How to adjust the carburetor of a walk-behind tractor with your own hands

The walk-behind tractor carburetor must be adjusted periodically to ensure proper operation of the mechanism. A possible cause of differences in the operation of the walk-behind tractor engine may be the carburetor. To do this, the device is disassembled, cleaned and adjusted (adjusted). Regardless of the brand of carburetor and the device on which it is installed, the principle of regulation is the same for everyone. The difference can only be in the number of revolutions.

How to adjust the carburetor of a walk-behind tractor

What should you pay attention to during a motor failure? If a carburetor malfunction occurs, the first thing you need to do is check the fullness of the fuel tank and the oil level. If there is enough fuel and oil, then proceed to inspect the spark plug. To do this, unscrew it and use the ignition to check the spark. Next, the flow of gasoline to the carburetor is tested. For this purpose, remove the hose from the fitting and monitor the flow of fuel. If fuel does not appear, then the filter mesh will most likely need to be cleaned. To do this, the fuel valve is unscrewed and all parts are washed with gasoline. The same is done with the carburetor jet.

Cleaning the carburetor is carried out as follows. To clean the device, you first need to remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the parts on which it is supported.

So, remove the carburetor and pour gasoline out of it. Carefully separate all parts of the device (nozzle, float) for further purging and cleaning. This manipulation is performed with a special cleaner.

In case of heavy contamination, you can use a compressor.

After cleaning, thoroughly dry all the parts and safely proceed to assembly. After assembly, adjust the carburetor for the walk-behind tractor.

We install the cleaned device using the standard gasket and secure it with nuts. Don't forget about the air filter, speed controller and gasoline supply hose.

Setting up the carburetor of a walk-behind tractor involves adjusting it. In order to adjust the carburetor yourself, you need to do the following steps:

- The low and full throttle screws must be tightened until they stop.

- Turn out the low and full throttle screws one and a half turns (we set the throttle valve in such a position that a gap of the appropriate size is formed between the base and the air duct).

- Start the engine and wait until it warms up.

- With the engine running, set the control lever to minimum speed.

- Achieve uninterrupted engine operation. To do this, you need to keep the idle speed to a minimum using the throttle screw.

- Set the idle speed to maximum using the idle screw.

- Set the idle speed to minimum using the throttle screw.

- Repeat steps 6 and 7 until continuous engine operation begins.

- Place the engine control lever on the gas.

- If an interruption occurs, unscrew the screw that regulates the quality of the mixture no more than 2.5 turns.

I would like to note that the carburetor adjustment on the Neva walk-behind tractor is carried out strictly according to the above instructions. The K-45 device installed on the Neva walk-behind tractor is single-chamber and horizontal. The float chamber is located in the central part. The throttle valve is flat.

The Neva walk-behind tractor uses the DM-1K engine, which is produced on. The manufacturer categorically does not use Chinese-made engines. This also applies to the production of motor cultivators.

Cultivator Mole: technical characteristics and operating instructions

The Mole cultivator is a model of the Soviet and Russian walk-behind tractor. The Mole cultivator is a model of the Soviet and Russian walk-behind tractor, the production of which was launched more than twenty years ago. Good technical characteristics have allowed it to be used to this day.

Content:

Cultivator Mole: technical characteristics and purpose

Gasoline walk-behind tractors "Mole" consist of the following main parts:

- gearbox;

- frame secured to the gearbox with bolts;

- handle for manual control;

- a bracket designed for the use of additional types of equipment;

- levers for switching speed and clutch.

Some modern models are characterized by the presence of reverse gear, switchable on the handle. Mounted equipment is mounted on gear input shafts.

The Mole cultivator is designed for plowing the soil

The purposes of the “Mole” cultivator are as follows:

- plowing the soil. Soil cutters are installed on the output gear shafts. The wheels are raised, and a coulter is attached to the bracket, through which braking is carried out and the depth of plowing is adjusted. A pair of external and a pair of internal cutters belong to the category of working bodies and movers of motor-cultivator equipment. On fairly light soils, the additional use of a third set of cutters is allowed, which improves the stability of the equipment;

- weeding activities involve installing special L-shaped weeders on the internal cutters;

- Weeding activities with preliminary hilling of potatoes involve replacing the coulter with a special hiller. The equipment is provided with metal wheels with ground hooks;

Plow plowing involves installing metal wheels and lugs on the gear shafts and attaching the plow

- To dig up potatoes, metal wheels and lugs are installed. The opener is replaced by a digger;

- plow plowing involves installing metal wheels and lugs on the gear shafts and attaching the plow;

- If you need to mow grass and make hay, you need to hang the mower on the front of the cultivator. Wheels must be installed on the geared output shafts;

- When pumping water from an open reservoir to the frame, it is necessary to install special pumping equipment. A V-belt drive is used to connect to the engine.

It is very convenient to equip it with a small-sized trolley with a load capacity of up to 200 kg. In this case, replacement with rubber wheels is performed.

Review of the Mole cultivator (video)

Operating instructions for the Mole motor cultivator

The instruction manual supplied with the unit allows you not only to use the motor cultivator correctly, but also to perform simple repairs yourself. The average service life can be significantly increased with strict adherence to all rules for operation, maintenance and storage.

The basic operating rules specified in the instructions are as follows:

- the first fifteen hours of operation are considered the running-in time of the device, therefore it is unacceptable to use the unit at full capacity;

- process the area in several passes, with a gradual increase in depth;

- it should be remembered that the space located between the rotor blades and the gear housing can become clogged with foreign objects, which requires monitoring and timely cleaning;

- When cultivating soil with a significant amount of plant debris and stones, it is recommended to carry out work at a reduced speed of rotation of the rotor blades.

The average service life of the Mole cultivator can be significantly increased with strict adherence to all operating rules

The motor cultivator can be transported in the luggage compartment of a car by laying the unit on its side with the starter turned upward, which will prevent oil from draining from the gearbox.

Filling the fuel tank, as well as adjusting the carburetor and activities related to maintenance must be carried out with the engine stopped. It is also necessary to strictly adhere to general fire safety rules when performing work with any flammable liquids.

It is very important to minimize the risk of fuel mixture coming into contact with a hot engine or muffler, and the engine is started with the clutch disengaged. The Krot cultivator is operated with installed covers.

Installing an imported engine on a Mole walk-behind tractor

It is generally accepted that the operation of such a model with an imported engine becomes more stable and convenient for the operator. In this case, minimal modifications to the frame will be required, and the whole process will consist of several fairly simple manipulations. Many owners of the Krot cultivator note that the best option is to install it on a Lifan-168FB engine with a power of 6.5 l/s. Also, good results are obtained by using the Patriot and SadkoDE-220 electric motor with a power of 4.2 l/s for installation.

Many owners of the Mole cultivator note that the best option is to install the Lifan-168FB engine

Do-it-yourself engine replacement algorithm:

- unscrew all fastenings on the factory engine, represented by four standard bolts;

- remove the muffler and gas wires and remove the factory engine from the frame;

- Mark all the drilling points on the frame, which will allow you to install the new engine. To do this, you need to install the new engine on the frame, put on a belt and move the motor along the frame to the required belt tension;

- mark areas for drilling a pair of through holes and drill them;

- secure the new engine to the frame using bolts 3.5 cm long;

- tighten a couple of bolts until they stop, then connect the system to the clutch, gas and muffling.

After the new engine is installed on the walk-behind tractor frame, you need to once again carefully inspect all connection points and test the operation of the unit.

Do-it-yourself repair of the Mole cultivator:

In the process of self-repair of the Mole model walk-behind tractor, not only old-style spare parts can be used, but also new, modern consumables.

How to replace the engine on a Mole cultivator (video)

We eliminate engine breakdowns

If the cultivator engine does not start:

- blow out with air or disassemble and clean the fuel supply system;

- clean or completely replace the filter;

- remove the blockage in the drain hole of the cap on the gas tank;

- Replace spark plugs or magneto.

If the engine stalls or runs rough:

- remove carbon deposits from spark plugs;

- tightly install the tip of the high-voltage wire onto the spark plug.

If the engine is not operating at full power:

- clean the carburetor;

- replace the crankcase cuff;

- loosen the fastening nuts and install the pulleys in one plane;

- adjust the tension level of the V-belt;

- replace the piston rings, piston and cylinder.

If defects in operation appear in the form of lack of starting, you need to check the serviceability of the spark plugs and suppressive resistance, make sure that the connection of high-voltage wires is secure and that there are no insulation violations, and also carefully inspect the gasoline hoses for cracks and through abrasions.

If the cultivator engine does not start, it is necessary to blow it out with air or disassemble and clean the fuel supply system

Adjusting the carburetor k60v

The engine of the Mole walk-behind tractor uses a K60V carburetor. If you need to perform self-regulation, you need to perform the following simple steps:

- dismantle the float chamber on the walk-behind tractor;

- bend the tongue to a distance of 15-17 mm.

The design contains a pair of adjusting screws: for throttle lift and quality parameters of the mixture used. In the process of tightening the second screw, the mixture is enriched and vice versa. Initially, the engine should be slightly warmed up, after which the idle speed is adjusted. The position of the screw is adjusted, which is responsible for the quality of the mixture. To do this, you need to screw this screw one or one and a half turns counterclockwise until it stops. Then you need to achieve an increase in the number of revolutions.

The engine of the Mole walk-behind tractor uses a K60V carburetor.

Replacing old-style spare parts

Old-style units and components require repairs much more often than any high-quality new models. It is this situation that explains the high popularity and demand for old-style parts and elements. It is quite problematic to purchase parts such as a gas tank cap, a spark plug cap or a starter pawl.

The design of the Krot motor-cultivator was initially well thought out and so simple that the owner of such a unit, who has even the most basic technical knowledge, can cope not only with independent repair of the equipment, but also with its modernization. Timely modernization significantly extends the average service life established by the manufacturer, facilitates the search for spare parts, and facilitates not only operation, but also maintenance.

How to replace bearings on a Mole cultivator (video)

The Mole model, a popular motor-cultivator in our country, is intended for use in regions characterized by moderate climatic conditions. The air temperature during operation can vary between 1-40°C, and the service life of the unit directly depends on strict adherence to all operating rules, proper maintenance and proper storage.

In order not to lose the material, be sure to save it to your social network VKontakte, Odnoklassniki, Facebook by simply clicking on the button below:

dachadecor.ru

Carburetor operating instructions

The gasoline that enters this device must not contain mechanical impurities. All parts are processed exclusively with gasoline. The use of solvent is not allowed, as the elasticity of the washer and rubber parts is damaged.

To dry parts, use compressed air. It is not recommended to clean small holes with wire or a needle. Installation after repair or cleaning must be carried out evenly to avoid bending or deformation of parts.

The float chamber must be tightly connected to the body. Before operation, you need to check the connection of the air filter. There should be no gasoline leaks.

Before starting the engine, you should prepare the carburetor. To do this, you need to make sure that gasoline does not leak from it. To do this, just open the fuel tap. Close the air damper and tighten the control lever until it stops. Open the throttle valve to 1/8 - 1/4 of the maximum stroke. At low air temperatures (below +5ºС), squeeze the seal until fuel comes out of the hole.

During startup, open the choke slightly, and after the engine warms up, open it completely.

Other carburetor malfunctions

Main problems encountered during operation:

- Excess air leakage - you may need to replace the gasket between the block head and the carburetor or tighten the fastening nuts. The throttle shaft may also be worn out and will need to be replaced. If the holes in which it is inserted are broken, you will have to replace the entire device.

- Overflow of the float chamber, which causes excess fuel to enter the combustion chamber. In some cases, there may be a lack of fuel in the chamber. In all cases, the wear of the shut-off needle, float and jets should be checked.

- Poor fuel supply to the carburetor. You should check the condition of the fuel filter and sump, gasoline hoses and inspect the fuel tank. In cases where the tank is heavily rusted inside, it is better to replace it. In some cases, it is advisable to rinse the container with a caustic soda solution.

- Increased fuel consumption. This may be caused by improper adjustment of the fuel supply system. You should try to configure it according to the instructions.

In some cases, it will be necessary to completely disassemble the carburetor. To do this you need:

- remove the carburetor from the engine head;

- remove remaining fuel from the float chamber of the product;

- Next, it is necessary to inspect the float fitting. If gasoline drips from it too slowly, then the fitting should be blown out with compressed air from a compressor or cylinder;

- after this you need to rotate the fitting 180 degrees; if after these manipulations fuel stops flowing from the carburetor, this means that the gasoline valve is in full working order.

Now you need to check all the jets.

For this you will need:

- Unscrew and remove the screws responsible for adjusting the full and low throttle.

- Remove the bottom and top covers of the device body.

- Wash the jets, clean the fuel tap.

- To wash the parts, it is best to use regular kerosene (gasoline), after which it is recommended to blow them with compressed air from a cylinder.

Carburetors of the Neva walk-behind tractor: features, purpose and operating rules

A carburetor for a walk-behind tractor is a connected part of the power system. The main task is to optimize the fuel to obtain a specific composition. The carburetor first of all needs constant monitoring of loads.

Regular checks, adjustments, and proper operation will help extend the service life of the device. In addition, this is influenced by the configuration of the equipment and the fuel used.

Device Features

The walk-behind tractor is a fairly powerful unit, with great strength, but at the same time of medium size, equipped with multifunctional equipment. The equipment is mainly produced with a gasoline, diesel or electric engine. The latter, by the way, are extremely rare. A carburetor is required for the added fuel to ignite. The manufacturer presents the following types:

- rotary - the simplest in structure, they are mainly equipped with small-sized engines of 12-15 cubic inches;

- plunger - in this case the design is more complicated, therefore it is used for assembling powerful walk-behind tractors.

Carburetion is carried out using the main parts:

- main piston;

- connecting part - fitting;

- fuel tank;

- high/low speed needle;

- Venuri tube.

So, the process begins with a piston moving upward, resulting in the creation of a vacuum. The carburetor absorbs air, and it subsequently moves through the Venuri tube. The movement of fuel (from the tank) is directed towards the engine, this is done using a connecting fitting, which operates due to the created vacuum. The liquid goes around the main needle, flows through the inlet socket, entering the Venuri tube. By pressing the gas lever, fuel is released due to the low speed needle. Next, the first needle is responsible for the flow of gasoline.

Among domestic craftsmen and agricultural workers, equipment of the Russian brands “Neva”, “Oka”, “Agro”, “Utra” is especially popular. It features optimal equipment, a high-quality, powerful carburetor. Russian buyers especially appreciate the Neva K-45 walk-behind tractors for their reliability and durability. The KMB-5 model is an older unit, so before purchasing, consult with a specialist who will provide a product that meets your needs.

For heavy loads, it is recommended to use MB-2 walk-behind tractors - they are equipped with powerful engines and feature reliable carburetors that can operate for many years without forced repairs. MB-1, in turn, is considered a lightweight type that optimizes the functional engine.

Device

The Mole walk-behind tractor is a fairly standard design without the use of frills. This model of walk-behind tractor began to be produced in 1983 in Moscow, but then the production of this unit expanded, so they began to be produced in Omsk.

They were equipped with factory engines, the power of which did not exceed 2.6 hp. It is attached, like the gearbox, to the frame using ordinary bolts. The declared power was not always enough, so many Mole owners adapted to some modifications, replacing the factory engine with more powerful models.

Adjustment recommendations

Unstable engine operation is the first signal to adjust the carburetor on the walk-behind tractor. Experts advise starting this procedure in early spring - just when you start the mechanism after winter “hibernation”, at the end of autumn - after the end of the load. Disassembly should be carried out in a bright, ventilated area. Setting up the Neva carburetor yourself is not at all difficult, the main thing is to follow the basic recommendations:

- warm up the engine for at least 5 minutes;

- screw the screws in until they stop;

- the screws, in turn, must be adjusted by 1.5 turns;

- set the gear lever to minimum speed;

- in the case of throttle control parts, set only the minimum speed;

- Make sure that the engine is running for the duration of the entire repair - turn it off when completed, then start it again to check/monitor the result;

- The idle speed is regulated by the idle screws - it is important to ensure non-stop operation of the engine;

- If all rules are followed, the carburetor will function quietly and without failures.

Operating rules

The device will last a long time if you follow the following recommendations.

- To keep the mechanism in working condition, it is important to monitor the composition of the supplied gasoline - it should not contain mechanical impurities.

- Before starting repair work, it is necessary to treat the parts with the same fuel. It is not recommended to use solvent, as it can reduce the elasticity of rubber parts and damage washers.

- It is best to dry parts by blowing with compressed air.

- Do not clean small holes, for example, with a needle or wire.

- Perform final assembly and installation of parts evenly - this way you can avoid deformation or bending of carburetor parts.

- Make sure that the float chamber is tightly connected to the body - future success lies precisely in their tightness.

- Before starting the mechanism, check how the air filter is connected - you should be wary of fluid leaks.

- To avoid leakage, the fuel valve must be opened, then the air damper must be closed, the control lever must be tightened tightly, and the throttle valve must be opened to 18-14. The seal should be pressed until drops of fuel appear (if the temperature has dropped to 5 degrees).

- When starting, the air damper must be opened slightly. As soon as the engine warms up, open it all the way.

Carburetor care for walk-behind tractor

It is possible to prevent the walk-behind tractor from frequent breakdowns or repairs only by carefully monitoring the operation of the mechanism. As has already become clear, it is important to carry out timely idle adjustment. In addition, do not forget to clean the carburetor, inspect the condition of the parts; to do this, you must first remove them; perhaps they need a complete replacement. For example, gaskets often wear out. Due to constant interaction with fuel liquid and air, the engine becomes heavily polluted. The filters that are installed on the unit will help reduce manual cleaning. In this case, they will have to be cleaned when they become very dirty.

The condition of the equipment is affected by the composition of the fuel being poured. Low-quality flammable liquid impairs the functioning and service of parts and the mechanism as a whole. It is for this reason that craftsmen often resort to replacing or repairing agricultural equipment. You can purchase new spare parts at automobile markets or in stores staffed by qualified specialists.

It is enough to name the model and serial number of the equipment, and you will be provided with appropriate assistance and a selection of quality parts. By the way, right in the store they can diagnose, clean, and replace you.

It is quite easy to adjust the Neva brand device even with your own hands. The main thing is to adhere to the above rules. It will not be superfluous to purchase a connection diagram for each part after repair work or setup, since incorrect installation of spare parts will lead to equipment malfunction - it simply will not start. Try to use high-quality fuel, make adjustments on time, and do not skimp on spare parts. After all, the operation of the entire mechanism depends on every detail.

In the next video you will find cleaning and flushing the carburetor from the Neva MB23 walk-behind tractor.

Possible malfunctions, repairs

Despite the simplicity of their design, Krot motor cultivators are extremely sensitive to contamination of individual components, parts, mechanisms and other components of the unit. Many problems during operation arise due to untimely replacement of consumables and neglect of basic rules for caring for equipment. The ironic slogan “Tanks are not afraid of dirt” does not work in this case.

Let's look at the most common problems and breakdowns that occur in the main components of the cultivator.

Engine

The first samples of Mole cultivators had many complaints specifically from the motors, which were unreliable and had a short service life. Equipment owners modified agricultural machines at their own risk. Often, new engines were installed on the units to replace the ones that had fallen into disrepair from other garden equipment: Forza, Patriot, Sadko, Lifan.

Thanks to factory design developments, cultivator models with engines Honda GC 120, Honda GC 135, Greenfield, GeoTeck, Subaru Robin EY-15D, Hammerman, INNOMOTOR , Briggs & Stratton from well-known Japanese, German, American, Hungarian, and Italian brands appeared.

Thanks to modern engines and innovative developments, the Mole has turned from a once narrowly functional milling cultivator into a universal agricultural machine, which is capable of performing any agricultural work on tillage, cultivating crops, as well as transporting goods and clearing territory.

Therefore, if your Mole motor cultivator still has an old two-stroke engine, urgently replace it with a new model and feel free to expand the functionality of the unit. The most budget-friendly and fairly reliable option is Lifan; “Americans” and “Japanese” will be more expensive, but subsequently they will require much less attention.

If the engine does not start:

- empty fuel tank or poor quality fuel;

- difficulty with ignition;

- consequences of decompression in the form of deformation of the exhaust valve, breakdown of piston group elements - it is necessary to disassemble the engine and replace worn-out parts.

The mole won't start!

Started up:

Ignition

The ignition may be completely absent or not fire in the following cases:

- If the magneto fails, it is replaced, since the device cannot be repaired.

- If there is no spark, the spark plug may have simply burned out; you should replace it with a new one.

- A sooty spark plug must be thoroughly cleaned and washed with gasoline.

- If there is a spark, but the equipment does not start, pay attention to the condition of the spark plug - if it is damp or wet, it means the insulation has been damaged. To eliminate the defect, it is enough to change the tip. In turn, a wet spark plug is most often caused by low-quality fuel.

- Due to excessive wetness of the spark plug and fuel leakage, there will also be no spark; you should bleed the engine using a manual starter, thereby drying the cylinder.

- Increased gap between the electrodes - it is necessary to set the optimal gap size.

- A dirty air filter is the most common cause of lack of spark, so it is necessary to systematically check its condition and change it in a timely manner.

- The integrity of the fuel line is damaged - the hoses should be replaced.

- Electrical system insulation failure.

- Check the position of the flywheel plates - they may be jamming the magnetic circuits.

Carburetor for the Neva walk-behind tractor: adjusting the device for models MB-1 and MB-2

Motoblocks today have become a very popular technique among farmers, summer residents and rural residents. Therefore, questions about their repair and correct operation never tire of leaving the Internet. Since sooner or later the equipment breaks down for various reasons, it is necessary to either contact a service center or solve the problem yourself. Many, of course, start doing repairs at home, which is much more economical than turning to specialists. But you need to remember that it’s worth knowing how to do it, or at least have the instructions at hand.

Today we will talk about a common problem with Neva walk-behind tractors, namely, we will provide detailed instructions for adjusting the carburetor of the MB-1 and MB-2 walk-behind tractor. Everyone knows that the carburetor is a very important part in the walk-behind tractor system. The efficiency and success of the functioning of the engine and other systems depends on it. So, we will tell you step-by-step instructions for adjusting the carburetor for the Neva MB 2 and MB-1 walk-behind tractor.

Do-it-yourself repair of the Mole motor cultivator

Before you start repairing the Mole motor cultivator yourself, you need to know whether it is subject to warranty service. If the warranty period has not yet expired, contact the appropriate workshop. There the equipment will be repaired and the warranty will be extended for a certain period of time.

You need to know that after turning on the walk-behind tractor for the first time, the engine is not given full load. The instructions indicate the break-in period, since all parts must be ground in, otherwise the engine and gearbox will have to be repaired in the near future.

But if your walk-behind tractor is already quite old and does not have warranty service, you can try to make a small repair of the mole walk-behind cultivator yourself. It is not very difficult and even a not very experienced person can cope with this task. "Mole" is a simple device. To do everything correctly, first read the instructions and the unit diagram, because knowing the structure of the machine, you can also repair it.

Frequent malfunctions

When we talk about repairing the Mole walk-behind tractor, it is worth listing the following breakdowns and how to fix them:

- Faulty ignition is a common failure of the Mole walk-behind tractor. First, check the spark plug - it is unscrewed and inspected. A dry spark plug indicates that the fuel mixture is not getting into the cylinder. If the spark plug is very “wet”, “pump” the engine with a manual starter - this way you can dry the cylinder. If there is a lot of carbon on the spark plug, clean it with fine sandpaper and gasoline.

- The gap between the electrodes is usually 0.8 mm, if necessary, adjust it.

Faulty ignition is a common reason for repairing the Krot motor cultivator.

- No spark. This means the spark plug is faulty, just install a new one (LINK to spark plugs from Aliexpress). It is also possible that there is no contact in the electrical circuit or the gap between the magnetic circuit and the ignition coil is broken.

The ignition of the Mole walk-behind tractor depends on the condition of the gasoline hoses, the insulation of high-voltage wires and their connections. Check everything carefully, the flywheel plates MUST NOT touch the magneto cores. Make sure there are no traces of touching.

- You need to check the air filter. If it is dirty, not enough air enters the carburetor. Even a dirty muffler affects engine power.

Have you been unable to find the ignition fault? Contact a specialist; you cannot cope with a serious problem on your own.

We give a small recommendation for selecting a specialist to repair the “Mole” - Profi.ru website. Select your city and look for a specialist; the probability of finding a good specialist is very high.

What to do if the problem is in the engine?

Most often, owners of cars of this brand are faced with engine problems, for example, it does not start or its performance is unsatisfactory. Among the signs of a breakdown: spontaneous stopping, power does not gain, interruptions are heard.

Here is a small instruction on how to determine the breakdown:

- Check the ignition;

- Make sure there is fuel in the gas tank;

- If you doubt the flow of fuel to the carburetor, check the fuel filter;

- Clean it if necessary;

- Start the cold engine;

- The carburetor choke must be closed.

If you cannot find the cause of the malfunction of the Mole motor cultivator and fix it yourself, contact a specialist

Prevention and operating rules

To prevent malfunctions of the Mole motor-cultivator, you need to know the basic rules for its storage and operation. They depend on how long the equipment will be inactive. If you will not use it for a long time, here are a few rules:

- You need to start the engine so many times that the carburetor remains empty.

- Machine parts that move and rotate must be carefully lubricated with high-quality oil.

- Daily maintenance is required.

- The surfaces of the walk-behind tractor are wiped daily with a rag soaked in the fuel mixture.

- If any parts fail, install new spare parts.

If you want to operate the Mole walk-behind tractor for a long time, without repairs, be sure to undergo maintenance. Do not buy cheap, “left-handed” spare parts. Only original spare parts will ensure high-quality operation of your equipment after repair. Regular inspection and maintenance guarantee a long service life.

Video instructions

If you don’t have a Mole cultivator yet, but are thinking about buying one, be sure to watch this useful video about all the advantages of this machine:

Thanks for the repost, friends:

- Do-it-yourself lawn mower repair - Feb 15, 2017

- Do-it-yourself curtains for the dacha - Aug 2, 2016

- Polyurethane foam Macroflex 750 ml: technical characteristics - May 10, 2016

- Foil penofol: technical characteristics - May 10, 2016

- Polypropylene pipes for heating: technical characteristics - May 10, 2016

Tags:

remontgeeks.ru

Details for adjusting the carburetor of Neva walk-behind tractors

To repair this device, you can safely use these guidelines in the picture and the tips below:

- Screw in the full throttle screw No. 1 and the low throttle screw No. 2 until the end.

- We unscrew the same 2 screws approximately 1 - 1.5 turns.

- We start and warm up the engine.

- Now we set the lever that controls the throttle until the engine turns off (that is, until the moment when it corresponds to the very minimum speed).

- We set the minimum stable idle speed with screw No. 3.

- Using screw No. 2, you need to set the idle speed to the maximum level.

- We adjust the minimum stable idle speed with screw No. 3.

- We carry out steps 6 and 7 until we get uninterrupted and stable idle operation of the engine at minimum speed.

- If there are still interruptions in operation, then screw No. 1 needs to be unscrewed and screwed back in. We carry out this operation until normal engine operation resumes.

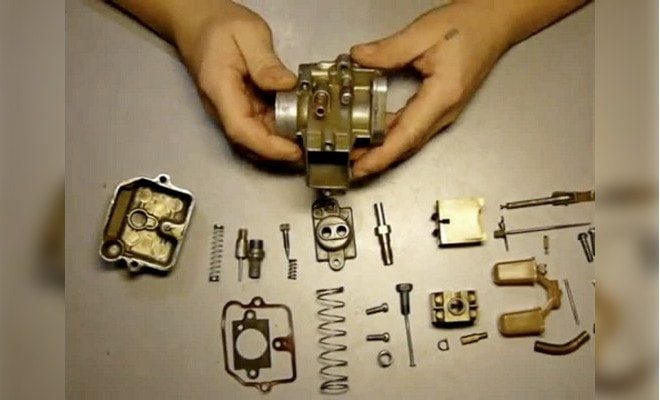

Carburetor repair of Mole walk-behind tractor

The carburetor motoblock "Mole" was manufactured in Soviet times . Despite the fact that the Soviet industry was famous for its high level of performance and reliability, this carburetor still had a number of disadvantages. To understand them, you must first do a complete analysis of its components:

- Remove the cover by unscrewing the bolt on it. Underneath we find a gasket made of gas-resistant material, as well as a spring that needs to be removed.

- Remove the damper located there under the cover.

- On the reverse side there is a float chamber, which also needs to be unscrewed. Remove the gasket.

- You then need to remove the float by removing the pin from the corresponding hole. Under the float there is a special needle, which also needs to be removed. On it we find a small eraser, which under no circumstances should be lost, so we carefully carry out all the manipulations.

- Unscrew the fitting under which the gasoline filter is located.

- Then you need to remove the nozzle. After this, we need to remove absolutely all the “guts” located in the carburetor body.

READ Grinder With Bosch Speed Control

Such disassembly is required. , because we access internal content that is considered the most problematic.

In other words, we turn this screw, but the mixture does not change, it remains constant.

To change this, you need to repair the carburetor located inside the mole. The main cause of problems with mixture adjustment. One thing. The fact is that inside the carburetor there is a special channel that leads to a tube located in the center of the carburetor.

Bulldozer. A tracked or wheeled excavator belonging to the class of special equipment. Monster bulldozers. The world's largest automotive equipment.

The products of a large number of world-famous manufacturers of snow blowers are presented on the market of our country. It's all about the legendary German snow blower Hatter.

Theoretically, this pipe should have a through hole connecting the same channel. The problem is that in some factory installations this pipe is angled, causing the channel and the hole in the pipe to not line up.

There are times when the hole is completely missing on the pipe, or it has insufficient diameter. To perform the repair, we need to perform several sequential steps:

- Unscrew both adjustment screws. Please note that the screws have different tapers. A propeller with a high-quality mixture has a larger cone.

- To pull the pipe inside, we need to slightly heat the part that is outside. To do this, you can use a small fire on a gas stove or heat it with a regular AL-KO lighter.

- Gray until he can't keep his hands on the matter. After this, we put the pin in the hole where the cover fastening bolt was located.

- Using a hammer, gently tap the inserted pin until the pipe pops out.

- As practice shows, the hole is drilled only on one side of the pipe, those. It's not end-to-end. We need to make a symmetrical hole on the other side of this tube or change what we have.

- If there is a second hole, but it has a smaller diameter than the first, then we need to sharpen it a little. To do this, use a regular round file and drill the edges of the hole.

- Then install the tube in the same place. This must be done so that the through hole on it and the hole on the channel coincide exactly.

- Before you put the tube in place, you need to warm up the carburetor body so that it can easily fall into place.

- Push the tube into place and use the same pin we used to push the tube into place. We tap lightly so that the pipe does not go too far inside. At the back we should see a hole located directly above the passage, which should line up with the channel.

- You need to make sure that the hole is strictly in the center.

- Take a thick wire and insert it into the channel hole. If everything is done correctly, the wire should freely pass further through the through hole in the pipe and come out of it as a continuation of the carburetor channel.

- If the wire is sticking, you need to lightly tap the pin, pushing the pipe slightly.

- Next you need to reassemble the carburetor in reverse order.

READ Setting up a Plow on a Walk-behind tractor

That's the whole process of necessary changes in the carburetor design. Thanks to them, the adjusting screw fully fulfills its obligations to change quality, which, in fact, was required of it.

Adjusting the KMB-5 carburetor on the Neva walk-behind tractor

This instruction is very clear and simple. By carefully following each step, you can easily resume operation of this device. Remember that in order for your unit to serve you faithfully for many years, you must do the following things:

- Carry out continuous diagnostics of the unit.

- Change the oil regularly.

- Adhere to all operating conditions.

These are key actions that will help prolong the performance of all elements and keep your equipment in shape. So follow these simple rules and enjoy the high-quality and efficient operation of your walk-behind tractor.

Carburetor K-45 for Neva walk-behind tractor

Auto mechanic, specializes in agricultural equipment

Neva walk-behind tractors have long won the recognition of farmers and owners of countryside plots. However, in order for equipment to serve for a long time and work properly, it must be used correctly. Proper engine maintenance is extremely important, but the carburetor is equally important.

Its task is to enrich the fuel with air and transport the combustible mixture to the engine. In order for this part to work smoothly, it requires adjustment from time to time. This allows you to minimize the amount of fuel consumed and increase the productivity of the device - a motor-cultivator or walk-behind tractor. Our article is devoted to how to properly adjust the carburetor of a Neva walk-behind tractor.

Don't forget to adjust the carburetor

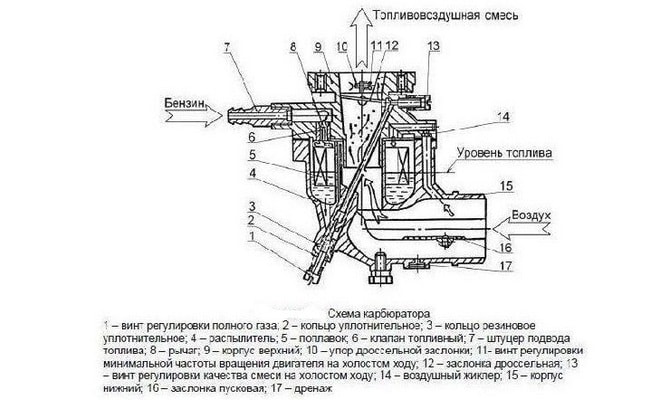

Carburetor design

The design of the Neva agricultural machinery carburetor is quite simple. Studying it will not be particularly difficult, but at the same time it will allow you to subsequently easily carry out not only adjustments, but also repairs - if such a need arises. This part includes the following components:

- a float connected to a locking needle valve;

- float chamber;

- a chamber in which the fuel is saturated with air;

- diffuser and fuel atomization system;

- throttle valve;

- air and fuel valves.

The task of the float connected to the needle-type valve is to act as a kind of regulator, determining the volume of gasoline in the float chamber. When the amount of fuel decreases, the float moves down and opens the valve, which “admits” a new volume of fuel into the chamber, replenishing it to the required amount. As the chamber fills, the float rises and, when sufficiently filled, closes the valve, preventing excess fuel in the chamber.

In this video you will learn how to disassemble a carburetor:

The function of the atomizer, located between the float and mixing chambers, is to distribute the fuel into the mixing chamber, in which it is saturated with air. Air enters this container through the inlet pipe. It is worth emphasizing here that the gasoline level in the float tank should always be several millimeters below the outlet channel. This is important because when the unit’s engine is turned off, fuel should not splash out of the float chamber, not only when it is on a flat surface, but also when the walk-behind tractor is standing on an incline.

Installing an imported engine on a Mole walk-behind tractor

It is generally accepted that the operation of such a model with an imported engine becomes more stable and convenient for the operator. In this case, minimal modifications to the frame will be required, and the whole process will consist of several fairly simple manipulations. Many owners of the Krot cultivator note that the best option is to install it on a Lifan-168FB engine with a power of 6.5 l/s. Patriot and SadkoDE-220 with a power of 4.2 l/s for installation

How to adjust the carburetor

There are several signs that indicate that the carburetor on your walk-behind tractor needs adjustment. Let's list them:

- the engine power of the unit has decreased sharply;

- the volume of fuel consumed has increased rapidly;

- the volume of exhaust gases has increased;

- after starting, the engine turns off spontaneously;

- At idle, the walk-behind tractor engine is unstable.

Each of these problems may have several reasons, including increased loads on the unit or, conversely, long downtime of the walk-behind tractor. An effective measure to eliminate them is to set up the unit. Doing this yourself is not at all difficult. To do this, you need to perform several steps:

- Before tuning, start the engine and warm it up - leave it running for 5 minutes.

- Turn off the device and leave it motionless on a horizontal surface. After this, turn the full and low throttle screws, first until they stop, and then one and a half turns in the opposite direction.

- Start the engine again and warm up for 5 minutes.

- Without turning off, adjust the engine speed control lever to the lowest speed.

- Adjust the throttle screw to the desired position - the one in which engine operation will be the most stable.

- Unscrew the carburetor low speed adjustment screw to the maximum position.

- Set the throttle valve screw to the minimum position.

- Adjust both of the above screws until the engine of the unit begins to demonstrate maximum uninterrupted operation.

- Having adjusted both screws, you need to set the engine speed lever to maximum gas.

- A check is required to complete the setup. To do this, the maximum speed adjustment screw is turned in one direction or the other by two and a half turns in order to check the smooth operation of the motor.

Important! After you have adjusted the mechanism, you should check the unit settings. If it shows uninterrupted operation, and gasoline consumption has decreased, it means that the setting was made correctly.

Common breakdowns

What machine elements may require the operator's close attention?

Let's list them:

- motor;

- magneto, ignition system;

- carburetor;

- gearbox;

- air filter, etc.

Now let’s take a closer look at all those malfunctions that can affect the performance of the unit, no matter what model it belongs to.

Does not start

So, what to do if the “Mole” does not start, what could be the reasons for this? The ignition fails or there is no ignition at all in the following cases:

- No spark. This could mean the spark plug is burnt out. In this case, you need to unscrew it and simply replace it with a new working one.

- The spark plug is smoked. A good cleaning will bring it back to life (remove carbon deposits, clean the contact), after which the spark plug must be thoroughly rinsed in gasoline.

- If the cultivator does not start, but there is a spark, then most likely the reason is a lack of insulation. We look at the candle again, in this case it is wet or slightly damp. You don't have to change the entire spark plug; you only need to replace the tip.

- Poor quality fuel may cause the cultivator to fail to ignite. It is for this reason that the spark gets wet, after which you will have to change the tip.

- Fuel dripping from the spark plug is another reason why the car will not start. To rectify the situation, it is necessary to drain the cylinder by bleeding the engine using a manual starter.

- The reason for the lack of ignition may also be problems with the fuel supply hoses. To restore the operation of the cultivator, it is necessary either to properly tighten the hoses, or, in case of rupture, replace them with new ones.

- Poor insulation of the electrical system (high and low voltage wires) can also cause the unit to not start.

- Pay attention to the air filter. If it is dirty, then problems with ignition are guaranteed. It needs to be either cleaned or replaced. Most often they resort to the second option, fortunately, this spare part is available both in price and in availability in the store.

- Failure of the magneto itself. This part cannot be repaired and is immediately replaced with a new one. How to check the magneto of the “Mole” motor-cultivator to make sure it is faulty? Yes, it’s very simple - if all the reasons why there may be no spark are excluded, then the cause of the malfunction is in the magneto. Many craftsmen rework the working magneto, thereby increasing its service life.

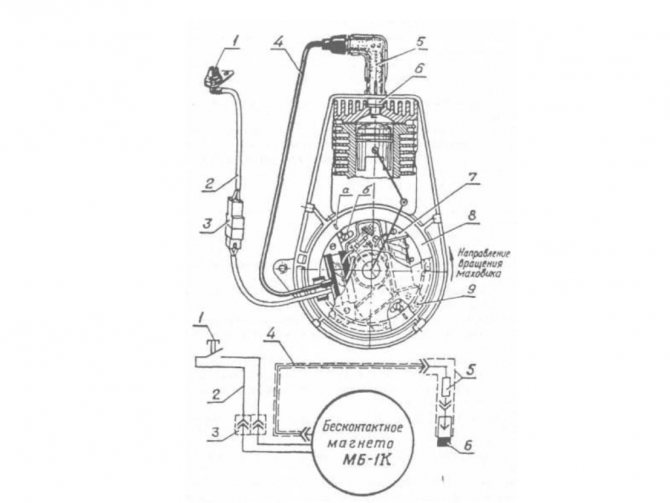

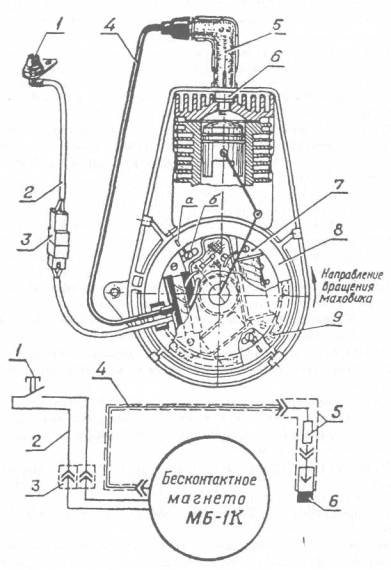

This is what the Magneto ignition circuit for the “Mole” motor cultivator might look like

- There may be no ignition if the flywheel plates jam the magneto cores.

- An incorrectly set gap between the electrodes will not allow a spark to escape.

Video review of the modernization of the ignition of the “Mole” motor cultivator

As you have seen, setting the ignition is not so difficult.

Engine

The main reasons that the “Mole” engine does not start are:

- lack of fuel (or its low quality);

- ignition problems discussed above;

- the appearance of decompression and, as a result, piston wear and deformation of the exhaust valve.

In the first case, it is enough to simply fill in the required amount of fuel (a mixture of gasoline with M-8V autolom oil) and all problems will be resolved. In the case of a compression failure, you will have to completely disassemble the engine and replace damaged parts, and this could be a piston or an o-ring.

Deformation of the exhaust valve becomes another cause of compression failure, which leads first to a loss of power of the “Mole” motor-cultivator, and then to starting problems.

|

To restore engine functionality, it is necessary to completely disassemble it. Having assessed the condition of the piston, replace it if necessary. We change the piston rings and exhaust valve. We examine the engine head, in particular the gas distribution mechanism, and if there is carbon deposits, we clean it. If structural elements are damaged, we replace them with serviceable ones.

Motor selection

During the Soviet Union, only domestically produced two-stroke single-piston engines were used, which were not particularly powerful. Today you can find “Mole” with a four-stroke imported engine. But if you still have the first model of a cultivator in your arsenal, then upgrading your “Mole” by replacing the motor is not at all difficult.

And here a new question arises: which engine is better to install on the unit? It’s not difficult to answer - those models that are installed in newer cars are suitable.

It is best to replace the domestic engine with an imported one:

Any of them will not only give the motor-cultivator a new life, but will also significantly increase the power and service life of the unit.

An excellent solution would be to install the Lifan engine on the “Mole” motor-cultivator. Such a motor provides the car with a long life, because in addition to reliability and efficiency, Lifans also stand out for their unpretentiousness and definitely do not require additional attention.

Video review of replacing the engine on a Lifan 168 F-2 with a Mole cultivator

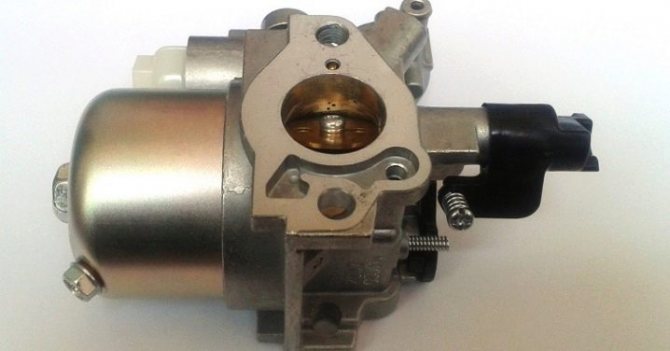

Carburetor

What is a carburetor and why do you need to adjust it? A carburetor is a small device designed to produce a fuel-air mixture. This mixture, with the help of a piston and a spark plug, will be maximally compressed and ignited, and the engine will start and continue to operate.

Carburetor adjustment must be carried out after the first working season.

Carburetor adjustment is one of the mandatory points included in the “maintenance” section of the unit. Thanks to timely inspection and repair, the service life of the cultivator will increase. In addition, inspection and adjustment are also necessary when the engine roars strongly for no apparent reason.

Before we start setting up, we need to familiarize ourselves with the design of the carburetor of the “Mole” cultivator:

So, to debug the fuel supply and ensure the required speed, you need to turn to two screws: the number of revolutions (in Fig.) and the quality of the fuel (Fig. ). Using these two screws, we adjust the fuel supply to the carburetor of the “Mole” motor-cultivator at idle speed. You must act very carefully; first check the state of the ignition.

Important! Thoroughly clean the carburetor, where necessary - strip it, wash it, where necessary - change parts. Then the Mole motor cultivator will serve you for a very long time.

Owners of the unit are often interested in how to start the “Mole” cultivator after winter. The reason for the lack of ignition is condensation in the carburetor that has accumulated during inactivity at changing temperatures. Complete disassembly of the device and further cleaning will help solve this problem. All kinds of additives found in low-quality fuel and dust that has seeped through the filter will also not contribute to the operation of the device.

Gearbox

The main task of the gearbox is to transmit torque from the engine to the shaft. The transmission of motion is carried out using a V-belt transmission. You can learn more about the design and repair of the gearbox of the “Mole” motor-cultivator by watching the video.

Video review of the Mole motor-cultivator gearbox

Reverse

The first modifications of the “Mole” are not equipped with a reverse function (reverse speed), which somewhat affected their performance characteristics and ease of working with such attachments as a cart, snow blower, mower, etc. To modify the “Mole”, the manufacturer released new modifications of it , already with a reverse function, which significantly increased the mobility of the cultivator.

Video review of the reverse function on the Mole motor-cultivator

Drive belt

The drive belt transmits torque from the engine to the gearbox. The cause of breakdown of the “Mole” motor-cultivator is often a rupture of the drive belt. This occurs due to the belt jamming during operation due to heavy loads on the working parts of the cultivator (hard soils, blunt cutters). The cutter bends and catches the belt with the knife, thereby rendering it unusable.

Drive belts for the “Mole” cultivator can have various modifications, but their dimensions are strictly defined: