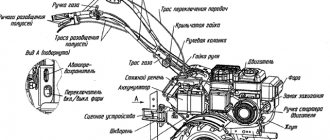

Attachments for the Neva and Neva mb 2 walk-behind tractor

The timeliness and quality of work on your summer cottage or garden can only be ensured if you have reliable and high-quality equipment. Today, manufacturers from around the world offer a lot of small-scale mechanization equipment designed to make work on the land easier. The most common among them are cultivators and walk-behind tractors.

Walk-behind tractors are rightly considered the most functional machines. Usually, it is advisable to buy attachments for Neva walk-behind tractors along with it. Effective work on the site is determined by what kind of unit you have and what attachments you want to use. A heavy walk-behind tractor will most likely disappoint you when carrying out agrotechnical care of plants (for example, weeding, loosening the top crust of the soil) at the dacha or in the garden. Using such a machine in a small area will be unprofitable and ineffective.

- First: in order for the walk-behind tractor to move freely between the rows, you will have to leave only one pair of cutters. However, the weight of the cutter will press them deeply into the ground, in fact the cutters will sink into it.

- Second: the walk-behind tractor is quite difficult to hold between the rows. It always falls on its side and damages plants in the aisles.

- Third: the cutters of walk-behind tractors rotate at a speed insufficient to completely destroy the weeds.

Therefore, before purchasing, it is necessary to clearly determine for which jobs it will be used. It may be that a powerful walk-behind tractor will require a lot of additional equipment, which, if not in full demand on the site, will be too expensive.

Harrowing with special equipment

In this case, cultivators were considered, as well as a hitch for a walk-behind tractor, but additional attention should be paid to the process of plowing the land:

- The work is being carried out in stages.

- A cultivator is attached to the equipment directly on the site.

- Then, by moving special equipment along or across the site, the soil is plowed.

This procedure is carried out before the actual sowing of agricultural land, as well as after harvesting, in order to significantly simplify the procedure for soil cultivation next year.

Important! If necessary, loosening the soil is carried out in two stages (the soil is dug up separately, and then loosened to small lumps).

Attachments for the Neva walk-behind tractor video

If you want to get a universal agricultural machine from the Neva walk-behind tractor, then a set of attachments for the walk-behind tractor will help to significantly expand its capabilities. The attachment to the Neva walk-behind tractor will allow you to perform tasks of various types of complexity, from plowing the soil to cleaning the site, watering it, etc.

At the link below you can watch a video showing the operation of various attachments on the Neva walk-behind tractor.

Speed reducers

The creeper is designed to increase the traction force of the unit by increasing the torque. For the Cascade walk-behind tractor, as for other units, the speed reducer is selected based on the power of the unit itself.

Creeper "ZIRKA-135"

That is, to a 6 hp walk-behind tractor. you need a device marked “for cars with a power of 6 hp.” For the Cascade walk-behind tractor, you can use Zirka creepers - 105-135 (width 50 cm, length 24 cm, weight 17 kg), Pubert, Solo, Husqvarna, Viking, Robix, TM Yarilo and others.

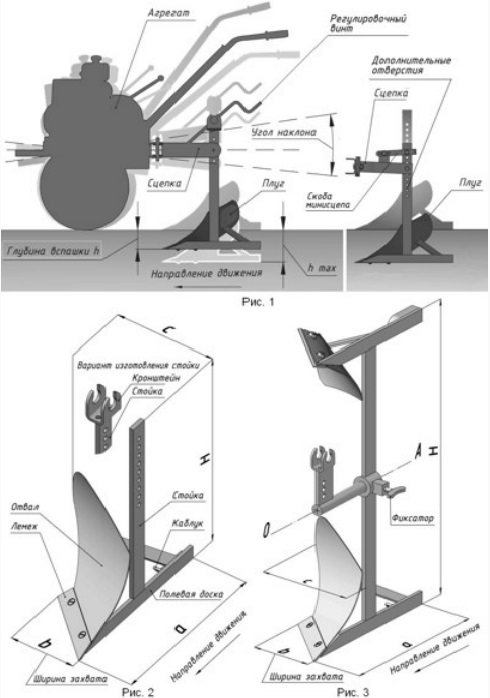

Reversible plow for walk-behind tractor Neva descriptions and advantages

A plow for a walk-behind tractor is used for plowing the ground, turning over the formation, as well as burying mineral and organic fertilizers. Plows for walk-behind tractors come in three types:

- The single body plow has one share and is suitable for plowing light soil.

- Reversible or reversible plows immediately turn the soil over thanks to their feather-curved shape. This plow can work on relatively hard soil, which, after plowing, becomes more crumbly and easier to further cultivate. There is practically no chance for weeds to grow in such soil.

- Rotary. Has several blades.

The design of a reversible plow is quite complex to manufacture, and only a professional can do it. This is due to increased requirements both for materials and for the process itself.

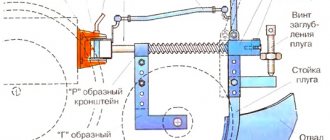

Zykov's reversible plow

One of the most widely used mounted plows is the Zykov reversible plow, which contains:

The right and left-side plow body, having a ploughshare for cutting the soil and a blade for wrapping and crushing the cut layer of soil;

- Rack for attaching the plow to the beam;

- A field board that rests against the wall of the furrow and ensures stability of the plow during operation;

- Support ski for stability of the plow;

- A feather that adds to the layer of soil to obtain a continuous arable land;

- Rotary mechanism with locks securing the plow bodies;

- Support wheel.

The reversible plow is attached to the Neva walk-behind tractor using an additional bracket KR-20N.

Assembly

The assembly of this structural element includes the following algorithm of actions:

- first of all, a strong, solid frame of the required dimensions is welded;

- the required number of fingers is prepared;

- structural elements are evenly welded to the frame;

- can be used for assembly with screws and nuts;

- then the coupling mechanism is welded;

- at the end the hitch is welded or screwed to the frame.

If necessary, additional attachments can also be machined for plowing and loosening the soil.

Motoblock Neva attachments - potato planter types and purpose

The demand for potato diggers for walk-behind tractors is growing steadily, which is not surprising, since they reduce the time of digging up potatoes many times over. There is a wide variety of attachments designed for digging up root crops, which, depending on the type of walk-behind tractor, allow you to process an area of up to one and a half hectares per shift.

At the same time, the quality of digging, in terms of damageability of tubers, is quite high, and even a teenager can work with a potato digger. Potato diggers are divided into single-row, double-row and three-row, which is determined by the number of simultaneously processed rows.

Vibrating-screen potato diggers

Vibrating potato diggers with a screening mechanism are compatible with all types of walk-behind tractors that have both water and air cooling. This potato digger is attached to the walk-behind tractor using a coupling unit. A potato digger for a vibrating-screen type walk-behind tractor digs up fruits, sifts the soil and places the dug potatoes on the soil surface.

Unlike a conventional potato digger, which can damage tubers, a vibrating digger gently lifts the soil and sifts it. The entire crop is removed, leaving practically nothing in the ground. Vibrating-screen potato diggers work well on soils of medium complexity and on light soils.

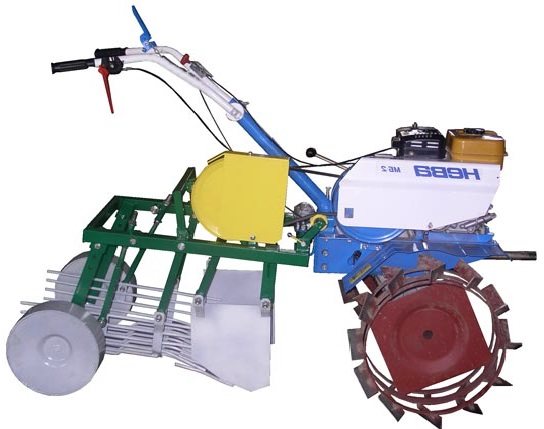

Potato digger for the Neva photo

The photo shows a single-row vibrating potato digger for the Neva walk-behind tractor, designed to mechanize the process of digging up root crops. Contains an active knife and a screen (screening mechanism).

By means of a belt drive in relation to the knife, the vibration of the screen, mounted on double ball bearings, is carried out. After finishing working with this potato digger, you will only need to collect the tubers manually.

It can also be used when harvesting beets, onions and garlic. The digging depth can be adjusted using support wheels. When adjusting the engine speed of the walk-behind tractor, the speed of soil sifting also changes.

Potato digger for walk-behind tractor Neva

A potato digger for the Neva walk-behind tractor of a vibrating-screening type will become your universal assistant in harvesting. By purchasing or making it, you will save energy, time and health, and, finally, enjoy the process of harvesting potatoes.

The use of special equipment will greatly facilitate this task both in a small summer cottage and in a large farm.

The main components of a potato planter are a bunker, as well as spoon-disc devices for planting. Each of the bunkers contains augers that feed the tubers directly to the planting apparatus, as well as shakers. All working elements are driven by a power take-off shaft.

Advantages of using a walk-behind potato planter

A potato planter will help plant potatoes evenly and at the required depth. The figure below shows a single-row potato planter APK-3, which is easily attached to various models of walk-behind tractors

The potato planting step is regulated by a specially designed mechanism using replaceable sprockets included in the planter kit. located on the Reliable and high-quality belt, driven by a chain drive, contains cups for collecting tubers.

Planting potatoes in 50 or 100 mm, recommended tuber size 40 mm, hopper capacity 20 liters, adjustable angle between hillers, step for planting potatoes in a row: with a gear with 14 teeth, a step of 190 mm, with a gear with 16 teeth, a step of 210 mm , with a gear with 18 teeth, the pitch is 250 mm, with a gear with 19 teeth, the pitch is 280 mm. The track width of the impellers is 550 or 650 mm, dimensions LxWxH 970x540x700, weight 41 kg.

A single-row potato planter is used for planting potatoes on previously prepared soil. It can be used on summer cottage plots of 5-10 acres, and on large farm fields of several hectares or more.

Hiller for walk-behind tractor Neva

Surely, many who have worked in the garden are familiar with such a gardener's tool as a hiller. This tool is hung on a walk-behind tractor, then pulled between the rows of plants. You drive a walk-behind tractor with a hiller between the potato beds, and with its wings it effortlessly sprinkles soil onto their roots.

Hillers are also used to form furrows for planting, to better loosen the soil and to top up plants. This unit also helps with soil cultivation.

How to choose hillers for a walk-behind tractor

There are hillers with a fixed or adjustable working width, as well as disk hillers for walk-behind tractors. If there are two or three hillers in front of you in the store at the same time, then you will not immediately decide which one is better to buy. What if there is even more choice? What type of this tool should you prefer?

Some will say that the safest thing to do is to try all the hillers in the garden and then make a choice, but you will also have to pay a lot for several pieces. The features of the most common hillers for Neva walk-behind tractors are described below.

Hiller with variable working width

The advantages of such a hiller over a hiller with a fixed working width are quite obvious. The figure shows a hiller for walk-behind tractors "Neva", "Oka", "Ugra", "Cascade".

As practice shows, such a hiller has the disadvantage of partially shedding the earth into the furrow. It’s a shame when you and your assistant, the walk-behind tractor, spend so much effort raising the soil to the plants, but it crumbles down into the furrow. So such a hiller is also not suitable for every gardener, and you need to think carefully before buying it.

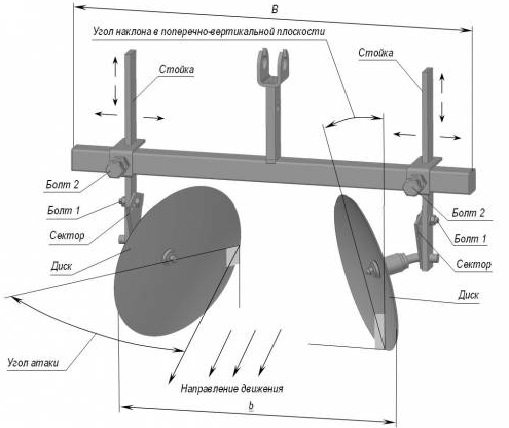

Disc hiller

The disc hiller is the most convenient and effective device due to its design. It usually costs more than its counterparts of other types, but this price is quite fair. The ridges after such a hiller turn out to be higher. Once you've worked with it, you probably won't want to work with other types of hillers.

The figure shows a disk hiller for walk-behind tractors “Neva”, “Oka”, “Ugra”, “Cascade”.

The height of the ridge is increased by bringing the disks closer together, increasing the depth and angle of attack of the disks. The height of the ridge is reduced by moving the discs apart, reducing the depth and angle of attack of the discs. To work with a hiller, the walk-behind tractor must be equipped with lugs to ensure reliable adhesion of the unit drive to the ground.

DIY disc hiller video

Homemade disc harrow

Designs with a disk mechanism can also be made independently. To do this you need:

- prepare the main frame of the structure;

- prepare attachments (disks);

- manufacture rotation mechanisms;

- prepare a trailer attachment;

- subsequently all this is combined into one mechanism.

Here it is necessary to take into account that the plowing disc is hung at the beginning of the frame, and the loosening element is mounted at the end of the entire structure.

This is interesting: how to make a harrow for a walk-behind tractor.