The “heart” of any gasoline-powered vehicle is the engine. Walk-behind tractors are no exception to this. Their motor part creates a working stroke, power potential, and declared productivity, which together make it possible to perform certain agricultural operations.

But often it is this working node that is the most vulnerable. Low-quality fuel, severe overloads, lack of regular diagnostics and many other reasons cause serious malfunctions, the timely detection and repair of which will determine its further performance. This article will be devoted to what types of breakdowns are most often characteristic of walk-behind tractor engines, and which ones can be diagnosed and fixed at home.

The walk-behind tractor starts and stalls: causes of malfunction and mechanisms for eliminating them

Owners of either brand new or used motor cultivators are not insured against a situation where the walk-behind tractor starts but immediately stalls at idle.

It can be caused by a number of factors:

- problems in the ignition system:

- loose or broken electrical contacts;

- spark plug malfunction. They can be installed only after unscrewing and external inspection. If the candle:

- dry - the cause of the malfunction lies in the carburetor, where gasoline is not supplied. It may occur due to clogging of its filter or a separate jet;

- wet - the engine does not develop speed due to an excess of fuel;

- covered with soot - the fact of its failure, which may result in the failure of an ignition spark to form. Testing with electrodes will help you finally verify this;

- after replacing or cleaning the spark plug, the electronics are examined - the integrity of the connections and the wires themselves, which may need repair due to strong vibration;

- shortage or poor quality of fuel . Often the engine does not gain speed due to an incorrectly prepared fuel mixture or debris in the carburetor. In this case, the repair begins with removing it from the walk-behind tractor body and cleaning it from dirt particles. At the same time, they change the fuel, after draining the old one and washing the fuel tank and supply hoses.

- Another reason that the walk-behind tractor starts up and immediately stalls, related to gasoline, may be depressurization of the gas tank itself. Very often this is observed after a long period of inactivity (for example, after winter), when the walk-behind tractor has not been used for a long time and has been stored with gross violations. After repairing or replacing the entire fuel tank, the functionality of the device is usually restored;

- cool weather, which often causes diesel equipment to stall. Therefore, in early spring, experts advise turning on the walk-behind tractor only after pouring hot water into the radiator;

- gearbox malfunction. The fact that the cultivator does not develop speed and stalls at idle is indicated by a characteristic knocking noise from the gearbox, which occurs against the background of a lack of lubricant.

Why is the chainsaw under load?

In some cases, a chainsaw under load cannot work properly and simply lags. A common cause of this behavior is improper carburetor adjustment or air flow through the crankshaft seal or carburetor gasket. And this behavior can occur due to a carburetor leak.

A saw that cannot operate under load will also oscillate to maintain idle speed. They will "float". Diagnostics begins with checking the tightness of the crankcase and carburetor. If air leaks are found at the crankshaft seals, they must be replaced. If an air leak is found in the carburetor, the cause can be corrected by installing a gasket repair kit.

Only after completing the above steps and sealing the engine crankcase with the carburetor can you begin to adjust the carburetor.

The reason for this algorithm is that if the air supply from the crankcase was not eliminated and the carburetor was simply adjusted prior to normal engine operation, the fuel mixture will contain more fuel than required for a sealed crankcase, which in turn will significantly increase its consumption. In addition, soot may appear in the engine, which will also negatively affect the further operation of the chainsaw.

READ How to Find out the Chainsaw Size for a Chainsaw

In some models of chainsaws, to ensure the operation of the fuel pump, special hoses are provided that transmit an air impulse from the crankcase to the carburetor fuel pump. If this hose is damaged, the saw will sit idle and not work at all under load.

You can watch the video below on how to replace a failed DIY impulse hose on a HUSQVARNA 142 chainsaw. He took the saw apart step by step, showed the impulse hose, and discussed the consequences of a failed HUSQVARNA 142.

Why does the walk-behind tractor work intermittently?

Despite the wear resistance of the motor part, it is not protected from malfunctions. The appearance of extraneous noises, jerks, and pauses in its operation are the main evidence that it needs urgent diagnosis and repair.

If the cultivator periodically stalls and does not develop speed, this may be due to:

- insufficient heating of the motor unit, which operates jerkily. A diesel cultivator, like a gasoline cultivator, requires at least 10 minutes to warm up;

- a broken starter cable, which is replaced with a new one instead of repair;

- loosening the screw ties between the starter and the motor;

- malfunctions of the ratchet, which prevents the normal operation of the starting unit;

- failure of the cylinder and pistons;

- low-quality gasoline, which is why the engine does not develop speed, does not develop speed and backfires. The situation can be corrected without repairs: after washing the fuel tank and hoses, they simply switch to new fuel.

It also happens that the engine “does not pull”, which can be seen in the overall productivity of the device.

This can be caused by:

- clogging of filtration components;

- ignition magneto failure.

Why does the walk-behind tractor stall under load?

The problem when the walk-behind tractor operates with periodic stalls and does not develop speed is perhaps the most common among gasoline and diesel units. If the walk-behind tractor starts and stalls, the main reasons for this phenomenon should be sought in the fuel supply and ignition systems, malfunctions of which may appear after 5 minutes of operation.

If the walk-behind tractor does not develop speed and stalls spontaneously, you need to check:

- aerofilter - if it becomes clogged, its surface is cleaned, washed or blown with a vacuum cleaner.

- quality of refueled fuel;

- ignition system - its diagnosis begins with a spark plug, the external condition of which is used to judge the functionality of the ignition.

In addition to the spark plug, other ignition failures of the walk-behind tractor are:

- incorrect gap between electrodes;

- mechanical damage to the electrical circuit;

- unadjusted angle between the magnetic part and the coil.

Repairing them yourself is allowed if this is provided for in the user manual for a specific walk-behind tractor model;

- muffler - the engine stalls during operation and does not develop speed due to a clogged muffler. To free it from combustion products, it is soaked in water with detergents and, after washing, dried;

- carburetor, the settings of which may be incorrect;

- cylinder-piston parts, due to which the engine does not develop speed under load. This can only be checked with a compression gauge.

It also happens that the cultivator suddenly stalls when tilted in both directions or only to the left or right. Most often this occurs due to insufficient oil level. At the moment of tilt, the lubricant remaining sensor in the crankcase may be triggered, which automatically blocks the motor.

Why does the walk-behind tractor shoot into the muffler?

Often, if the engine system malfunctions, the walk-behind tractor not only does not develop speed, but also produces obvious, ear-piercing sounds emanating from the muffler. After this, it smokes and stalls, which clearly causes concern to users.

The cause of this problem may be:

- excessive intake of oil into gasoline or diesel, due to which its combustion is accompanied by the release of unnaturally acrid smoke. In this case, the repair consists only of cleaning the fuel system and refueling with high-quality fuel;

- failure to adjust the ignition or failure of its components - first of all, pay attention to the gap between the electrodes and, if necessary, set it in accordance with the operating instructions;

- incomplete combustion of fuel in the engine cylinder. In this case, repair of the walk-behind tractor engine begins with disassembling the entire cylinder-piston group, which is cleaned and checked for defects. It must be remembered that after such manipulations it will not be superfluous to reconfigure the carburetor.

Summarize

At the first sign of a chainsaw malfunction, it is necessary to carry out a full diagnosis. To avoid damage to your saw due to improper maintenance, it is best to leave the job of identifying and repairing engine problems to professionals. And most importantly, you don't want to use a chainsaw with minor defects because it will lead to even bigger problems.

Source

There are several simple rules for operating and maintaining chainsaws, the observance of which will increase their service life. Preparing the correct fuel mixture, regularly cleaning filters and periodically replacing parts will save you from having to repair the tool for a long time. If it is impossible to avoid a breakdown, you can find out the cause yourself. This applies to all brands of chainsaws, from the more complex Husqvarna and Stihl models to the simplest Makita and Patriot models.

Chainsaws immediately

What to do if immediately after starting the chainsaw? First you need to check the fuel in the gas tank. If its level is insufficient, the fuel mixture must be prepared in strict accordance with the ratio of gasoline and oil specified in the operating instructions. Gasoline must have the highest possible octane number, and the required brand of oil is usually indicated in the chainsaw's passport.

Next, check the spark plug, as well as the contact of its tip with the high-voltage wire. The gap between them should be no more than 0.5 mm. If necessary, the candle is cleaned of carbon deposits and dried. It is recommended to periodically replace the spark plug with a new one. The reasons why the tool stops when you press the gas are hidden in the fuel filter or carburetor jet. Cleaning the gas filter will not take much time and effort, but it is better to entrust disassembly and cleaning of the carburetor to service center specialists.

READ Adjusting the Ignition of the Ural Chainsaw

Chainsaw chains idling

It is common to see a chainsaw idling. First of all, you should check the muffler and, if it is dirty, clean it of any resin deposits. Also on the carburetors of some models and others there are bolts marked H and L - respectively, rough and fine installation. By adjusting the L bolt while the chainsaw is running to increase its speed (turning the bolt only half a turn), you can solve this problem. Adjusting the carburetor requires an electronic tachometer and is a rather labor-intensive process. That is why in such cases it is better to turn to professionals.

Chainsaws during loading

If the chainsaw is under load, the cause may be the fuel system or a dirty air filter. Changing the fuel to the correct gas/oil ratio or cleaning the air filter are universal solutions to this problem. An incorrectly prepared mixture of low-quality gasoline and, for example, motor oil is the main reason for the failure of a chainsaw, including when it heats up and lags.

Chainsaws at tilt

When the chainsaw is positioned horizontally, the fuel pipe lies at the bottom of the fuel tank; when the tool is tilted, the pipe is above the fuel mixture, that is, in the air. This is why the chainsaw stands on its side.

What to do if the walk-behind tractor engine does not start well when hot?

If the walk-behind tractor does not develop speed when hot, fault diagnosis is carried out in the following sequence:

- after several unsuccessful startup attempts, the spark plug is examined as described above. If possible, it is better to immediately replace it with a new one in order to completely eliminate questions on this point;

- check the compression and vacuum level in the gas tank;

- in a dark room, see if the wiring is sparking;

- make sure that when heated, a spark is definitely formed. In addition to the spark plug, a faulty ignition coil can also prevent sparking.

Other causes of malfunction include:

- lack or incorrect filling of oil, due to which the triggered oil level sensor blocks the operation of the engine part;

- failure of the valve in the fuel tank, which is supposed to maintain gasoline pressure. As a result, its liquid contents do not flow into the carburetor.

Repairing walk-behind tractors, and especially their power plant, is a responsible matter that requires literacy and good dexterity. This applies not only to domestic favorites - the Neva, Cascade, Agro walk-behind tractors, but also imported ones, for example, Honda. But this does not mean that repairing them yourself is impossible. Having a minimum amount of knowledge and following our recommendations above, you can eliminate any malfunctions at home.

Owners of walk-behind tractors and cultivators sooner or later face a typical problem when their workhorse does not start or starts, but stalls when the air damper is opened, begins to “shoot” or rev. To eliminate this annoying problem, you need to find out the reason why it occurs, and then carry out the proper repairs.

Reasons why the walk-behind tractor does not start and how to eliminate them

There are several reasons why a motorcycle does not start when starting. These include:

- Damage to the carburetor (in walk-behind tractors with a gasoline engine);

- Malfunction of ignition/glow devices;

- Low lubrication level.

When strange changes appear in a motor cultivator and its operation becomes unstable, the carburetor is checked first. In this important unit, the formation of the fuel-air mixture (FA) occurs and its dosing for supply to the cylinders of the internal combustion engine (ICE). And if the jets become clogged, an obstruction occurs in the fuel system, as a result of which the carburetor loses its ability to start the engine. To eliminate the malfunction, the fuel line is repaired, which involves partially disassembling the carburetor, flushing the pump, and blowing the nozzles through the fuel fitting.

Sometimes the reason that a walk-behind tractor does not start lies in the malfunction of the spark plugs, which play an important role in starting a carburetor internal combustion engine, or the glow plugs that ensure the start of a diesel engine. If the igniter devices become wet, which happens due to fuel assemblies being thrown into them, then the spark begins to disappear on them. In the absence of sparking, the air-fuel mixture does not ignite, and therefore the engine cannot start. This problem can be solved in different ways:

- Make minor repairs and replace non-working spark plugs with new ones;

- Burn the flooded candles and use fire to clean them of traces of gasoline.

Motorized equipment does not start due to damage to the glow plugs. In a diesel engine, fuel ignition occurs from contact with hot air, which is heated in the cylinder by compression by the piston. This happens without problems when the diesel engine has already warmed up and the operating temperature in it is maintained by the heated cylinder walls. But in cold weather, and especially in winter, the engine is heated using incandescent devices, and if they fail, it will not be possible to start the walk-behind tractor.

If, upon inspection of a carburetor engine or diesel engine, no defective spark plugs were identified, but the problems remain, and are also accompanied by popping noises in the muffler, you should check the functionality of all devices responsible for the flammability of the fuel. A malfunction in them can also be the reason that the walk-behind tractor does not start. It is better to carry out diagnostics at a service center, where professionals will find the cause of the damage and competently carry out repairs.

The motorcycle will not start even if the level of lubricant in the engine is insufficient. Some models are equipped with special control sensors, which, in the event of a lack of lubrication, prevent the engine from starting. Particular attention should be paid to those machine options that do not have such sensors. Sooner or later, the level of the lubricant mixture will reach a critical value and if it is not replenished to normal, this will soon lead to wear of parts and, as a consequence, to a major overhaul of the engine.

Why does a chainsaw start and stop immediately?

The chainsaw starts and immediately forgets; the reason for this behavior can be hidden in the carburetor. A faulty fuel pump or malfunction of the main fuel jet can cause this behavior of the saw. The inability to operate the chainsaw after starting requires a full diagnosis at a service center.

READ Husqvarna Chainsaw Oil Which To Use

All of the above options for engine malfunction have similar causes, which, depending on their negligence, can have different manifestations. For example, if a little air is sucked into the crankcase, its operation will not change much, the engine power will decrease slightly, the maximum speed will increase, and it will be able to warm up a little. In the middle stages of an air leak, the engine will stall at idle and become very hot during operation. A severe air leak will make the saw impossible to operate, it will immediately start and stop.

In parallel with visible manifestations of malfunctions, such as the inoperability of the chainsaw after starting, processes will occur inside the engine during its failure that irreversibly lead the saw to the most serious consequences, such as melting of the piston, jamming of the crankshaft.

Preparing the walk-behind tractor for start-up

Problems with starting the engine can occur not only with used walk-behind tractors and cultivators, but also with new ones just purchased at the store. Therefore, before starting the walk-behind tractor for the first time, be it Cascade, Neva, Mole, Bison, Centaur, you need to read its operating manual, then carefully examine all connections and, of course, check the oil level in the internal combustion engine.

It is necessary to study the instructions compiled by the manufacturer in order to find out what operating cycle the engine has: four-stroke (like Forte, Centaur, Lifan, Bison) or two-stroke. This is important to know, since models with a two-stroke engine (like the Mole cultivator) require a special combustible mixture consisting of gasoline and oil in a certain proportion. Due to the fuel mismatch, the equipment will stall, and the spark plugs and fuel line may also be damaged, which can lead to fuel pump failure - and this is a direct path to expensive repairs at a service station. You can determine whether the fuel is suitable for a motorcycle by looking at the smoke. If the quality of gasoline is poor, it will have a white color, as happens when the car is tilted too much.

DIY walk-behind tractor repair

Unfortunately, any equipment sometimes breaks down, so its owner needs to be able to troubleshoot problems on his own. Of course, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs free of charge.

Often, damage to a cultivator or walk-behind tractor occurs due to improper operation - when they fill in with bad fuel, allow heavy loads, or do not replenish the loss of lubricating fluid in time. Then the car begins to stall, stall, pick up speed poorly (especially if it has an electric motor), or even stops starting altogether. But, knowing the structure of the unit and the operating principle of its mechanisms, you can identify the cause of the damage yourself and carry out quality repairs.

Fuel system repair

A breakdown of the fuel system can be confirmed if the engine:

- does not start;

- stalls under load;

- does not function stably at idle speed.

To eliminate the malfunction, first check the condition of all filters, including air and oil. If they are slightly clogged, they are blown with compressed air or washed; if they are heavily contaminated, they are replaced with new ones. Then the carburetor is disassembled, the parts are washed with a special cleaner, and the fuel mixture supply valve, tank and piston system are cleaned with gasoline. After drying, carefully carry out the reverse installation.

After the engine is completely assembled, the crankshaft is cranked by hand - it is important that the piston moves freely and the valves work flawlessly. Then pour in fresh lubricant, start the engine and leave it to idle. Be sure to check the flow of fuel into the cylinder. Perhaps, after such repairs, the cause of the malfunction will be eliminated, and the walk-behind tractor will begin to function without interruption.

Ignition system repair

You can judge the breakdown of devices for igniting fuel assemblies by the signs when the engine:

- It starts, but stalls at idle;

- Does not start even with good fuel supply;

- It works at idle, but with some interruptions.

To find out the reason, first check the condition of the spark plugs: if there is damage to the insulator, replace them. Next, inspect the electrodes and, if necessary, adjust the gap between them. The condition of high-voltage wires is checked for oxidation of the tips and damage to the insulation - damaged wires must be replaced with new ones. Without such repairs, the spark may completely disappear or will travel through the insulation, breaking through to the engine body, and will not be able to ignite the fuel assembly.

If at this stage no defect with a spark is detected, then perhaps the reason that the equipment does not start or stalls lies in the generator or coil (for models such as Neva, Cascade, it serves to generate a spark). To check the generator, a measuring device is connected to its terminals. Scroll the starter pulley of the walk-behind tractor and record the readings of the device - they should be in the range of 12-16 W. If the indicators are normal, then the reason is in the ignition coil and after replacing it, you can put a load on the engine. Most likely, after such repairs, its functionality will resume completely.

Transmission repair

The following factors indicate a transmission malfunction:

- The working shaft is motionless, and the output shaft rotates;

- The engine speed does not correspond to the working shaft speed;

- The engine seems to be “choking” under the load.

If at least one of the listed reasons appears, immediately check the presence of lubricant in the gearbox. The lubricant in it must be normal, since lubricant prevents “dry” friction of moving parts and prevents them from overheating.

Then the gearbox is disassembled, the gears are inspected, and the chain tension is checked. Whole parts are washed in kerosene, and damaged parts are replaced with new ones. After this, the structure is assembled and care is taken to prevent the gears from misaligning.

Do-it-yourself troubleshooting

Success in self-repairing a walk-behind tractor largely depends on how correctly you diagnose the unit. The reasons that the walk-behind tractor does not start may be hidden in the following:

- Due to blockages, air does not pass through the air filter;

- The hole in the fuel tank cap is clogged;

- Debris has accumulated in the fuel supply channels;

- Carburetor failure.

Each of these malfunctions is quite easy and quick to fix with your own hands. If this is not the cause of the breakdown, and the unit still does not start, then you should unscrew the spark plug and check for oil stains on it. If you find oil or thick carbon deposits on the spark plug, the part needs to be cleaned and dried. In addition, the cylinder of the walk-behind tractor will also need drying - to do this, you need to sharply pull out the starter cable several times.

Read also: Diagram of a Chinese charger for a car battery

It is often difficult to start a walk-behind tractor due to the lack of fuel in the combustion chamber. In this case, the candle will be completely dry. If this is the cause of the breakdown, then the following measures will need to be taken:

- Completely drain the old fuel;

- Thoroughly rinse the fuel tank;

- Clean the air filter from blockages;

- Blow out the fuel supply hose with compressed air;

- Blow out the carburetor jets;

- Fill the tank with fresh gasoline;

- Open the fuel tap;

- Blow out the breathing passage inside the fuel tank cap.

Before restarting, you will need to manually prime the fuel by pressing the fuel pump primer several times. After starting the engine, be sure to give it time to warm up, after which you can start working with the walk-behind tractor.

If all of the above steps did not help, and the walk-behind tractor still does not start, then check the intake and exhaust valves - if they do not fit tightly to the seats, the parts will need to be adjusted by turning the corresponding screws clockwise.

Also, if the walk-behind tractor does not start, we advise you to pay attention to its muffler - after prolonged operation, carbon deposits accumulate on its walls, which must be regularly removed using compressed air.

Why does it stall under load?

“The walk-behind tractor stalled during operation” - you can often hear from the mouths of users of these units. The problem may be a malfunction of the fuel supply system or ignition system.

In the first case, check the spark plug. If it is not wet, it means that fuel liquid does not enter the engine cylinder.

Important! Pay attention to the fuel level. The problem could also be with the fuel valve if it is tight.

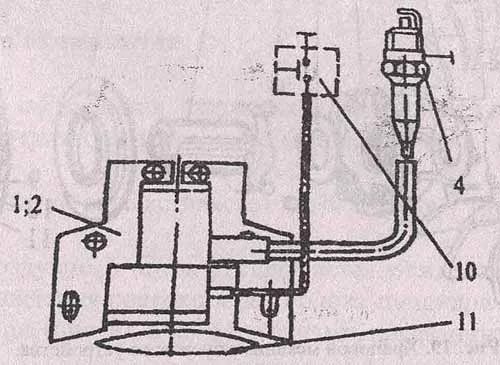

In this video you will find out why the walk-behind tractor does not develop power: In another case, also make sure that the spark plug is working properly. It shouldn't be wet. Otherwise, you will need to adjust the ignition system again. For this:

- remove the cover that protects the ignition system;

- rotate the flywheel of the power unit until the contacts open;

- determine the distance between such elements of the ignition breaker as the anvil and the hammer;

- rotate the flywheel until the piston reaches its highest point;

- move the flywheel to a position where the clutch engages;

- turn the flywheel again in the opposite direction;

- fix the distance between the interrupting contact and the cam at 0.33 mm;

- securely fasten the cam and return the protective cover to its place.

Now the motor is working again and it will withstand a stable load.

Important! So that, if such situations arise again, we can promptly begin repairs. Otherwise, parts and main mechanisms will wear out and deteriorate much faster.

In addition to the above, other reasons for failure of the ignition system:

- muffler contamination;

- incorrect carburetor settings;

- mechanical defects in the electrical circuit.

Doesn't develop speed

If the engine is in good working order, but the walk-behind tractor does not develop speed, then it is possible:

- the air filter is clogged. As a result, not all the air enters the carburetor, and the fuel becomes oversaturated;

- low quality fuel fluid;

- parts of the ignition system have failed. As mentioned earlier, it is necessary to check the spark plug, correct the gap between the electrodes, and pay attention to the mechanical integrity of the electrical circuit;

- if necessary, clean the carburetor and adjust it correctly;

- the operation of pistons and cylinders is interconnected with engine power.

Therefore, pay attention to the condition of the pistons and cylinders. Their external damage can significantly reduce the compression value.

For example, cleaning the carburetor may solve the problem

Carburetor malfunction

As soon as you begin to notice any changes in the operation of the Cascade walk-behind tractor, first of all you need to check the carburetor. It has combustion plugs, and if they are completely dry, then fuel simply does not reach the carburetor itself. There may be a blockage somewhere - in the filter or in the nozzle.

After you remove the carburetor, you must completely remove gasoline from it. Blowing is carried out through the fuel fitting, and the unit itself must be in the same position as inside the walk-behind tractor.

Read also: How much does a good screwdriver cost?

To correct fuel obstruction, the float tongue inside the fuel chamber must be adjusted. The last step is to purge the nozzle. First you need to wash all the parts in gasoline, but under no circumstances wipe them. The moisture should drain on its own. After this, the carburetor is assembled.

Carburetor adjustment is carried out as follows. First, warm up the engine and set the idle speed to its lowest setting. You need to screw in the screw to adjust the gas. After this, you need to add gas and move the control lever. By adjusting by tightening the gas screw, you will achieve normal performance readings of the walk-behind tractor.

Why does the walk-behind tractor stall when the air damper is open?

The carburetor air damper, in other words “choke”, is necessary for normal engine starting and its further stable operation. If the damper is not adjusted correctly, for example, when it is not completely closed, the engine may not start at all.

One of the common reasons for the incorrect operation of the power unit is air leaks. The reason for this may be depressurization of the carburetor. Check the spark plugs, tighten them if necessary, tighten the connecting bolts. If this does not help, replace the gaskets.

The engine will stall even with the air damper open. You can adjust it until it moves normally, without shifting or snagging.

The walk-behind tractor starts and stalls: causes and repairs

Probably every person who is somehow connected with agriculture has encountered the fact that a walk-behind tractor starts up and immediately stalls. The causes of this problem may be:

- low quality fuel or clogged carburetor. It is necessary to clean the carburetor of excess debris and dirt, get rid of old fuel, and pour new fuel into a clean tank;

- a long pause in the operation of the walk-behind tractor could provoke depressurization of the fuel tank;

- ignition system malfunction. First you need to check whether the candle is clean enough. Next is the condition of the wires. And if this does not help, then the problem is in the electrodes. Set the correct gap between them and everything will work again;

- gearbox malfunction. Make sure there is enough lubricant;

- insufficient amount of fuel mixture for normal operation. It may leak through an unnoticeable hole in the fuel tank. There are two solutions: either get rid of the crack by mechanical intervention or install a new fuel tank;

- Another reason why a walk-behind tractor stalls during operation is low air temperature, due to which almost all diesel-powered equipment does not start. Therefore, before starting, be sure to pour warm water into the radiator.

Troubleshooting these problems does not require any special technical or engineering knowledge or skills. You just need to strictly follow the instructions. You can also contact us for repairs, where professional craftsmen will do everything quickly and with a guarantee.

Video: Walk-behind tractor smokes and stalls

This problem occurs due to excess air entering the carburetor. In the event of such a malfunction, the gas trigger must be compressed twice. Once the engine has started, work must be completed well before work begins.

If you cannot cope with the problems of your garden walk-behind tractor, walk-behind tractor, walk-behind tractor will not start, contact the Alfa-Rost repair shop in Rostov-on-Don. We guarantee high-quality repairs of gasoline walk-behind tractors using original components, which are always in our warehouse.

Source

Motoblock. This is a useful economic unit that greatly simplifies land and home operations. Like any other piece of equipment, units can break. But it is quite possible to repair a walk-behind tractor engine with your own hands, following simple recommendations.

READ Motoblock Neva 2 How much Oil