Turbocharger operation

The design of the turbocharger allows it to operate according to this principle of operation - when exhaust gases enter the turbine, they begin to rotate the rotor. The impellers of a centrifugal compressor are rigidly mounted on the rotor and rotate at the same angular speed as the rotor itself.

The higher the energy of the exhaust gases, the faster the turbine wheels rotate and the more oxygen gets in, the more fuel is burned and the more powerful the turbocharger itself works.

The rotation speed of the turbocharger shaft and impellers can be quite high and reach up to 150,000 rpm.

Many turbochargers have the ability to change the geometry of the turbine using a special mechanism. The design of this device has an additional ring with guide vanes that can be controlled. They can maintain the flow of exhaust gases not only constant, but also change this flow.

At low speeds of the turbocharger, with low flow, the cross-section of the turbine decreases and due to this, the flow rate of gases entering the wheel increases. Which leads, accordingly, to an increase in power.

At high operating speeds, the cross-section of the turbine is larger, and the blades completely open the gas supply. The gas flow capacity is greater.

What is RTD? This is a fuel pressure regulator that creates the required fuel pressure to the injectors. If it malfunctions, the engine receives fuel in an erratic volume.

This ability to adjust the cross-sectional area of the turbine makes it possible to reduce fuel consumption and minimize harmful exhaust emissions. A turbocharger with the ability to independently change the geometry of the turbine increases the efficiency of the device at both high and low speeds.

Operating principle of a steam turbine

The turbine consists of a metal cylinder, inside of which there is a shaft (1) with impellers (disks) fixed on it (2). The disks contain metal blades of a special, curved shape. Tubular nozzles (3) are located between the impellers, from which jets of hot steam erupt at high speed, exerting powerful pressure on the blades. The steam temperature is close to 6000C. Inside the turbine, the steam expands, cools and then, after condensation, is sent back to the boiler-heater using a pump.

Rice. 3. How does a steam turbine work?

The steam pressure on the blades causes the turbine shaft to rotate - work is done. When a turbine shaft is connected to an electric generator shaft (rotor), electric current is generated. The shaft rotation speed reaches 3000 rpm. To increase the rotation speed, modern turbines use not one, but a large number of disks attached to a common shaft. The steam puts pressure on the blades of all the disks at once, which increases the efficiency of the turbine.

Note that the turbine can only rotate in one direction and its speed can vary within wide limits. Another advantage of turbines is the absence of shocks that occur in the internal combustion engine when the pistons move back and forth. The efficiency of modern turbine units can reach 40-50%, and the power can reach 1500 MW.

The discoverer of the principle of operation of a steam turbine is considered to be the Greek mathematician Heron of Alexandria (1st century AD), who proposed using the reactive properties of hot steam to rotate a metal ball. Further development and improvement of this idea continued until the end of the 19th century. Scientists and engineers from many countries at different times contributed to improving the design of this engine. For example, a multi-stage turbine designed to rotate the rotor of an electric generator was patented in 1885 by the English mechanic Charles Parsons. And the design of a nozzle for steam turbines, allowing for supersonic gas velocities, was proposed by the Swedish engineer Gustaf de Laval in 1890. Now this nozzle is called the “Laval nozzle”.

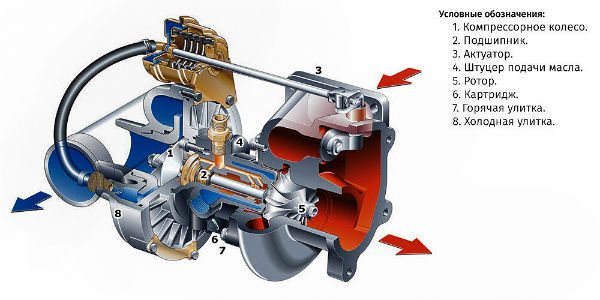

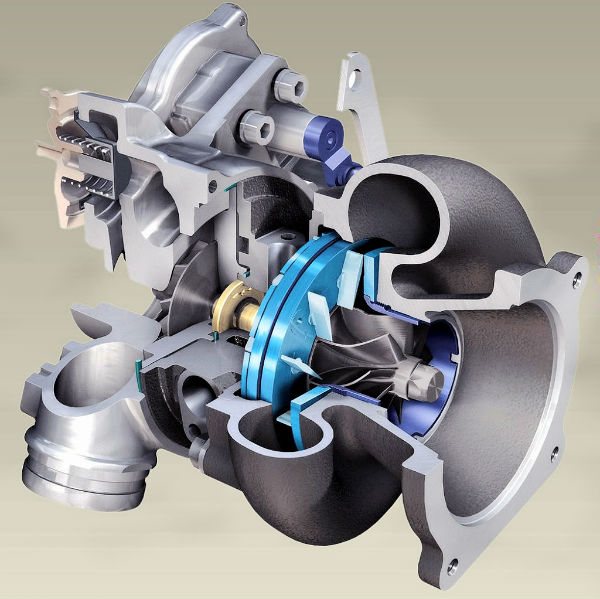

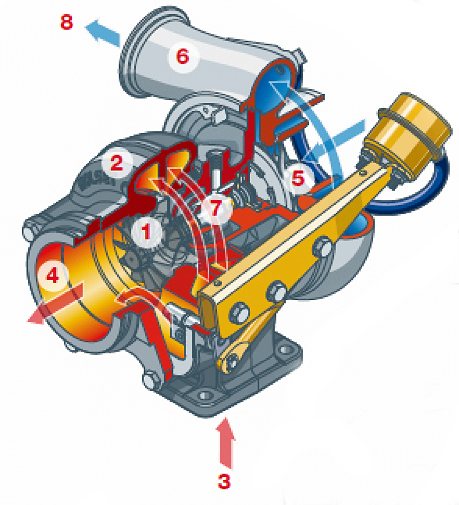

Turbocharger device

The turbocharger consists of:

- turbines;

- compressor.

The turbine consists of:

- impeller (1);

- housing (2).

The housing serves to direct the flow of exhaust gases (3) to the turbine impeller. The exhaust gases drive the impeller. The gas flow rotates the impeller and is discharged through the exhaust gas outlet area.

The compressor consists of:

- impeller (5);

- housing (6).

The principle of operation of a compressor is the opposite of the principle of operation of a turbine. A forged steel shaft, on which the impeller is rigidly mounted, is connected to the turbine. The impeller, when the turbine rotates at high speeds, captures and compresses air. Next, a phenomenon occurs - diffusion. That is, the air flow in the compressor housing, which has low pressure and high speed, is converted into a flow of air with high pressure and low speed. Next, compressed air (8) is directed to the engine, this ensures the combustion of more fuel (so that the fuel burns completely) and increases the power of the car’s internal combustion engine.

- Turbine impeller.

- Turbine housing.

- Exhaust waste gases.

- Exhaust gas removal area.

- Compressor impeller.

- Compressor housing.

- Forged steel shaft.

- Compressed air.

Turbochargers: pros and cons

The operating principle of conventional compressors, which are driven by a belt or crank drive, is that the design and operating principle of such devices consume engine energy. Additional load is placed on the engine.

Turbochargers use wasted energy. This principle of operation is almost ideal, since the exhaust gases are simply thrown out, and here they also serve as a drive for the rotor and the wheels sitting on it.

Turbocharging can produce up to 300 hp per liter of volume. An engine with an installed turbocharger (turbocharger) can develop 40% more power than an internal combustion engine without it. In addition, turbocharged engines are much more economical. An internal combustion engine without a turbocharger has low efficiency due to friction losses and low thermal efficiency.

Accordingly, with an increase in engine volume without turbocharging, the efficiency is even lower. Small-volume turbocharged engines are more efficient than larger-volume internal combustion engines.

Disadvantages of turbochargers

When using this device, the so-called turbojam effect appears. Since the drive is carried out without a mechanical connection to the engine shaft, and due to the physical influence of gases, sometimes a discrepancy appears in the operation of the turbocharger and the engine itself. That is, the power that the driver sets by pressing the gas pedal does not correspond to the power of the compressor. Such problems in the operation of motor components can be identified if you perform car diagnostics using a laptop.

Turbochargers also have disadvantages that are inherent in conventional compressors. In order for them to work as efficiently as possible, they must rotate at maximum speed. In addition, with this mode of operation, the temperature of some parts reaches 1000 C, and there is also difficulty in lubrication and heat removal.

High temperatures reduce the quality of the lubricant and create a very hot incoming air stream. Cooling of forced air is a thorny issue. To ensure effective cooling, the intercooler is selected with special care based on the operating mode of the device.

The design of the turbocharger device, like any other pumping device, must have a bleed valve installed (to relieve excess pressure). The turbine is a little more complicated. In the turbine, in addition to monitoring excess boost pressure, it is also necessary to bypass exhaust gases in order to reduce excess pressure in the intake manifold to prevent the formation of excessively high rotor speeds at high engine speeds.

To increase the service life of the turbocharger, the turbine must be allowed to cool at idle mode after operating at very high speeds. It is enough to let it idle for a few minutes, then the engine can be turned off.

For the convenience of drivers, a special turbo timer has been created. A turbo timer is an electronic device that, after turning off the ignition switch, allows the engine to run for some time in order to operate the turbocharger in a gentle mode and not break it. It can be programmed for a specific time or made to work depending on the heating temperature of the engine. If there is no turbo timer, then the driver must wait a few minutes at idle and not turn off the engine immediately.

Cons of turbocharged engines

Turbocharged engines also have obvious disadvantages, which for many drivers outweigh the existing advantages:

Cost of purchase and maintenance. Structurally, turbocharged engines are more complex. Accordingly, the cost of such units is higher. On average, a car with a turbocharged engine costs 10-20% more than its “brother” with a naturally aspirated engine. But not only is the initial cost higher for turbocharged engines, so is the cost of servicing. In addition, not all services undertake work with turbocharged engines;- Higher chance of breakdown. Since the turbine design is more complex, such engines are less reliable than atmospheric ones. But recently this situation has improved significantly, and manufacturers have managed to achieve sufficient reliability of turbocharged engines, but only with proper operation. In the instructions for a car with a turbocharged engine, you can find information that the engine should be allowed to “rest” at idle speed after prolonged operation. If the trip lasted more than 2 hours, you need to let the engine idle for 10 minutes before turning it off;

- Picky about fuel and oil. Turbocharged engines are more picky about the quality of fuel and oil. It is recommended to fill such engines only with high octane fuel, and also to use oils from trusted manufacturers;

- High fuel consumption during aggressive driving. It was noted above that a turbocharged engine allows for increased power, and it is quite economical. This is true, but it all depends on your driving style. If the driver aggressively presses the accelerator pedal when starting from each traffic light, the consumption of a turbocharged engine will be higher than that of a naturally aspirated one;

- Increased requirements for air quality. The owner of a car with a turbocharged engine needs to carefully monitor the quality of the air supplied and change the air filter more often.

When properly used, a turbocharged engine can last no less than an atmospheric one.

( 121 votes, average: 4.37 out of 5)

MPI car engine

Selection of NGK spark plugs

Related Posts

Mechanical supercharger or turbocharger: which is better?

Engines with turbochargers are produced in mass production, which reduces their prices. Installing it in an internal combustion engine yourself, tuning it, is a rather complicated task, which without special skills will be difficult to do with your own hands.

Analogues - centrifugal mechanical superchargers have a simple design and are easier to operate. Car tuning and chip tuning studios have ready-made solutions for some engines - ready-made turbocharger kits. Turbochargers are in demand.