Device

The operating principle of a four-stroke internal combustion engine is completely identical to a two-stroke engine. The main difference between four-stroke engines and two-stroke engines is the number of piston strokes per crankshaft revolution. For example, if the piston moves only up and down during one revolution of the crankshaft, then it is two-stroke, and if it moves four times, then it is four-stroke. Today this type is very common in the automotive industry. A four-stroke engine has four jobs that it performs in one rotation of the crankshaft.

- The first operating cycle of a four-stroke engine is intake, at which time the combustion chamber receives and ignites fuel, which burns and forms compression.

- Compression is the second cycle, at this time the piston moves down and causes the crankshaft to rotate. The pistons are installed in pairs, with two pistons at the bottom and the other two at the top.

- The third cycle is expansion.

- The fourth cycle is exhaust gas removal. At this moment, the exhaust valves open, which discharge gases into the manifold.

There are many operating diagrams for this internal combustion device on the Internet, so finding a diagram is not difficult. Having examined the diagram, it will become much easier to understand the operating principle and structure of such an internal combustion engine.

content .. 11 12 17 ..WORK CYCLES OF DIESEL LOCOMOTIVES

Four-stroke diesel - operating diagram

The first stroke is air intake (Fig. 19). When the piston moves from top dead center to bottom (let's assume that the piston moves due to the rotation of the crankshaft by inertia), the intake valve is opened under the action of a special mechanism, thus allowing air access to the cylinder; exhaust valve is closed.

The second stroke is compression. Having passed the bottom dead center, the piston, driven by the crankshaft, begins to move upward: the volume of the cylinder decreases. Since both valves - inlet and outlet - are closed at this time, the piston compresses the air filling the cylinder. When the piston is near c. m.t., the air is compressed to a pressure of 2.94 - 4.9 MPa (30-50 kgf/cm2). This stroke is therefore called the compression stroke. Due to such compression, the air temperature in the diesel cylinder rises to 500-600°C.

The third stroke is gas expansion. As the piston approaches top dead center, a portion of fuel is injected into the cylinder through the injector. Fuel injection pressure (not to be confused with gas pressure!), reaching up to 98 MPa (1000 kgf/cm2), is created by a fuel pump (not shown in the diagram). In the cylinder, fuel is mixed with compressed air and self-ignition occurs. The process of fuel combustion is accompanied by an increase in temperature and gas pressure. When fuel burns, the temperature of the gases in the cylinder reaches 1500 - 1800 ° C, and the pressure increases (depending on the design and power of the diesel engine) to 4.9 - 11.7 MPa (50 - 120 kgf/cm2). Under the influence of high gas pressure, the piston moves to bottom dead center, and the combustion products expand. As already indicated, this third

The stroke is the working stroke of the piston because only during this stroke the piston does useful work. The temperature and pressure of gases after expansion decrease significantly. In the third stroke, just like in the second, the intake and exhaust valves are closed.

The fourth stroke is the release of gases. At the end of the third stroke, the exhaust valve opens and exhaust gases begin to flow into the manifold. When the piston moves back upward, the volume of the cylinder decreases, the gases are pushed out by the piston through the open exhaust valve. The process of releasing exhaust gases, i.e. cleaning the cylinder for subsequent air intake, ends slightly after the piston passes top dead center. Why this is done, we will soon find out, but for now we note that the fourth cycle is the closing one in the cycle; after it, all strokes are repeated from the beginning: 1) intake, 2) compression, 3) expansion, 4) exhaust, etc. So, in a four-stroke diesel engine, the working cycle is carried out in four strokes (stroke) of the piston.

Is it good that in a four-stroke diesel engine only one of the strokes - expansion - is working, and three are preparatory? Yes and no. It’s good because the engine cylinders are thoroughly cleaned of exhaust gases. It’s bad because for one power stroke there are three auxiliary strokes, during which the engine does not produce work. Consequently, in four-stroke diesel engines, about 3/4 of the cycle time is spent on auxiliary operations - intake, compression and exhaust. Is it possible to reduce this time, reduce the duration of the working cycle?

Rice. 19, Operation diagram of a four-stroke diesel engine

content .. 11 12 17 ..

Story

Such a motor was first officially introduced by Alphon de Rocher back in 1861. In fact, there is information that confirms that the engine was introduced before this in 1854. It was very similar to the four-stroke, but the drawings and diagrams for it were lost, due to which Alfon de Rocher was the first to officially launch it.

Despite the fact that this motor was released in 1861, the first vehicle that could move on such an engine was released in the same year. Therefore, the four-stroke cycle has the second name “Otto cycle”. Thus, by 1864, about 300 copies of the four-stroke engine had already been produced.

Engine operation

As already noted, the operation of a four-stroke engine consists of four strokes of the piston or two revolutions of the crankshaft.

- Inlet . The piston moves downward, opening the intake valve. From the carburetor the combustible mixture enters the cylinder. When the piston reaches the bottom position, the intake valve closes.

- Compression . The piston moves upward, causing the combustible mixture to compress. When it approaches the top point, the compressed gasoline ignites.

- Extension . Gasoline ignites and burns. As a result, the flammable gases are stretched and the piston moves downwards. In this case, two valves are closed.

- Release . The crankshaft continues to move around its axis by inertia, and the piston moves upward. At the same time, the exhaust valve opens and exhaust gases enter the pipe. When the valve passes the dead center, the intake valve closes.

Read also: DIY inverter from a computer power supply

Repair

Like all mechanisms in a car, the engine is imperfect and falls into disrepair from time to time. In order for a car or other vehicle to move, the engine must be working. Breakdowns vary, ranging from the most minor problems to the most complex.

Simple breakdowns include the replacement of small units and components, but serious breakdowns involve complete disassembly and replacement of parts, often with changes to the cylinder block. It often happens that the piston in the cylinder moves unevenly, and this spoils the surface of the cylinder, after which the cylinder block must either be sharpened or replaced with a new one. In order to prevent this, the engine must be properly and promptly cared for. Processes for caring for the piston group include timely replacement of rings on the pistons.

Please note that engine maintenance should only be carried out in accordance with the manufacturer’s instructions, subject to weather conditions.

If something irreparable does happen, the engine needs to be repaired.

It happens that the motor can no longer be repaired, and it just needs to be replaced with a new one. In this case, you just need to purchase a new motor and insert it in place of the old one. The problem is that a new engine or one from another car costs a lot of money, which the owners of a broken car often don’t have at their disposal, so they have to repair the old motor.

In order to begin repairing the engine, you first need to disassemble it.

- Before disassembling it, you need to drain the oil. Each car drains it differently, so in order to know how to do this specifically on your car, you need to know the oil change diagram.

- After draining the oil, you can begin disassembly. The first step is to disconnect all hoses and sensors leading to the motor.

- Having turned everything off, you can begin the process of removing the motor. Most often, it is mounted differently on each car, based on this, you need to find a detailed diagram of the engine and fastenings to the car frame.

- After removal, it must be placed in a place suitable for disassembly. It should only be removed from the car using a special lift. If there is none, then it can be disassembled directly in the engine compartment.

In order to repair something in a car, you need to understand something about it. Most often, familiar auto mechanics or scientific literature come to the rescue.

After the engine has been completely repaired, assembled and started, a run-in of the engine is required. It must be at least 5000 kilometers. This is necessary so that all the parts get used to each other and work correctly. During break-in, the car will produce incomplete power and generate a lot of heat. Therefore, to remove heat, you need to turn on the stove in order to avoid overheating of the engine.

How does a four stroke engine work?

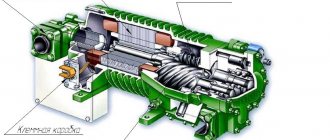

Structurally, the working cycle of a typical four-stroke unit is ensured by the operation of the following elements:

- cylinder;

- piston - performs reciprocating movements inside the cylinder;

- intake valve - controls the process of supplying the air-fuel mixture to the combustion chamber;

- exhaust valve - controls the process of exhaust gases ejecting from the cylinder;

- spark plug - ignites the resulting air-fuel mixture;

- crankshaft;

- camshaft - controls the opening and closing of valves;

- belt or chain drive;

- crank mechanism - translates the movement of the piston into rotation of the crankshaft.

Read also: What to make a wick for solar gas

Duty cycle of a four-stroke engine

The working cycle of such a mechanism consists of four cycles, during which the following processes are implemented:

- Intake (fuel and air injection). At the beginning of the cycle, the piston is at TDC. At the moment when the crankshaft begins to rotate, it acts on the piston and moves it to BDC. This leads to the formation of vacuum in the cylinder chamber. The camshaft acts on the intake valve, gradually opening it. When the piston is in its extreme position, the valve is completely open, resulting in intense injection of fuel and air into the cylinder chamber.

- Compression (increasing the pressure of the combustible mixture). In the second stage, the piston begins to move back to the top dead center of the compression stroke. The crankshaft makes another turn and both valves are completely closed. The internal pressure increases to 1.8 MPa and the temperature of the combustible mixture rises to 600 C°.

- Expansion (working stroke). When the piston reaches the top position in the combustion chamber, the maximum compression is set to 5 MPa and the spark plug is fired. This leads to combustion of the mixture and an increase in temperature to 2500 C°. Pressure and temperature lead to an intense impact on the piston, and it begins to move back to BDC. The crankshaft makes another turn, and thus the thermal energy is converted into useful work. The camshaft opens the exhaust valve, and when the piston reaches BDC, it is fully open. As a result, the exhaust gases begin to gradually leave the chamber, and the pressure and temperature decrease.

- Exhaust (removal of exhaust gases). The engine crankshaft turns and the piston begins to move to the top point. This leads to the expulsion of exhaust gases and an even greater decrease in temperature and a decrease in pressure to 0.1 MPa. Next, a new cycle begins, during which these processes are repeated again.

During each stroke, the engine crankshaft rotates 180°. During a full working cycle, the crankshaft rotates 720°.

The four-stroke engine has become widespread. It can work with both gasoline and diesel fuel. The difference between the operating cycle for a diesel engine is that the ignition of the air-fuel mixture does not occur from a spark, but from high pressure and temperature at the end point of the compression stroke.