Important information about Gas bridges of the 66th — logbook Nissan Safari Forest Safari 1993 on DRIVE2

If anyone operates Gas-66 axles, they know that problems with bearings in the hubs periodically arise. And modern, non-USSR bearings in general often suck. And in mud, rivers, shock loads and with large wheels it’s even worse... It turns out that when the bearings work, they need lubrication. And the bearings in the hubs of the 66th are lubricated with grease like grease. It heats up during operation and is thrown by centrifugal force towards the walls. Residues are produced from the working track of the bearing and problems begin. And if some water leaks into the rivers... After all sorts of experiments with lubricants, I did it simply - On the hubs there are drillings for two bolts of the pumping tube cover. They are not end-to-end. I drilled one channel completely on each hub and screwed the grease fittings in there. (After I took them off a couple of times, now I just screw in a bolt, and when necessary I screw in the grease fitting) And, periodically, I add liquid lubricant through the grease fitting, just like in the bridge. Then again consistent, etc. When there is enough solid oil in the bridge, but it is at the edges, liquid lubricant allows it to get back to the bearings... Plus you can always renew it. I had a case when I discovered in the first third of the trip that I could already fry eggs on the rear hub - but I had to go. I found a gun with sealant residue in the car. Having got rid of the sealant, I filled the tube with grease and unscrewed the bolt with the channel and injected grease into it. Then, on the trip, again. When we arrived back, we disassembled the hub - small pieces with rounded edges remained from the bearing race. But the car arrived. (the case was with Yellow). After that, I always check the hub tamper with my hand while on the road. And if they are very warm or differ in temperature from the others, then I simply syringe them and the problem goes away. Cheap and cheerful...

www.drive2.com

GAZ 66: Army hardening - Avtotsentr.ua

| This year the famous all-terrain vehicle GAZ-66 (4x4) turned 40 years old. These well-designed machines began rolling off the assembly line in July 1964 and remained in production for 35 years. Many of them are still in service today, both in the army and in civilian life. |

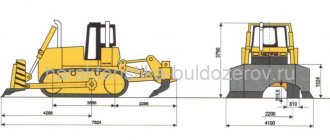

GAZ-66 was a fundamentally new model, which replaced the all-wheel drive truck GAZ-63. Unlike its predecessor, this car had a cab-over-engine layout, was equipped with a new V-twin engine and had a metal cargo platform. The car had a lower center of gravity and had better cross-country ability. A characteristic feature was the presence of a centralized system for regulating the internal air pressure in the tires. True, it was absent on some early production samples, but since 1968 it has become mandatory.

The modification of the car without a winch was designated as GAZ-66-01, with a winch - GAZ-66-02. In 1985, the car was modernized and a number of its operational characteristics were improved. The basic version received an index of 66-11.

Since 1993, diesel versions have also been offered: the GAZ-66-41 model was equipped with a 4-cylinder GAZ-544 diesel engine (75 hp). Its external difference is the gable “civilian” rear wheels. And the GAZ-66-42 car was equipped with a turbocharged version of the diesel engine with a capacity of 116 hp. With.

The 66th was exported to the countries of Eastern Europe, Central Asia, the Middle East and Latin America. In total, from July 1964 to July 1999, 965,941 GAZ-66s were produced, more than 70% of which were supplied to specialized factories for further assembly with van bodies and various equipment.

Cabin

GAZ-66 has a cabover layout and a two-seater cabin. The driver and passenger are separated from each other by a wide hood, through which access to the engine is provided.

The cabin is ascetic in a military way, there is no plastic or velor, there is only metal around, only covered in places with fiberboard panels, and even a hood cover. Near the driver and passenger there are mounts for a Kalashnikov assault rifle, and on the hood - for a night vision device. The angle of the seat backs is adjustable, and to change their position in the horizontal plane you will have to use a wrench.

In winter, the cabin is quite warm, but this is due not so much to the heater as to the hood heating up from the engine. Some drivers completely remove the hood cover for the winter, then even severe frosts are not scary.

Indicators for oil pressure and temperature, fuel level and battery charging provide the necessary information about the condition of the engine. A little to the right of the instrument panel there is a pressure gauge for the tire pressure regulation system.

The paintwork of the cabin is very durable - on our roads we sometimes see 25-year-old cars with perfectly preserved “original” paint.

Engine and transmission

Most cars are equipped with V-shaped 8-cylinder petrol engines ZMZ-66-01, which are distinguished by their great “appetite”. However, it can be reduced somewhat by pouring high-quality oil into the engine. This also applies to the transmission: instead of TAP-15 oil, pour TAD-17 into the gearbox housing, transfer case, front and rear axles, fuel consumption can be reduced to 5 liters per 100 km.

A serviceable engine starts easily in any frost, but requires quite a long warm-up. For this reason, the use of insulation installed on the radiator lining is mandatory. This will not only reduce warm-up time and save fuel, but will also significantly increase the temperature in the cabin.

The GAZ-66 is equipped with a 4-speed gearbox, a transfer case with a reduction gear and cam-type self-locking differentials.

Steering and chassis

The GAZ-66 is equipped with power steering, which allows you to turn its impressively sized wheels without much effort.

Thanks to wide tires, even quite large potholes on the roads go unnoticed. Hydraulic shock absorbers installed on both axles of the car also contribute to this.

In general, the steering is very reliable, but requires constant maintenance. Steering rods should be lubricated every 2 thousand km, and when driving on unpaved roads, the maintenance frequency is reduced to 1.2 thousand km.

Cars of different years of production have different braking systems. On earlier copies, the main brake cylinder was borrowed from the “21st” Volga; it has only one circuit and a vacuum brake booster. If the hydraulic drive or cuffs of the vehicle's brake cylinders are damaged, the brakes will fail. Since 1985, this drawback of the “66s” has been eliminated, the brake drive has become dual-circuit, and each line has its own “vacuum seal.”

Due to their off-road design, tires not only have a short service life, but also cause a lot of noise when driving on hard surfaces, which often even drowns out the engine.

Electrical equipment does not cause any special problems. The car is equipped with a powerful 85-amp generator, which allows you to use a large number of additional consumers without unpleasant consequences.

GAZ-66 is a reliable car, but in order for it to serve for a long time and not fail in difficult times, it requires frequent and labor-intensive maintenance. There are 45 lubrication points on it, and on a car equipped with a winch - 55. To this you still need to add a lot of various adjustment work.

Despite the “gluttony” engine, labor-intensive maintenance and lack of sufficient comfort in the cabin, the GAZ-66 still has its admirers. And this is due primarily to its excellent cross-country ability.

| GAZ-66-01 | GAZ-66-40 |

| flatbed truck | ||

| Dimensions, L/W/H, mm | 5805/2322/2440 | |

| Wheelbase, mm | 3300 | |

| Ground clearance, mm | 315 | |

| Load capacity, kg | 2000 | |

| Total weight, kg | 5840 (6010)* | 6050 (6220)* |

| Gross weight of the road train, kg | 7800 | 8050 |

| Cargo dimensions. platform, L/W/H, mm | 3313/2050/510890 | |

| Loading height, mm | 1110 | |

| Turning radius, m | 9,5 | |

| Tank volume (both), l | 210 | |

| Engine | ||

| Brand | ZMZ-6601 | 5441.10 |

| Type | petrol. | turbodiesel |

| Disp. and number of cylinders/cl. on cylinder | V8/2 | R4 |

| Working volume, cm cubic. | 4250 | 4750 |

| Power, l. s/rpm | 115/3200 | 116/2400 |

| Max. cr. torque, Nm/rpm | 290/2250 | 390/1500 |

| Transmission | ||

| Gearbox, type | fur. 4-st. | fur. 4-st. |

| Chassis | ||

| Front/rear brakes | drum/drum | |

| Suspension front/rear | stuck spring/hung springs | |

| Tires | 12,00-18 | |

| Performance indicators | ||

| Max. speed, km/h | 95 | ]85 |

| Consumption, l/100 km (at 60 km/h) | 24 | 17 |

| Used car price | 1500 – 5500 USD e. | |

| Prices for new spare parts, UAH. |

Front/rear brake pads

| 200 (set) | |

| Oil filter | 8 – 12 |

| Front wheel bearing | 90 |

| Axle shaft assembly (with bearing) | 320 |

| Shock absorber | 60 – 80 |

| Clutch kit | 250 |

| water pump | 120 – 150 |

| Radiator | 930 |

| Muffler | 45 – 60 |

| Generator | 360 – 400 |

| Starter | 320 – 380 |

| Camshaft | 280 – 300 |

| Timing gear (1 pc.) | from 55 |

Evgeniy Sokur Photo by Vladislav Boyko

If you find an error, please select a piece of text and press Ctrl+Enter.

www.autocentre.ua

How much does gas 53 weigh - Car lover's blog

In the 60s of the last century, the plant, today called GAZ Group, began producing medium-duty trucks.

New power units, transmission mechanisms, cabin and body, and controls were installed on the trucks.

Models of series 52, 53, 66 formed a line of universal trucks, which, in the interests of the national economy, provided transportation in industry, for agricultural and construction needs.

Modifications and release history

The car was the most popular truck of the Union republics. There were 4 million conventional, dump truck and specialized vehicles operating on the country's roads.

In 1961-1967 GAZ-53F was produced. Six-cylinder 82 liters. With. The GAZ-11 engine with a four-speed gearbox ensured the transportation of 3,500 kg of cargo, consuming 24 liters of low-octane gasoline for a run of 100 km.

https://www.youtube.com/watch?v=LD35jDWONLk

By the planned release time of the model, the V-shaped eight-cylinder power unit was not in production.

For the 53F, the six-cylinder GAZ-11 was boosted, increasing the compression of the mixture. There was no ready-made hypoid rear axle, so they installed a mechanism with bevel gears from the 51A model (the car is shown in the photo).

Objectively, in terms of its technical characteristics, the GAZ-53F car was a transitional model between the 51A series (with a load of 2,500 kg) and the SAZ-53B series (with a load capacity of a ton more), which was achieved by an increased base to 3.7 m and new tires 8 ,25-20, mounted on steel disks.

The car was used not only as a dump truck, but also a sewage truck, fuel trucks and milk tankers were common.

The GAZ-53 was not a complete design; due to frequent failures of parts and mechanisms, it was not popular among drivers and repair workers of motor transport enterprises. The truck with a clearly weak engine and an unreliable axle was produced until 1967.

From 1964 to 1983, models of the 53 and 53A series with a cargo load of 3,500 and 4,000 kg hit the roads. More powerful power unit ZMZ-53 with 115 hp. With. ensured an increase in the speed parameter to 85 km/h with gasoline consumption of 25 liters per 100 km.

Differences between the 53A line and the 53

The car models have the following differences:

- reinforced front axle;

- new cardan design;

- more reliable steering gear design;

- new radiator grille;

- turn signals are duplicated by repeaters on the wings of the cabin;

- the presence of electric windshield wipers;

- cabin heating.

In 1973, model 53A was awarded the USSR State Quality Mark. Expanding the functionality of the vehicle, the production of chassis 53 01 for covered bodies and special equipment was launched.

Chassis 53 02 was a platform for the use of a dump truck body and was equipped with a power removal device for a hydraulic pump.

Trucks of models 53 50 and 53 70 were exported. The vehicles were readily purchased in Belgium, Finland, and in socialist countries. In Bulgaria and Cuba, trucks were assembled from kits supplied from GAZ.

Model 53 12 was produced from 1983 to 1992, as a further development of the 53rd line. The truck was equipped with an eight-cylinder ZMZ-511 engine.

Power parameter is 120 hp. With. made it possible to increase the load to 4.5 tons, and the speed indicator to 90 km/h.

Gasoline consumption increased to 30 liters, but provision was made for installing equipment for refueling with liquefied or compressed gas.

Technical characteristics of the basic on-board vehicle GAZ-53:

| Index | Unit change | Meaning |

| Production period | 1964-1983 | |

| Limit dimensions (length, width, height) | mm | 6 395, 2 380, 2 220 |

| Fuel consumption | l/100 km | 24 |

| Total places | 3 | |

| Load | kg | 4 000 |

| Fully loaded weight | kg | 7 400 |

| Base between wheel axles | mm | 3 700 |

| Ground clearance is minimal | mm | 265 |

| Speed | km/h | up to 85 |

| Power unit | ZMZ-53 | |

| Clutch mechanism | one disk, dry type, with lever drive | |

| checkpoint | by four steps | |

| Rear axle main gear | single, conical, hypoid | |

| Steering column | globoid worm and three-comb roller | |

| Tire size | 8,25-20 | |

| Brake device | drum-type mechanism on all axes, with hydraulic drive |

The engine on the GAZ-53 (ZMZ-53) truck is a V-shaped, eight-cylinder (two rows of four cylinders), carburetor type, operating on a four-stroke cycle.

The working volume of the internal combustion engine cylinders of the GAZ-53 car is 4.25 liters (with a cylinder cross-sectional size of 92 mm and piston strokes of 80 mm).

Technical specifications for power 115 hp. With. The GAZ-53 engine is started using a starter.

The nominal crankshaft revolutions per minute are 3,200. The mixture compression ratio is 6.7.

Systems and mechanisms

The cylinder block is made of casting from Al-4 alloy, after casting it is sealed by heat treatment and impregnation with synthetic resin. This is a monoblock V-shaped design with an angle along the cylinder axes of 90 degrees.

The cavities of the block and cast iron liners for the pistons form the water cooling jacket of the engine. The possibility of repair replacement of sleeves is provided (5 groups with letter designations). The clutch housing is secured to the end of the block with threaded rods.

The piston group is cast from Al-30 aluminum alloy. The piston is round in shape with a flat bottom; three grooves are cut into its body for oil scraper and compression rings.

Pistons are divided into 5 repair groups according to their own diameter (letter marking) and into 4 groups according to the diameter of the piston pin hole (color marking).

The block heads are made of Al-4 alloy. Valve seats are made of cast iron, guide bushings are made of copper-graphite ceramics. The block and cylinder heads are connected by threaded rods through gaskets made of asbestos board reinforced with steel.

The crankshaft is cast from cast iron, with connecting rod journals, bearings and counterweights formed on it. The shaft undergoes dynamic and static balancing.

Axial movement of the crankshaft is eliminated by two washers installed on either side of the first journal support. It is sealed in the block with oil-sinking grooves, oil seals and asbestos packing.

THIS IS INTERESTING: How much oil is in a box of VAZ 2107 5 mortar

The gas distribution mechanism with overhead valve installation ensures the intake of the working mixture into the cylinders and the exhaust of exhaust gas.

The device consists of: camshafts and gears, pushers, rocker arms, rods, valves, guide bushings and springs.

The camshaft is forged from steel. It has five bearing journals, cams, a gear drive for an oil pump and an ignition distributor.

The power system includes: a 90-liter gas tank, pipelines, a mechanically driven diaphragm pump, fuel filtering devices and a two-chamber K-126 carburetor - a device for preparing a fuel-air mixture.

The lubrication system supplies oil to the rubbing parts under pressure and gravity. Gear oil pump driven by a camshaft, full-flow oil filter, serviceable.

The air preparation filter is serviceable, inertial, with sedimentation of polluting particles in an oil bath.

Cooling system with water pump, closed type, liquid. It consists of a water jacket of the cylinder block, radiator, pump, thermostat, shutters, fan, fan casing, radiator cap and connecting hoses. Capacity – 22 liters. Contact ignition system.

Model 53 12

The truck is designed to transport cargo weighing up to 4,500 kg on asphalt and dirt roads. The machine allowed operation at temperatures from +40 to -40º C.

Option 53 12 is a deep modernization of the 53A model with better indicators in terms of fuel economy, repair regulations and safety.

Increasing the power of the power plant and the use of new radial tires made it possible to increase the dynamics and cross-country ability of the vehicle.

Cars of the 53 27 and 53 19 series ran on compressed and liquefied gas.

The ZMZ-53-11 power unit received a sectional oil pump, a full-flow filter device, new cylinder heads with an increased compression parameter, and the crankcase ventilation was switched to a closed circuit.

The car had strengthened: spring suspension, frame elements, cross member (beam) of the axle. It was possible to reduce exhaust toxicity by 19%.

In the future, the car will be equipped with a front-view triplex, a contactless ignition system, new lighting equipment, emergency signals, and a hydraulic vacuum booster with brake pressure distribution along the axes.

Dump truck

The truck was produced for transporting bulk cargo in the interests of agriculture and industry. Due to the hydraulic system, the unloading process was mechanized.

The capacity of the all-metal body platform is 5 cubic meters. A special mechanism allows mechanical unloading on one of the working sides.

The dump truck was produced on the GAZ-53 02 chassis with a frame shortened by 270 mm at the rear. The wheelbase remained the same. Equipped with a power take-off shaft.

The platform was equipped with a gear-type hydraulic pump, which, through a system of control valves, ensured the operation of a three-link hydraulic cylinder for lifting the body.

The rear hitch and towing devices have been moved to the sides of the frame.

Problematic issues of the entire series

The car series has the following disadvantages:

- short service life of the clutch and braking system;

- significant fuel consumption;

- unreliable: connection of parts of the cardan transmission, distributor and variator of the ignition coil;

- engine rear main bearing oil seal leaking.

The 53 Series medium-duty truck has proven to be a technically simple, reliable vehicle that is easy to drive. Durable cars with a discreet design can still be found on rural roads in the regions.

The machine can be serviced and repaired in a private garage, in a rural workshop, or in the field. Spare parts for cars are cheap and not in short supply.

When replacing oil and filter elements within the scheduled time frame, the engine life before overhaul can exceed 400 thousand km.

And in conclusion, let’s watch a video of a test drive of the GAZ-53 truck, and also find out the opinion of experts about the technical characteristics of the car:

Source: https://vipauto-barnaul.ru/ekspluatatsiya/skolko-vesit-gaz-53.html

GAZ 2705 | Car lubrication

| Lubrication point name | Col. points | Col. lubricant material | Name of lubricant, oil | Periodicity | Work performed | ||

| TO-1 | TO-2 | CO | |||||

| Engine lubrication system | 1 | 6 l | See table. 11.5 | + | + | — | Change the oil and oil filter filter element (see section 4.1) - ZMZ-4025, 4026. Change the oil and oil filter - engines 4215, ZMZ-4061, 4063. |

| Ignition sensor-distributor rotor bushing (421 ZMZ-4025, 4026) | 1 | Engine oil | — | + | — | Lubricate the rotor bushing with 4-5 drops | |

| Gearbox housing | 1 | 1.2 l | At temperatures from -25° C to +40° C, Super T-3 oil. Duplicating oils: TSp-15K, Ufalub Unitrans, Devon SuperT. At temperatures from -40° C to +20° C oil "Lukoil TM-5" SAE 75W90 | — — | + +++ | — — | Check the level and, if necessary, top up to the level of the lower edge of the filler hole (for the plug located on the right side) or 7 mm below the level of the lower edge of the filler hole (for the plug located on the left side). Change the oil, clean the magnetic drain plug. |

| Cardan joint needle bearings | 3 | 60 g | Oil "Super T-3". Duplicating oils: Ufalub Unitras, Devon Super T | — | + | — | Change through grease nipples until fresh grease comes out from under all seals |

| Bushings and support bearings for steering knuckles | 2 | 25 g | Solidol S Backup lubricant Solidol Zh | + | + | — | Lubricate through the grease nipple until grease appears from under the support bearing seal and from the gap between the upper knuckle boss and the beam. If grease comes out from under the pin cover, it is necessary to tighten the cover mounting bolts and wash the pin joint with a mixture of transmission oil and kerosene in a 1:1 ratio through a grease nipple |

| Rear axle housing | 1 | 3.0 l (2.2* l) | At temperatures from -25° C to +40° C, Super T-3 oil. Duplicate oils: Ufalyub Unitrans, Devon SuperT. At temperatures from -40° C to +20° C, Lukoil TM5 oil SAE 75W90 | — — | + +++ | — — | Check the level and, if necessary, top up to the level of the control plug. Change the oil, clean the magnetic drain plug after operating at low temperatures on oil with the addition of diesel fuel, change the oil in the spring |

| Rear wheel bearings | 4 | 66 g | At temperatures from -25° C to +40° C, Super T-3 oil. Duplicate oils: Ufalyub Unitrans, Devon SuperT. At temperatures from -40° C to +20° C, Lukoil TM5 oil SAE 75W90 | — | +++ | — | When changing the oil in the rear axle, remove the hubs, wash them with kerosene, dry them, put 15 g of lubricant in each bearing and in the cavity between the working edges of the cuffs to 2/3 of the volume. Lubricate the working edges of the cuff with a thin layer of lubricant. |

| Front wheel hub bearings | 4 | 270 g | Litol-24. Backup lubricant LITA | — | +++ | — | Remove the hubs, wash with kerosene, dry, put fresh lubricant 15 g in the internal bearings, 10 g in the outer bearings, 110 g in the cavity of the hubs and in the cavity between the working edges of the cuffs, lubricating the edges with a thin layer of lubricant. Install the hubs and adjust the bearings |

| Shock absorbers | 4 | 0.28x4=112 g | AZh-12T. Duplicating fluid - spindle oil AU | — | — | — | Change fluid if necessary |

| Steering gear housing | 1 | 0.45-0.5 l | Oil “Super T-3” Duplicate oils: “Ufalub Unitrans”, “Devon Super T” | — | + | — | Check the level and top up if necessary. The oil level should be within 15mm down from the bottom edge of the filler hole |

| Steering shaft seal | 1 | 5 g | Litol-24 lubricant. Backup lubricant LITA | — | — | + | Move the lip of the seal and lubricate the working surface of the shaft |

| Steering universal joints | 4 | 7 g | Litol-24. Backup lubricants: Solidol S, Solidol Zh | — | — | + | Lubricate through the grease nipple until fresh grease appears. |

| Brake master cylinder refill reservoir | 1 | 0.52 l | Brake fluid "ROSDOT". Duplicating liquid "Tom" | — | — | + | Change the fluid twice a year (in spring) |

| Clutch master cylinder reservoir | 1 | 0.2 l | Brake fluid "ROSDOT". Duplicating liquid "Tom" | — | — | + | Change the fluid twice a year (in spring) |

| Battery terminals | 2 | 10 g | PVC grease or grease | — | — | + | Apply a thin layer |

| Locks and door lock drives (external and internal) | 28 | 40 g | VMGZ or MGE10A oil | — | + | + | |

| Door lock switches | 4 | 8 g | Litol-24. Backup lubricant LITA | — | — | + | Rinse before lubricating |

| Cab door limiters | 2 | 2 g | Litol-24. Backup lubricant LITA | — | — | + | Lubricate the lever as needed if squeaking occurs. |

| Rubbing surfaces of side door guides | 3 | 30 g | Litol-24. Backup lubricant LITA | — | + | — | Wipe before lubricating |

| Hood lock | 1 | 1 g | VMGZ or MGE10A oil | If necessary, if the latch jams | |||

| Hood lock drive | 1 | 15 g | Litol-24. Backup lubricant LITA | — | — | + | Rinse before lubricating. Lubricate the rubbing surfaces with a thin layer |

| Hood hinges | 2 | 2 g | VMGZ or MGE10A oil | — | — | + | Lubricate if necessary if squeaking occurs |

| Van and Bus Side Door Upper Roller Bearing | 1 | 20 g | Litol-24, LITA or CIATIM-201 | + | + | — | Apply lubricant |

| Engine cooling system | 1 | 9.7** l 11.5*** l | Coolants TOSOL-A40M, OZh-40, “Lena”, “Thermosol”, Brand A-40 | — | — | + | Check density during seasonal maintenance |

automn.ru

TRUCKS GAZ, ZIL, KAMAZ, URAL, MAZ, KRAZ

_________________________________________________________________________________________

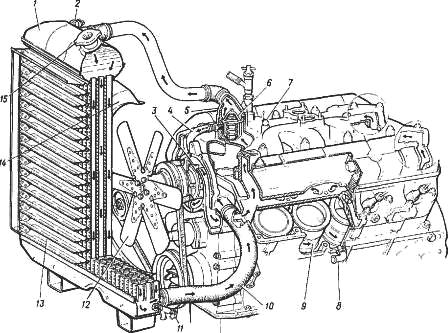

Maintenance of the GAZ-53 engine cooling system

The GAZ-53 engine cooling system (Fig. 1) is liquid, closed, with forced circulation of liquid, filled with low-freezing liquid Antifreeze. The GAZ-53 cooling system consists of an engine water jacket, a water pump, a radiator, a thermostat, a fan with a casing, blinds, a radiator cap (with valves) and connecting hoses. System capacity - 21.5 liters. The most favorable temperature regime for engine operation is within 80 - 90 °C. The specified temperature is maintained using thermostat 6, which operates automatically, and blinds controlled by the driver.

In addition, there is a warning light on the instrument panel that lights up when the coolant temperature rises to 104–109 °C. Sensor 2 of the signaling device (TM104-T) is screwed into the upper radiator tank. When the lamp lights up, you should immediately stop the engine, find out and eliminate the cause of its overheating. Thermostat GAZ-53 with solid filler, single-valve TS 108 (Fig. 2). It is installed in a special cavity at the coolant outlet from the inlet pipe. Thermostat consists of valve 3, seat 2, thermal power element 5 with rod 1 and spring 4, where L is the valve stroke. Fig.2. GAZ-53 thermostat The thermostat valve begins to open at a temperature of 78-82 °C, and at a temperature of 93-95 °C it is completely open. Water pump (pump) GAZ-53 of centrifugal type (Fig. 3). Roller 2 of the water pump rotates in two ball bearings and has flats at the ends. The pump impeller is pressed onto one end of the shaft, and the hub onto the other. The impeller is secured with a bolt screwed into a threaded hole in the end of the shaft. The hub is secured with a nut screwed onto the threaded end of the shaft. Ball bearings with a spacer sleeve between them are sandwiched between the pulley hub and the thrust ring; They have felt seals at the outer ends, mounted in the outer races of bearings secured in the housing with a locking ring. Fig.3. Water pump (pump) GAZ-53 The cavity of the GAZ-53 pump, in which the coolant circulates, is separated from the cavity in which the bearings are mounted, by a rubber self-moving oil seal with a sealing washer made of a graphite-lead composition. A spring 8, brass clips 9 and 10, a cuff 11, a sealing washer 12 are installed in the recess of the pump impeller and are locked with a ring 13. The liquid seeping through the oil seal flows out through the hole 7 in the housing 3. Through a grease nipple 5 screwed into the water pump housing pump (pump), the bearings are lubricated until the grease appears in the control hole 4.

Excess grease should be removed immediately to prevent it from getting on the fan and water pump drive belts and pulley tracks. Oily belts and grooves should be wiped with a rag lightly moistened with gasoline. Litol-24 grease is used to lubricate the bearings. It is allowed to use a fatty lubricant as a backup. The GAZ-53 radiator of the cooling system (see Fig. 1) is a tubular-tape, copper-brass, consisting of brass (upper and lower) tanks, a set of vertical brass flat-oval tubes with corrugated copper strips placed between them, radiator mounting plates , radiator plugs and drain valve. Two steel side plates are soldered to the upper and lower radiator tanks, which give the radiator the necessary rigidity and also provide the ability to attach the fan casing to it. The GAZ-53 radiator is attached in the lower part to special brackets on the frame using rubber gaskets and in the upper part - with two rods.

The radiator cap has two valves: a steam valve, which opens at an excess pressure of 45 - 60 kPa, and an air valve, which opens at a vacuum of 1 - 10 kPa. The fan is six-blade, metal, consists of two crosses, between which the blades are riveted, and is attached together with a pulley with four bolts to the pump shaft hub. The fan is statically balanced and driven by a V-belt from the crankshaft pulley. The belt is tensioned by turning the generator, which is driven by the same belt. The correct belt tension is checked by pressing a spring dynamometer on it with a force of 34 - 44 N. In this case, the fan belt should bend by 10 - 15 mm. The GAZ-53 fan casing is stamped metal and significantly increases the efficiency of the fan. The blinds are metal, plate, controlled by a wire rod from the driver's seat. The draft handle has several fixed positions for closing the blinds to ensure the required temperature conditions for the engine. The upper tank of the GAZ-53 radiator must be filled to the filler neck. A decrease in temperature leads to a decrease in the fluid level, and therefore, at low temperatures, its level in the radiator may decrease. However, even at temperatures below - 30°C, the liquid level in the radiator must be at least 50 mm above the ends of the cooling tubes. As the engine warms up, the coolant level rises as the coolant temperature rises.

At subzero temperatures, it is permissible to check the fluid level on a warm engine by removing the cap from the radiator and making sure that there is coolant in the upper radiator tank; install the plug in place, paying attention to its installation; the plug must tightly close the radiator neck to ensure the tightness of the cooling system; warm up the engine to a temperature above 90 °C. If you frequently add fluid, you should check the tightness of the GAZ-53 cooling system. It is allowed to temporarily add water to the cooling system. The procedure for filling water is: cool the engine, remove the radiator cap, fill the radiator with water to the specified level, and replace the radiator cap. It should be borne in mind that when water is added, the freezing point of the mixture increases, therefore, at the first opportunity, the system must be repaired and filled with Antifreeze A-40. Antifreeze A-65 and antifreeze brands “40” and “65” can be used as a low-freezing coolant. Filling with low-freezing liquids must be done carefully, without spilling it. During daily inspection, before leaving, check the tension of the fan belts. The belt is tensioned correctly if, under a load of 35 - 45 N, in the middle of the section between the generator and fan pulleys, the deflection is within 10 - 15 mm. The tension is controlled with a spring dynamometer. In case of jamming, wash it in kerosene and lubricate the blind rod with grease, having first removed it from the shell. If the system is filled with low-freezing liquid in CO (autumn), check the density of the coolant, which should be 1.078–1.085 g/cm3 at 20°C. After 4 years of operation of the car, the coolant is changed, having first flushed the cooling system, for which the coolant is drained, the system is filled with water, the engine is started and warmed up, then, after stopping, the water is drained, after the engine has cooled, the system is filled with water again, and the flushing is repeated. The liquid from the GAZ-53 cooling system is drained with the radiator cap open through three taps: on the right side of the cylinder block, on the radiator and on the cabin heater hose. When using water in a cooling system, it should be borne in mind that the use of good-quality water is one of the main conditions for technically correct operation of engines, preventing the formation of scale and corrosion in the cooling system, which can lead to serious problems, for example, blockage of radiator tubes. The GAZ-53 cooling system should be filled with soft, clean water, preferably rain or snow. The use of water with high hardness - artesian or spring water, and especially sea water - is unacceptable. The water in the cooling system should be changed but less frequently. It is necessary to drain the water into a clean container so that it can be refilled into the system. Fig.4. Flushing the GAZ-53 cooling system 1 - radiator; 2 — cylinder block; 3 - water pump In spring and autumn, if water is used, the cooling system is flushed. The engine water jacket and radiator are washed separately.

Washing is carried out in the direction opposite to the water circulation during system operation (Fig. 4). When flushing the engine water jacket, it is necessary to remove the thermostat and unscrew the drain valves. The radiator is removed and washed separately. The GAZ-53 radiator is repaired only if there is a small number of destroyed tubes (no more than 4 pieces) and they are soldered in no more than five places in the core.

The solder flow should not exceed 1.5 cm2. After soldering, the cooling plates and corrugated tapes are straightened, and the radiator is checked for leaks. The most typical malfunctions of the pump are water leakage through the impeller oil seal as a result of wear of the sealing washer or oil seal collar and wear of the roller bearing. These faults are eliminated by replacing worn parts with new ones. Remove the GAZ-53 water pump from the timing gear cover. Holding the pulley hub in a vice, unscrew the bolt securing the water pump impeller and remove the washers. A puller is used to press the impeller off the pump shaft. Before removing the impeller, in order not to damage the threads in the water pump shaft, it is necessary to place a washer between the end of the shaft and the puller bolt.

Remove the locking ring and take out the sealing washer, oil seal seal, seal rings and seal spring. Wash and clean the water pump parts. The impeller and oil seal are assembled, for which purpose the oil seal spring, oil seal cages, rubber cuff, sealing washer are placed in succession in the rear recess on the impeller, and all these parts are secured with a locking ring. If the absolute amount of wear on the sealing washer is small, it can be reinstalled by turning the unworn side towards the water pump housing. The end of the pump body, along which the sealing washer operates, is lubricated with a thin layer of graphite lubricant before pressing the impeller onto the pump shaft. This improves the quality of running-in of the working surfaces of the sealing washer and the end of the pump body. Press the impeller onto the roller. Pressing is carried out until the impeller hub stops at the end of the roller flat.

Put a spring washer and a flat washer on the impeller fastening bolt and screw the bolt into the rear end of the shaft until it stops; screw the pump to the timing gear cover, replacing its gasket with a new one.

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

- GAZ-3307 clutch maintenance

- Steering system GAZ-3307

- Gearbox parts for GAZ-3307

- Maintenance of the rear axle GAZ-3307

- Maintenance of the fuel system of the D-245 diesel engine

- Clutch GAZ-3309 with a diesel engine

- Operations for disassembling the GAZ-3309 gearbox

- GAZ-3309 front axle service

- Repair of cardan shafts of GAZ-3309 cars

_________________________________________________________________________________________

_________________________________________________________________________________________

- Operations for assembling basic components of the ZIL-130 engine

- Service and repair operations for the ZIL-130 gearbox

- Maintenance and repair of ZIL-130 clutch

- Repair and adjustment of the rear axle ZIL-130

_________________________________________________________________________________________

- KAMAZ-4310, 43118, 43114

- KAMAZ-5320, 55111, 53212, 5511, 55102

- KAMAZ-65115, 6520, 65117

- KAMAZ-4308

- Engine KAMAZ-740

_________________________________________________________________________________________

- Parts of the cylinder block and head of the YaMZ-236 engine

- Service maintenance of the YaMZ-236 piston group and crankshaft

- Diagnostics and technical adjustments of the YaMZ-236 engine

- Design and adjustment of fuel injection pump and injectors of the YaMZ-236 engine

- Cylinder block and piston YaMZ-238

- Components of the YaMZ-238 diesel fuel supply system

- Design and adjustment of the fuel injection pump of the YaMZ-238 diesel engine

- Technical design of the YaMZ-239 gearbox

_________________________________________________________________________________________

- Components of the front axle and steering rods of the Maz-5516, 5440

- Steering system of Maz-5516, 5440 cars

- Clutch and gearbox parts Maz-5516, 5440

- Maintenance of drive axles of MAZ-5516, 5440 vehicles

- Power steering for Maz-5551, 5335 cars

- Maintenance of cardan transmission of Maz-5551, 5335 cars

- Maintenance and adjustment of clutch MAZ-5551, 5335

- Repair and service of the rear axle of MAZ-5551, 5335 cars

_________________________________________________________________________________________

- Gearbox Ural-4320

- Construction and adjustment of Ural-4320 bridges

- Maintenance of transfer case Ural-4320

- Steering components Ural-4320

_________________________________________________________________________________________

- Servicing the KRAZ-255, 260 gearbox

- Steering mechanism and power steering Kraz-255, 260

- Adjustments and repairs of the power steering cylinder and steering rods of the Kraz car

- Drive axle components and drive shafts Kraz-255, 260

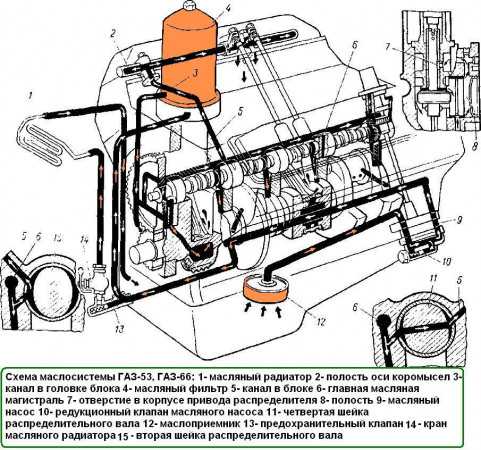

Engine lubrication system GAZ-66, GAZ-53

Page 1 of 2

The engines have a mixed (pressure and splash) lubrication system.

Under pressure, oil is supplied to the main and connecting rod bearings of the crankshaft, and to the camshaft bearings.

Oil is supplied to the rocker arm bushings with pulsating pressure through the hollow axles of the rocker arms, into which it enters through channels coming from the second and fourth camshaft bearings. Oil is supplied to the rest of the engine parts by gravity and splashing.

To cool the oil, the engines are equipped with an oil cooler installed in front of the cooling system radiator.

The pressure drop in the lubrication system is mainly caused by wear of the oil pump parts or the crankshaft and camshaft bearings. With significant wear, the oil pump begins to operate noisily. To identify pump faults, it must be removed from the engine and disassembled. But you should start disassembling the pump only after checking the condition of the pressure relief valve, since it may cause abnormal pressure in the oil system (a weakened spring, a stuck plunger, etc.).

To make sure that the pressure reducing valve is working properly, you need to unscrew its plug, remove the spring and make sure that the plunger moves in its seat freely, without jamming, and that the spring is in normal condition.

The free length of the spring should be 50 mm. The force of the valve spring when compressed by 10 mm should be equal to 4.6 kg. When the force weakens, the spring is replaced with a new one, since placing washers under it or stretching it to increase the force is strictly prohibited.

Disassembling the oil pump

1. Remove the pump together with the gasket from the cylinder block.

2. Remove the lower section housing with the driven gear and gasket.

3. Remove the oil pump lower drive gear and gear key from the pump shaft.

4. Remove the oil pump baffle with gasket.

5. Remove the driven gear of the upper section of the pump from the housing.

6. Remove the shaft with the drive gear of the upper section from the pump housing.

7. After disassembling the pump, thoroughly rinse, dry and inspect all its parts.

8. If wear from the gear is found on the oil pump partition, grind it until traces of wear are eliminated. If there is significant wear on the section housings, replace the pump with a new one.

When making repairs, keep the following in mind.

The distance from the end of the roller with a hexagonal hole to the upper end of the drive gear of the upper section of the pump should be 40 ± 0.15 mm.

A hole with a diameter of 4 mm for the gear mounting pin on the pump shaft is drilled to a depth of 23 ± 0.5 mm at a distance of 15 mm from the end of the gear. Elevation of the pin above the plane of the tooth cavity is not allowed.

autoruk.ru

What motor oils and fluids to use

For the lubrication system, it is recommended to use all-season oil M-8V or M-6/10V. But if you work in severe frosty conditions, then you will need ASZp-6 oil. For the gearbox, it is better to use all-season oil TAP-15v, from minus 25 to minus 30, use TSp-10, and if the temperature is even lower, then fill in TSp-15K with a small addition of diesel fuel for diesel gas 3307. The same oils Can also be used for steering gear. The main gear housing should be filled with all-season oil TSp-14gip; in very severe frosts - TSz-9gip. For shock absorbers you will need AJ-12T fluid, or spindle oil. Use Tom as brake fluid.

Of course, all this data is taken from the manufacturer's recommendations, and if necessary, you can use modern oils or fluids. But do not forget to consult with specialists.

Curb weight 3200 kg. Including: front axle 1435 kg. on the rear axle 1765 kg.

Gross weight 7850 kg. Including: front axle 1875 kg. on the rear axle 5975 kg.

Permissible trailer weight: with inertia-hydraulic brake drive 3500 kg. not equipped with a brake system 750 kg.

Max climbability of vehicles 25% The same with a road train 18% Vehicle run-out from 50 km/h 660 m. Braking distance of vehicles from 50 km/h 25 m.

Control fuel consumption of cars: l/100 km: at 60 km/h 19.6 l. at 80 km/h 26.4 l.

Turning radius: on the outer wheel 8 m. Overall 9 m.

Engine.

Mod.ZMZ-53-1 1. petrol, V-shaped (900), 8 cylinders, 92×80 mm, 4.25 l, compression ratio - 7.6, operating order 1-5-4-2-6 -3-7-8, power 88.5 kW (120 hp) at 3200 rpm, torque 284.5 (29 kgf-m) at 2000-2500 rpm, K-135 carburetor, air filter - inertia-oil. The installation of a pre-heater PZHB-1 2 heat with a capacity of 10,400 kcal/h (power 1-2 kW) is provided.

Transmission.

The clutch is single-disk, with peripheral springs, the release drive is hydraulic. Gearbox - 4-speed, gear. numbers: I-6.55; II-3.09; III-1.71; IV-1.0; ZX-7.77. The cardan transmission consists of two shafts with an intermediate support. The main gear is a single hypoid, gear. number 6.17.

Wheels and tires.

Wheels - disc, rim. 6.0B-20 with side rings, fastening with 6 studs. Tires 8.25R20 (240R508) models U-2 (K-84) or K-55A, front wheel tire pressure 4.5; rear - 6.3 kgf/cm. sq. Number of wheels 6+1

Suspension.

Dependent: front - on semi-elliptic springs with shock absorbers; rear - on semi-elliptic springs with additional springs; the ends of the main sheets of all springs are installed in rubber pads of the support brackets.

Brakes.

Working brake system - with drum mechanisms with a diameter of 380 mm, width of the front linings 80, rear - 100 mm, dual-circuit hydraulic drive (separate along the axes), hydraulic vacuum booster. The parking brake is a transmission drum (diameter 220 mm, lining width 60 mm), with a mechanical drive. Spare brake - any of the circuits of the service brake system.