Principle of operation

If we consider the principle of operation of the trimmer, then it is similar to a manual scythe. The difference is that it is equipped with a motor, with its help the cutting element is rotated.

Manufacturing companies produce the following models of mowers:

- On which a gasoline engine is installed. These garden tools have a fuel tank, this is their distinctive feature.

- Devices with an electric motor. These tools are lighter because they do not have a fuel tank. But when choosing such models, you need to take into account that they require a power source to operate.

All electric scythes can be divided into those that run on batteries and models that are connected to the electrical network. Each type has its own characteristics, but they affect the power supply. If you do not take it into account, the remaining parts of the design are similar for different devices.

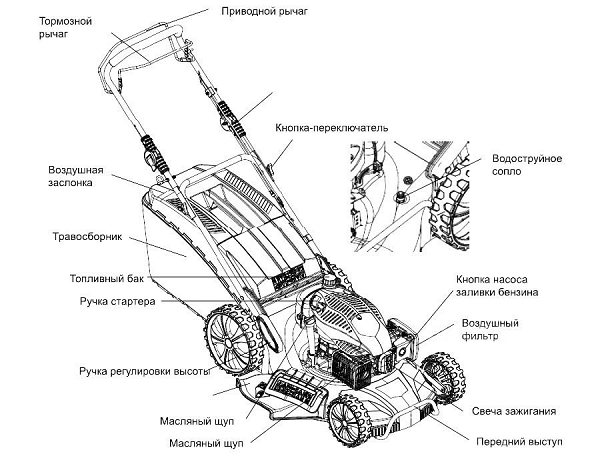

If you take any trimmer model, it consists of the following elements:

- motor;

- fuel tank (gasoline brush cutters do not have one);

- levers that control the mower;

- knife for cutting grass;

- barbell;

- a spool with a wound line used to cut grass;

- protective casing;

- bevel gearbox.

The engine is placed near the mowing head and can be installed from below or from above. Only those models that have a straight rod have a gearbox. If it is curved, then the main bearing becomes the connecting element. It consists of 2 bushings.

A fishing line is used as a cutting device. It can be easily replaced with steel knives and discs; they can be made of plastic or metal.

The choice of cutting element depends on how hard the grass will have to be cut. Most often, fishing line is used in the work; it is called cord. There are products of different shapes on sale; spiral and round ones are in demand among buyers.

The fishing line is wound onto a reel, it is inserted into the bobbin, while the 2 ends of the wire remain free. When the mower engine starts running, the bobbin rotates and the grass is cut with the free ends of the line.

Manufacturers

When choosing an oil, you should pay close attention to its manufacturer. It is better to choose a brand that is recommended by the lawn mower manufacturer. In the equipment instructions you can find information about the oil filled, the frequency of its replacement and recommendations for choosing a working fluid.

Additionally, many lawn mower manufacturers make their own oils, which will need to be replaced if you want to honor your equipment warranty. In addition, the instructions provide general characteristics that the oil must meet. When choosing a fluid replacement, you need to focus on this list. This will allow you to select the oil that best meets the manufacturer's requirements.

- Among all the companies that present their products on the Russian market, the best are Shell Helix Ultra . These oils are popular in all countries. Shell specialists have been working for 40 years to create a unique technology for producing synthetic oil from natural gas. The resulting product is characterized by an improved composition, which currently has no analogues. The manufacturer adds the necessary additives to the base composition, which allows you to obtain products with different characteristics. This oil should only be purchased at specialized retail outlets, as major fakes are often found.

- The company also presents quality products. Molly liqueur . The manufacturer produces several product lines that have different purposes. This range includes products for the care of garden equipment. Such oils are intended for long-term operation of trimmers and lawn mowers; their technical characteristics are developed in accordance with the features of modern technology and manufacturer recommendations.

READ How to Adjust the Belt on a Lawnmower

Liqui Moly adds additive packages to lawn mowers that are essential to reduce equipment wear and keep engines clean. The main advantage of such liquids is environmental friendliness, since they are created on a plant basis. Liqui Moly lawn oils comply with all environmental standards.

The Razenmacher company produces a good mineral lubricant that has been specially developed for gardening equipment. This tool can be used to service 4-stroke engines with various cooling systems. Rasenmacher can only be used at positive temperatures. The manufacturer has carefully developed and selected additives for its product. The result of these actions was a wide range of functionality:

- Maintaining pressure in the system at a stable level;

- Effective lubrication of all necessary parts;

- Maintaining oil viscosity throughout its service life, until the next replacement;

- Providing excellent engine protection against natural wear;

- Minimum evaporation rate.

How to use a trimmer correctly

Garden trimmers are efficient. Beginners think that operating a lawn mower is easy because you just need to plug it in or add fuel, but this is not entirely true.

The performance of a garden tool and its service life directly depend on operating conditions. Therefore, before using the trimmer, you need to do some preparatory work.

The lawn from which the grass needs to be mowed is carefully inspected. Be sure to remove glass and large stones. If they fly out from under a running mower, they can injure a person. Wire is removed from the lawn, because it can get wrapped around the rotating element and break the mower.

After this, they proceed to installing the cutting system. There are low-power trimmers on sale that use only fishing line. It is designed for mowing succulent and soft grass. But there are models with a power of more than 1 kilowatt, on which metal knives are installed. They are used to cut thistles and other tough weeds and trim young bushes.

In order to replace the cord with knives, you need to unscrew the fastening nut and install the cutting element. Then the nut must be returned to its place and tightened with a wrench.

The operator must take care of his own safety. When mowing grass, you need to wear thick protective clothing. To protect your eyes, use special glasses; they will protect you from dust, grass and flying debris. Hands are covered with gloves.

The electric trimmer is plugged in, and battery models are charged for several hours before use. Fuel is poured into a gasoline mower.

The mower is held so that the spool or blade is parallel to the ground. When the tool is installed in the correct position, turn on the motor. After the grass is cut, the mower is turned off.

First start

Before the first start, the operator assembles the mower; the procedure is described in the instructions that come with the product.

If the trimmer is gasoline, it must be checked before use. The fuel tank is filled up to the neck.

The engine needs to get used to the fuel, so when first started it should run for several minutes without load. After this, start mowing the grass.

Run-in

Gasoline mowers must be tested before use. The operator turns on the engine and lets it idle for a while. It is necessary to ensure that the engine does not overheat, there should be no load.

When running the lawn mower, the load is increased gradually. If you start work at high speeds, the motor will not run in well, which will affect the further operation of the mower.

When starting for the first time, you should not completely exhaust the temporary resource. After the engine is idling, you can proceed to cultivating the lawn. The brush cutter should run for no more than 15 minutes, after which the motor should be turned off and allowed to cool down.

If you need to break in an electric trimmer, first assemble the braid. Then do test runs at least 3-5 times. If the engine is running well, move on to mowing. At first they work for no more than 5 minutes, then the duration of work is gradually increased.

How to put on a belt

If the tool has a shoulder mount, hang it on your shoulder before starting work. The trimmer is fixed on both shoulders if it has a backpack mount.

The model with a bicycle handle is held with 2 hands, the D-shaped handle is clasped with the palm of your hand. The belt should be worn so that it is comfortable, then your back will not get tired.

How to mow the lawn so that it is smooth

To ensure that the grass on the lawn is cut evenly, you need to lower the mower as low as possible while working. The area must be divided into squares. You need to work moving clockwise. In this case, the hay will always lie on the left, without getting in the way under your feet.

Mow for hay

It is better to mow hay not with a fishing line, but with a metal disc. The grass is cut at the root, maintaining its length as much as possible.

Mowing tall grass

If you need to mow tall grass, this is done in several passes. Treat the lawn 2-3 times. The rotating part is lowered from top to bottom, in this case the grass is not wound onto the reel.

The operator must remember that grass wound on a reel will cause the motor to overheat. If this happens, the lawn mower is turned off and the reel is cleaned.

It is most effective to mow the grass with the ends of the fishing line, rather than the entire length. In the second case, the tool works worse, and the motor may overload. If you need to trim the grass over a large area, the trimmer should be tilted towards the mowing side to increase efficiency.

Operation in wet weather

Electric mowers cannot be used in the rain, as there may be a short circuit. When the precipitation stops, you need to wait for the grass to dry.

Not all gasoline mowers are protected from moisture, so some manufacturers prohibit the use of mowers in the rain.

Mowing duration

An electric grass trimmer can be used for no more than 20 minutes, after which you need to take a break for the same amount of time. Violation of the operating mode has a negative impact on the engine, reducing its service life.

How to use electric lawn mowers?

The use of these devices involves not only mowing the grass, but also maintenance before and after mowing .

In addition, new devices also require proper assembly, since most of them come as separate units located in a common box.

Since the assembly methodology for each model is different, we recommend that you carefully read the relevant section of the device's operating instructions, which is also often called the user manual.

Preparing for work

Before starting work, begin an external inspection of the device, paying special attention to the integrity of the insulation of wires, including extension cords; in addition, do not forget to check all threaded connections. In addition, carefully inspect the mower body for cracks or dents; do not use such a device; first you need to disassemble it and check the condition of the internal parts and mechanisms.

READ How to Use a Trimmer Line

If everything is in order, place the device on a flat surface, connect the extension cords to the outlet and turn on the engine - the mower should operate without shock or vibration . After 10-20 seconds, if there is no smell of smoke, turn off the engine and disconnect the extension cords from the electrical outlet.

If there is:

- Vibration

- Knocking;

- Some unusual sounds;

- The smell of smoke,

First, eliminate their causes and only then, after passing the next test, start mowing the grass. In addition, do not forget to check the condition of the cutting edge of the knife , unplug the device and wait for the motor shaft to complete.

On drum mowers, check the condition of the drum blades and the sharpness of the blade, if sharpened, by strictly following the operating instructions.

If you plan to work with a grass catcher, check its condition and install it on the mower to make sure it fits snugly.

If you find that the grass catcher is loose, troubleshoot and correct the cause, most often it is grass that was not noticed during harvesting.

Also check the ease of rotation of the wheels; if one or more of them rotate tightly, then check the condition of the bushings or bearings, and if necessary, clear them of grass.

If the owner's manual recommends lubricating bushings or bearings, do so with the least amount of rotational resistance possible.

Additionally, remove any solid objects from the area , including:

- Sticks;

- Branches

- Fittings;

- Large and medium stones.

Lawn mowing

Let's move on to the question of how to mow the grass. Start cutting the grass by unwinding the extension cord and placing it in the large loops to avoid twisting when removing the mower from the socket. You can put it with a snake or any other way, as long as when you remove the lawn mower, it does not get tangled or interfere with the lawn mower.

Next, set the optimal cutting height for that section, and then plug the cable into the outlet first, then the mower into the cable .

On the vast majority of models, the engine is started using a button and lever; this is described in more detail in the operating instructions. After starting the engine, move the lawn mower away from the outlet, carefully push the non-propelled model in front of you due to physical force, activate the self-propelled drive using the special lever.

The speed should be such that even a collision with thick grass does not reduce the engine speed (they are controlled by the ear). If the speed drops and the sound of the mower changes, stop moving forward and turn back a little , then continue moving forward, but at a lower speed.

When working in rear discharge mode, including with a grasshopper installed, the snake is the optimal method in this area.

To do this, first move along the edge of the area as far as possible, then turn the lawnmower and move to the side cutting width, then move the device into the socket .

When turning right, the extension should be to the left of the mower; if on the left, then on the right. To reduce the likelihood of the wire getting under the knife, it can be thrown over the elbow of the corresponding hand. That is, when turning to the right, turn your left elbow, and when turning to the left, turn to the right.

When working in side discharge mode, the cable should always be on the opposite side, and to reduce the likelihood of being caught under the knife, it can also be thrown over your elbow.

When working with grass, pay attention not only to the content indicator, but also to the sound produced by the lawn mower. If the sound has changed but there is no area with thicker grass, then the grass catcher is full, so you need to stop the engine and remove the grass clippings.

What clothes to wear

The choice of clothing affects the safety and efficiency of mowing your grass.

So work with the lawnmower:

- Long sleeve button down shirt;

- Long trousers made of thick fabric;

- Shoes that cover the foot with durable corrugated soles;

- Glasses or mask;

- Hat or cap (on a hot sunny day).

How long can I use?

The optimal operating mode for each model is described in the instructions for the lawn mower.

If for any reason this document is not available, then follow the 15/10 rule , that is, cut the grass for 15 minutes and then wait 10 minutes for the engine to cool.

However, this mode is only optimal for cutting grass that is less than twice the cutting height of the lawn mower.

- Higher vegetation;

- Has a thick stem;

- Grows densely (field grass, including shrubs)

Then working hours should be reduced by 2-3 times.

Avoiding overheating of the engine, checking its temperature after each period of operation will help to do this:

- Release the engine start lever;

- Disconnect the lawnmower plug from the extension cord;

- Touch the engine with your back hand.

How to use a lawn mower trimmer

Surely many owners of summer cottages have encountered the problem of clearing weeds from a certain area where, for example, fruit trees grow densely. Using a regular scythe here is not easy - you can’t swing it, a hoe is time-consuming and labor-intensive, and a lawnmower won’t get through. But there is still a way out: you can use a trimmer (motor mower), which has long been used abroad for cutting grass in hard-to-reach places.

Before purchasing or renting a trimmer or brush cutter, you need to decide for what purpose you need it. If the intended area for mowing grass is from four to six acres, then it is better to use a trimmer. If the area of the cultivated area is more than six acres, you need a lawn mower. Today we will focus on the first option – the trimmer.

There are two types of trimmers: electric and gasoline.

The first ones are less powerful, suitable for work in a summer cottage, where it is possible to connect to the electrical network for direct power supply or recharging batteries.

The latter are equipped with gasoline engines, they are more autonomous and are suitable for those gardeners and summer residents who do not have the opportunity to connect to an outlet. In addition, in terms of energy reserves, gasoline trimmers give a head start to electric trimmers - they work 10-15 minutes longer than plug-in trimmers.

Gasoline trimmers

As a rule, gasoline trimmers are equipped with two-stroke engines, the power of which is about two horsepower / 1.5 kW. Based on the location of the engine, such devices are divided into top-propelled and backpack-mounted.

Top-engine gasoline trimmers (gasoline tools) are suitable for mowing grass in small areas with uneven terrain. Due to the fact that the engine on such a device is located on the top of the handle, it is convenient for them to balance and reach hard-to-reach areas. Such trimmers, in particular, are produced by the German company Solo.

For example, the Solo 142B model is designed to work in large areas with uneven terrain. It has an ergonomic handle, similar to a bicycle handlebar. At the top of the trimmer there is a two-stroke, 2.6-horsepower motor, and at the bottom there is a cutting mechanism. Depending on the hardness of the grass being cut, you can use one of two cutting tools: a three-pronged knife (for tough grass, small shrubs) or a fishing line (for thin-stemmed weeds). The fuel tank volume of this trimmer is 0.7 liters; on average, this amount of fuel is enough for 45-60 minutes of operation.

Trimmers with a backpack engine and a flexible shaft are used for mowing grass in large areas. They are more convenient to use, since their engine (with a power of about 2.5-3 hp or more) is attached to the back, which allows the mower not to get tired while processing large areas.

The model of the Italian company Oleo-Mac 446 BP Ergo is an example of such a backpack device. The vibrations of the powerful motor (2.8 hp) mounted behind the back on special backpack mounts are practically not felt during operation - thanks to a special vibration suppression system. The fuel tank of the device has a volume of 1.5 liters, which is enough for 1.5 hours of operation. The set of such a device includes several types of knives, which allows you to remove grass of any hardness, bushes and even small trees.

Electric trimmers

This type of trimmer is what any gardener who has a small garden plot needs to mow soft-stemmed weeds or lawn grasses. According to their design, electric trimmers are divided into top- and bottom-motor.

Top-engine electric trimmers, following the example of gasoline trimmers, are designed for mowing grass in areas with uneven terrain. Another important distinctive feature of such devices: they can mow wet grass, while this is contraindicated for lower-motor electric trimmers - there is a risk of short circuit.

An example of a top-motor trimmer is the model of the German manufacturer of garden equipment Gardena - ProCut 800. The device is equipped with an 800-watt electric motor, which is powered from an outlet. They can process small areas of up to six acres. The cutting mechanism is a fishing line.

Bottom-engine electric trimmers are usually equipped with small-capacity rechargeable batteries, and such devices are intended for mowing grass in areas with flat terrain.

The Gardena AccuCut 400 Li model is equipped with a lithium-ion battery (18 V/1.6 Ah) and is designed for short-term (the charge is enough for 30 minutes of operation) mowing grass on flat areas. The rotary handle of the device helps to mow the grass at the edges of the lawn.

How to use the trimmer

Step 1: Install the cutting mechanism.

Depending on the type of weed, we select a cutting tool: for soft-stemmed grasses - fishing line, for hard-stemmed and small shrubs - a knife. Unscrew the nut securing the cutting mechanism and install the cutting tool. Tighten the nut - the mechanism is ready for operation.

Note: Some trimmers do not have replaceable cutting tools, so you can start using them right away.

Action 2. Preparing the trimmer for work.

If the trimmer is electric, charge the battery or plug in the motor. If it is gasoline, fill the tank with fuel. Then, depending on the type of trimmer, we adapt it to ourselves (upper motor – hung with a loop on the shoulder, backpack – by the shoulders, lower motor – we take hold of the handles). We hold the trimmer above the grass so that its cutting mechanism is parallel to the treated area. Let's start the engine.

Action 3. Mowing.

Cutting grass with a trimmer is carried out with simple movements. It is important to remember that the cutting mechanism of the device rotates counterclockwise, so that the grass clippings will fall onto the already processed area. The first is from right to left in front of you (this is how we cut off the top of the grass). The second is from left to right (this is how we remove the remaining grass).

It is better to divide a large area of the cultivated area into squares, and mow the grass on them, moving from one to another along the outside of each square.

When mowing grass on slopes, it is recommended to mow from below, moving parallel to the sloping area. We reached the edge, came back, stood a little higher - and repeated the same route - until the site was completely mowed.

To mow grass in an area where there are trees, it is better to use a line cutting mechanism, and you need to mow along the perimeter of the area, going around the tree around the trunk.

Action 4. Finish work.

After finishing mowing all the grass in the area, you need to turn off the engine, remove the trimmer (for shoulder and backpack devices), and clean the cutting mechanism from grass residues.

How to mow with a lawnmower

Any advertisement presents a modern lawn mower as a universal tool that can do the work of a dozen mowers in an hour. In addition to high productivity, the lawn mower allows you to obtain good quality lawn and mow successfully, regardless of qualifications, with relatively little physical exertion. But working with a lawn mower is not so easy; it requires certain skill in operating the machine and good knowledge of the terrain.

Practice working with a lawn mower

Any complex technical device requires some time to get used to. If you have not had experience working with any type of mower, the first thing you will need to do is study the instructions in order to clearly understand which levers and knobs are used to control the lawn mower engine, and which ones are used to adjust the cutting parameters. In addition, you will need to learn how to adjust the position of the cutting edge of the lawn mower so as to mow the grass in an even and neat layer, leaving the required 3-4 cm of vegetation throughout the entire area.

Adjusting and starting the lawn mower engine

Maintenance and adjustment of engine speed is considered to be the most difficult stage in preparing a lawn mower for work. Therefore, before starting to fight with complex equipment, even if you have some experience, be sure to read and re-read the operating instructions. A typical procedure for preparing a new motor for operation looks something like this:

- The lawn mower must be placed on a flat and solid surface, with all folding elements and handles screwed into the working position. The wheel drive lever must be turned off. If your mower is equipped with a spark shut-off system, be sure to set it to the off state;

- It is necessary to mow only with an absolutely working lawn mower, so before starting the engine, you need to inspect it and make sure that there are no oil or fuel leaks. Using a gloved hand, check the tightness of the chip on the spark plug and begin filling with fuel and oil;

- Filling liquids is carried out using dipsticks; for the engine oil sump it will be necessary to fill the lubricant according to the middle measurement, no more. If you overfill, liquid may squeeze out of the vent or through the gasket;

- Be sure to change the oil after break-in. If you decide to use semi-synthetics, do not switch to mineral water, and vice versa. For approximately the first 20-30 hours after running in the engine, you need to mow the grass at medium and low speeds. The performance will be low, but in the end you will significantly gain in the service life of the motor; after just a couple of mowings you will be able to mow in normal mode.

What kind of oil should I put in my lawn mower? High-quality mineral or semi-synthetic. The most correct thing to do would be to follow the manufacturer's recommendations rather than follow the advice of the motor oil seller.

Do not believe the fables of sellers and advertising slogans about preliminary running-in of engines at the enterprise. This procedure is fully carried out at the enterprise only for powerful high-speed motors with a high degree of boost.

The easiest way to mow is with high-octane unleaded fuel, but only if you are 100% sure of the quality of the gasoline. The lawn mower engine keeps speed well and practically does not heat up. American and Chinese engines work fine on the A-92, European versions may be more capricious in the choice of gasoline. For two-stroke engines, gasoline is mixed with special oil in a ratio of 50:1.

We start the engine in the following sequence:

- Before starting, we check the position of the lawn mower's motion control handle; the transmission must be turned off, otherwise, at the moment the engine starts, the mower will begin to move and mow on its own. Turn off the power to the magneto or ignition system and turn the motor shaft several times using the starting cord or using the starter.

- We turn on the ignition, close the choke and try to start the engine.

- If the start does not work, turn off the ignition, open the air damper and, after turning the shaft with the starter for a few seconds, ventilate the combustion chamber.

- After successfully starting the engine, move the gas control lever to a position corresponding to the speed between medium and lowest.

The lawn mower engine should only be started if there are no fuel leaks at the pipe connections.

Almost all models have the ability to mow and dump grass into the grass catcher, so we choose a convenient place to park the lawn mower in order to remove and unload the grass box and re-equip the machine or simply inspect it if necessary. There will also be fuel, tools and spare spark plugs.

Adjusting the lawn mower blades

Before you start mowing, adjust the height of the blades above the ground level. Most often, the mower body is raised above the grass with one handle, less often with two - for each pair of wheels, this helps to mow lawns with very dense and heavy grass.

The heavier the mower body, the lower the cutting edges can be. Most often this is a value of 20-25 mm. It is good to mow soft grass with a low position of the cutting plane; for hard and high grass, it is necessary to adjust not only the ground clearance, but also the angle of inclination of the lawn mower body.

Leaning forward helps compensate for the mower tilting backward if you push the handle too hard. Especially if the grass is wet, it is difficult to mow and the rear drive wheels may slip. For a front-wheel drive lawnmower, this tilt only degrades the mower's performance, causing skipping and leaving the surface uneven.

Handle adjustment

Modern lawn mowers make it possible to adjust the position of the handle to suit any height or characteristics of a person’s constitution and physique. It is easiest to mow and guide the cart if your hands on the handle are at the level of the center of gravity of the body or 2-3 cm higher.

If the lawn mower is heavy, the control handle requires quite a lot of force, so when choosing a model, choose a design with an aluminum or steel tubular frame.

This is especially true for front-wheel drive lawn mower models. Owners of mowers with a driven front end like to hang the front axle, thereby reducing traction and correcting the direction of movement of the machine, turning the body on the rear axle with the handle in the desired direction.

How to mow without making big mistakes

First of all, you need to mow without putting too much extra force on the control handle. The lawn mower was designed without taking into account such overload on the rear axle. For the front-wheel drive version of the mower, this degrades the cutting quality. When working on a rear-wheel drive version, such “assistance” wears out the transmission and leads to the appearance of potholes in the lawn, making mowing more difficult. In addition, this can easily damage the blade, motor, or cut grass on the ground.

The art of mowing with a lawnmower comes with practice. Most often, the direction of movement is adjusted by moving the handle left or right. In particularly difficult cases, you can even mow along a complex trajectory by slightly tilting the lawn mower body to the left or right, increasing the traction of the wheels on one side and loosening it on the other. Control techniques are simple, but require practice and skill.

It is considered the most difficult to mow near a curb or fence. This kind of work requires accuracy and a good eye. Most often, damage to knives occurs when trying to mow in areas interspersed with crushed stone or under the edge of a stone blind area.

How's the mower?

The basis of any device of this type is:

- Powerful frame;

- The four-stroke gasoline engine is frame-mounted;

- A deck with a cutting blade, which is directly or via a friction drive connected to the motor shaft;

- Chassis, that is, wheels attached to the frame through a shaft with bearings, including sliding ones (hub-shaft) or with bolts;

- Transmission (self-propelled only);

- Folding handle with controls installed on it.

The frame is the backbone of any lawn mower as it is attached to the engine and other components. On some models, the frame is an integral part of the deck.

The main elements for making a frame are:

- Become;

- Aluminum;

- Plastic.

The steel frame has very high strength, so this device can be used in the most difficult conditions. However, it is very vulnerable to corrosion, which occurs due to the exposure of the frame to water and various substances arising during mowing or rotting caused by poor cleaning of the device after use.

An aluminum frame does not have these disadvantages, since aluminum is inert to water and weak acids , but its production is much more expensive due to the higher cost of the raw material. The wood of such a frame performs only decorative functions.

The plastic frame is very cheap and, like aluminum, is not afraid of water or acids, but its mechanical strength is ten times less than that of aluminum or steel counterparts, so devices with a plastic frame can only be used for a regular lawn mower.

Any attempt to cut tall grass or weeds with them, and also to blow the knife into an unexpected obstacle, will cause the plastic to crack, so over time the whole structure began to vibrate , and then it could fall apart.

Engine

Lawnmowers are equipped with four-stroke gasoline engines of varying power, but the general layout of these engines is the same.

At the bottom there is an oil reservoir (sump) into which oil is supplied and where it flows after lubricating all engine elements.

Above the engine crankcase. The cylinder block and crankshaft with a plain bearing and connecting rod pass through the crankcase through high-quality seals , preventing oil leakage.

The combustion chamber is installed on the side of the unit, i.e. A cylinder and a piston with piston rings, as well as a cooling radiator that removes excess heat from this element. On the combustion chamber side is the engine head, which houses the camshaft and valves.

The crankshaft and camshaft are connected by a chain drive with gears of different sizes, so that in 2 revolutions of the crankshaft the camshaft rotates only 1 time.

The following blocks are connected to the crankshaft:

- Manual or electric starter;

- Generator;

- Ignition system sensors;

- A friction clutch or adapter sleeve that protects the shaft from deformation when the knives suddenly stop.

Engine power depends on three parameters:

- Cylinder diameter;

- Piston stroke;

- Maximum crankshaft rotation speed.

The cylinder diameter and piston stroke form the volume of the combustion chamber, so some manufacturers in the documentation for the lawn mower indicate not horsepower (hp) or kilowatt (kW), but the volume in cubic centimeters (cm 3). ).

It is difficult to determine the most vulnerable part of the engine, because overload damages valves and rings , and when using bad oil or not changing it in a timely manner, the crankshaft plain bearings (liners) and the contact points of the piston and cylinder are the most damaged.

The main purpose of the deck is not only to prevent the grass from spreading in different directions, but also to create conditions for the rotating blade, which blows air, so that it lifts the shredded grass, making it easier to mow.

The pan is made from the same materials as the frame. , and on some models both parts are a single unit.

When cutting grass, the blade rotates at high speed, so it not only cuts the vegetation, but also scatters chopped green matter, including vegetable juice, as well as small seeds or soil if the blade encounters it.

We have already spoken in detail about the activity of these microorganisms (bacteria), as well as about the products that they produce. Organic acids produced by bacteria very slowly eat away at the paint that protects steel floors, and when the paint is damaged, they eat away at the metal, resulting in rust.

Most mowers are equipped with special fittings. , through which the log is washed with a stream of water, and in the absence of such adjustment, the lawn mower will have to turn over and be washed with a stream of water from a hose. Indeed, in addition to the corrosive effects, the green matter adjacent to the inner walls of the deck prevents the creation of a vortex that lifts the grass in the blade area, resulting in a sharp decrease in cutting quality. ,

Chassis

Chassis differ both in the number of wheels and in the way they are installed.

They are divided by the number of wheels:

- Two-wheeled (this chassis is used only for trimming wheels and machines intended for mowing weeds or hay);

- Three-wheeled (such chassis are characterized by maximum maneuverability);

- Four-wheeled.

According to the method of fastening the wheels, the chassis is divided into:

- Bolted connection (the cheapest, but extremely unreliable type of connection, requiring constant tightening of the bolt or nut);

- On a common axis with plugs (this method of fastening is more reliable than bolts, but the plugs must be frequently cleaned and lubricated, otherwise they become clogged with mown grass, which sharply increases the resistance to movement);

- On a common axis with bearings (this is the most reliable and convenient type of chassis, since the bearings are protected from the ingress of crushed grass, as well as from the factory applied amount of oil necessary for the entire service life of the unit).

Transfer method

The gearbox is only installed on self-propelled models, as it transfers rotational energy from the engine to the wheels.

The following gear types:

- Mechanical (belt), the belt of which not only transmits energy to the wheel drive, but also performs the function of traction, connecting the wheels to the rotating engine shaft or disconnecting them.

- Mechanical (variator). It also has a belt that acts as traction, as well as various types of variators that change the speed of rotation of the wheels.

- Hydraulic. Such transmissions can be with or without a belt. Moreover, all the major manufacturers of self-propelled vehicles that we talked about here are trying to develop their own types of hydraulic transmissions, and are also constantly improving their reliability and ease of use.

In manual transmissions, the most vulnerable parts are the belt and gear , but the belt is classified as a consumable item, so timely replacement will protect against serious problems.

Beltless hydraulic transmissions do not have these disadvantages, but they do require the hydraulic fluid to be changed periodically, following the manufacturer's recommendations.

READ How to Properly Wind Line on a Carver Lawn Mower

The handle is complex with controls

On the folding handle, most of the controls are installed , like here:

- Engine stop button;

- Accelerator handle (gas);

- Lever for connecting the knife to the motor shaft;

- Drive connection lever (self-propelled only);

- Lever for changing the driving speed (only on models with CVT or hydrostatic transmission).

All controls are connected to the respective implements and mowers using an electric or cable drive, and both types of drives require periodic maintenance. In addition, the folding handle has a mechanism for changing its height , which allows you to adjust the lawn mower to a person of any height.

How to use a garden lawn mower correctly?

Before using a lawn mower, remember that its sharp blade is a source of danger. Preparation for work, operation, and aftercare are important. Not only your safety, but also the service life of the unit depends on this. By protecting yourself, you will protect your equipment.

Agree, you will not put a person without a license behind the wheel of your car, much less a child. Just like a professional will not allow an inexperienced user to pick up a chainsaw. Is it dangerous!

Do you think this topic does not deserve attention? Then you should familiarize yourself with the statistics: according to the American School of Public Health, every year about 80,000 people consult a doctor after working with a lawn mower, 32% of all cases are associated with amputation of toes.

Preparation

By carefully reading the operating instructions, you will avoid danger. Only after a detailed study of the safety rules can you begin work. Install the handle and attach the grass catcher. If the lawn mower is gasoline, oil and fuel are poured into it. Then set the desired mowing height.

Many units have a safety device. If the machine has a locking system against spontaneous activation, then it starts only after pressing a special button. The button can then be released and the machine will operate as long as the lever is held down. As soon as you release it, the knife will stop rotating. For a gasoline lawn mower, the ignition key should be considered a safety element; without it, the unit cannot be started.

In order to quickly stop the device, you must be well aware of the information presented above.

Before each switching on, it is necessary to check the condition of the knife, electrical cable, and housing for serviceability and absence of damage. Foreign objects such as stones, sticks, etc. should be removed from the lawn - they can damage the machine.

Before work, it is better to wear strong, closed shoes and long trousers. It is better to work in the morning or afternoon, under good visibility conditions. Animals, people, and especially small children should not be nearby.

Storage

Store lawnmowers in a dry, well-ventilated area. For short-term storage, no preparatory steps are required; simply roll up the device in the designated area and fold the handle.

If the expiration date exceeds a couple of months, the device must be prepared for that. Follow these steps :

- Draining gasoline and oil;

- Dry the body;

- Maybe traction and bearings;

- Check and sharpen the knife if necessary.

Draining gasoline and oil

This operation is necessary for two reasons:

- Long-term storage of fuels and lubricants loses some of their characteristics, so starting the engine after a long period of inactivity with gasoline or oil remaining after use this year can seriously damage the engine and shorten its service life.

- If the unit is to be turned upside down or placed in an upright position during storage, fuel and lubricant may leak, contaminating the floor and frame of the mower, filling the area with a strong oil odor and creating a fire hazard.

The method for draining these fluids depends on the design of the mower and is described in detail in the operating instructions.

If there is no manual operation, the mower should be placed on a table (this way fuel and lubricants are drained only after the engine has cooled), tilted to the side at a 45 degree angle and carefully inspect the engine and fuel tank underneath for holes .

If there are none, first unscrew the gas cap and turn the mower upside down to store the gas, then tighten the gas cap.

Before draining the oil, it is necessary to pull the recoil starter 5-10 times without turning on the ignition so that the oil pump supplies oil to all friction parts of the engine, as a result of which they will be protected from moisture until spring. Then you need to unscrew the oil filler cap and turn the device over again, wait until the liquid flows completely, and then return the cap to its place.

Some mower models are equipped with engines whose manufacturers claim that the engines do not need to be replaced with oil, but only topped up. This is not a very fair statement because the engine can run on old oil that is constantly replenished with new oil, but only for a limited time, such as 500 or 1000 hours.

Therefore, before winter, whether to drain oil into mowers with such an engine or not to drain it, everyone will have to decide individually.

If you are putting quality oil into an engine that meets its SAE and other specifications, you can not only drain the old oil but also add new oil, but this procedure must be performed on a hot engine , hence it is only used where there is a special hole.

Then the oil filter is washed with diesel fuel or gasoline (if it is installed on the model and can be washed) and new oil is added, then, without turning on the ignition, disconnect the recoil starter cable 5-10 times to lubricate all friction engine parts with new oil.

Drying the body

Proper maintenance includes washing the body after each use, which makes it very likely that water droplets left on the body will freeze and damage paints or parts in the winter .

Therefore, before leaving the lawn mower for long-term (winter) storage, it is necessary to thoroughly blow out the body from all sides with a blower, paying special attention to the articulation of the wheel axles and bushings, which act as bearings.

If the wheel axles are mounted on bearings, the bearings must be thoroughly blown in all available directions to remove even the smallest particles of moisture.

Preservation of rod and bearing

It is necessary to use WD-40 liquid to treat the inner surface of all cable drives (rods) in order to remove water from them, and then fill them with a syringe of 0.2-0.5 cm 3 of engine oil.

If this is not done, then in 3-5 years there is a high probability that cables will begin to get rid of, which will lead to the inability to slow down the engine and other problems.

Some models of mowers provide lubrication of bearings, including sliding ones (shaft-sleeve) through special grease fittings. Before winter, such bearings should be filled with oil recommended by the manufacturer . Using a syringe for maintenance (extrusion) of the chassis of old cars.

Checking and sharpening the knife

The sharper the knife, the less load on the engine, which means its service life is longer. The most important thing to sharpen a knife is to maintain balance, because if one side is heavier than the other, even by half a gram, it will result in severe impacts that will negatively affect the life of the crankshaft bearings.

READ Petrol Lawn Mower Malfunctions

If it is moved to the side, then sharpening removes more metal from that side, constantly checking the balance. also take the knife for sharpening to a specialized workshop ; we repair and service gasoline mowers or install a new one instead.

In any case, before installing a sharpened or new blade, it is advisable to check its balance, because this is many times easier and cheaper than replacing bearings and a broken engine crankshaft through an unbalanced blade.

General operating rules

After reading the introductory rules, you can start the engine and start moving along the lawn at an even pace, without turning back. You can reverse as long as you turn off the engine. When working on a slope, you need to move along it, and not up and down.

It is advisable to cut the grass when it and the soil are dry. Electric lawn mowers must not be used in wet weather.

If any obstructions occur, turn off the mower and move away from it. If you need to clean the deck, wait until the blade finally stops. Even a special container - a grass catcher - is best cleaned with the engine off. Never leave the lawnmower unattended, especially if children may approach it.

Individual protection means

There are special protective equipment for working with a lawn mower. For your hearing, you can use headphones or earplugs. Hearing impairment can occur with prolonged exposure to sound levels of about 90 dB, which is exactly what lawn mowers have. The loudest models are those with an internal combustion engine; their level can exceed 100 dB. Most manufacturers focus on low machine noise levels.

Use goggles to protect your eyes from dust and small debris. Gloves are a must. They will protect your hands from calluses, especially if there is no rubber pad on the handle.

After the haircut

After use, the lawn mower must be cleaned; such care will ensure the longevity of the device. It is not enough to simply wipe the knife blade. Before cleaning the machine, unplug the power cord and turn off the fuel supply or battery. Place the machine on a hard surface.

Soil and grass residues can be cleaned with a rag or brush from the deck, knife, or grass catcher. Then it is necessary to process the remaining part of the body, as well as the air intake grilles.

Deterioration of the haircut is most often associated with improper adjustment of the knives. The cutting mechanism must be checked carefully by placing a sheet of paper between the rotating blade and the lower knife. If it is cut evenly, then everything is in order, if not, then you need to tighten the screws.

Electric lawn mowers. When caring for such machines, you should check the condition of the electrical cable for breaks or insulation damage. You should only use a high-quality extension cord. It is also necessary to use an outlet with a residual current device (RCD). The mains voltage must be supplied within normal limits to ensure the safety of the unit.

Cordless lawn mowers. Servicing such machines requires careful attention to the charger and battery. It is very important to completely exclude moisture and protect the battery from overheating. It is strictly forbidden to store the battery near small metal objects - there is a possibility that the poles may short out and a fire may occur. If the battery is damaged, it may release gas or liquid that can cause respiratory tract and skin irritation. A faulty machine must only be disposed of; the battery must not be opened under any circumstances!

Gasoline lawn mowers. Primary care should be directed towards engine maintenance. Users with extensive experience recommend keeping a journal in which you need to note planned and performed operations: changing spark plugs, oil, etc. Remember - fuel is explosive! The tool must be refueled with the engine turned off. Smoking is prohibited during this process! Oil can only be added when the device has cooled down. A lawnmower with the engine running should not be left indoors - you can be poisoned by exhaust fumes.

If the lawnmower does not work

The operating brochures contain a table with a list of faults and a description of measures to eliminate them. Many problems can be eliminated on your own, because some of them are not a breakdown. If the lawn mower moves with difficulty, then most likely the blades, wheels, and air intake are contaminated with grass. In some cases, replacement of consumables is required: spark plugs, knife.

To prevent serious malfunctions, identify and replace defective parts in a timely manner. In difficult cases, contact the service center.

Safety rules are easy to follow! It is enough to approach the work wisely and follow the instructions. Over time, this will become a habit and will become a guarantee of your well-being, as well as ensure the proper operation of the lawn mower you purchased.

Malfunctions and repairs: how to diagnose and fix

Here is a list of common faults :

- The engine does not turn on or off periodically.

- The knife does not rotate when the engine is running.

- Strong vibration from the mower.

- The machine does not cut the grass well.

- The engine is hot or smells of smoke.

- The riding mower does not move forward well when the wheel drive lever is depressed or does not move at all.

The electric motor does not turn on or off periodically

The most common cause of this error is one of the plugs being disconnected from the corresponding outlet . This is because the extension cord was pulled out too far and pulled the plug out of the socket. If the engine starts and suddenly stops for no reason, bypass the extension cord and check the contacts.

If all the plugs are connected to the appropriate sockets, check the mains voltage; it is possible that some additional powerful tool has turned on the lawn mower and the energy consumption has reached a critical value.

When this happens, the fuses (plugs) trip, so you need to check them, if they are off, you will have to look for an additional electrical device that has increased the load on the home network to a critical level.

In older homes, the same effect is caused by faulty wiring, in which bad contacts heat up under load, leading to :

- Melting insulation;

- Occurrence of current leaks;

- Short circuit.

You'll need to check out this pincer .

Do not use any other measuring instruments for this purpose, as only clamps allow such work to be carried out without direct contact with electricity.

Remember - touching a bare conductor or contact under voltage of 220 volts is fatal!

First turn off all electrical consumers, then measure the current entering the house, if the wiring works and you remember to turn off any appliance, then the current consumption will be zero. Then plug in the mower and have a helper start cutting the grass so you can measure the current in the extension cord.

It must correspond to the power of the mower engine, which can be determined by the formula P = IU, where :

- P is power in watts.

- U is voltage in volts.

- I am the current in amperes.

Once you're sure the current you're using to cut the grass is correct, unplug the mower and connect the clippers to the input wires that carry electricity into the house, then have a helper continue cutting the grass and monitor the current. , expecting congestion.

If the current increases not only at the entrance to the house, but also at the extension cord, the problem is either the extension cord or the mower itself, so replace the cord first.

READ Lawn Mower Engine Disassembly

If this does not help, you need to disassemble the lawn mower and carefully check all contacts and the condition of the motor windings. However, for such work it is necessary to have a good understanding of electrical engineering and be able to repair it, since it is necessary not only to eliminate the damage or replace the faulty part, but also to eliminate the cause that led to such a defect.

If you do not know how to do this, then contact a specialized workshop .

The knife does not rotate when the engine is running

The cause of this malfunction may be:

- The motor bearing is jammed;

- The blade shaft bearing is jammed (only on mowers with a synchronous motor);

- Weak tension in the blade drive belt (only on mowers with a synchronous motor);

- Weak tightening of the bolt holding the knife;

- Losing a knife.

To determine the exact cause and fix the problem, turn the electric lawn mower that is not running upside down and turn the blade.

If it rotates without resistance, then the lawnmower has one of the following injuries :

- Cut off the knife clamps;

- The knife bolt is not tightened;

- The knife drive belt is torn or stretched;

- Worn motor or blade pulleys.

To check the tightness of the bolt, shake the knife, removing one or another edge from the seat; if the screw is not tightened, something hangs , if it sits firmly, then the problem is different.

To check and adjust the tension of the blade drive belt, you must remove the motor, so we recommend doing this yourself only if you are familiar with the mower and know how to remove and reinstall its motor. This process differs for different mowers, so it is impossible to prepare universal instructions.

After disassembling the engine, do the following:

- Check the condition of all parts of the belt tensioner; bearings, rubber rings and springs must be in good condition;

- Remove the belt and check its length (for this house there should always be a spare belt);

- Check the condition of both pulleys, paying particular attention to the inside surface where the belt runs and locking the shaft.

Repair or replace faulty parts, then reassemble the mower and check the blade operation. As an example of such a repair, we suggest you watch this video:

Strong vibration of the mower

Strong vibration occurs because the knife :

- Wear unevenly;

- Deformed;

- Badly fixed.

An external inspection, even without removing the knife, will show its deformation or poor fixation. If it is not bent or secured properly, balance it as described above, then install it on the mower and check its operation.

On devices that are mounted directly on the shaft, measure the distance from the log to both edges of the knife; if it differs by at least 1 mm, the shaft is bent and such a motor must be replaced. You can also check the condition of the drive shaft on units with a synchronous motor.

If the drive shaft is running, check the motor by turning the pulley on its shaft and see if any edge lifts up. If one edge of the pulley is even slightly different in height, replace the motor rotor or the entire motor.

The machine does not cut the grass well

If there is an uneven surface after the lawn mower passes, first check the condition of the grass catcher and the rear window through which the grass flies when the grass box and the window are clogged , the machine cannot cut the grass effectively.

If the grass catcher and window are ok, check the engine. The easiest way to do this is to make a sound when cutting the grass - with an induction motor the sound should only change slightly when cutting thick grass or when the mower speed is too high, but with a synchronous motor it should never change.

If the sound of the induction motor changes, even if the movement is not too fast, but the motor does not overheat or smell of smoke, it means that you are moving the mower too fast and the motor is not producing enough power.

Reduce the speed of the mower so that the operating sound does not change, and check the quality of mowing - if it does not change, the problem lies in the control of the cutting mechanism; if the cutting quality is better, you will either need to mow slower or buy a more powerful model.

If the problem is with the cutter drive, it will need to be repaired as described above.

Engine is hot or smoky

If the engine speed does not decrease while cutting grass and the operating time does not exceed the maximum permissible values taking into account the characteristics of the grass, but the engine gets hotter than it should, then the problem may be :

- Low or high voltage;

- Faulty bearings;

- Interwave circuit winding;

- Wear of synchronous motor brushes;

- Shaft misalignment caused by motor misalignment.

If the voltage does not differ by more than 5%, that is, 210-230 V, the problem is with the lawn mower, so unplug the machine and turn it over. Then turn the blade several times, if it turns without much effort and without jamming, the problem is not in the bearings or crankshaft, but in the electrical part of the engine.

Turn the mower over onto its wheels and remove the protective cover. If the engine smells like smoke or is burning, there is an intermittent circuit and the unit needs to be replaced. If there is no strong burning smell, check the brushes and all connections, there is a bad contact somewhere that heats up under heavy load.

You can find a connection with a poor connection using melted or charred insulation . If the problem is with the plug, disconnect the contacts and clean them with a special spray such as KONTAKT 61 REXANT. If the solder joint is problematic, unsolder it, then carefully remove and caulk the pins, then solder again.

Self-propelled lawnmower moves poorly or does not move forward at all when the drive lever is pulled

If the lawn mower does not move or drives poorly, then proceed according to this algorithm , we proceed to the next step only after we have completed all the steps of the previous step and made sure that the mechanism works:

- Make sure the drive cable is not damaged. To do this, press the wheel drive lever several times and see if the cable moves the drive lever.

- Adjust the length of the drive cable (refer to your mower's instructions for this procedure) by moving the drive lever to the on position.

- Disassemble the belt drive mechanism and check the condition of its parts, if necessary, replace worn or damaged elements.

- Check the operation of the gearbox, remove the belt from the pulley and turn the pulley several times, this should cause the wheels to rotate. Then press the wheel with your finger and turn the pulley again, the force generated by the wheel should be several times greater than the force applied to the pulley. If the transmission does not operate properly, replace it.

- Assemble the motor drive and adjust the length of the cable so that the wheels begin to rotate when the lever is pressed about halfway.