Design Features

If you are the owner of a country house or a summer cottage, then you certainly have to deal with grass, weeds and unnecessary shrubs.

Lawn grass is quite easy to remove with a regular garden lawn mower , but unfortunately, such equipment will not be able to cope with large weeds, shoots and bushes.

Important! Do not use wheel trimmers to control large weeds; they are intended solely for cutting grass. Otherwise, the device will quickly fail.

In this case, you need to use special mowers designed for cutting taller and denser grass. Thanks to the features of this technique, it can easily rid you of unnecessary growth on the site.

Classification

Note that various types of structures are known, and their list is not limited to the three listed. However, it is the rotary and segment type mowers, as well as the “cart” type, that are not only the most in demand, but are also easily accessible for assembly at home. Each type of design has its own characteristics and its own advantages and disadvantages, significant in some operating conditions and insignificant in others.

Rotary

Equipment of this type is intended primarily for cutting off thickets of weeds and thin bushes. Having a rotary type device on your farm, you can remove grass over large areas without much effort. The second name for this mower is disc mower, since the design of the device involves disks, inside of which moving knives are located. The number of disks varies depending on the design, but typically there are two or three. Installing a rotary mower on a walk-behind tractor usually involves front mounting, but there are types of disc devices that are mounted on the side or rear, being semi-trailer or trailed.

The operating principle of this equipment involves transmitting torque from the support wheel to the disks. The disks themselves are mounted on a frame supported by a slide. Thanks to the same slide, the cutting height of plants can also be adjusted. The discs are arranged in a row, and the more of them, the wider the swath. Such mowers are used both on pastures and on large garden farms.

Segmental

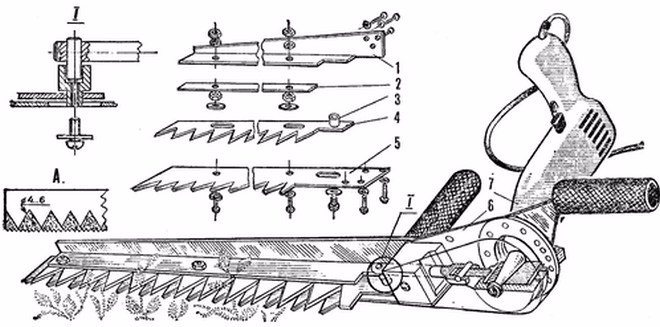

The design of a segment mower is extremely simple. It includes a frame and bars fixed on it (usually there are two of them). Knives are placed between the bars, making back-and-forth movements according to the principle of scissors. Moreover, the work of the segments alternates - while one is in motion, the other is motionless. The grass is cut quickly and evenly, and the design features of the device allow it to be successfully used for mowing on surfaces with complex terrain.

The frame is placed on support wheels, making it possible to place it either frontally or mount it behind the walk-behind tractor. As in the rotary type, the design includes a slide that allows you to adjust the height of grass cutting. Due to the peculiarities of the operating principle, devices of this type cope well with weeds with thick stems, successfully mow dry plants and are very effective in preparing green fodder.

One of the main advantages noted by users is the availability, ease of use of devices of this type and fairly rare breakdowns. However, segment mowers also have disadvantages. These include low productivity; in addition, equipment of this type is not very suitable for mowing short plants.

Mower wagon

Equipment of this type is usually aggregated with heavy walk-behind tractors equipped with water cooling systems. Mower-carts are designed for large-scale work - cutting large quantities of tall and thick weeds and bushes, large hay harvests. Sometimes the design is equipped with a rake, which greatly simplifies the collection of mowed grass. As with other types of structures, there are slides to adjust the cutting height.

List of sources

- oselhoztehnike.ru

- vsemotobloki.com

- SpecMahina.ru

- tytdacha.ru

- stroy-podskazka.ru

- mastertraktor.ru

- NashSad.su

- Author: Sergey

Share with your friends!

Types of mowers for walk-behind tractors

There are several types of mowers , a detailed description of which will be given below:

- rotary;

- segmental;

- mower-cart.

Each type of equipment has its own characteristics and is designed to perform work of a certain complexity.

Rotary

A rotary lawn mower is an ideal option for a summer cottage. Its operation is based on the principle of a scythe: thanks to the rotation of the built-in legs at high speed, a fairly powerful air flow is formed, which draws the grass into the structure or throws it in the other direction.

- Electrical. The advantage of such a device is noiselessness and environmental friendliness. The mechanism is quite lightweight, low cost, and easy to operate. The downside of the tool is that it is connected to an outlet or other power source. As a rule, such mowers have little power. An electric device may be suitable for owners of small lawns.

- Gasoline. With such a unit you are not afraid of any thickets or territories. The mower has high power and is not connected to a power source. The disadvantages of the model include heavy weight, noise during operation and, of course, exhaust gases.

Did you know? The simplest mower, the trimmer, was invented in 1971 in the USA, Texas.

To make the right choice between two types of lawn mowers, you need to think carefully about the purposes for which you need the device and what areas you plan to process.

You will also need a lawn mower on the site. You can use it to mulch the lawn, and in case of a breakdown, you can repair the lawn mower yourself.

Segmental

If you need to get rid of tall grass, you should use this type of mowing machine . Thanks to the segmented knives and the features of the device, the grass is cut evenly, which allows it to be evenly laid on the surface.

The power level of this type of device ranges from 3 to 6 horsepower. This type of equipment has a working width of up to 120 cm. Some models can be equipped with special mechanisms that allow operation at 7 speeds.

The device is capable of combating weeds whose stems are up to 3 cm thick. Thanks to the presence of adjustments, you can set the mowing height parameter. There are several types of adjustments:

- stepped: you need to set a specific height from those proposed;

- smooth: it is possible to choose a height that is within the limits established by the manufacturer.

Important! Protect yourself before using the mower: check that the bolts that secure the blades and discs are securely tightened.

Mower wagon

This type is the most interesting. It can safely be called universal, since its characteristics allow the tool to be used in summer and winter.

In the winter season, the mower will easily cope with the functions of a snow blower. With this tool you can mow tough grass and remove ice crust.

Rotary mower

The rotary mower for the Neva walk-behind tractor is designed for mowing grass and shrubs that have a stem up to 1 cm in diameter. The mowed grass is located on the surface in even rows, this simplifies its collection and drying. Due to its small size and compactness, the equipment is easy to transport.

Walk-behind tractors are aggregated with mounted rotary mowers from the front, from the drive of the units through a V-belt.

The rotary mower is available in two versions:

- with 1 disk;

- with 2 discs.

Both options are suitable for Neva walk-behind tractors.

Rotary attachments are widely used among farmers because... copes with a large volume of work and perfectly tolerates complex surface irregularities.

Single disc rotary mower

The rotary mower with 1 disc is represented by the KR-05 model, specially produced (St. Petersburg) for the Neva walk-behind tractor.

The design of the model is compact, simple, consists of 1 large disk, which allows you to maneuver and mow grass and shrubs in difficult places.

The rotary mower KR-05 has the following technical characteristics:

- Travel speed is 2-4 km/h.

- Productivity - 0.15 ha/hour.

- Working width - 560 mm.

- Disk rotation speed - 2500 rpm.

- Mowing height - 1000 mm.

- Machine weight - 30 kg.

- Machine dimensions - 700x700x680 mm.

The mower is suitable for the Neva walk-behind tractor (MB-2, MB), Kadvi, Oka.

Advantages of the KR-05 model:

- compactness;

- mobility;

- ease of use;

- simplicity of design;

- high security;

- easy installation on a walk-behind tractor;

- high maneuverability;

- affordable price.

From user reviews it is clear that it is not as effective as a mower with 2 discs, but it is in the lead in terms of maneuverability and work in confined spaces.

Double disc rotary mower

For mowing coarse stem and grass vegetation, grain crops, small shrubs over large areas, a mounted mechanism with 2 discs is often used. It works effectively on a flat surface without obstacles: trees, holes, hills, fences. It works worse on uneven surfaces and is more difficult to operate, but farmers also use it in small areas, roadsides, and slopes with a slight lateral slope and steepness.

The cut grass is evenly placed in separate rows, dried naturally and collected.

For the Neva walk-behind tractor, a Zarya rotary mower with 2 discs, manufactured by Kaluga Engine OJSC, is used.

The operating principle of the mower for the Neva walk-behind tractor is simple.

There are 4 knives on the disks, which are attached with cotter pins. When the discs rotate towards each other, a centrifugal force is created that pushes the knives out. The cutting blades work as long as the walk-behind tractor engine is running.

Mowing with 2 discs significantly increases the mowing area. For Zarya it is 80 cm and is an excellent indicator.

The grass cutting height is adjusted using a special slide.

Zarya for the Neva walk-behind tractor has the following characteristics:

- Machine dimensions - 810x930x780 mm.

- Weight - 33 kg.

- Processing width - 800 mm.

- Operating speed - 2.87 km/h.

- Mowing height - up to 1000 mm.

- Productivity - 0.2 ha/hour.

- The rotation speed of the cutting disc is 2370-2635 rpm.

- Adjustable cutting height - 3-10 cm.

The disadvantages of the Zarya rotary mounted mezanism are as follows:

- The need to thoroughly check the device before starting. Improper fastening of knives can lead to increased injury.

- Constant control of movements.

- There are restrictions on the grass that can be cut. It should be up to 1 m and erect.

https://youtube.com/watch?v=ZtXWnhs-v2A

According to user reviews, the Zarya mower is distinguished by its quality, reliability, and trouble-free operation.

How to make a rotary mower: step-by-step instructions

very popular lately .

If you have the desire and time, you can make a good unit yourself. We suggest that you familiarize yourself with the instructions for constructing a rotary mower.

Required material and tools

Before you start making a lawn mower, you need to prepare the following materials and parts of the future device:

- disk from a grain seeder - 2 pcs;

- chain from a chainsaw gearbox - 1 pc.;

- knives made of hardened metal - 8 pcs;

- tavern;

- opener

Among the tools you may need:

- screwdriver;

- pliers;

- nuts;

- carbide drills;

- drill.

Did you know? Because of its design, the mower-cart was popularly called “horse-mounted.”

Once the materials and tools have been prepared, you can proceed directly to assembly.

Process description

First of all, you will need to drill a hole on the disks using a carbide drill with a diameter of 6 mm. Then you need to attach the shredder to the opener, and the knives to the shredder.

Please note that the distance between the shredder and the knife should be several mm greater than the thickness of the knife. This moment is very important and necessary so that with the help of centrifugal force the knives are straightened from the disk, which would ensure the performance of the main function - mowing the grass. A prerequisite is the rotation of the knife 360°. This will protect it from damage when colliding with stones or hard objects.

To make the knife fastening axes, you will need carbon steel, the diameter of which must be at least 8 mm. It is necessary to tighten the axle until it stops using a disk.

There will be no difficulties in assembling the rotary mower if you strictly follow the recommendations.

Homemade mower for walk-behind tractor (rotary, segmental)

They have backs with segments and drive lever cages attached to them. Clamps and runners are also attached to the beam at both ends. A wheel is installed on the main frame. You can take it from an old stroller. The cutting part begins to work under the influence of the walk-behind tractor PTO.

This can be seen in detail in the figure, where: 1 - main frame; 2- braces; 3-gear wheel; 4-adjustment and fixation of the braking system; 5-pawl fixing brake; 6 and 8 main arcs; 7-housing for hinges; 9-leg; gas line; regulator valve; container for gasoline; lever; 14 and levers.

Such a mower will easily cut the grass without chopping it.

You can see how such a do-it-yourself mower works in the video. This device can be used as a mower in summer and as a snow blower in winter. To do this, in the winter version they put stars on the mower, and in the summer, when it’s time to mow the grass, they put the knives from the mower.

This model can also be classified as rotary, but it is more complex. The grass that can be mowed with this model may have a hard structure, and the snow in winter may have an icy crust. The design of this model is made of two drums, which are connected by a frame and a conveyor belt with hooks.

Homemade rotary mower on a walk-behind tractor

The cart is made by welding pipes, metal corners, in general, any metal that can be found. Plywood and wheels are attached to the frame. Wheels can be taken from a children's bicycle or stroller. The entire frame from the stroller will also fit.

Take thick plywood; it is better to generally use a metal sheet. The dimensions of the mower frame can be different, but the proposed ones are 80x40 cm. The main working body of this mower is assembled from drums 5, conveyor belt 3, frame 10, 16, 17, 18,20, brackets 19, hook corners 4.

For drums, you can use large diameter tin cans. The lids and bottom are cut out of them. In their place two wooden circles are mounted. After all, the main goal pursued by the creators of a homemade mower is saving money and achieving maximum results.

Some models that ordinary gardeners come up with often surprise professionals with their design and simplicity of design. Typically, homemade mowers for walk-behind tractors are designed as a frontal type: rotary mower, segment mower and cart mower. When making a mower base yourself, they often use the designs of factory models. Most parts are purchased in stores and then used in their designs.

The welded frame is the basis for the segment and rotary mower. It is made from metal corners, measuring 4x4cm.

Making a segment mower with your own hands

This type of device can also be made independently. Below we will tell you how to make a mower with your own hands .

What is needed for making

To make the device you need to prepare:

- metal beam 15x50x120mm;

- knives;

- disks;

- wheel.

In addition to the materials listed, prepare standard tools: screwdriver, drill, pliers, bolts.

Step-by-step instruction

To assemble the unit yourself, you must follow the instructions :

- holes are drilled in the metal beam that will fit the M8 bolt;

- check that each blade has a segment on the back;

- make sure that the blade has a clip for the drive lever;

- fix the knives on both sides of the beam;

- attach clamps and runners to the beams;

- install the wheel on the frame.

With the help of the walk-behind tractor shaft, the assembled mechanism will move, thereby rotating the knives. They can perform both rotational and back-and-forth movements. It is thanks to this moment that thick stems of weeds will be easily cut off. Please note that they are not crushed.

How to make a mower for a walk-behind tractor with your own hands?

It often happens that for some reason the manufacturer does not have a special mower on sale specifically for this model, or that it does not suit its characteristics. In this case, it is not difficult to work on a homemade version. Full production on the basis of one's own farm will be demonstrated using the example of segmental variation.

You should prepare a frame from welded corners and pipes; the frame can be covered with plywood and wheels can be attached to it. The tape is made of rubber ring-shaped. It is convenient to secure it with duralumin plates. Clamps are also welded onto the frame to install the cutting strip. For the latter, a strip with metal blades is attached to a pre-prepared pipe with holes using M8 bolts.

Homemade mower-cart with your own hands

Using a riding mower, you can easily get rid of grass that has a wide stem. Let's look at the manufacturing features of the unit.

Materials and tools

To assemble the mower you will need:

- frame made of metal corners;

- 4 wheels;

- metal sheet or plywood (size 80x40cm);

- 2 cans;

- 8 metal discs;

- 4 blades;

- sleeve;

- drum;

- bolts;

- transport tape.

Did you know? The wider and larger the wheels on the mower, the less they damage the lawn and do not leave marks behind them.

Having the listed materials available, you can begin assembling the device using a standard set of tools.

Action List

We suggest that you familiarize yourself with the instructions for assembling the mower :

- Place a metal sheet on the frame.

- Install two cans without a lid or bottom onto the frame. Instead of the bottom, install metal disks, the outer diameter is 20 cm, the inner diameter is 17 cm.

- Connect the disks in pairs: fasten them with bolts.

- Attach the blades to the discs so that there is an equal distance between them, which would allow them to rotate freely.

- Insert the bushing into the drum part and secure it firmly to the frame.

- Place a sheet made of steel angles on the frame.

- Connect the drums. For this you will need a transfer tape.

- Fasten the lower drum bushing, and attach the corners to the latter.

At the final stage, you need to make sure that there is a protective element on the blade, after which you can install the assembled structure on the walk-behind tractor.

Proper installation of the mower on the walk-behind tractor

The newly purchased product must be correctly installed on the equipment in order to ensure the required performance and quality of workmanship. Let's look at the approximate order of assembly and installation using the rotary version as an example:

- We check the delivery contents (the set may differ from model to model, but, as a rule, this includes a drive belt, frame, fitting, fasteners, rotor cover, hydraulic hose, support slides, hydraulic cylinder, drive belt tension system, rotors with knives, spare parts);

2. We mount the frame to the walk-behind tractor mounts so that it is 45 degrees with the vertical plane and so that the splined parts look up;

We invite you to familiarize yourself with a DIY wooden buffet

3. We install the rotors on the frame so that their knives are located at the bottom. It is important that they fit completely onto the slot;

4. Attach the rotor cover to the same slot;

5. We fix it with the attached cotter pins and nuts;

6. We install the tension system by pulling out the cotter pin and unscrewing the lock nut on the pulley. The next step is to carefully knock out the pulley so that the key does not get lost. When the system is correctly installed, its handle will be directed upward and secured with bolts from spare parts;

7. Next, we fasten the slides to the frame with bolts from spare parts so that their concave part faces inward;

8. We push the frame rings - they should be located outside the walk-behind tractor frame. After this, we finally connect the mower to the second one;

9. We throw the drive belt onto the pulley in the direction of travel. It is important that the walk-behind tractor and mower maintain alignment;

10. We install the hydraulic cylinder - hydraulic hose system (if such a connection is provided on the walk-behind tractor).

Upon completion of assembly, the product must be prepared for use:

- activate reverse on motorcycles;

- remove weights from the wheels (if any);

- put the engine at low speed;

- make a test run on a level area without interference, checking the quality of the result and, if necessary, adjusting the blades and speed.