Mower KRN-2.1

The rotary mower KRN-2.1 is produced not by one, but by several manufacturers. For example, it is worth noting the Moscow region in Lyubertsy, which produces equipment from Belarusian spare parts; Smolensk enterprise "Smolenskspetstekh"; Kirov PKF "Rakita". However, equipment from Tver is more popular due to its reliability and durability. It is worth saying that at present the model of the mounted mower KRN-2.1 is not produced in its pure form. Usually, the letter “A” is added at the end of the name, indicating the base model, or “B”. The model with the letter “B” has a slightly modified design - pulleys of the same diameter are used, as a result of which the tractor PTO speed increases to 1000 rpm.

Purpose

The KRN 2.1 rotary mower easily mows small bushes, removes weeds, cuts large masses of tall grass, and cleans pasture lands. At the same time, minor surface slopes and complex terrain are not an obstacle to work. It is also effective to use this model of rotary mower in areas where the yield is more than 15 tons per hectare. The equipment is able to work in any climatic zones and is aggregated with power units of 0.9-1.4 traction class through the hitch system of the tractor used.

Advantages and disadvantages

Equipment advantages:

- an even cut obtained thanks to rapidly rotating sharp blade knives;

- thanks to the even laying, quick sweeping of stacks and transportation of mowed grass is possible;

- a protection device, when triggered, the knives evade obstacles;

- all working units and the gearbox are covered with a protective casing;

- the ability to mow grass in areas with difficult terrain and road slopes, as well as in any weather;

- relatively low price compared to foreign analogues.

However, the mounted rotary mower KRN-2.1 still has some disadvantages:

- the performance of rotary mowers is lower than that of segmented models;

- when working at low speeds, grass can wrap around the rotor nuts, but this does not happen at high speeds;

- Although mowers from foreign manufacturers are considered more reliable and efficient, however, after using KRN-2.1, the grass grows back much faster.

Specifications

Characteristics of a rotary mower

Experts classify these units into the following types:

- Devices that cut and lay grass on the cob;

- Machines that mow and roll grass;

- Rotary mowers on a walk-behind tractor, mowing and cutting grass.

Some models submerge and compact the grass when mowing and laying it in a swarm. When considering the installation method, experts highlight devices such as trailed, semi-mounted and mowers.

This device consists of a rear, front and side cutting system. Devices with 1,2,3 or 5 bar are installed on the tractor. The rotor belt is started under the action of the tractor shaft or wheels.

In the photo - a rotary mower on a mini-tractor

The units in question are installed on the tractor and walk-behind tractor in a horizontal position. The knife and connecting rod must move in the same plane. The Polish tractor mower is used to work on a small plot of land. The front model divides the land into units.

Before buying a rotary mower on a walking tractor, study the principle of its operation. If you want to mow high-yielding and dead grasses, weeds, a rotary device is used. This mower is independently attached to a walk-behind tractor or walk-behind tractor. The equipment consists of a rod to which knives are attached.

The grinding machine device consists of a rotor, frame, drive mechanism, and pipeline. The operating principle of a rotary mower on a walking tractor: when the machine moves, the vegetation is tilted with a shield and then mowed with a knife. The grass rises, lies down, falls into the container.

If you need to quickly cultivate the land, then a Polish mower is used for a tractor or walk-behind tractor with several cutting elements. Experts recommend purchasing the following devices, taking into account the following criteria:

- Grass cutting height;

- Implementation;

- Knife speed.

Plus a rotary mower on a mini-tractor. The presence of a damping device that protects the knife from various obstacles. Additional benefits of the device include:

- Easy to use;

- Strict regime;

- Save time

Model range of units

A rotary mower for a walk-behind tractor can be presented in the following models:

- "Dawn". Installed using a gearbox and additional brackets. The device is used for mowing grass, small shrubs and cereals. The width of the structure is 70-80 cm. If necessary, the device is used when cultivating rocky soil;

- "Dawn 1". Used for cultivating soil in hard-to-reach places;

- "Fast KNS-0.8". Allows you to mow grass up to 2 m high;

- "KM-0.5". Compact model with a 50 cm wide bevel

Models of rotary mowers for mini tractors:

- Z083 MINI. Designed for mowing grass over a large area. This model is not used in mountainous areas;

- 135 135. Mow and mow the grass. The model is equipped with 8 knives;

- "KP-2.1M". The installed rotary mower for mini tractors allows you to cultivate the ground with hard objects;

- Z-069 Wirax. Polish model with which you can handle a large plot. The grass is cut and placed in rolls;

- KRN-2,1-b. Mowing grass in difficult terrain;

- SB-1200. Semi-assembled model of Czech production. Using this mobile design, you can replicate the terrain.

Mower shown for Z-069 Wirax tractor

Appliances

If necessary, you can make a rotary mower on a walking tractor and mini-tractor with your own hands. To manufacture equipment for a walk-behind tractor, you need a welding machine, fittings, tape measure, and metal corners.

The frame of a homemade rotary mower for a walk-behind tractor is made of metal corners (4x4 cm). Then install the bearings. The next step is the manufacture of the working part of the device.

The resulting structure will grind fine grass and mow down tall weeds. The Neva self-propelled rotary mower for a walk-behind tractor consists of two discs removed from the seeders, a gearbox and a chain from a chainsaw.

READ Saw Calm How to Assemble

You will need 4 knives for each blade. The cutting elements are made of hardened metal. To install them, drill holes with a diameter of 6 mm. The cutting elements are attached to the walk-behind tractor using a tire. This maintains a gap between these elements (1-2 mm).

This design ensures fast grass cutting.

Pictured is a simple homemade mower for a tractor.

During operation of a walk-behind tractor with a rotary mower, it is possible to rotate the blades 360 degrees.

The axis of the device is made of carbon steel with a diameter of more than 8 mm. To allow the knives to move freely, the axis is extended with a disk. The discs are mounted on the frame, connecting them to the drive. The discs should rotate opposite each other (to ensure that the grass clippings are stacked in rows).

extra work

To improve the walk-behind tractor, you can make your own adapter. This small trailer serves as a cab with the ability to mount a mounted rotary mower. The rotation of the handles is controlled by the walk-behind tractor. The length of the steering wheel is taken into account before making the adapter. The trailer axle is made from motorcycle sidecar suspension elements. Experts recommend making a bridge from a steel angle measuring 40x40x2. Square pipes are welded to strengthen the adapter.

Homemade rotary mower for mini tractor is handmade using old iron batteries and a barrel. The device consists of cutting elements, a casing and a frame. A rotary mower glides along the ground with discs underneath.

The photo shows a homemade mower for a walk-behind tractor

To make the frame, use 40 cm corners. The unit is equipped with the blades of an old rotary mower. If a Polish model is used, it must be accelerated by 3 cm. Otherwise, the traction on the mini tractor will not be enough.

2 disks with a diameter of 39 cm are cut from a metal sheet 4 mm thick. Knives are attached to them (they should rotate freely). When moving under the influence of centrifugal force, the cutting elements will mow the grass.

Scoop discs (diameter 45 cm) are used to make lower supports. Shafts can be made of metal pipe with a diameter of 30 mm. The device is equipped with two bearings:

- The first is installed in a pipe;

- Second. In a welded pulley.

The disk and knives are placed on the shaft. The pulleys are welded to the pipe. The resulting design allows you to capture a section with a width of 110-115 cm. In this case, the shaft rotation is 1400. The device has a cover. To extend the service life of the belt, it is recommended to install a bearing at the junction of the mower and the mini tractor. To simplify the design, experts advise welding the lower disk to the frame. Specific speed. 10 km/h. In this case, the grass is cut to a height of 5 cm. The resulting rotary mower is used for harvesting corn.

Mower KRN-2.1B

A modification of the KRN-2.1B rotary mower is designed for mowing high-yielding and laid-down grasses at high speeds with laying the cut plant mass in the swath. This model of equipment can be used on slopes up to 100, while the modification with the letter “D” is used on inclined surfaces up to 300, which allows you to mow grass on steep road slopes and dams. The KRN-2.1B rotary mower is equipped with a safety device that allows you to protect the cutting elements from damage when colliding with an obstacle.

The working part of the mower consists of four rotors located on the frame and equipped with eight plate knives, hinged. Suspension springs allow you to fairly accurately copy the terrain of the area and ensure an even cut of vegetation across the entire working width. The KRN-2.1B mower is aggregated with MTZ-80/82, LTZ-55.

Advantages of the KRN-2.1B mower:

- the all-welded beam of the working unit increases the tightness;

- due to the fact that the rotor supports are removable, repairs can be carried out without disassembling the timber;

- the pallet protects the cutting unit from abrasion on the soil;

- possibility of mowing in areas with a surface slope of up to 35˚.

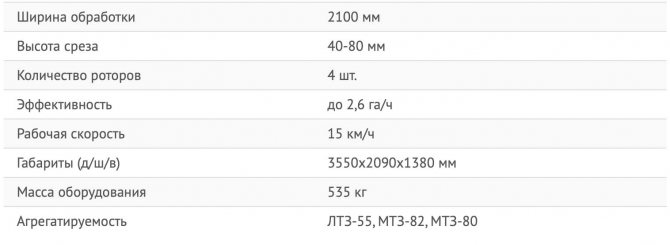

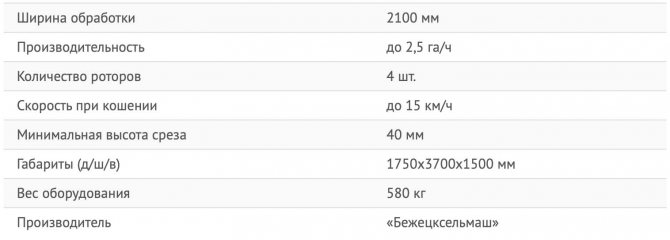

Brief characteristics

Working with a mounted rotary mower

Before you start working with a rotary mower, you should first check the track. If the dimensions are smaller or larger than 1.4-1.5 m, then it is necessary to adjust to normal. Afterwards, you need to adjust the length of the central tractor link.

Set the hydraulic system distributor to the “floating” position, then secure the rods with the axles of the attachment, and the cardan drive with the tractor PTO. Using a bracket, attach the casing chain to the central tractor link, maintaining a slight slack. It is necessary to install locking devices included in the equipment set on the longitudinal rods. Connect the hydraulic systems of both units, then lift the mower and adjust the axis of the hitch frame.

Before you start mowing, you should run the equipment in idle mode for a couple of hours. After that, check the condition of the bearings, nuts and belts, and only then start working.

On smooth terrain, you can maintain a speed of about 15 km/h, and on uneven terrain – a little lower. The mower must operate at its maximum cutting width and therefore the tractor should be driven so that the inner shoe is as close as possible to the edge of the cut vegetation. If an obstacle is detected using hydraulics, the working unit must be lifted, and during transportation it must also be secured using a transport rod and a stopper.

When moving the rotary mower over significant distances, it is brought into a vertical position, for which it is necessary to use the hydraulic system of the tractor and secure it using a transport rod and a locking device pin.

Video: How to Assemble a Rotary Mower

Source

Unfortunately, most owners of walk-behind tractors and mini-tractors do not always use them to their full potential, and they hire other equipment to mow the lawn or field. Although this is possible with a rotary mower. The cost of such a tool is too high, so it is much more profitable to create it yourself. We will look at how to make a rotary mower from available materials below.

- Operating principle of a rotary mower

- Features of rotary mowers

- Make a rotary mower

- Homemade rotary mower made from scrap materials

- Cost of purchased rotary mowers

Operating principle of a rotary mower

There is a wide variety of mowers on the modern agricultural tool market. The most popular are rotating devices. Thanks to their design, they have high performance and are easy to operate both on a large tractor and on a walking tractor.

The operating principle of a rotary mower is to create rotational movements in the rotor, which has a round shape.

A rotary mower has the shape of a rectangular beam to which rotors with blades are attached. They are responsible for ensuring that plants are trimmed correctly.

Rotary mowers are very popular due to their efficiency. The fact is that these devices use direct energy coming from the tractor. Therefore, they do not need to produce a specific type of energy. At the same time, labor productivity increases several times. These mowers are used in the process of mowing grass, weeds, and dead plants; they are called not only rotary, but also rotary.

READ Disassembling the Engine of a Petrol Mower

If you compare a rotary mower with an alternative, then the first one. The efficiency is more than 70%, and for others - up to 40%.

The rotary mower is attached to a transport device, which is a tractor, mini-tractor or walk-behind tractor.

There are three types of such mowers, these are devices:

- Trailer type;

- Semi-assembled type;

- Installed type.

The first type of rotary mowers is attached to the vehicle in a three-point manner, so the angle of inclination of the device can be adjusted.

Prefabricated mowers are ideal for working on small plots of land. Semi-mounted mowers are recommended for large areas, while trailed rotary mowers are used for work on uneven ground.

The rotary mower has a wide range of applications. Perfectly cuts grass for further laying in rollers. In addition, there are rotary mowers that not only cut the grass, but also chop and collect it. The principle of operation of such a device is to trim plants, feed them with special knives, which are crushed and transported in containers.

Features of rotary mowers

In general, there are several types of mowers for mini tractors or walk-behind tractors that you can build yourself. Because this way you can achieve maximum cost savings and at the same time get a quality tool.

Home made mowers:

- Rotation;

- Trailed;

- Segmented.

The basis of the rotary mower is a welded metal structure in the form of a frame. For its manufacture, it is necessary to have metal corners of a standard size of 40x40 mm. The hull sections are mounted on a wheeled mounting structure. Then you should select the type of workpiece, which depends on the location of this tool.

Photo with rotary mower:

The scope of application of a home rotary mower extends to mowing grass or lawn. But keep in mind that it is recommended to only cut tall grass with this mower as it will chop up short grass. To make such a lawn mower yourself, you must have:

- Chainsaws;

- Two discs are removed from a grain seeder.

Only hardened steel is used to make knives. Each disc must have four knives.

On each of the disks you need to drill holes for the knives; their diameter should not exceed six millimeters. The knives are secured with a pin. In this case, leave a small gap between the knife and the holder; its thickness should be two millimeters thicker than the blade. In addition, care should be taken to install a protective housing.

Make a rotary mower

The design of a homemade rotary mower for a mini-tractor includes knives that ensure grass mowing. The knives are mounted on a special disk device. The drive shaft is used to provide movement. The mower glides along the ground with the lower discs.

To make a welded frame, use the corners, you can use old scrap metal. To save time on making knives, use an old tractor rotor. But in this case, in order to improve traction and make the lawn mower more productive, the tractor rotor should be reduced by several centimeters from 2 to 4, depending on the power of the mini-tractor. This type of mower has a boom height of no more than 350 mm.

To design the rotor yourself, you need to remove a metal sheet and cut two circles in the form of disks from it, each diameter is 390 mm. To save on purchasing sheet metal, you can use the bottom of an old chest. In the center, the legs are welded to disks that ensure their rotation. Thanks to centrifugal force, the process of mowing the grass will occur.

Carefully monitor the strength of the fastening when welding the legs, as the joints must be as reliable as possible.

The disk removed from the cleaning device is suitable as a lower support; its diameter should not exceed forty-five centimeters. An old metal pipe with a cross-section of no more than three centimeters is suitable for the axial shaft. To manufacture the structure, the presence of bearings No. 180 106 is also required. A hole for the lower bearing must be provided on the pipe section, and a second bearing must be installed on the surface of the pulleys. This requires a welded pulley.

READ What are mowers, straw cutters and others for?

Place the disc with knives on the previously prepared shaft. Then use a welding machine to weld the pulley to the pipe. The structure will rotate with two bearings.

This model of rotary mower is characterized by the presence of a grip of 1.10-1.15 cm, and the number of shaft revolutions reaches 1500 pcs. The lawnmower must be mounted and then welded to a welded frame of metal angles. To ensure safe operation, care must be taken when installing the housing. It is recommended to install an additional bearing at the junction of the tractor and mower, directly at the area where the belt is connected to eight, which will make this connection more durable and ensure smooth operation of the mower, in addition, belt friction will be reduced.

To simplify this model of rotary mower, it is necessary to weld the lower disk directly to the metal structure from the corner.

This model of rotary mower allows you to mow at a speed of 8-12 km per hour. A fast mowing process will shred the grass, while a slow mowing process will. Integral. This mower is capable of cutting 6-8 cm of vegetation. It is used for cutting grass or weeding gardens.

Homemade rotary mower made from scrap materials

Materials for production:

- Four wheels of the same size, with a diameter of up to 45 cm;

- Two axles for mounting wheels;

- Metal sheet;

- The bottom of a metal old barrel;

- Four knives;

- Nuts and screws for fastening knives;

- Welding machine;

- Chainsaws;

- Control knob or tube for making it.

Instead of wheels, you can use an old stroller with metal wheels. He has a chainsaw that will rotate the so-called rotor.

Replacing the tire will help temporarily reposition the pulleys. At the bottom of the stroller there is a metal sheet that must be cut using a sander according to the dimensions of the stroller. Additionally, you need to cut a disk-shaped bottom out of the metal barrel. From another barrel or available tools, cut out a body whose diameter will be slightly larger than that of the disk. You can make an aluminum shed that will help you keep your grass trimmed. Use the handle to control the lawnmower, if it comes from a stroller, use it; otherwise, design the handle yourself. Attach the knives to the disk, make sure the joints are strong. Then all the parts are assembled by welding. First, a metal sheet is attached to the stroller, then a casing is attached to its surface and a disc is inserted into it. When the chainsaw is started, this mechanic rotates and cuts the grass.

Criterias of choice

When choosing a mounted rotary mower, you should decide what crops are going to be mowed, what tractors they will be installed on and what the terrain and size of the areas being processed are.

If you plan to mow thick-stemmed hard crops, then the power of the equipment should be greater than that of mowers used for cutting soft grasses.

A variety of rotary mower models can be suitable for tractors, but it is best to use equipment from the same manufacturer as the power unit, or recommended for use with it.

The choice of mower is also greatly influenced by the availability of spare parts for the equipment and, of course, its price.