High-quality parts for the walk-behind tractor ensure excellent and long-term operation of the unit, especially for generator belts, the dimensions of which must correspond to the design features of the device.

You should not hope that the purchase of more powerful belts will increase the functionality of the “technical assistant” itself, because their goal is to realize the potential of the walk-behind tractor, and not to raise it to the highest level. Modern belts for walk-behind tractors are made of polyurethane and neoprene. These materials are considered more durable and wear-resistant, but still, even they cannot withstand enormous loads from time to time and tear.

Features of belts for walk-behind tractors Cascade

There are not many models of Perm Cascade walk-behind tractors on the market. And the more difficult it is to maintain this type of equipment, since all components must be selected specifically for a specific type of equipment. After all, even belts from walk-behind tractors of the same company, but of different models, can differ significantly. And such an alternative will result in rapid damage to the part and, possibly, breakdown of the walk-behind tractor itself.

Therefore, when selecting a new belt, it is very important to check the data in the operating instructions and the markings of the old part.

Types of belts

The belts on a walk-behind tractor are as follows:

- wedge

- forward travel

- reverse

The following table will help you in the process of selecting a belt.

You can replace the belt yourself. To tighten the belt, you need to apply some force, but it is important not to overdo it so that it does not break.

You not only need to choose the right belt for the Neva walk-behind tractor, but also know how to install it. First make sure you have all the dimensions correct. The belt replacement processes for the units of these two samples differ from one another. For MB-1 the sequence of actions is as follows:

- the first step is to remove the casing from the V-belt mechanism;

- Next, you need to carefully remove the back bar from the pulley;

- take the key and make the spring-loaded roller weaker;

- the part itself is removed;

- The next step is to tighten the new belt;

- Ultimately, we return to their place those parts that were removed and strengthen them.

For MB-2 we see a slightly different course of action:

- the first action is similar to the previous scheme;

- then loosen the strap tension in the same way;

- next you need to unscrew the screws that secure the bracket;

- take out the belt;

- we adjust the pulleys;

- we place another part into the mechanism (remember that you first need to tension it onto the gearbox shaft, and then onto the pulley located in the motor);

- putting everything back together again.

As a rule, the belt is reinstalled if some kind of breakdown occurs during operation. But sometimes equipment owners simply want to replace the part with a newer and less worn one. In addition, there is another way to increase the productivity of the walk-behind tractor - you can install a second belt. Installing the second belt on the Neva walk-behind tractor takes approximately ten minutes.

In general, when replacing a belt on a Neva, you should take into account what developments this or that modification is based on. For example, the Neva mini (MK-100) differs from other models in that its production uses designs made back in Soviet times. The following video will tell you more about choosing a belt and replacing it.

Motoblocks, as you know, come in two types: those running on a chain or belt drive. In the latter, the belt is a spare part that is used to transmit torque from the engine to attachments. Also, the V-belt drive simultaneously performs the functions of transmission and clutch. The tension of the belt itself is carried out using a pulley tensioner.

It should be noted that a belt is easier to maintain than a chain, since it does not need to be lubricated, and replacing a worn part does not leave any special problems. Let's find out what the features of drive belts for walk-behind tractors are.

Rules for operating drive belts for walk-behind tractors

A modern belt, unlike its predecessor, is made not of rubber, but of neoprene or polyurethane. These materials are more wear-resistant and last longer. But, one way or another, the belts still wear out and break. Let's consider the basic rules for using belts for walk-behind tractors.

Firstly, choosing the right belt is very important. The product must be intact, have no protruding threads, and not stretch. The new belt cannot be bent or stretched, otherwise it will become unusable even before use. You should also definitely check the condition of the pulley (the wheel through which rotation is transmitted from one shaft to another): there should be no defects on it that could cause damage to the belt during its movement. The sizes of belts for walk-behind tractors depend, first of all, on the type of walk-behind tractor itself (“Cascade”, “Zubr”, “Neva”, “Salyut”, etc.) The discrepancy between their sizes and types often leads to rapid wear of the belt.

Secondly, you need to know how to replace the belt, because you will have to do it yourself more than once. In order to replace the drive belt, it is necessary to leave it in neutral when turning off the engine, and then remove the protective cover and remove the old belt, which is no longer needed. To attach a new belt to the walk-behind tractor, remove the pulley from the drive and put the belt on the gearbox pulley first, and then on the engine pulley. Of course, the belts should not twist or sag: the correct operation of the entire unit depends on this. Also keep in mind that if your walk-behind tractor uses two belts, then both of them need to be changed at once. Otherwise, different loads will be placed on the cords, leading to premature failure of one of them.

What is the size of the belt on the Cascade walk-behind tractor?

Cascade walk-behind tractors have forward and reverse belts. As a rule of thumb, reverse belts are less likely to wear out because they are used less. Their markings and sizes also differ. For forward belts, these are products marked A-1180 and A-1213 GOST-1284. For reverse gear, these are products marked A-1400. The value “A” in this code means 13 mm.

The most suitable belt for replacement would be the belt from the Mole walk-behind tractor, some models of which have identical technical characteristics.

Belts for the Neva walk-behind tractor, features, dimensions, tension

Belt dimensions for the Neva walk-behind tractor - information necessary for every owner of this equipment. Belt type, length, tension and adjustment, V-belt transmission malfunctions are issues that we will try to sort out in this article.

While writing this article, I came across one interesting fact: information about the types and sizes of belts for Neva walk-behind tractors and others is presented on the Internet mainly by online stores that offer to buy their products. In this case, errors occur very often.

Therefore, when purchasing a belt, you need to be very careful and refer to the operating instructions for your walk-behind tractor. The data on this page is collected from catalogs from Red October and from the instructions for walk-behind tractors.

There are a large number of modifications of Neva walk-behind tractors. It happens that there are different belt sizes for the MB-2 walk-behind tractor with different engines (see lines 3 and 4 of the table below)

Table of belts used for Neva walk-behind tractors and cultivators

| Type of walk-behind tractor Neva | Belt type |

| MB-1 old modification | Drive belt A-1180 VN-T GOST 1284.1-80 - GOST 1284.3-80 (forward) Drive belt 0-1400T GOST 1284.1-80 - GOST 1284.3-80 (reverse) |

| MB-1 | A53 (1380) |

| MB-2 | A-45 13×1143Li A1180Ld or A1180 GOST 1284.2-89 |

| MB-2S-9.0 PRO | A46.5 A (1213) |

| MB-3 | А52 13х1320 Li А1350Ld |

| MB-23 | A49 (data differs in different catalogues)A50 13×1270Li A1300Ld |

| MB Compact | A47 (1200 Li A47 (1230 professional A)) |

| MK-75 | FSCOUZ36 |

| MK-80 | А37 13940 Li А 970 Ld |

| MK-80R | Z31 1/2 10x805Li Z825Ld |

| MK-100 | A-100 GOST 1284.1-89 |

| MK-200 | A44 |

Table of applicability of pulleys and belts on Neva MB 2 walk-behind tractors

| Modification | Engine | Belt type | |

| Model | Ø c/v | ||

| MB-2K-6.2 | DM-1K (JSC "Red October-Neva") | Ø25 | A1180 GOST 1284.2-89 or A45 13×1143Li A1180Ld |

| MB-2K-7.5 | DM-1K-7.5 (JSC "Red October-Neva") | Ø25 | |

| MB-2B-6.0 | I/C 6.0 (Briggs&Stratton) | Ø19 | |

| MB-2B-6.0 PRO | Vanguard 6.0 (Briggs&Stratton) mod.117 | Ø19 | |

| Vanguard 6.0 (Briggs&Stratton) mod.118 | |||

| MB-2B-6.5 PRO | Vanguard 6.5 (Briggs&Stratton | Ø19 | |

| MB-2B-7.5 | Vanguard 7.5 (Briggs&Stratton) mod.1384320190E1DD1001 | Ø19 | |

| Vanguard 7.5 (Briggs&Stratton) mod.1384320162E1DD1001 | Ø25.4 | ||

| MB-2B-5.5M | I/C 5.5 (Briggs&Stratton) | Ø19 | |

| MB-2N-5.5 | HONDA GX200 | Ø19 | |

| MB-2B-6.5 | I/C 6.5 (Briggs&Stratton) | Ø19 | |

| MB-2S-6.0 PRO | EX17 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| MB-2S-7.0 PRO | EX21 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| More details on the types and sizes of pulley belts and cables used for Neva walk-behind tractors and cultivators of other modifications can be found here |

Download the table of applicability of pulleys and belts for Neva walk-behind tractors of various modifications with different engines: tablica-skivov-remnei2013.xls

Designation of V-belts

The V-belt drive for walk-behind tractors of types MB - 1 and MB - 2 performs the function of transmission and clutch mechanism and provides:

— transmission of torque from the engine crankshaft to the input shaft of the gearbox:

- disconnecting the engine from the gearbox during gear shifting and smoothly connecting them again, eliminating sudden changes in load on the engine:

— smooth starting of the walk-behind tractor and stopping it without stopping the engine.

The V-belt transmissions of the MB-2 and MB-1 walk-behind tractors are structurally different, which is caused by the use of different types of gearboxes in them

Possible malfunctions of the V-belt drive

| Nature of the malfunction | Possible reason | Elimination method |

| Incomplete clutch disengagement | Belt tension when the clutch lever is pressed is greater than normal | Set the normal belt tension with the clutch lever pressed, ensuring deflection of the upper belt branch within 8-10 mm when a force of 5 kG is applied to its middle part between the pulleys. |

| Incomplete clutch engagement | 1. Belt tension when the clutch lever is pressed is less than normal 2. Belt delamination | 1. Same 2. Replace belt |

Checking the tension and adjusting the belt of the Neva walk-behind tractor

Walk-behind tractor Cascade: replacing belts

To quickly and efficiently make a replacement on the Cascade walk-behind tractor, follow this algorithm:

- Stop the engine and put the gear in neutral.

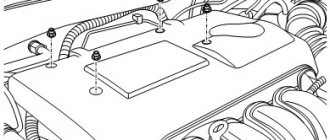

- Remove the protective cover.

- Remove the old belts.

- Install a new belt. Remove the pulley from the engine, pull the belt onto the gearbox pulley, and reinstall the motor pulley.

- Make sure that it is not twisted and that it is positioned strictly parallel to the grooves of both gearboxes.

- Reinstall the protective cover.

Also, do not forget about the rules for storing and using the product itself to extend its service life. Do not bend or stretch it - this may deform and damage the part. Monitor the condition of the pulley and promptly remove minor defects (scratches, chips, scratches, cracks).

The size of the belts on the Cascade walk-behind tractor and the procedure for replacing them

Different units use belts of different sizes. Thus, the Cascade walk-behind tractor uses A-1180 or A-1213 GOST 1284 belts for forward travel, and A-1400 belts for reverse travel. The prefix “A” stands for 13 mm.

Before proceeding with removing or replacing the belt, it is necessary to dismantle the protective casing, unscrew the pulley, which has three streams; it is attached with a key and a locking ring to the shaft. When removing the ring you need to be careful not to break it. The material from which it is made is very fragile.

Next, we should move the reverse belt pulley forward to tighten the three-groove pulley, after which we can remove the belt without interference. If it is simply very worn, you can cut it off with a knife.

Next, we check the belts and, if necessary, replace them with exactly the same ones. If there are two of them on the walk-behind tractor, then it is better to replace both of them at once. If you replace only one belt, they will have different degrees of tension, and the new one will take on more load, which will lead to its rapid wear.

We begin to assemble everything in reverse order. We tighten the belts onto the gear pulley, then install the motor pulley, check the tension rollers and make sure that the belts are installed evenly, without distortions. Don't forget to put the protective covers in place and secure them.

Direct drive. Advantages and disadvantages

The direct drive mower has an asynchronous motor. Does not require replacement of brushes, there is no additional unit where the belt needs to be changed. The mower body may be slightly smaller and lighter. And if you also have a powerful motor, then this is a very serious argument that can lead to the purchase of such a lawn mower. And if you look at all these facts, a logical question arises. Why make a belt driven lawn mower because the induction line has so many advantages? In fact, there are pitfalls here, and quite significant ones.

READ How to Change Al-Ko Lawn Mower Engine Oil

As you know, in our country, unfortunately, there are old electrical networks, and the voltage usually does not correspond to 220 V. Practice shows that outside the city in private homes, where electrical equipment is mainly used for the garden, the average voltage is from 180 to 200 V. Why is an asynchronous motor dangerous? It cannot reach the required number of revolutions, its efficiency decreases, and the knife, in turn, ceases to effectively mow the grass. In the brush. Vice versa. This increases the starting current to maintain the desired speed and maintain performance. But this causes the engine to heat up faster. Let's look at everything "behind" and "against" direct drive.

Pros:

- High efficiency and long service life;

- It has a low noise level and reduced vibration transmitted to the lawn mower body;

- The service life reaches 3-5 thousand hours, especially when installing universal rotary joints in the shaft;

- Provides high torque at low engine speeds.

Minutes:

- Heavy weight although smaller in size than waist design;

- The price may be higher than belt drive;

- When the mower blade hits a rock or thick branch, the overload is transferred to the engine, which can lead to severe damage and complete failure, which in turn can completely replace the mower.

The importance of the drive belt in the design of Neva cultivators

The design of modern Neva walk-behind tractors is quite simple: there is a welded frame (supporting part) in which the engine is localized, the revolutions of which are transmitted to other components through the shafts. The chassis is usually represented by two small wheels. All mechanisms are controlled using combined levers located on the handles of the devices.

Any Nevsky walk-behind tractor contains 2 types of shafts:

- Crank;

- Spreading.

The job of the drive mechanism is to transmit speed from the crankshaft to the camshaft.

Depending on what acts as a belt, the drive can be:

- Chain - represented by a hinged chain connecting the drive and the driven sprocket, between which the traction potential is transmitted;

- Belt - transmits power due to friction forces.

READ What types of lawn mowers are there?

The former are less difficult to care for, do not require stress and, when they are compact, provide good performance. Belts, with their price and simplicity, compensate for rapid wear and significant overall dimensions.

Thanks to the large number of modifications released under the Neva brand, they all belong to the group of belt-driven equipment. An important advantage of these cultivators is the overhead camshaft, which contributes to more efficient cooling and, therefore, less wear on the belts themselves.