Self-propelled mower KS-100 "PALESSE CS100"

Self-propelled mower KS-100

The self-propelled mower ks100 allows you not only to mow the grass, but also to perform a number of other typical jobs that accompany this. In particular, this model can cut grass, lay it in windrows and flatten it. The mower works with different crops - grains, cereals, legumes and others.

Design Features

The designers made sure that the ks100 mower performed its duties as best as possible. When designing, the emphasis was placed specifically on the header. The mower works efficiently, quickly and productively in different conditions.

- The ks100 mower is equipped with a high-quality header. The width of the header for mowing the tawa is 5 meters. This is 1 meter more than the equipment in lower class mowers.

- Roller-type mower with augers and flattening apparatus.

- Of great importance for any mower is the ability to follow the topography of the field. This self-propelled machine is equipped with a header that copies the terrain automatically. Moreover, it does this both in the transverse and longitudinal directions. This allows you to cut the grass almost perfectly.

- The cutting height of the herbs is adjusted by the operator, after which the automation takes care of the rest. The cutting level remains the same and perfectly level until the operator changes the settings.

- Thanks to its design features, the ks100 mower performs well not only on a flat field, but also on rather difficult areas, rocky fields, on ups and downs. It can also be used at night.

Chassis

The mower's chassis corresponds to its purpose and class.

- The ks100 model is equipped with a D-245S3A-2518 engine. The engine has proven itself well in the field as trouble-free and quite powerful. Equally important is economical fuel consumption.

- The power of the installed engine is 200 liters per second. This power is enough to cope with any task of mowing, flattening and laying grass.

- Fuel tank capacity 200 l. This is enough to carry out work and not be distracted by refueling for quite a long time. The tank is made of modern materials and is protected from rust.

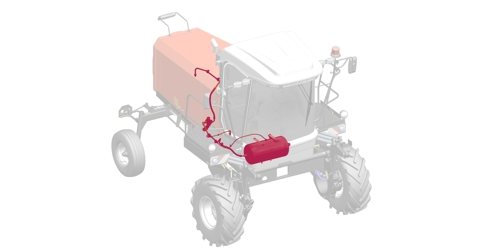

- The drive system is driven by a hydrostatic transmission, which is quite typical for a modern mower.

- The mower has a transport cart, which makes it easy to move the header into the transport position. After this, you can use public roads without much difficulty. Upon arrival at the field, the header is no less easily transferred to the working position. This does not require special equipment or special devices.

Comfortable cabin

The quality of his work largely depends on the condition of the operator. To relieve the operator from excessive stress and extreme fatigue, the designers of the ks100 mower tried to make the cabin as comfortable as possible.

- The comfortable seat is adjustable exactly as needed - in accordance with your own configuration and height.

- Large viewing windows allow you to monitor your surroundings. If an unforeseen, emergency situation arises, the operator will not miss it.

- The cabin of the ks100 mower is protected from dust, noise and vibration.

- The control panel, sensors, control handle - everything is well thought out, grouped according to meaning and easy to remember. On the control handle, the designers have placed not only the ability to regulate the speed of the mower and the direction of its travel, but also other important parameters that may require quick response.

Self-propelled mower KSU-1

The KSU-1 universal self-propelled mower is a smart way to solve several problems at the same time. It allows you to mow and windrow cereals, legumes and cereal crops with high profitability; mow, flatten and chop forage grasses. Powerful, maneuverable and versatile, this mower is ideal for farms that actively use separate harvesting and livestock farming.

MOTOR INSTALLATION

The self-propelled mower is equipped with a 7.12 liter engine. with a rotation speed of 2200 rpm. and a power of 157 hp. Reliable, economical and unpretentious, they have proven themselves in agricultural machinery.

Pneumatic system

To increase the autonomy of the machine, since 2014, power vehicles have been equipped with a pneumatic system as standard. It consists of a 100-liter receiver and a compressor with automatic pressure maintenance from 4 to 8 bar, convenient pneumatic tools and a quick-release coupling for connection, which reduces the complexity of servicing the mower. The air reserve in the system with the engine turned off is enough for 5 minutes - quite enough for routine maintenance.

Mounted universal system

Provides assembly of all adapters with a self-propelled universal mower without the use of additional or replaceable parts. In this case, connecting the working unit will not take even 15 minutes.

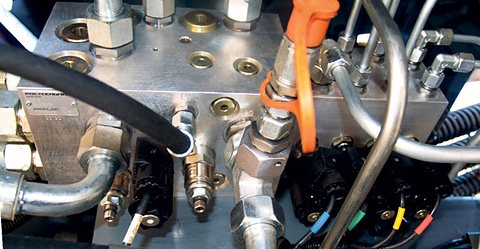

Hydraulics

The KSU-1 hydraulic system uses new solutions aimed at increasing reliability and ease of maintenance. A single hydraulic tank (50 l) and a single hydraulic control unit simplify the design and increase ease of maintenance. The presence of a variable displacement pump ensures a more economical use of power taken from the engine, thereby increasing its fuel efficiency.

Drive adapters

The operation of the roller conveyor header DF 900 and DF 700 is ensured by a hydraulic drive, since its use does not involve peak loads. This allows you to adjust the operating parameters of the unit (conveyor speed, roll location and reel rotation speed) from the operator’s workplace.

The drive of the adapters - mower-conditioner GH 500c, front rotary mower DM 350c, mounted mower-chopper JS 270 - is carried out through the PTO mounted on the power unit.

Adviser system

The mower uses a modern on-board computer aimed at convenient use and maintenance of the equipment. Among the system functions the following can be noted:

— collection and processing of information about the state of systems and components of the machine, displaying these parameters on the screen; — counting, storing and displaying quality indicators of KSU operation (hours worked, distance traveled, area harvested); — informing about the need for repairs or routine maintenance; : — Accounting for consumed fuel.

Chassis drive

The KSU-1 chassis drive uses wheel motors, which ensures smooth adjustment of the machine speed. The portal design of the drive and steering axles with a harvesting clearance of 1000 mm provides the necessary transport clearance, allowing the mower to move freely over windrows of any height and width.

Copy system

It is well known that the tractor attachment, consisting of lifting arms and lower longitudinal links, interconnected by braces of the central link and a hydraulic cylinder, does not ensure that the headers follow the field topography, which reduces the overall efficiency of work. The KSU-1 self-propelled mower is equipped with a system that ensures that all offered headers follow the terrain in the longitudinal and transverse directions. At the same time, all connecting places on the adapters are unified to ensure maximum convenience and minimize aggregation time. All measures taken together made it possible to achieve increased efficiency in the use of adapters.

Steered rear axle

A balanced-type steered bridge with a swing angle around the embedment of ±8° has increased stability and provides better maneuvering capabilities, especially when crossing ditches and exiting the field onto the highway. The original design of the steering linkage allows you to turn virtually on the spot, provides movement both forward and backward while maintaining reliable control.

COMFORT AND FUNCTIONALITY

The KSU-1 workstation fully meets modern ergonomic requirements. The Comfort Cab is equipped as standard with an adjustable seat and steering column, air conditioning, heater, refrigerator, sunshade and audio system. Control is carried out using a remote control located to the right of the operator’s chair and an anatomically adjusted joystick with operational buttons. Parameters relevant for the current process are automatically displayed on the monitor of the Adviser on-board system, which greatly facilitates control over the operation of components and assemblies, and panoramic glazing provides all-round visibility.

ADAPTERS

Roller conveyor headers DF 900 (9.0 m) and DF 700 (7.0 m)

Designed for harvesting cereals, cereal crops, green grasses with placing the cut mass in a right-handed, central, left-handed or double-pass windrow.

The drive of all working parts is hydraulically powered and controlled from the operator’s workplace. Productivity DF 900 - 10.5 ha/h, DF 700 - 8 ha/h at a travel speed of 12 km/h.

Mower-conditioner GH 500R (5.0 m)

A mower-conditioner with a segment-finger cutting device is designed for mowing, with or without flattening, seeded and natural grasses and laying them in a windrow. The productivity of the unit is 5.8 ha/h at a speed of 12 km/h.

Mower-conditioner GH 500R (5.0 m)

A mower-conditioner with a segment-finger cutting device is designed for mowing, with or without flattening, seeded and natural grasses and laying them in a windrow. The productivity of the unit is 5.8 ha/h at a speed of 12 km/h.

Mounted mower-chopper JS 270 (2.7 m)

It is used for mowing, chopping and loading into a nearby vehicle natural, seeded grasses and other forage crops with a height of no more than 2 m, except for raised bed crops. They are used for green feeding of animals and for laying haylage. Productivity - up to 40 t/h.