Features of the Neva walk-behind tractors

There are many modifications of this walk-behind tractor (MB-2, MB-23, etc.). Each device has its own type of belt. Mostly MB-1 walk-behind tractors are used - motor-cultivators of the old modification. It should be noted that the operation of the MB-1 and MB-2 devices is based on a V-belt transmission mechanism. This system ensures that the unit moves forward and backward, respectively; without its help, the device simply will not work. Motoblocks of the MB-1 modification have a built-in V-belt transmission for both strokes. In MB-2 editions, only one forward gear is used. Based on this, in order to choose a belt for the Neva walk-behind tractor, you should stock up on the following data:

- you need to know the type of belt that matches your specific unit model;

- belt length;

- degree of tension of the part;

- type of V-belt transmission (for certain modifications).

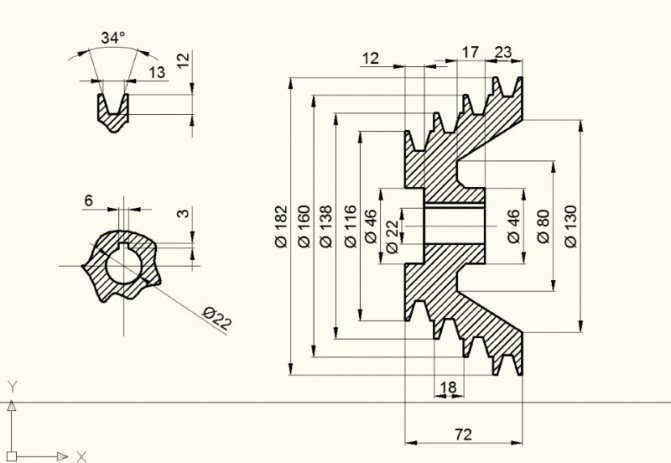

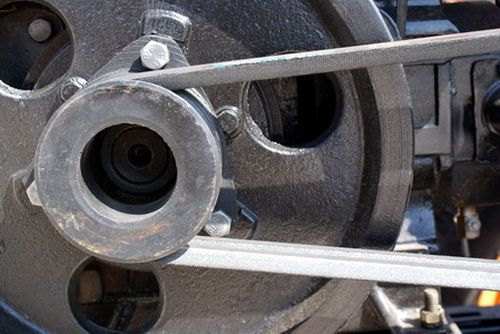

Pulley image in the drawings

From the drawing of the product, its structure, dimensions and manufacturing method should be completely clear. For standard products, the designation of the pulleys must be indicated on the drawing.

In order to correctly and accurately manufacture a non-standard pulley, its drawing must meet certain requirements. You can choose the correct angle of the pulley groove if you use a standard series of slopes for the drawing.

The pulley is usually depicted in drawings in two forms:

- section by a secant plane passing through the axis of rotation;

- side view.

The side view, as for other parts with axial symmetry, is not shown in full, but in half. For pulleys that have spokes in their design, it is permissible not to depict everything, but to provide a drawing of one part indicating their number.

The incision must be constructed so that there is at least one spoke in its plane. There is no need to hatch the spokes on the section. If the part is made solid, the cut plane is hatched, as usual in the drawing.

Main dimensions and parameters, such as:

- rim and hub diameter;

- V-belt profile;

- mating radii;

- groove slopes, etc., are marked on the cut.

An additional view of the drawing shows a cross-section of a spoke. If its shape is variable, then several additional types of drawing are made.

An image of the mounting location for the key with dimensions and an indication of the surface quality is also shown in an additional view of the drawing.

If instead of knitting needles, to facilitate the construction, several holes are provided in the body of the part, their number and dimensions are indicated on the section, and it is permissible not to construct a side view in the drawing.

Replacing belts on walk-behind tractors "Neva" MB-1 and MB-2

You not only need to choose the right belt for the Neva walk-behind tractor, but also know how to install it. First make sure you have all the dimensions correct. The belt replacement processes for the units of these two samples differ from one another. For MB-1 the sequence of actions is as follows:

- the first step is to remove the casing from the V-belt mechanism;

- Next, you need to carefully remove the back bar from the pulley;

- take the key and make the spring-loaded roller weaker;

- the part itself is removed;

- The next step is to tighten the new belt;

- Ultimately, we return to their place those parts that were removed and strengthen them.

For MB-2 we see a slightly different course of action:

- the first action is similar to the previous scheme;

- then loosen the strap tension in the same way;

- next you need to unscrew the screws that secure the bracket;

- take out the belt;

- we adjust the pulleys;

- we place another part into the mechanism (remember that you first need to tension it onto the gearbox shaft, and then onto the pulley located in the motor);

- putting everything back together again.

As a rule, the belt is reinstalled if some kind of breakdown occurs during operation. But sometimes equipment owners simply want to replace the part with a newer and less worn one. In addition, there is another way to increase the productivity of the walk-behind tractor - you can install a second belt. Installing the second belt on the Neva walk-behind tractor takes approximately ten minutes.

In general, when replacing a belt on a Neva, you should take into account what developments this or that modification is based on. For example, the Neva mini (MK-100) differs from other models in that its production uses designs made back in Soviet times. The following video will tell you more about choosing a belt and replacing it.

What is a PTO on a walk-behind tractor - description and functions

A power take-off shaft is an element that is necessary for installing various types of attachments on a walk-behind tractor. Walk-behind tractors with a power take-off shaft allow the use of such types of attachments as mulchers, seeders, harrows, stump grinders, mounted mowers, as well as attachments installed directly into the trailers used for work.

The main function of the power take-off shaft is to receive and transmit rotational forces from the engine to the attachment. In most cases, this important element is located at the rear of the walk-behind tractor, which allows you to connect almost all known types of attachments to it.

Among the main advantages of the power take-off shaft are its versatility, high strength and reliability. In addition to the advantages, the PTO has several significant disadvantages, which include the large weight of the element and the need to use an additional gearbox with it.

Features of belts for Neva walk-behind tractors

Accordingly, the selected belt for the Neva walk-behind tractor must match the model of agricultural machinery used. The MB-1 and MB-2 walk-behind tractors often have a V-belt drive. It is thanks to the wedge transmission that the unit is able to move forward and backward. If the V-belt mechanism of the machine fails, the walk-behind tractor will not be able to function normally.

MB-1 walk-behind tractors have forward and reverse gears. MB-2 models only move forward. Because of this difference, the same belts cannot be used.

It is not difficult to select a drive belt if you pay attention to the following nuances:

- the selected type must match the model of the equipment;

- belt dimensions;

- stage of tensioning the part;

- V-belt transmission type.

If you look at the data described above, you can choose the right belt for a specific walk-behind tractor model.

Types of belts installed on equipment:

- Wedge;

- Forward parts;

- Reverse gear elements.

To simplify the selection process, it is worth using a table. It indicates the correspondence between belts and equipment models.

Belt sizes for Neva walk-behind tractors

When selecting drive belts, you need to pay special attention to their sizes. You can use the table provided to determine the part you need.

You should first measure the distance from the pulleys to the rollers; a new element will be mounted to them. This will allow you to select more accurate belt dimensions.

Tensioning the Neva walk-behind tractor belt: algorithm of actions

The Neva MB-2 and MB-1 walk-behind tractors are characterized by different belt arrangements. Therefore, the installation diagram of the parts will be different.

Tensioning the belt on the MB-1 model is performed in a certain way:

- Initially, the casing is removed from the V-belt mechanism;

- Carefully remove the back bar from the pulley;

- The key loosens the spring-loaded roller;

- The old element is dismantled and a new one can be installed;

- Pre-dismantled spare parts of the unit are installed.

It is worth considering how to replace the belt for units of the MB-1 model range:

- The shield and casing of the V-belt system are removed;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts that secure the bracket are loosened;

- The forward drive belt is removed;

- New elements are installed and tensioned, everything is secured and previously removed parts are returned to their place.

The belt adjustment on the Neva MB-2 walk-behind tractor is carried out as follows:

- The casing is removed;

- The screw loosens the tension of the standard belt;

- All screws holding the bracket to the unit body are removed;

- The old part is pulled out and the pulleys are adjusted;

- Before installing the belt, the spaces between the elements are thoroughly wiped, the hoses are blown out;

- A new belt is being installed. One end is connected to the gearbox shaft, the other to a pulley located in the motor;

- The structure can be completely restored.

More details on how to tighten the belt on a Neva walk-behind tractor can be found in the video provided.

Basically, they tighten a new element when the walk-behind tractor breaks down. Much less often, replacement is performed in advance to prevent malfunctions during operation of the unit. In any case, you need to carry out the work of replacing the belt carefully, since if it is over-tensioned, its breakage is inevitable.

During intensive use of Neva MB-1 and MB-2 walk-behind tractors, many of their owners are faced with a broken alternator belt. Because of this, the equipment used completely fails, losing the ability to start and solve its immediate problems. Regular checking and timely replacement of the element will help to avoid this problem. And to choose a belt for the Neva walk-behind tractor, you need to study its main factory features.

Operation and maintenance of Neva MB-2

Changing the engine oil

The manufacturer recommends using such well-known brands of motor oil for the walk-behind tractor as LUKOIL - standard SAE 10W30 API SF/CC, as well as RAVENOL SAE 30 API CD/SF.

At temperatures above 4 degrees Celsius, using thickened types of oils (for example, 10W30 brand) will lead to increased consumption of this type of fuel, so in the cold season it is recommended to check the engine oil level more often, preventing its level from dropping below normal.

The oil change is carried out after the walk-behind tractor has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is completely drained from the tank, after which new oil is added until the oil level reaches a special mark. The drain plug is then tightened tightly and wiped dry.

First launch and testing of the Neva MB-2 walk-behind tractor

The first start must be carried out according to the following scheme:

- make sure that the walk-behind tractor is in complete condition (the height of the steering bar and handles must correspond to the user’s height);

- You can start the engine only if the walk-behind tractor is located on a flat surface;

- check the oil and fuel levels in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- The idle time (without load and movement) should be about 10 minutes, then you can move and operate the walk-behind tractor.

The break-in period is considered to be the first 20 hours of operation of the walk-behind tractor, after which it is necessary to change the oil

During this period it is most important:

- do not operate at full throttle;

- work only on pre-prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that are included in the kit;

- The Neva MB-2 walk-behind tractor can only be loaded at ¾ power during the run-in period;

- gear shifting in the gearbox can only be done when the rotation of the drive pulley has completely stopped;

After the first 20 hours of operation after the first start, the engine oil should be changed.

Types of belts for Neva walk-behind tractors

The basic devices of the most popular agricultural implements of the Neva brand include two working shafts - a crankshaft and a distribution shaft. To operate each of them, the factory design of the models includes belts, which, according to the method of transmitting torque, are divided into conventional and chain transmissions.

To maintain the function of the chain system, the MB-1 and MB-2 walk-behind tractors are equipped with factory sprockets. Frictional force is responsible for the continuous operation of a conventional transmission in the design of these agricultural units.

Tensioning the Neva walk-behind tractor belt - how to do it correctly?

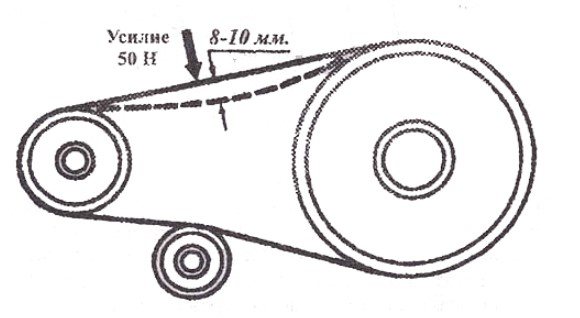

Immediately after replacement, mandatory adjustment of the belt on the Neva walk-behind tractor must be performed.

To do this correctly, the operator will need:

- Carefully inspect the operating pulleys and make sure that there is no debris or signs of corrosion left on them. If they are, then it will need to be fixed;

- Unscrew the fastening nuts with a special wrench - this will give the operator the opportunity to release the standard motor part of the walk-behind tractor and freely move the engine in its longitudinal plane;

- Install the 19 key on the thread provided on the surface of the built-in adjusting screw;

- Approach or move the walk-behind tractor engine as necessary to tension the drive element being used;

- Slowly tighten the belt on the Neva walk-behind tractor. At the same time, the main thing is not to overtighten it, otherwise it will lose its operating parameters;

- Inspect the belt and make sure that there are no distortions in it - otherwise the element will fly off the surface of the pulley or jam;

- Turn the adjusting screw in the opposite direction, firmly securing the belt in the structure of the agricultural implement;

- Screw in the previously removed mounting nuts.

When adjusting the belt tension on the MB-1 and MB-2 walk-behind tractors, it is important to ensure not only that it is not overtightened.

Too low a tension level can also cause numerous problems:

- increased vibration on one side of the walk-behind tractor - this will not only worsen the quality of tillage, but will also gradually put the equipment out of action;

- an increase in the volume of exhaust gases when the power unit is idling;

- constant wheel slipping even when moving on a flat asphalt surface - this will increase tire wear and reduce the performance of the Neva walk-behind tractor;

- the appearance of a bluish coating on the surface of the built-in pulleys, which can cause them to break.

It is important to remember that after replacing the belt, you need to run it in. To do this, you will need to start the walk-behind tractor and give it time to work without load. After this, the pressure on the structure can be gradually increased.

There is no spark on the walk-behind tractor - reasons and solutions

No spark

This is one of the typical malfunctions of the ignition system of a walk-behind tractor. The most common causes of this are carbon deposits on the spark plug or deterioration of the spark plug. In this case, unscrew the spark plug and carefully inspect its side and center electrodes. If the spark plug is covered with soot formed as a result of pouring the fuel mixture into the part, then cleaning the spark plug will not be enough - you will need to check the fuel system pipes for leaks from the walk-behind tractor. Examples of cases of heavily fouled fuel spark plugs are clearly visible in the photograph.

If the spark has disappeared, then in any case you will need to thoroughly clean the spark plug. The best way to do this is to heat it over a gas burner and then scrape the dried fuel off the surface. After cleaning the parts, the tip should be placed on top of it and brought to the body of the walk-behind tractor. The spark plug should be held so that its electrode is approximately 1 millimeter from the engine housing. In this case, try starting the walk-behind tractor with your other hand.

If the spark plug is fully activated, a spark will be generated at the bottom of the spark plug and will jump out and strike the engine housing. If this does not happen, you need to examine the distance between the side and center electrodes. The blade should be placed between them, and if it fits tightly between the two electrodes, the gap is optimal. If the blade is hanging, you need to tap any hard object on the back of the center electrode. As a result, it will move, after which you will need to try again to start the walk-behind tractor engine.

READ Make a Boat Motor from a Trimmer

Self-testing magneto for walk-behind tractor

Another important element of the walk-behind tractor ignition system is the magnet. If a node fails, it is also subject to intense performance scrutiny. It's quite easy to check the magnetic block. To do this, you need to clean the spark plug from deposits accumulated on its surface and make sure that it is in good working order. Then place the cap with the operating drive on the spark plug. Next, the lower part of the spark plug should be raised towards the magneto housing and begin to rotate the flywheel located in the engine.

If the spark does not appear in the magnet on the walking tractor, the element will fail. In this case, it will be necessary to replace the magnet of the walk-behind tractor's ignition system to prevent wear and tear on other mechanisms of the unit.

How to check the ignition coil on a walk-behind tractor?

Check and, if necessary, repair the ignition coil, following the same principle as the magnetic unit.

The following factors indicate that your off-road tractor's ignition coil has failed.

- Weak spark or its complete absence;

- Smell of melted plastic where the ignition coil is installed;

- A crackling sound appears when you try to start the walk-behind tractor.

In any of these cases, you will need to carefully inspect the ignition coil of the walk-behind tractor. To do this, it is best to completely disassemble it. To do this, first unscrew the mounting bolts and remove the top cover of the ignition switch housing. Then you need to disconnect the high-voltage wire and, carefully pulling out the coil, remove it from the housing. After this, you need to carefully inspect the part for signs of melting - if you see black spots on the coil, it is likely that the generated current did not reach the spark plug, causing the ignition coil to be exposed to voltage. This problem is especially often encountered by farmers whose walk-behind tractors are equipped with contactless ignition.

The reason why current did not reach the spark plug is due to poor contacts in the high voltage wire. In this case, repairing the ignition of an off-road tractor comes down to stripping the wires or completely replacing them. In walk-behind tractors where an electronic ignition system is installed, in the event of a break, the wire is automatically turned off due to the presence of a special fuse. On agricultural machines with other types of ignition systems, the wire must be manually disconnected in the event of a malfunction.

Preventing breakdowns of the walk-behind tractor ignition system

To avoid the need to repair the ignition system of a walk-behind tractor, you must follow a number of simple rules. Following these rules will extend the life of the device and save time and money for the equipment owner.

Experts advise:

- Avoid using the walk-behind tractor in wet weather, during frosts, as well as in conditions of sudden changes in temperature and humidity;

- Do not attempt to start the unit if there is a smell of melted plastic;

- If necessary, install trailers on the tractor that protect parts of the ignition system from moisture;

- Change the spark plug at least once every 3 months. In case of intensive use of the walk-behind tractor, the frequency of part replacement can be increased;

- Use high-quality motor oil - using the wrong composition will result in the spark plug constantly filling with the fuel mixture;

- Regularly check the parts of the ignition system to eliminate the slightest possibility of the walk-behind tractor operating with hanging wires or other damage;

- Try not to apply a walk-behind tractor with a hot engine to heavy loads - this will lead to accelerated wear of important components of the unit, including its ignition system.

How to extend the service life of belts?

There are several rules that, if followed, will help increase the working life of the drive elements. Their list includes:

- the use of Neva brand agricultural implements strictly for their intended purpose - the use of medium-power equipment for plowing large areas with virgin soils is not allowed;

- avoiding any impacts of equipment on foreign solid objects - otherwise the operator risks damaging the pulleys and belts installed on them;

- observing the correct order when starting Neva walk-behind tractors - their engines need to be given enough time to warm up. Otherwise, cold belts will work under increased loads, which will significantly accelerate their wear;

- timely cleaning of the drive elements and the space under them - otherwise moisture and dirt will gradually destroy the elastic sheath of the belts;

- use for replacement only belts selected in accordance with the table of their sizes - unsuitable drive elements will disrupt the operation of the pulleys and the engine;

- monitoring the condition and level of lubrication of the pulleys - rollers without a sufficient amount of oil will run “dry”, due to which belt wear will increase several times;

- sequential gear shifting - if you “jump” between gears while operating Neva walk-behind tractors, this will lead to a rupture or distortion of the belt.

While working on the site, the manufacturer of the Neva MB-1 and MB-2 walk-behind tractors advises taking short breaks, which will allow the heated engine and the belts installed in the structure of the equipment to cool down a little.

“>