Description of the GAZ-4301 (4301) model

Engine

Model - 542.10 Type - Diesel, four-stroke (air-cooled) Number of cylinders - 6 Cylinder operating order - 1-5-3-6-2-4 Direction of crankshaft rotation - Right Cylinder diameter and piston stroke, mm - 105x120 Working volume, l — 6.23 Compression ratio — 18 Rated engine power at 2800 rpm, kW (hp) — 92 (125) Maximum torque at 1600-1800 rpm, N m (kgf m) — 37 ( 37) Maximum idle speed, no more, rpm - 3040 Minimum idle speed, rpm - 575–625 Ventilation system - Closed High pressure fuel pump (HPF) - In-line, with a mechanical two-mode centrifugal regulator Fuel low pressure pump - piston type Fuel priming pump - plunger type for manual pumping of fuel Injectors - closed type, needle lifting pressure 17.16 MPa (175 kgf/cm 2 )

Fuel filters: coarse - Sump filter with fine mesh filter element — With paper replaceable filter elements

Air filter - Dry type, with a replaceable filter element and a maximum clogging indicator Cooling system - Air with a gear-driven fan through an adjustable fluid coupling Starting aid - Electric torch device (EFD) Starting heater - Air diesel

Transmission

Clutch - Single disc, dry friction, permanently closed, with a diaphragm spring. Clutch drive - hydraulic Gearbox - Mechanical, five-speed, three-way, with synchronizers in 2nd, 3rd, 4th and 5th gears Gear ratios: I - 6.286; II - 3.391; III - 2.133; IV - 1.351; V - 1.0; z.x. — 5.429 Cardan transmission — Two open-type shafts with an intermediate support, three universal joints on needle bearings Main transmission — Conical, hypoid type. Gear ratio 5.857 Differential - Bevel, gear with positive locking Control of the locking mechanism - Remote, pneumatic crane

Chassis

Wheels - Disc, with a two-component rim, with a split bead ring Tires - Pneumatic, radial, size 8.25P20, ply rate - NS12

Tire pressure, kPa (kgf/cm2): front wheels - 370 (3.8) rear wheels - 540 (5.5)

Wheel toe-in, mm — 0–3 Front suspension — On two longitudinal semi-elliptical springs with an additional rubber compression spring Rear suspension — On two longitudinal semi-elliptical springs with additional springs Shock absorbers — Hydraulic, telescopic, double-acting, installed on the front axle

Steering

Steering mechanism - Globoid worm with a three-ridge roller on a ball bearing. Gear ratio - 21.3 (average) Power steering - Hydraulic

Brakes

Service braking system - Dual-circuit, with separate axle braking, with a pneumohydraulic drive and two pneumatic boosters, with drum brakes on all wheels, has a two-wire pneumatic outlet for controlling the trailer brakes. Backup brake system - Each circuit of the service brake system Parking brake system The function of the parking brake system is performed by the brake mechanisms of the rear wheels, which are mechanically driven

Electrical equipment

Type - Single-wire, negative terminals of current sources are connected to the car body Rated voltage, V - 24 Generator - 5101.3701 alternating current with built-in rectifier and voltage regulator Batteries - Two 6ST-110A, each with a capacity of 110 Ah Starter - 3002.3708 Headlights - Two FG122- BB1 Front lights - PF130AB Rear lights - 35.3716 Instrument and starter switch - 2101.3704000-10 with anti-theft device Windshield wiper - 201.5205010 Windshield washer - 1112.5208000-03

Cabin

Cabin - Double, two-door, metal, equipped with seat belt attachment points Cabin heater - Oil, with two radiators included in the engine lubrication system Independent heater - Air, two-mode, runs on diesel fuel Seats - Separate - driver and passenger Tail - Metal with hood alligator type and folding grille facing

technical specifications (fuel pump, engine, rear axle, spare parts), photos, reviews, videos

The eighties of the last century were significant for the Gorky Automobile Plant. After all, it was then that the first diesel dump truck of this brand, GAZ-4301, was released, which deserves special attention.

GAZ 66: technical characteristics (tuning, fuel consumption, compressor, brake system), price, video, photo.

KamAZ 5410 is here.

For a color diagram of the Gas 3307 electrical equipment, see the article.

Specifications

GAZ-4301 has the following indicators:

- the total weight of the vehicle is 8 tons;

- permissible axle loads: front – 3 tons, rear – 5;

- has a lifting capacity of 4.5 tons;

- the equipped car has a mass of 3.5 tons;

- the clutch is single-plate, permanently closed, has a dry friction function, and has a diaphragm spring;

- five speeds on a 5-speed manual transmission;

- spring suspension;

- the chassis consists of disc wheels with a two-component rim and a split bead ring and pneumatic radial tires;

- The two-seat, two-door cab has places for fastening seat belts. It is heated;

- The car is equipped with a hydraulic pump.

For the conversion of trucks, special permits from the traffic police are required. Information and a list of documents can be found in the article by following the link.

Driving force

The GAZ-4301 truck is equipped with a four-stroke diesel engine model 542.10. Under the hood of this “beast” is 125 hp. The block consists of six cylinders. They are arranged in a row and work in the order 1-5-3-6-2-4.

Thanks to the air cooling system, the machine does not require a radiator or coolant. The “heart” of the car is a licensed copy of the German one.

At the GAZ plant it was the only diesel engine manufactured personally.

Pump and rear axle

The GAZ-4301 has two types of fuel pump. The first is with a low-compression piston injector to directly supply fuel, and the second is with a high-compression mechanical centrifugal adjustable dual-mode in-line injector. It is possible to pump diesel fuel manually.

To make the truck more stable, some components and assemblies were replaced and improved. For example, engineers updated the gearbox; on the rear axle of the GAZ-4301, remote control of the differential lock using a pneumatic valve appeared. The front axle has also been improved.

Spare parts

It will not be difficult to find spare parts for the GAZ-4301, since at one time a sufficient number of cars of this model were produced.

You can buy components and spare parts for the engine, body, transmission, chassis, electrical equipment and others both on the Internet and in car stores. They are often sold by private owners, at used car dealerships.

GAZ 53: technical characteristics (gearbox, steering, electrical diagram), video, photos, model modifications, history of creation and reviews.

Technical characteristics of KamAZ 43114 here.

Read about MAZ 500 in this article.

Reviews

GAZ-4301 is economical, does not require frequent repairs, and performs well as a towing vehicle.

Driving properties are good, as for an old model.

The disadvantages include the rapid failure of the brake system and compressor.

Conclusion

From the above we can conclude that the model is worthy and has more advantages than disadvantages. It can serve as a faithful assistant and “workhorse” for many years.

More information on the website

spectechzone.com

Design and technical characteristics of GAZ-4301

The GAZ-4301 medium-duty truck appeared in the plant's production program in 1984. The car differed from previous models in the use of a diesel engine developed by specialists from the Gorky Automobile Plant based on the Steyr unit. Due to difficulties with development, serial production of the truck began only in 1993, and a few years later the assembly was discontinued.

Device and characteristics

The car is designed to work on paved roads, as well as dirt roads with a compacted surface. The equipment was supplied in several configurations, differing in the presence of a pre-heater and the design of the on-board platform. The plant shipped a special chassis designed for the manufacture of agricultural dump trucks with 3-way unloading.

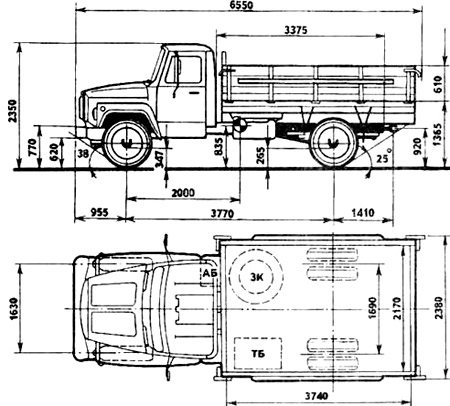

Dimensions of GAZ-4301 and technical characteristics:

- length - 6420 mm;

- width (without rear view mirrors) - 2380 mm;

- height (with awning) - 2870 mm;

- loaded weight (without installing an awning) - 3900 kg;

- load capacity - 5000 kg;

- speed on a horizontal section of the highway with a load - 85 km/h;

- climbability - 25%;

- turning radius (along the axis of the outer wheel) - 8.0 m.

Description of the parameters of an all-metal cargo platform with 3 folding sides:

- length - 3490 mm;

- width - 2170 mm;

- side height - 510 mm.

The truck used improved fastening of the wheel rims to the hubs, which included footless nuts. The fuel tank has an original shape, with the neck located in the center. There is a battery switch on the side. The steering mechanism is equipped with a hydraulic booster, and the cabin has 2 separate seats.

Engine

The GAZ-4301 engine is built on the basis of an in-line 6-cylinder block with a volume of 6.23 liters. The engine was produced by the GAZ plant and is designated 542-10. The unit operates on a 4-stroke cycle; the design does not provide for a turbocharger. The diesel engine develops power of 125 hp. with a compression ratio of 16. The advantage of the engine is the torque increased to 37 kgf*m, which was achieved at 1600-1800 rpm.

The cooling system included an axial fan and guide deflectors. The outer surface of the cylinders has ribs that improve heat transfer. Each cylinder is made as a separate quick-release part with an individual head mounted on the crankcase through a copper ring.

To drive the fan, gears of the gas distribution mechanism are used, the rotation speed is adjusted by a hydraulic coupling. An in-line plunger pump with a speed controller is used to supply fuel. Part of the fuel equipment is located behind the left footrest.

Transmission

The trucks used a 5-speed manual transmission, equipped with synchronizers at all forward speeds except 1. The highest gear was direct.

Characteristics of the GAZ 4301 truck

Brand nameAbarthACAcuraAlfa RomeoAROAsiaAston MartinAstraAudiBAWBeifang BenchiBeijingBentleyBMWBrillianceBugattiBuickBYDCadillacChanaChanganChangFengChangheCheryChevroletChryslerCitroenDaciaDadiDaewooDAFDaihatsuDatsunDerwaysDodgeDong FengEagleFAWFerrariFiatFordFotonFreightlin erGeelyGMCGreat WallGrozHafeiHaimaHaniaHINOHoldenHondaHOWOHuachenHummerHyundaiInfinitiInternationalIntrallIran KhodroIsuzuIvecoJACJaguarJCBJeepKenworthKiaLADALamborghiniLanciaLand RoverLDVLexusLifanLincolnLotusLuxgenMACKMANMaseratiMazdaMercedes-BenzMercuryMGM iniMitsubishiMorganNissanOldsmobileOpelOtokarPeterbiltPeugeotPlymouthPontiacPorscheProtonRange RoverRavonRenaultRolls-RoyceRoverSaabSamsungSaturnScaniaScionSeatSetraShaanxiShacmanSkodaSMASmartSpykerSsangYongSubaruSuzukiTataTatraTeslaToyotaTVRVauxhallVolkswagenVol voVortexWartburgWestern StarWiesmannXinKaiYUEJINZhonghuaZhongxingZotyeZukBusAuto catalogCar partsCar stickersAZLK (Moskvich)Promotional offersAtlases and mapsBAZBelazBogdanVAZ (Lada)VISGAZGas equipmentTrucksEnginesDoninvestZAZZILIZHKAvZka MAZCarburetorsMaps and AtlasesATVsCombine-harvestersKRAZBody repairLIAZLiterature for driving schoolsLiterature for STOBOAT motorsLUAZMAZMopedsMotorboatsMotor scootersMotorcyclesPAZPostersRoad rulesMiscellaneousSale RAFAgricultural machineryScootersStreet racingTagazTests on traffic rulesTractorsTuningUAZURALTraining literatureExam papersElectrical equipmentCar encyclopediaLegal assistanceModel name Show

Characteristics of the GAZ 4301 truck

| GAZ 4301 (1984-1994) | |||||||||||||

| Body | |||||||||||||

| Truck | |||||||||||||

| |||||||||||||

| Engine | |||||||||||||

| 4.75 | |||||||||||||

| Engine's type: | Diesel, V8, 16-valve | ||||||||||||

| Gas distribution system: | OHV | ||||||||||||

| Supply system: | Carburetor | ||||||||||||

| Power, hp/at rpm: | 119 / 3200 | ||||||||||||

| Torque, N•m / rpm: | 191 / 3500 | ||||||||||||

| Transmission: | MCP |

| Number of gears: | 5 |

| Rear: | Spring |

| Power steering: | — |

| Rear: | Drums |

| Systems: | — |

| Acceleration time to 100 km/h, sec.: | — |

| Tire size: | 8.25 R20 |

| Fuel tank volume, l: | 100 |

| Fuel type: | Gasoline A-92, diesel fuel |

| Fuel consumption (in the city), l. per 100 km: | 16.0-19.6 |

| Fuel consumption (outside the city), l. per 100 km: | — |

autoinform96.com

Owner reviews and prices

The cost of model 4301 trucks on the secondary market does not exceed 200 thousand rubles. Most of the machines are equipped with MMZ diesel engines from agricultural machinery, since the production of original spare parts ceased in the late 90s.

Dmitry, Vladimir region

Worked for several years on a flatbed truck 4301. The vehicle is equipped with a diesel engine, which provided reliable acceleration with a full load. Fuel equipment required regular maintenance. The weak point was the compressor of the pneumatic system, which was repaired every 3-4 months. The truck had a rear axle with a differential lock, which helped overcome muddy dirt roads.

Alexander, Leningrad region

In the mid-2000s, he worked on a van built on chassis 4301. The vehicle had low fuel consumption (no more than 16-17 liters per 100 km) and carried up to 5 tons of cargo. Several times I had to rebuild the rear axle, which could not withstand the loads when slipping. The big disadvantage was the lack of spare parts for the engine.

Car GAZ-SAZ-3507

Since the beginning of 1984, the Saransk plant has mastered the production of the new GAZ-SAZ-3507 truck. Subsequently, its modifications were developed:

- GAZ-SAZ-35071 with a diesel engine D-245 (based on the GAZ 3309);

- GAZ-SAZ-3507-01 with a ZMZ-5231 gasoline engine (based on the GAZ 3307);

- GAZ-SAZ-25041 with tilting only backwards and preliminary lifting of the body.

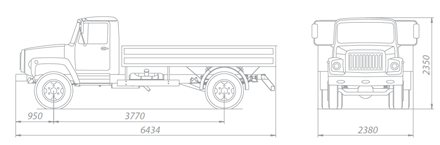

Characteristics of the GAZ 33072 chassis

For the GAZ-SAZ-3507-01 model, the basis was the chassis of the GAZ 33072 dump truck. The technical characteristics of the chassis are as follows:

- Engine – ZMZ 5231 (gasoline), eight cylinders, V-shaped;

- Engine power – 125 hp. With.;

- Number of seats in the cabin – 2 (including the driver);

- Load capacity – 4.25 tons;

- Constant maximum speed – 90 km/h;

- Wheel drive – rear (4x2);

- Wheelbase - 3.77 m;

- Fuel consumption per 100 km at a speed of 60 km/h – 19.6 l;

- The weight of a fully loaded vehicle is 7.94 tons;

- Curb weight - 3.6 tons;

- Vehicle dimensions (length/width/height) – 6.47/ 2.4/ 2.46 m, height with extended sides – 2.88 m;

- The fuel used is A-80 gasoline.

Historical overview of GAZ 4301

GAZ 4301 was released as an experimental model (1982) thanks to the development engineers of the Gorky Automobile Plant. The reason for its appearance was the following: the CPSU Central Committee decided to develop diesel trucks and put them into production. After submitting the first samples, they were sent for revision. Then it underwent thorough testing on large highways, sowing, and harvesting, before the production model GAZ 4301 (1993) was put into production. Until 1992, a small batch of trucks was produced, which were used only on large collective farms.

This machine has become competitive in the field of cargo transportation. Its advantages compared to the GAZ 53 are a new turbodiesel, use as a road train, a new cabin, chassis, and power steering. Load capacity of GAZ 4301 is 4.5 tons. The maximum load on the front axles is 3 tons, on the rear axles – 5 tons. The technical characteristics of the GAZ 4301 require special attention. Photo GAZ 4301:

GAZ-SAZ-35071 dump truck: technical characteristics

The GAZ-SAZ-35071 dump truck is placed on the GAZ-3309 base chassis, which largely determines its technical features. The machine is designed for use on roads and highways with hard surfaces and is adapted for light off-road driving. Due to the suspension characteristics of the base chassis, the dump truck is not suitable for heavy off-road conditions and can perform simple operations for the transportation and automatic unloading of various materials.

Body

The Saransk plant installs a metal body with folding sides as a working unit on the base chassis. The dump truck is unloaded in three directions: left, back and right. Optionally the following can be installed:

- board assistants;

- extension sides of increased height;

- side seals;

- an awning with a frame attached to it.

According to the manufacturer of the dump truck, the equipment is intended primarily for transporting agricultural cargo. The equipment is suitable for unloading fine bulk materials. The body is lifted through a hydraulic system with a telescopic cylinder.

Engine and transmission

The GAZ-SAZ-35071 dump truck is equipped with a power unit from the Minsk Motor Plant model D-245.7 E3. Based on the engine markings, you can immediately understand that the unit belongs to the third environmental class. For domestic technology, this fact alone is a serious achievement.

The engine belongs to the class of in-line four-stroke units with turbocharging, a cooling system and direct fuel injection. The diesel engine produces 87.5 kW of power output. Control tests have shown that the specific consumption of diesel fuel when driving a car at a speed of 60 km/h does not exceed 14 liters per 100 km. Maximum torque is achieved at 1500 crankshaft revolutions and is 413 Nm. The maximum engine speed is 2400 rpm.

In addition to the engine, a five-speed manual gearbox is installed. The gearbox is of the synchronized type. Together with the engine, the unit accelerates the car to 90 km/h maximum transport speed.

The chassis is a spring dependent suspension with hydraulic telescopic shock absorbers on the front axle. The rear axle is the drive axle, the front axle is the driven axle. The dual-circuit braking system uses drum mechanisms on the rear and front wheels. Steering without hydraulic booster.

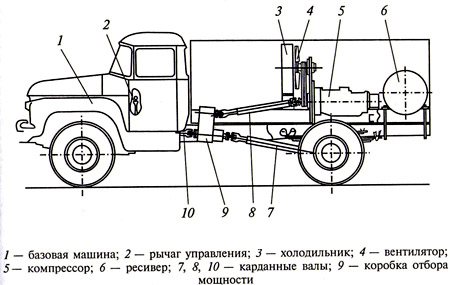

To control work processes, the GAZ-SAZ-35071 dump truck is equipped with a power take-off. The unit is a mechanical unit combined with a pump and control valve and operating at one speed. The PTO drive is from the reverse gear of the gearbox. The OM is controlled from the driver's cabin using special levers.

Motor: device and features

The GAZ 4301 was radically different from previously released models in that it was the first to use a new powerful engine - a diesel engine. A GAZ 542 engine with six cylinders was installed. Its power was 125 liters per second. Its appearance was associated with a license purchased from Deutz. The GAZ 542 engine itself was developed by the Austrian company Steyr. He became a pioneer in the production of diesel engines at the Soviet plant. The car's diesel fuel consumption is only 16 liters per hundred kilometers.

The engine is equipped with two pumps. They serve diesel fuel:

- the first, a low-compression piston fuel injector, maintains low pressure;

- the second - a high-compression mechanical centrifugal adjustable dual-mode in-line injector - provides high-level compression.

If necessary, the driver can manually pump up the diesel himself. This is possible thanks to a special fuel priming pump.

If a situation arises when the engine operates for a sufficiently long time, several types of fuel purification systems are provided:

- The third system is associated with dry air filtration. This is possible thanks to filtration components that can be changed and a contamination sensor. Cooling of the motor is provided by a fluid coupling and a six-wheel fan transmission.

- Secondary – fine, or deep, type of cleaning. It is provided with paper filter components.

- Primary – a rough type of cleaning. A filter separator is used here. It is equipped with mesh components.

Gearbox and brake system

The gearbox was redesigned by engineers to improve the quality of the car. As a result, the working resource reserve has increased and noise has decreased. It occurred when changing gears. The gearbox is manual, five-speed. Every transmission is synchronized. The exceptions were the first and the back.

Gearbox components:

- single disc closed clutch. The type of friction characteristic of it is dry;

- spring diaphragm;

- hydraulic installation.

The brake system has two circuits . The wheels are equipped with built-in units with two indifferent drives, which are independent of each other. The braking effect is distributed to all wheels, in a smooth braking situation - in a ratio of approximately 60 to 40. Of this, 60% falls on the front wheels, and 40% on the rear wheels. GAZ 4301 diesel is also equipped with a separate brake system. A pneumatic installation is provided for the trailer.

Each wheel has a removable brake drum. This makes car maintenance easier. If you need to eliminate any defects or completely replace solid drums, you can resort to improvised means, remove and replace them under normal conditions. Brake drums are wear-resistant and high-strength cast iron products.

The braking system of this truck has a special device. Thanks to it, the gaps in the shoe-drum pair are automatically adjusted.

The rear wheels have mechanically driven brake units. They are a parking brake. There are special ventilation hatches on the wheel rims, which ensures good airflow to the drums.

Vehicle control system and suspension

The steering system of this production model of the car includes a hydraulic booster, which improves driving performance. It significantly eases the effort when turning and reduces the steering gear ratio. As a result of its use, there was no need to turn the steering wheel intensively when necessary. This was a great advantage of the car when driving in a narrow, confined space. Turning has become less energy-consuming, and the driver has become less tired. The wheel turning mechanism includes a globoidal-type worm gear and a 3-ridge wheel on a bearing. This allows you to smooth out shocks to the steering wheel when driving on an uneven, bumpy road, making it easier to control a truck in a difficult situation (a broken tire, stones and cobblestones on the road).

The car suspension combines the body, the supporting frame and the wheel part. Its purpose is to evenly distribute the load during movement and reduce the negative impact of impacts. If the suspension is done correctly, the movement will be smooth and the truck will be stable while driving.

The GAZ 4301 diesel uses two types of suspension:

- Front suspension. It consists of two front springs (semi-ellipse type) and rubber plates (compression kit). Its goal is to reduce the load and optimally distribute it to the supporting parts while driving.

- Rear suspension. This includes two springs and leaf springs. Its purpose is to smooth out and reduce impacts on the body. This is due to hydraulic shock absorbers attached to the frame and axle supports.

general information

The technical characteristics of the GAZ 4301 are distinguished by their individual features, such as non-standard parts and elements aimed at improving the quality of operation of the truck. This:

- electric torch It is necessary to simplify starting a diesel engine;

- shock-absorbing chair. Provides comfort and softening to the driver while driving;

- sophisticated, specially designed ventilation system;

- new heating system;

- optimal device for blowing the front glass.

In parallel with the GAZ 4301, another model was actively produced on its chassis - the GAZ 4509 (1992). The focus of this agricultural dump truck is to work as part of the 8.6-ton GAZ-6008 dump truck. Technical characteristics of GAZ 4509: load capacity – 4.25 tons, diesel engine, fuel consumption – 15.4 liters per 100 km, maximum speed – 85 km/h.

This production model of the car is superior in its characteristics when compared with other models of a similar type. Drivers most often give positive reviews about this truck.

The only thing that confuses them today is that due to the originality of the parts, spare parts for repairs are very difficult to find. The only thing that can save you is disassembling the car, where you can pick up the necessary used spare parts.

Reasons for discontinuation

Despite its popularity, the GAZ 4301 diesel was discontinued. What are the reasons?

- Insufficient level of engine quality and vehicle cross-country ability → low demand in the market.

- Heavy engine → increased load on the front wheels → insufficient cross-country ability, getting stuck on a soft surface.

- The crisis of the nineties: lack of necessary financing and assistance from the state → low sales and demand for such cars → increasing prices for them → discontinuation of turbodiesel production.

The GAZ 4301 diesel truck is still used in agriculture and is a favorite of drivers. To this day, it is competitive when choosing between domestic and foreign production of trucks.

Engine 542 for GAZ-4301 - Repair. Spare parts

Home > Engine 542 for GAZ-4301

It differs from its predecessors in the use of a diesel engine with the possibility of constant operation as part of a road train. Serial production of the GAZ-4301 truck was launched in 1992. The car was produced with a 6-cylinder air-cooled diesel engine GAZ-542 with a power of 125 hp, which was a licensed copy of the Deutz engine (the license was purchased for a whole family of diesel engines of different power). GAZ-542 is the first diesel engine produced by the Gorky Automobile Plant. GAZ-4301 was produced until 1994. A total of 28,158 trucks of the GAZ-4301 family rolled off the assembly line.

In addition to the engine, other components and mechanisms of the car also have special features: front axle, gearbox, rear axle with optional differential lock, suspension, frame, driveline. Another difference from the previous 53 series cars is the dual-circuit brake system with hydraulic drive and two pneumatic boosters. Good stability of the car was ensured by a low center of gravity and a wide track of the front and rear wheels.

The following are aimed at improving the consumer qualities of the GAZ-4301: an effective heating and ventilation system, an electric torch device to facilitate engine starting, a device for blowing and washing a semi-panoramic windshield, an adjustable sprung driver's seat, and power steering.

There are also external differences between the GAZ-4301 and the GAZ-3307, but they are not significant. These are original wheel rims with four small holes between the ventilation windows (such wheels cannot be installed on cars of other models, since in the GAZ-4301 the disk is centered on the hub not by the conical part of the wheel nuts and liners, but by the central hole) and two main brake cylinders with pneumatic boosters (two small “flying saucers”), which are located on the left side of the frame behind the cockpit in front of the fuel tank.

Despite the fact that the car was discontinued almost 20 years ago, it is still in demand and competes with imported equipment. First of all, this is explained by the fact that prices for GAZ-4301 spare parts are an order of magnitude lower than for foreign analogues of this class. The car has reliability and high cross-country ability and can easily cope with off-road conditions, frosts and other difficulties that arise during operation in Russia. However, there are also disadvantages. The most important of them is the problem of finding the necessary part. And this problem is felt more and more by the owners of the GAZ-4301 diesel engine every year.

But we hasten to please you. To solve this problem, you just need to call us or come to our store for the necessary spare part. Our store offers a wide range of spare parts for the GAZ-4301 car. From us you can purchase not only small parts, but also components, assembled units and parts for the GAZ-542 engine. New and used spare parts are available for sale.

Quality, reliability and compliance with the norms and standards established in the Russian Federation, as well as reasonable prices are the main reasons why the owner of a 542 diesel engine, having contacted us once, becomes our regular and beloved client.

www.gdu-nn.ru

GAZ-4301

GAZ-4301 is the first medium-duty truck using a diesel power plant. The development of this model and preparation for mass production took a fairly long period of time, and despite this, the truck spent only a couple of years on the assembly line.

In the early 1980s, the Gorky Automobile Plant began developing a completely new truck. It was assigned the factory index GAZ-4301. In 1983, the first experimental series of machines reached serious testing. Since the main area of application was planned to be performing various agricultural tasks, the machine was tested under similar conditions. At first, collective farms near Moscow became the venue for the event. Later, the trucks took part in a test rally of 9 thousand kilometers. The entire route began in Gorky, then ran through Kuibyshev, Aralsk and Tashkent, and the finish line was the Pamir Mountains.

As a result of the tests, the GAZ-4301 performed quite well, and here, it would seem, the model should have been sent into mass production. But due to certain circumstances in the country, the production of new trucks began only in 1992.

Simultaneously with the release of this model, the Saransk Dump Truck Plant developed on its basis a modified version of the grain truck, which received the factory index GAZ-SAZ-4509. This modification, like the base truck, was designed for work in rural areas, but had a dump body. GAZ-SAZ-4509 could be used as a single truck or together with a trailer, also a dump truck of the GKB-8536 brand.

Further development of the GAZ-4301 truck and its modifications would lead to quite great success, since they had good prospects for this. But due to the collapse of the USSR, almost all agricultural enterprises, which these trucks were aimed at, simply disappeared. At least in the form in which they previously existed.

Later, another problem appeared, but for the standard GAZ-4301, associated with changes in economic conditions in the country. Demand for the car fell sharply, which is why in 1995 it was decided to end mass production of diesel trucks.

Differences

After this model, serial production of another truck, the GAZ-3307, continued. In terms of appearance, it was practically a copy of the GAZ-4301, but if you look closely at the two cars, you can notice several differences.

For example, the GAZ-4301 has a high air intake pipe and a more powerful and wider frame structure. In addition, even the wheel rims are different. Both machines have different mounting holes. And if for the GAZ-3307 you can still find alternative wheels, then for the GAZ-4301 only your own wheels are installed.

Diesel truck GAZ-4301

The creation of the GAZ-4301 dump truck began in the early 90s of the last century. The first prototypes of the car appeared in 1982. They were sent for practical tests, during which the equipment covered more than 9 thousand kilometers on all types of roads in all kinds of weather conditions. The machine was also tested during sowing and harvesting work.

The development of this model was slow. In 1984, the designers prepared the first industrial batch, but it only reached serial production in 1992. The assembly was carried out under license from a German company for two years. During this time, just over 28 thousand copies came out of the Gorky Automobile Plant. The production version differed from the first prototypes in a number of design solutions.

Device

Technical characteristics of GAZ-4301:

- Engine volume - 6.23 l;

- Power - 125 hp at 2.8 thousand rpm;

- The piston stroke is 120 mm.

Engine

The car was equipped with a GAZ-542 power plant, which developed up to 125 horsepower. It had six cylinders and was complemented by an air cooling system. The motor was assembled under a license from a German company. 4301 diesel is the first and last unit of this category, which was assembled by engineers at the Gorky enterprise. Consumers characterized it as best-selling with a high supply of working life and maintainability.

The fuel system performed several tasks: it fed the power plant, stored and purified diesel fuel. It consisted of two pumping mechanisms:

- Low compression piston injector;

- Dual-mode in-line injector with high compression and adjustment.

A special pump was responsible for pumping up the fuel, which allowed the driver to do this manually. The purification system was implemented at a high level. It consisted of two fuel filters (coarse and fine) and a device for removing dust and dirt from the air. The latter was accompanied by a sensor informing the driver about the degree of contamination. A gear fan provided air cooling for the engine.

Transmission and gearbox

Loading…

It consisted of a dry clutch with one disc. Its device was supplemented with a spring diaphragm and hydraulics. The mechanical gearbox consisted of five stages: four forward and one rear. To improve the quality of the GAZ-4301 gearbox, engineers equipped it with synchronizers at all speeds except first and reverse. A pair of open shafts and an intermediate support made up the driveline. Its design also included three hinges on bearings.

Brakes

The GAZ-4301 brake system consisted of two circuits. There were three mechanisms: working, spare and parking. Each wheel was equipped with brake mechanisms, thanks to which the GAZ-4301 car had good braking. To activate them, two autonomous drives were used. Years of operation have shown that the vehicle did not seriously deviate from the trajectory of movement during sudden braking. This was achieved by blocking all wheels after activating the brake mechanism (all wheels received the same degree of load).

During smooth braking (deceleration 0.6 m/s), the loads were distributed differently. The front axle of the GAZ-4301 received 60%, and the rear axle - 40%. The designers managed to achieve this result by using two pneumatic boosters and a hydraulic drive in the GAZ-4301 brakes. The brake cylinders were located at the rear of the frame.

The solid drums that equipped each wheel were made of cast iron. At the front they were installed on the edges of the hubs, and at the rear - on the edges of the axle shafts. They could be dismantled in the field using improvised means to eliminate defects or completely replace them. The gaps between the pads and drums were regulated by an automatic system. The parking brake applied to the rear wheels. This was accomplished through the operation of a mechanical drive.

To improve ease of use, the vehicle structure was equipped with the following design solutions:

- Electric torch mechanism, which simplifies the launch of the power unit;

- Suspension driver's seat with adjustment;

- Modern (in those years) heating equipment with blowing onto the windshield;

- A simple ventilation system that provides fresh air in the required quantity.

Thanks to these components, the developers have improved the operating conditions of the truck.

Distinctive features

The first unique feature is the wheels, which differed from analogues and other developments of the Gorky Automobile Plant. They consisted of oblong ventilation windows and additional holes (four of each). Wheels from 4301 could not be installed on other cars, since only this model had a disc rim centered on the hub with a hole in the center, and not with a conical part of the fasteners. Each tire was equipped with a two-component rim with a split bead, the core of which was made of steel thread. This ensured reliable fastening and complete sealing.

Radial tires were equipped with a pneumatic mechanism. The compression of the front and rear wheels varied. Wheel alignment was set in the range of 0-3 millimeters. Unification of the main technical components made it possible to reduce the cost of spare parts and simplify repair work.

The cabin has received a modern design in its years. It consisted of two doors and accommodated a driver and a passenger. Every person in the cabin could use a seat belt. The air intake pipe is located on the left side. The oil heating equipment consisted of two radiators. The material came from the lubrication system. In addition to the main heater, there was an autonomous heater powered by diesel fuel. The sofa in the salon was separate. The plumage was made of steel elements. The hood tilted forward, which provided full access to the technical components of the vehicle.

The steering mechanism was based on a globoidal worm with a three-ridge wheel. It was mounted on a ball bearing. An indisputable advantage over its main competitors is the presence of power steering. This made it easier to turn the steering wheel. Thanks to the hydraulic booster, rotations were reduced from 5-6 revolutions to 3. With this mechanism, the vehicle became more maneuverable in urban conditions.

Controllability was improved by installing hydraulics. It reduced impacts on the steering wheel caused by uneven roads or collisions with large cobblestones and other objects. It also simplified movement in case of a tire puncture.

To improve the quality of the dump truck, engineers made a number of serious improvements to the design:

- We changed the design of the main technical components, making it more reliable;

- The gearbox was redesigned, increasing the service life and reducing noise from gear shifting;

- The rear axle was updated, the driver remotely controlled the differential lock;

- Amendments were made to the front axle design;

- We redesigned the piston GAZ-4301, increasing the “endurance” of the engine.

The frame turned out to be strong and durable. It withstood serious mechanical stress. The front suspension served as a connector between the wheel support parts and the body using special spare parts. Thanks to the special design (two front semi-elliptical springs with a rubber compression kit), it was possible to reduce the loads and distribute them evenly between all the front wheel supports. This negatively affected the maneuverability of the equipment. The rear suspension had exactly the same device, only it was supplemented with GAZ-4301 auxiliary springs.

The front axle was equipped with telescopic hydraulic shock absorbers. They softened the loads on the frame caused by uneven road surfaces.

Electrical equipment of the 1-wire type was connected to the housing. The mains voltage is 24 V. To ensure stable operation of the electrics, it was supplemented with a rectifier and voltage stabilizer. The wiring diagram for this car can be easily found on the Internet. With its help, electrical equipment can be easily repaired.

What can be concluded?

GAZ-4301 in its years turned out to be a new way of development of the Gorky Automobile Plant. Transport was ahead of its time, since in the 80-90s of the last century diesel was of poor quality. This led to low demand, as due to poor fuel the engine quickly broke down and required serious repairs.

Another significant disadvantage was the low cross-country ability compared to gasoline counterparts. The main problem was the high mass of the front axle. It increased due to the large weight of the power plant. This led to the car getting stuck in the mud.

Due to the crisis in the 90s, the state reduced orders for agricultural machinery. Model 4301 trucks were assembled in small batches. Such production volumes increased the cost of diesel engines, which made the production of this product unprofitable. This led to the project's closure in 1994.

20 years later, in the era of high-quality diesel fuel, these trucks found a second life. Due to their low cost (compared to foreign analogues), the proliferation of components and maintainability, they are in high demand in agriculture and other industries. If you repair old copies and replace problematic technical components, the machine will work stably for a long time and without serious breakdowns. Economic payback does not exceed 2-3 years.

my-weapon.info

Cabin

GAZ-4301 was equipped with a two-door all-metal cabin designed for two people. Inside there are places for attaching seat belts. The standard heating system has two radiators connected to the lubrication system of the power unit. In addition, the truck cabin also has an independent air heater with two operating modes. This heater uses diesel fuel to operate.

If on previous models, which are the GAZ-52 and GAZ-53 trucks, one large sofa was used as seats, then in the new car the manufacturer installed two separate seats, one for the driver and the other for the passenger.

The driver's seat has a suspension that includes a coil spring and a hydraulic shock absorber. This design allows you to further smooth out road irregularities, thereby making work more comfortable.

In addition, the engineers also thought through the driver’s seating position. The seat is equipped with several adjustments, which allows the driver to fit quite comfortably depending on his body type. The longitudinal position of the seat in the cabin is changed by means of a slide with eight fixed positions. The backrest is equipped with three fixed positions, setting the angle of inclination to 4, 7 and 10 degrees. This possibility is provided by a hinge mechanism that continuously changes the degree of inclination of this backrest. There is a folding seat inside for the passenger. The use of a folding mechanism facilitated easy access to the independent heater.

Dump truck GAZ-SAZ 53B

The dump truck has a shortened frame by 300 mm, which is why the spare wheel was moved under the body behind the driver. Both suspensions are on leaf springs, shock absorbers are installed only on the front suspension. On the first releases of trucks, the edges of the main sheets were bent and formed an “ear” for fastening, and at this point they were fastened through the bushing using spring pins.

The gasoline tank is located under the driver, the filler neck is located immediately behind the driver's door. The modification was carried out from 1966 to 1984; in addition to Saransk, cars with dumping equipment were produced at the Frunzensky Automobile Assembly Plant.

The most famous truck from the times of the USSR is considered to be the GAZ-53, in addition, it also surpassed its counterparts in terms of production quantity. GAZ-53 can be classified as a medium-tonnage truck.

The GAZ-53 truck has rear-wheel drive, and various modifications of trucks were produced on its basis, including dump trucks. GAZ 53 dump trucks were marked as GAZ-SAZ 53B. GAZ 53 dump trucks were produced from 1966 to 1974.

Cabin

The dump truck cabin has space for two people. Such a dump truck could load 3.5 tons, despite the fact that the weight of the equipped dump truck reached 3 tons 750 kg. The dump truck was 6.38 m long, 2.475 m wide, and 2.575 m high. Its wheelbase reached 3.7 m.

Engine

Like all 53 models, the GAZ 53 dump truck was equipped with a carburetor engine that could run on both natural gas and gasoline. The engine was installed V-shaped with eight cylinders. The engine consumed 24 liters per 100 km, which is not so much for trucks of that time.

V-shaped engine for GAZ 53 dump truck

Transmission

The gearbox is mechanical, consisting of four stages. The GAZ 53 dump truck was equipped with a single-plate dry clutch and a single hypoid final drive. The steering was equipped with a pair of globoid worms with a three-ridge roller. The tire diameter was 20 inches.

Although the production of a dump truck based on the GAZ 53 was discontinued a long time ago, this modification of the truck is still on the road, and therefore a sufficient number of people are interested in its technical characteristics and tips for repairing this truck.

Chassis characteristics

The dump truck was equipped with a 4.25 liter 8-cylinder engine, its cylinder block and cylinder heads were cast from Al 4 aluminum alloy. The gearbox was 4-speed manual, the vehicle had rear-wheel drive.

Dump truck gearbox

- Length/width/height of the cabin – 6.4 m/ 2.47 m/ 2.2 m;

- Load capacity – 3.5 tons;

- Curb weight - 3.75 tons;

- The weight of a fully loaded vehicle is 7.4 tons;

- Ground clearance (clearance) – 0.265 m;

- Wheelbase – 3.7 m;

- Fuel consumption per 100 km at a speed of 40 km/h – 24 l;

- Tire size – 8.25-20 inches;

- The rated power of the internal combustion engine is 115 hp. With.;

- Engine type – carburetor;

- The compression ratio in the engine cylinders is 7.6;

- Steering – worm-type steering mechanism, without power steering;

- The number of seats in the cabin is two, including the driver.

Tipper equipment

The GAZ-SAZ 53B dump truck is released from the load by tipping the body. The direction of unloading can be side or rear. The body of the Gas 53 dump truck is metal, the vehicle's load capacity is less than that of the flatbed version.

Tipping the dump truck body sideways

The dump truck body drive is hydraulic. The lifting device is a hydraulic cylinder; the hydraulic system uses liquid oil; the hydraulic cylinder is rigidly connected to the platform. The cylinder is filled with oil through pipelines by a gear pump, which in turn is driven by the power take-off. Depending on which part of the cylinder is filled with oil, the body is raised or lowered. The lifting and lowering is controlled by a crane; it contains three valves:

- Body lowering valve;

- Safety valve;

- Check valve.

The lowering valve allows oil to flow into the oil tank when the pump is not running and the platform is lowered.

Drawing of the mechanism of the GAZ 53 dump truck

The safety valve limits the maximum pressure in the system to 115–120 kgf/cm², preventing overload at a load capacity higher than the established norm. The check valve prevents spontaneous lowering of the body.

The hydraulic cylinder of the device is telescopic, it contains three plungers. At the bottom of the cylinder (at the bottom) there is a fitting for filling the cavity with oil. The device itself contains three plungers - one per telescopic section of the hydraulic cylinder. The installed protective rings on the plungers protect the rubbing surfaces from dirt and dust.

The oil tank of the dump truck is located behind the cab, between the metal body and the frame. The tank is metal, welded, made of stamped thin steel sheets. There is a plug at the bottom to drain the oil, and an oil filter at the top. The oil filter has a fitting at the inlet that connects to the control valve.

The power take-off has a mechanical connection to the gearbox and is needed to transfer power from the gas 53 engine to the oil pump of the dumping equipment. The PTO is controlled by a lever from the cabin; the lever has two fixed positions - neutral and “lift”.

The oil pump is mounted on the PTO body, the pump sections communicate with the control valve and the oil tank capacity.

Brake system

The car has a dual-circuit braking system, modern for its time, consisting of a service, spare and parking brake.

All truck wheels are equipped with drum brakes with two independent drives. For ease of control, the braking system has pneumatic boosters and a hydraulic drive.

It is worth noting that drum mechanisms have a special device that automatically adjusts the gap between the shoes and the drum.

Chassis

The GAZ-4301 has a dependent suspension at the front, which has two longitudinal semi-elliptic springs. There is also an additional rubber compression buffer that prevents the springs from sagging.

The rear suspension is implemented according to a similar design. It also has longitudinal semi-elliptical springs and additional metal springs that act as shock absorbers. Speaking of shock absorbers: the front suspension is equipped with hydraulic, telescopic, bi-directional shock absorbers.

Specialists increased the energy intensity of the spring suspension and limited their deflection under the weight of the load by installing rubber compression buffers, which are located on the side member of the frame structure near the front axle.

The lower flange of the side members at the rear of the frame structure has almost the same buffers that limit the degree of deflection of the springs.

Peculiarities

Despite its rather short history, the GAZ-4301 truck has quite a lot of different reviews, most of which are positive. As the owners note, this truck is a simple, durable, unpretentious and load-lifting vehicle that can cope with many different tasks.

Fuel consumption

The model has a soft and very effective suspension. As practice has shown, the truck engine has an average diesel fuel consumption when driving in urban conditions from 19 to 22 liters per 100 kilometers. On the highway, fuel consumption rarely exceeds 17 liters per 100 kilometers.