheels. Almost any materials are suitable for them. An iron tube would be an excellent choice for an axle.

Then, it is advisable to weld two circles on both sides of the concrete cutting. According to the diameter, you need to attach several wires (using a welding machine), the diameter of which does not exceed 8 mm.

On the inside of the axle, it is necessary to leave space for placing the bearing and further installation of a homemade plane cutter. Since the walk-behind tractor body is not always made of very durable material, the main emphasis is on the axle. After the bearing is attached, a plate should be welded to it.

Flat cutter blades can be created from separated mower parts. Their lightness and compactness make them ideal cutting element components. It is important to make sure that they are securely fastened, otherwise the structure will move from side to side and will not perform its task efficiently.

To limit the depth of immersion, small wheels are often used. A standard children's car can be an excellent “donor”.

The wheels themselves can be supplemented with iron parts so that the plastic does not deteriorate while driving. The immersion depth must be at least 5 cm.

To increase the weight on the flat cutter for the cultivator and increase the pressure for entering the soil, you can weld a weighting agent in the form of any part. If the necessary components are missing, you can use a basket of bricks, but such a solution is not convenient.

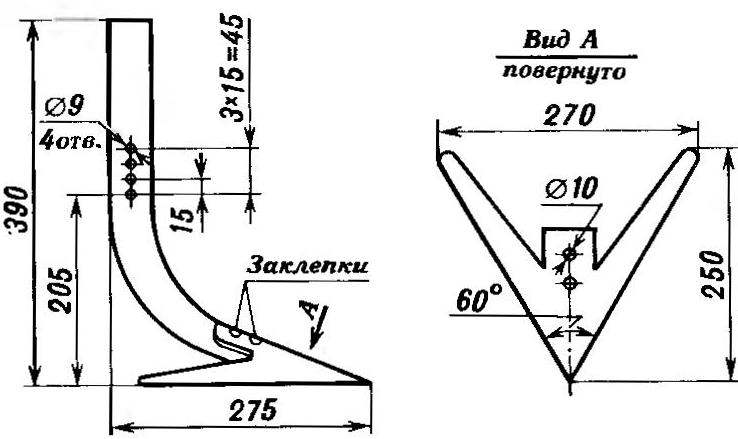

For a better understanding of the design features, it is suggested that you familiarize yourself with the drawings. The presented videos can also serve as a guide, because on these materials many craftsmen share their experience with users and reveal the secrets of creating truly durable and reliable attachments for walk-behind tractors.

It is worth noting that the created flat cutter is suitable for both Neva walk-behind tractors and equipment from the brands Centaur, Salyut and others. The versatility of the product allows you to create a truly excellent assistant at home and without any special financial costs!

Homemade trailer for walk-behind tractor

Now let’s look at the design and capabilities of a homemade trailer for a walk-behind tractor. Sometimes manufacturers themselves do not make them for the walk-behind tractor they sell, or they make them of poor quality; they often bend when transporting cargo, where the trailer connects to the wheels. The best thing is a homemade trailer for a walk-behind tractor; it will be 2-3 times cheaper and, accordingly, more reliable.

First, we make the body of the future trailer. To do this, we take steel pipes with a rectangular cross-section or we can use corners as in the case of lugs.

We need to use a grinder to cut the pipes at right angles and then we can sheathe the body with wood or metal. We attach a driver's seat to the front.

This way you can operate a walk-behind tractor with a trolley while sitting and holding it by the walk-behind tractor control handles.

We invite you to familiarize yourself with dark-colored linden honey

When our body is ready, it’s time to think about how our cart will ride. We need to make a wheel axle by taking the rear axle from a passenger car and removing the gearbox from it. You can also use a metal rod turned around the edges as an axle so that you can put on the wheels for the cart.

When the trailer is ready, you still need to attach it to the walk-behind tractor. Hitch the trailer to the walk-behind tractor using a swivel unit. To make it, we take a pipe with a rectangular cross-section and weld it to the lower edge of the cart so that a regular triangle is formed, and the edge of the body is the base of this triangle.

We also mentioned the manufacture of a rotating unit. It is a cylinder with a console on two bearings. This design of the device allows the wheels of the cart and walk-behind tractor to move independently of each other.

Below you can see drawings of a standard trolley for a walk-behind tractor

Types of cultivators

Let's look at the types of cultivators. The main parameters that you need to pay attention to are the weight of the mechanism and its power.

Heavy

Heavy mechanisms weigh up to 60 kg, and power reaches 6 hp. Such cultivators are equipped with their own engine, or are attached to a walk-behind tractor.

For more information about the operation of a heavy cultivator, watch the video:

Average

Medium mechanisms are the most common type in private households. Their weight is 45-60 kg, power is from 4 to 6 hp. The soil is cultivated to a depth of 25-28 cm.

Lungs

Lightweight mechanisms – characterized by reduced weight (up to 40 kg). They cultivate the soil to a shallower depth - up to 18 cm.

Medium and light mechanisms can be assembled with your own hands using minimal technical knowledge.

Weeding potatoes with a walk-behind tractor

The use of small-scale mechanization in vegetable gardens and small summer cottages has simplified the work and life of many potato growers.

For weeding potato rows, the walk-behind tractor is equipped with the following equipment: rotating cutters and pointed paws. The cutter is driven by the power take-off shaft, and the paw follows the unevenness of the soil, loosening a small layer of soil. Loosening using the equipment in question is carried out to a depth of up to 4 centimeters, but if the soil is swollen, then the depth of tillage is increased to 7 centimeters.

The paws for the walk-behind tractor must be mounted on special slats with slight overlap. This equipment must be set at a certain angle, taking into account the width of the rows, with one of them going in front, the second behind. This placement is necessary to clean the equipment from cut weeds. The paws are pointed or one-sided in the form of curved blades.

See also: Growing potatoes from eyes and dividing the bush

Weeding potatoes using a walk-behind tractor is no different from processing the rows of other crops: carrots, beets. Weeds need to be cut off some time after they appear above the soil surface, and not when they have grown and are well rooted.

Device

Select the power of the cultivator. Power is perhaps the most important parameter. The larger it is, the higher the speed of work and the greater the depth of plowing. But along with power, the weight of the unit and its price also increase.

A lot depends on the material for the knives. The better the material, the longer the service life, the better the quality of work.

Hand cultivators are used in subsidiary farming ; they are the easiest to make, as well as repair or replace. For their manufacture, parts and materials from other failed mechanisms are often used, which allows saving on materials.

The cultivator can be used not only by itself, but also in conjunction with a walk-behind tractor - then the cultivator is used as a replaceable attachment.

How to do it yourself?

Before making a cultivator, treat metal parts against corrosion. If this treatment is not carried out, metal parts will quickly rust from frequent contact with the soil. If you treat it with a special anti-corrosion compound, then the device will last you much longer.

To make the working part, square steel plates are taken. The size may be different, for a walk-behind tractor it is 150*150 mm. For cutters, plates of 25*4 cm are taken.

Drill a hole in each plate. Connect both plates (square and rectangular) together in pairs so that they look like a cutter. Bolts are used for fastening. If you use welding, the product will not be as reliable.

Once you have connected the plates, make another hole and secure them to the steel pipe. We will need two pipes fastened together with cutters. After this, the pipe can be attached to the walk-behind tractor shaft .

Simple models of cultivators can be made without a drawing, especially if you have engineering and technical experience. It is advisable to assemble more complex models of cultivators for a walk-behind tractor with your own hands according to drawings indicating all the required dimensions.

Weeding

A do-it-yourself weeding cultivator for a walk-behind tractor is used not only for loosening, but also for weeding. The design of the weeding cultivator has some unique features.

A hanging frame is used as a base. On one side the frame is attached to the walk-behind tractor, and on the other side it rests on one or more wheels. Special paws are installed on the frame, which cut weeds at the root, and can also loosen the soil to a shallow depth.

Hilling potatoes with a walk-behind tractor: video, description

Planting, weeding, and hilling potatoes with a walk-behind tractor

Potatoes are grown for the harvest of tubers, which are a modified shortened shoot. They develop on other types of underground elongated shoots called stolon. Plants with this type of root system require special care.

For the normal development of stolons with tubers, special conditions are required:

- sufficient soil moisture;

- good access of oxygen;

- suitable temperature;

- strong greens that additionally nourish the root system.

Regular watering and protection from pests will help in caring for potatoes, but for access to oxygen and better heating of the root tubers, hilling is necessary.

Hilling up potatoes helps saturate the soil with oxygen and helps increase productivity

The procedure promotes the following processes:

- increases the layer of soil above the rhizome, which helps maintain temperature and humidity;

- removes crust, makes the soil looser;

- helps to “hide” the tubers from sunlight to prevent the production of solanine;

- minimizes weed growth.

To minimize the amount of time and labor spent when planting, weeding and hilling potatoes, it is recommended to use a walk-behind tractor with special devices.

Our material will help you choose a walk-behind tractor according to your needs.

Planting potatoes with a walk-behind tractor

Planting work on large areas takes a lot of time and effort. But using gardening equipment can significantly speed up the process.

Plowing land for potatoes with a walk-behind tractor

Before planting potatoes with a walk-behind tractor, preliminary preparation is necessary:

- careful selection of planting material;

- soaking and preparing tubers (if required);

- plowing the soil with a shovel (or tilling with a walk-behind tractor using a hanging plow);

- applying fertilizers before planting potatoes.

Planting potatoes with a walk-behind tractor

When planting, you should adhere to the following rules:

- the distance between rows should vary between 55-65 cm;

- the gap between plants is 20-30 cm;

- planting depth – 12-14 cm;

- The furrows should be as even as possible.

To carry out all planting work with a walk-behind tractor, they additionally use a hiller, a special potato planter, and a plow.

Weeding and hilling potatoes with a walk-behind tractor: video and photo description of the procedure

To get a good harvest in the future, it is important not to miss the optimal time for hilling. The primary procedure can be carried out when the young bushes have grown by 13-15 cm.

When to hill up potatoes

In central Russia, potato planting begins on the “May holidays” - in early May. And the optimal time for hilling is at the beginning or middle of June, depending on weather conditions.

For hilling, the walk-behind tractor is equipped with lugs and a coupling with the hiller.

If the spring turns out to be cold, germination slows down, and with early warming, the plant develops faster. The first hilling of potatoes with a walk-behind tractor should be carried out, focusing on the condition of the seedlings.

As a rule, for maximum yields it is enough to carry out 2-3 hillings per season. The best time to carry out the procedures is after rain or watering. The soil becomes soft and the risk of root damage is reduced.

You will find additional information on calculating the timing of hilling potatoes in our article.

Hilling potatoes with a walk-behind tractor video

To perform work with a walk-behind tractor, it is necessary to install a hiller, a hitch, and lugs on it. For a small area, equipment with a low power of 6-7 hp is quite sufficient. With. For example, units such as “Salyut” or “Neva” are suitable for performing such work.

If, when cultivating the soil, the machine slips due to lack of weight, experienced gardeners use weighting agents for ballast, installing them on the body or on the front part.

Weeding potatoes with a walk-behind tractor video

A special attachment for weeding potatoes – “Hedgehog” – will help you get rid of weeds. It is attached to the walk-behind tractor and consists of interconnected rings with spikes, which, when rotated in the ground, pull out weeds by the roots.

It is also possible to weed potatoes with homemade devices, which can be either manual or automatic. It should be taken into account that the use of manual devices increases the time spent on crop processing by at least three times.

Additional hilling methods

There are also manual methods for hilling potatoes:

- raking the earth under each bush using a hoe;

- the use of a special plow designed for two people.

Hilling potatoes by hand

As practice has shown, the most effective method is using a walk-behind tractor. This mechanized device will help you complete the job three times faster than using manual techniques.

Bottom line

Using a walk-behind tractor and attachments for planting, weeding and hilling potatoes, you can effectively and quickly cultivate a fairly large area, significantly increasing the yield without much time and labor. The modern device can be used not only for growing, but also used in harvesting potatoes.

Source: https://vsadu.ru/post/okuchivanie-kartofelya-motoblokom-video-opisanie.html