In winter, owners of cars with a diesel engine have many problems starting the engine. Unprepared diesel fuel thickens, becomes cloudy and becomes waxy both in the tank itself and in the lines already at -5°, not to mention lower temperatures.

With the onset of frost, a cold start of such an engine becomes simply impossible, and the engine itself, although in good working order, operates intermittently and stalls while driving. The KAMAZ pre-heater will help eliminate the problem and reduce the load on the engine. This is a separate category of devices that has individual characteristics and operating features.

Purpose of the device

In any KAMAZ 65115 or other modification, at temperatures below -15°C, a problem arises - the fuel acquires a viscous structure. Because of this, the engine injectors are not able to provide the necessary fuel spray, and the crank mechanism is very difficult to turn. That is why on KAMAZ one of the most useful additional devices is the pre-heater.

Before starting the engine, the device will warm it up to the optimal temperature, ensuring a stable start. As for the KAMAZ brand, in this case the device is mounted if the ambient air temperature reaches below -15°C. Some models are capable of performing several functions at once, including warming up the car cabin.

Unit features

For KAMAZ vehicles, autonomous liquid pre-heaters are used, which operate on diesel fuel. The main advantage of these variations is that they can provide effective engine warming up with minimal consumption.

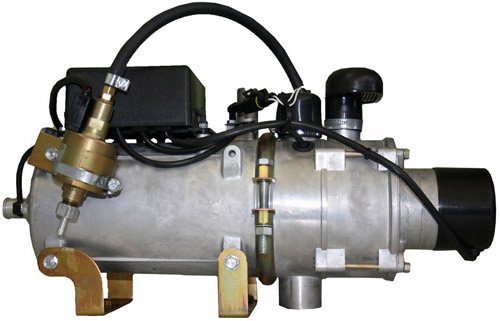

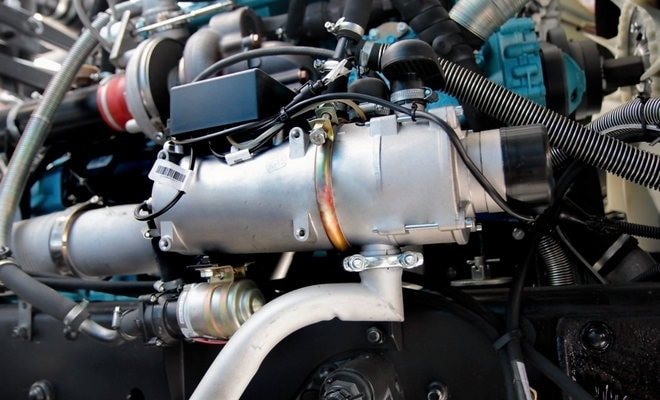

Pre-heater KamAZ

It should also be noted that the device connects to the car’s electrical network, but does not consume a lot of electricity. It turns out that when using the KAMAZ preheater, the battery operates autonomously and does not require third-party power sources.

In more outdated truck models, simple devices of the 4310, 520 series are installed. These variations have a simple design and do not differ in complex installation schemes. Modern units are in great demand in new KAMAZ vehicles, buses, special equipment and tractors. But despite the difference in functions, the operating principle of the devices consists of standard steps.

VIDEO: Preheating a cold engine

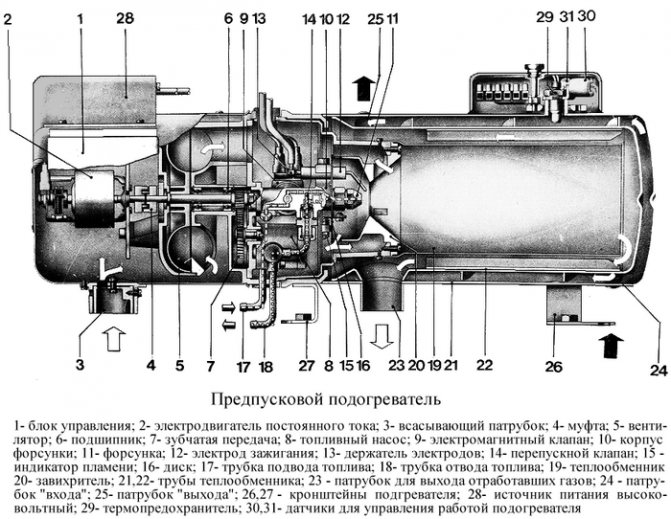

Design and device

The design of the KAMAZ pre-heater includes several main components:

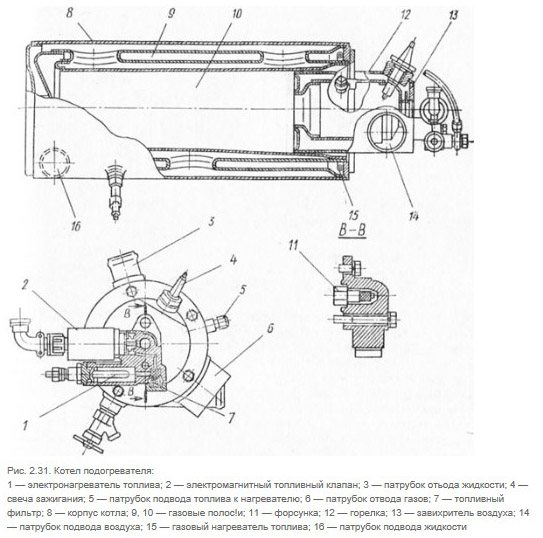

- boiler room;

- burner;

- water pump;

- remote control device.

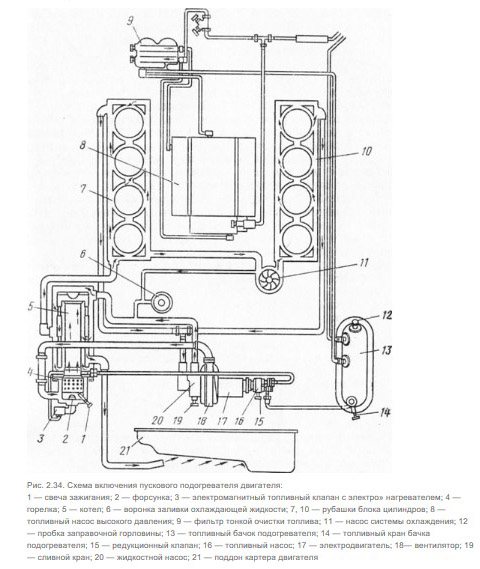

The main element is the boiler compartment, which consists of 4 durable cylinders that form a heat exchanger. This part includes 2 cavities that facilitate the unhindered passage of exhaust gas and coolant circulation. There are 3 tubes on the outer part of the engine heater, 2 of them are intended for draining or supplying antifreeze, one is for exhaust gas removal.

Pre-heater device

The exhaust gases hit the damped part of the boiler, which due to this action change direction and flow to the outlet pipe. In this case, thermal energy is consumed for heating in the engine sump.

On the reverse side, at the open end of the boiler compartment, a burner is mounted, which includes:

- spark plug;

- nozzle;

- valve;

- fuel heater;

- gas heater.

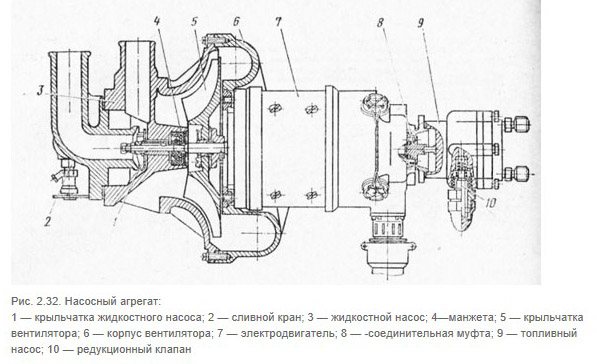

The pump is considered a separate unit that combines three main pumps - liquid, fuel, air. It is in this system that it differs from other types of pre-heaters.

For example, a modification of the PZD 30 heater has a pumping apparatus, which is designed as a separate unit. Such a device is installed both above the boiler room and in any most convenient place. In this case, the device is connected with hoses of different diameters and lengths.

Pumping unit design

Devices 15-8106 and other similar analogues are mounted on the edge of the boiler, near the burner. This installation option makes it possible to eliminate the need to use long hoses, which leads to a significant reduction in the dimensional parameters of the entire preheater.

Boiler heater design

The remote control device has an electronic unit, with the help of which the operating modes are configured in 4 main positions. This element also allows you to configure relays, various fuses, and a spark plug switch.

It should be noted that modern modifications in the design have a variety of controllers. First of all, users note the temperature and flame sensor. These elements make it easier to turn on the device and make it possible to fully control its operation.

Circuit diagram for switching on the engine starting heater

This eliminates the possibility of breakdowns requiring repair. But according to the principle of operation, these models of KAMAZ heaters do not have any special differences.

Recommendations for use

The key to a long service life of any equipment is compliance with the rules of use. In general, the following stages should be distinguished:

- Check the volume of coolant and fuel in the tank; if necessary, pump up or top up the mixture.

- The program regulator is directed to the fixed position “Three”. This action will start the fan and fuel mixture heater, and the boiler compartment will also be purged. At this moment, a portion of fuel is prepared for ignition. The operating time interval of the third program completely depends on the temperature regime of the atmospheric air: for -20°C you will need to hold it for only 25 seconds, -30°C - 35 seconds, -50°C - 1.5 minutes.

Connection diagram of the heater to the engine cooling system

- The program switch switches to the non-fixed “Two” mode. Here the valve at the inlet of the fuel pipe opens and the spark plug starts. The fuel is preheated under high pressure in the burner, at the same moment it is mixed with oxygen, forming a fuel mixture, which the candle ignites upon contact. As a rule, ignition is carried out in the first 15 seconds; when this mode is reached, a corresponding noise is generated.

- After the combustion chamber starts functioning, the “First” work program starts and is fixed. This task renders the spark plug inoperative, at which point the heater operates in main mode. The exhaust gases transfer their temperature to the coolant, and thanks to its circulation through the heater and the engine, it heats the power unit.

- When the temperature of the KAMAZ pre-heater reaches 70-80°C, the lever will need to be returned to level “Three”. This manipulation will allow you to close the valve on the fuel pipe without stopping the operation of the fan. As a result, the rotating element will completely purify the boiler from the remaining gases formed.

- After 30 sec. you need to turn on the “Zero” mode to completely stop the operation of the preheater. The final step is to close the solenoid fuel valve.

The preheater is considered a high hazard. If used incorrectly or made a mistake during installation, this particular device can become the primary cause of fire.

While the heater is operating, you need to stay nearby and ensure that no leaks form. If a liquid leak is detected, the device must be turned off immediately and not used until the problem is resolved.

Starting the KamAZ engine using the PZD-30 pre-heater must be done in the following order:

- Turn on the battery switch;

- Open the tap on the fuel tank of the heater and fill the heater power supply system with fuel, making several pumping movements with the manual fuel priming pump.

- Set the heater switch knob to position III and press the electric heater button for a time depending on the ambient temperature: 60 s at temperatures up to minus 40 ° C; 90s - up to minus 50°C;

- Move the switch to position I and hold it in this position (no more than 30 s) until a characteristic hum appears in the heat exchanger, indicating that the fuel in the burner has ignited;

- Release the switch, which will automatically move to position II; a continued, even hum in the heat exchanger indicates that the heater is operating in a stable mode.

If the start of the heater fails, you need to turn the switch to position 0 and after 1 minute. repeat start. If after two attempts with switching to position I for 30 s with intervals between attempts of 1 min. If the heater does not start working, then you need to find the problem and fix it.

When the liquid in the engine cooling system warms up to 70-80°C, it is necessary to stop the fuel supply by setting the switch to position III. Then, after 15-20 seconds (after the flame noise in the boiler has completely stopped), you need to move the switch to position 0 and close the valve of the heater fuel tank. After this, you need to start the engine by pressing the clutch pedal all the way.

Starting the engine using PZD-30 when filling the cooling system with water:

- Prepare 35-40 liters of soft water without mechanical impurities;

- Close the radiator shutters, the cab heater valve (see Fig. 3) and raise the cab;

- Remove the expansion tank and heater funnel plugs. Close all drain valves. If the taps are frozen, close them while the engine is warming up after water begins to flow out of the taps;

- Before filling the cooling system with water, perform a test run of the heater and turn it off after 10-15 hours of operation.

- Pour 2 liters of water into the heat exchanger of the heater through a funnel and immediately turn on the heater.

- Immediately after the heater starts operating, add an additional 4 liters of water and tighten the funnel cap.

If the heater starts unsuccessfully or stops spontaneously, the start must be repeated, and if it fails, immediately drain the water from the system.

When the engine warms up to the temperature corresponding to the opening temperature of the thermostat valves (which will be indicated by the appearance of steam from the filler neck of the expansion tank), you need to fill the cooling system to its full volume (until water flows through the control valve) through the neck of the expansion tank, then close the neck with a plug .

After filling the cooling system with water, you should lower the cabin and let the heater run until the engine warms up, and then turn off the heater and close the valve of the heater fuel tank and start the engine.

When the engine is running at an average crankshaft speed, open the cabin heater tap and, after filling the heating system with hot water, add water to the expansion tank to 2/3 of its volume.

Error codes

Error codes PJ 14TS:

- If the LED blinks once, then the breakdown may be due to overheating of the heat exchanger or the temperature difference reported by the overheating and temperature sensors.

- If the LED element flashes 2 times, the error may be caused by the exhausted number of engine starts.

- The LED flashing three times is a preheater malfunction due to flame interruption.

- When the LED flashes 4 times, the problem may be a faulty spark plug or blower motor.

- 5 times means the flame indicator is broken.

- 6 times are errors in the operation of the overheating and temperature sensors.

- When the LED flashes 7 times, it is recommended to check the integrity of the circulation pump, fuel cell, control relay and heater.

- If the LED flashes 8 times, it means that the connection between the control panel and the control unit has been lost.

- 9 times - the voltage was turned off or reduced.

- 10 times - exceeding the time allotted for ventilation.

Why doesn't it start

If the preheater does not work, the reason for this may be the following:

- The electric motor of the pumping mechanism does not start.

- The fuel liquid in the PZD boiler does not ignite.

- The fuse was turned off.

- Electric motor relay failure or switch failure.

- An open circuit that connects the wires between the relay and the electric motor.

- Malfunction of the engine itself.

- There is no spark between the spark plug electrodes.

- The overheating and temperature sensors failed.

- Disconnected or reduced voltage in the system.

- The spark plugs have failed.

- The blower motor was damaged.

- There is no communication between control systems.

- The number of engine starts has been exhausted.

- Overheating of heat exchange equipment.

- The flame indicator has failed.

- The supply pipe was damaged.

PZD 14TS-10 Teplostar: purpose

diesel

pre-heater is a device designed for installation on trucks that provides fuel heating at low temperatures (down to minus forty-five degrees Celsius). The following functions of such equipment can be distinguished:

- Ensures reliable engine starting regardless of temperature conditions.

- If necessary, the engine and even the vehicle interior are heated (with the engine running).

- The interior and windshield are heated (ice is removed that interferes with visibility) while the engine is not running.

- If necessary, the heater can be started in manual mode (the operating cycle will be three or eight hours).