What an Attachable Tool Kit Can Do

The universal nature of the walk-behind tractor design means that additional working tools and equipment are used exclusively as attachments for the walk-behind tractor. During operation, it can be easily removed and replaced, without interfering with the design of the walk-behind tractor.

The vast majority of attachments for walk-behind tractors are developed and produced primarily for cultivating soil and growing vegetable and grain crops in small areas of personal plots. Therefore, all attachments can be classified into three categories:

- Equipment for plowing, cultivating, milling, cutting furrows, drawing and harrowing soil. To work with soil preparation, the largest number of attachments and attachments are produced, both by manufacturers of walk-behind tractors and by companies that sell agricultural tools;

- Additional mechanization used for fine work with planting seeds and harvesting, these also include motor cultivators, mowers and other equipment for working in beds;

- Auxiliary attachments and attachments. Oddly enough, auxiliary work, transport operations and use as a snow blower account for almost half of the operating hours of a walk-behind tractor with attached equipment.

Important! Due to the high degree of unification of the design of the main unit with the motor, owners of different models of walk-behind tractors can partially adapt attachments and attachments for “foreign” models to their units. Especially when it comes to “Soviet” models.

How to choose a reliable walk-behind tractor for your garden and garden? What criteria should be followed?

If the questions are: “What to choose? Which walk-behind tractor is better? How to choose the right “garden helper” and not make a mistake?” are relevant to you, then you should listen to the advice described below.

- First you need to decide on the conditions in which the unit will operate. The design specifics must fully correspond to the area of the site;

- In order to efficiently cultivate virgin lands, you should choose professional models that are heavy and powerful, since lightweight models will “jump” and cause discomfort to the operator;

- The best choice for constantly cultivated soil will be light walk-behind tractors, since they will be able to move freely and not load like heavy ones;

- You should decide on the types of work to be performed, because large walk-behind tractors are perfect for working with attachments, while to focus on cutters you need to choose simpler options;

- If a person plans to use the rear accessories most often, he needs to choose models weighing more than 100 kg. Fans of maneuverability and convenience are better off saving up money and buying models with a power take-off shaft and an active cutter;

- Always pay attention to the characteristics and do not ignore the information provided in the operating instructions, since each walk-behind tractor has its own characteristics.

Typical attachment options for walk-behind tractors

Manufacturers of equipment for walk-behind tractors have divided the entire range of attachments into two groups:

- Complex devices with power take-off from the power unit to drive working tools. Such equipment options cost a lot, but are in high demand among walk-behind tractor owners. This is, first of all, equipment for planting seeds and harvesting crops;

- Simple attachments and additional accessories, most of them are sold complete with the walk-behind tractor or are available for an additional fee. Extensions, lugs, towbars, they are inexpensive, but without them the efficiency of the unit is noticeably reduced.

Motoblock device

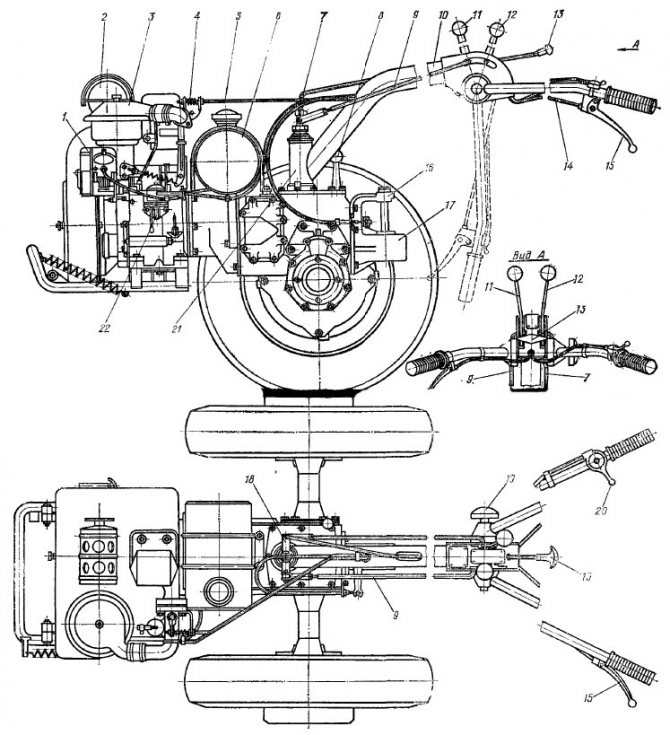

An important point: almost all machines have the same device and differ only in small details. In order for a person to have a basic understanding of the design, it should consist of a chassis, engine, controls and transmission. It is necessary to consider the diagram of a walk-behind tractor using the example of the MTZ-05 model:

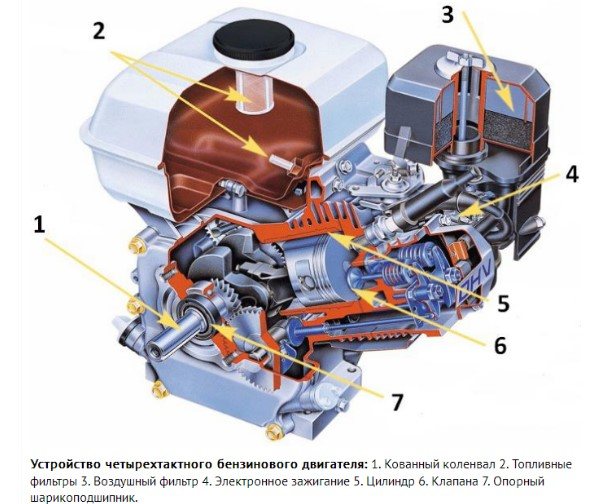

As for the engine, in this regard modern manufacturers give preference to classic internal combustion options. Many not particularly powerful products are accompanied by four-stroke gasoline internal combustion engines, and diesel engines are installed on heavier options.

A single-cylinder four-stroke engine (gasoline) can be used in those units that are designed for a small cultivated area and a small garden. It consists of:

- crank mechanism;

- control systems;

- gas distribution mechanism;

- component parts;

- lubrication, ignition, cooling systems;

- starting systems, exhaust gas removal, air supply.

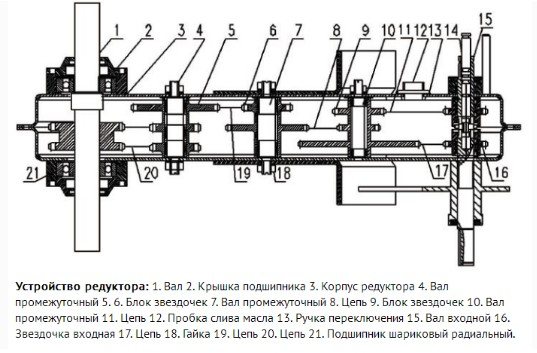

As for the transmission, its main task is to transmit rotating motion from the engine to the wheels. It also determines the direction and speed of movement.

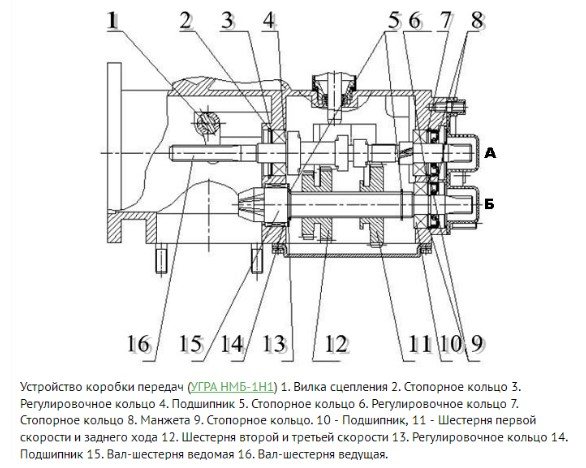

The gearbox changes the gear ratio and transmission of rotation from the gearbox pulley to the wheels. You should consider the diagram of this component in more detail.

Thanks to the gearbox, gears are changed. Often these are 6 (forward) and 2 (backward).

The chassis is very similar to a frame with wheels and basic components of a walk-behind tractor attached to it. The controls themselves consist of a steering column, gear shift rod, gas and clutch control levers, etc.

To make working with a walk-behind tractor in the garden from planting to harvesting comfortable and productive, you should choose among the varieties of walk-behind tractors those that can productively carry out the tasks assigned to them.

The simplest attachments and attachments for a walk-behind tractor

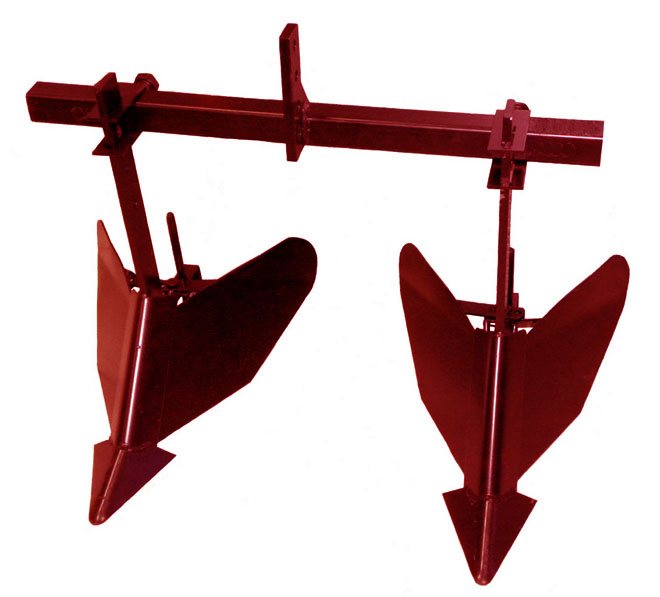

Such devices include a number of plows, milling cutters, and hillers for universal purposes.

Most of them are single-row, but for heavy models of walk-behind tractors, multi-row ones can also be used, most often these are cutters and cultivators.

For each walk-behind tractor model, the manufacturer produces a whole range of extensions and attachments that can increase the wheelbase and increase the stability of hitches for installing a plow or knife hiller. In some cases, using hitches, you can attach small harrows or rakes to the walk-behind tractor, the use of which can significantly increase the efficiency of working with mown plants and their remains in the ground.

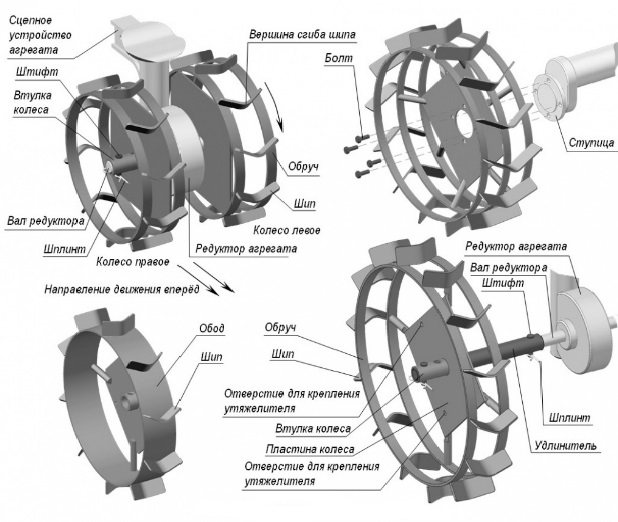

A mandatory tool is lugs installed on walk-behind tractors for heavy work - plowing or milling the soil. To work on particularly difficult areas, you can use additional reinforced lugs with hanging loads.

The second most popular after the plow are cutters for cultivating land. Usually they use double ones, but if desired, you can supply tools with an increased number of knives.

Motoblock carburetor design

To properly adjust or clean the carburetor on a walk-behind tractor, you must first say a few words about its design.

READ Adjusting the Hiller on the Motoblock

It is known that the carburetor in a walk-behind tractor is a certain part of the fuel system and performs the function of atomizing fuel enriched to the required extent with oxygen. Most modern walk-behind tractors run on gasoline engines (although there are alternatives: diesel and electric). Their designs are mainly of two types: rotating (simple in design and designed for less powerful engines) and piston (for more powerful walk-behind tractors, multi-element).

Externally, a carburetor for a walk-behind tractor looks like this:

The internal structure of the carburetor of the K 45 type walk-behind tractor, which runs on gasoline, looks schematically like this:

Attachments for salute walk-behind tractor

Currently, in the list of additional devices for walk-behind tractors, the most popular are relatively new models - seeders, potato planters, harvesting devices and snow removal tools. Nozzles and mechanized units for planting seeds allow sowing to be carried out at the most optimal time, when the deadline is days or even hours.

For example, additional devices for sowing small seeds and grain crops. The design of the attachment is very similar to that used for full tractor-mounted seed drills.

Potato planters KS-1, with a weight of just over 40 kg, allow approximately 100-120 kg of seed potatoes to be planted in a prepared furrow in an hour to an hour and a half. The seed is loaded into the hopper and driven by the planter's chain drive to be placed into the soil at precisely measured intervals. It is clear that before operating the attachment, it is necessary to cultivate and cut furrows in the ground.

No less interesting is the equipment for digging and harvesting potatoes. You can simply dig the tubers out of the ground with a special type of plow, but it is better to use a more universal version of attachments that help even partially harvest the crop.

It is worth mentioning a separate category of attachments used for mowing green mass. For example, a rotary mower for Salyut with a chain drive of the cutting tool allows you to mow the grass many times faster than when using a self-propelled lawn mower. The hinged design of the GPM-1 rake allows you to remove mown hay without much effort.

A disc hiller or flat cutter is perfect for hilling and cultivating row spacing.

In addition to cultivating the land and harvesting crops, you can use special attachments for Salyut, designed for watering and spraying shrubs and trees. This is a water pump capable of creating pressure up to 5 atm.

Motoblocks and accessories for them for cultivating land

The plow was previously mentioned for good reason; it is this attachment that is considered the main one for preparing the soil for the upcoming sowing by plowing. But the use of this device should be determined by the large area of the allotment; for small areas it is enough to use cultivation with cutters, which are installed instead of wheels or hung as separate equipment for walk-behind tractors. They perform loosening and weeding of potatoes. For greater efficiency, the walk-behind tractor can move on lugs, which provide contact with the soil better than conventional treads.

.

Separately installed cutters are convenient because the wheels give the walk-behind tractor smooth movement, and the blades rotating in the opposite direction easily sink into the ground without being pulled out of it on hard areas.

An important device is the harrow, the main purpose of which is to loosen the soil by breaking up large lumps, as well as removing dry plants and pulling out weed roots. Attachments of this type are rotary, disk and toothed. Very often, to form even rows of beds, hillers are needed, which are V-shaped plowshares that, when paired, easily rake the soil into a high furrow. There are also disk models, the paired rotating elements of which are installed at an angle of 45 degrees to the motion vector.

Snow removal attachments

Experience working with walk-behind tractors has shown that, when properly equipped with attachments, a walk-behind tractor works perfectly as a snow blower. One of the most successful options for a mounted snow blower is the SMB-1 mounted kit.

Using a rotary blade and ejector, the snow blower is capable of removing compacted snow up to 200 mm thick from the road surface, and the entire mass of snow is thrown to the side of the road at a distance of up to five meters. An alternative to using such equipment may be using a tractor or working with a shovel.

To clear wet snow, you can use a mounted plow blade. A blade one meter wide makes it possible to lift and remove heavy snow saturated with water and ice up to 30 cm thick. At the same time, the installed equipment includes an additional handle that allows you to change the direction of the cut. If you wish and have a sufficiently powerful engine, you can even cut off the top part of the turf on sandy soil with a walk-behind tractor. Essentially, a blade shovel and adapter can turn a walk-behind tractor into a miniature bulldozer

The final final sweeping of the canvas can be done using a snow blower based on a rotary broom. This attachment will not only remove dirt and stone from the road surface, but is also capable of removing ice and compressed frozen snow up to 10 mm thick.

Adjusting the walk-behind tractor carburetor

Instability of the cylinder block indicates the need for carburetor adjustment. The need to perform this procedure usually arises before the start of the growing season, when the equipment has not been used for a long time, or after it, when the cultivator has been subjected to significant loads for a long time. The engine must be warmed up before making adjustments. The actual workflow looks like this:

- The screws that adjust low and high throttle are fully tightened and then backed out about one and a half turns.

- The engine is started by the starter or manually and warms up for about 10 minutes.

- The lever controlling the power unit must be set to the minimum position, but the engine must not stop.

- The throttle valve adjusting screw will help you adjust the minimum idle speed so that the operation of the diesel engine is stable, without any extraneous noise or stalling.

- The rotation of the screws allows you to accurately determine the amount of combustible mixture entering the engine.

- Tightening the propeller helps enrich the mixture, and unscrewing it, on the contrary, increases the volume of air entering the engine;

READ Ushm Zubr 125 With Speed Adjustment

Use the idle screw to adjust the maximum idle speed. The same should be done at minimum speed using the screw locking screw. The essence of this adjustment is that the valve screw allows you to adjust the angle at which it is closed;

The lever responsible for controlling the engine must be moved to the “gas” position. If the operation of the cultivator is still not stable, then the screw with full throttle is adjusted to achieve the ideal stroke. However, the maximum permissible propeller speed is 2.5.

The accuracy of carburetor adjustment can also be determined by how the spark plug looks after a short period of operation under load. If the working mixture is ideal, the spark plug will not leave soot or traces of fuel, which indicate that the fuel mixture is too lean or, conversely, too rich. It should be noted, however, that soot or traces of fuel on the spark plug may indicate not only incorrect adjustment, but also more serious problems with the Chinese or domestic walk-behind tractor, including a faulty ignition or cooling system.

Adjusting the care of track valves

Over time, under high loads, the valve clearance of the engine cylinder block changes. The reason for this may be wear and tear of parts. Insufficient distance leads to the fact that the gas distribution stages change significantly, as a result of which it is impossible to achieve a sufficient compression ratio, the power device operates intermittently and does not achieve the declared power. In particularly severe situations, even valve deformation is observed. If the gap is too large, significant mechanical noise is recorded, valve timing also changes significantly, valves open for too short a time, causing the cylinder to not fill properly, power loss and failures occur. Adjustment of the gap is necessary immediately as soon as the engine fails or produces significant noise. Ideally, an adjustable motor should be cool.

So, first you need to get to the flywheel. It is on this part that the upper dead center value is marked. The flywheel is hidden under a cover, so it needs to be removed. Before removing the cover, remove the air filter oil bath. To make it easier when removing the cover, you can secure all the latches with rubber bands. The wrench unscrews all bolted connections, after which the cover can be removed without problems.

On the flywheel you can see marks indicating TDC, as well as the values of 5, 10 and 20 degrees. The 20 degree mark indicates the injection of a combustible mixture. The flywheel should be brought to top dead center, guided by the relevant section. The valve cover is unscrewed and removed.

The following tools should be used during the setup process:

- Screwdriver;

- 10mm wrench;

- Blade 0.1 mm thick.

According to the technical data sheet, the engine valve clearance of the cylinder block is from 0.1 to 0.15 millimeters, and therefore can be adjusted very precisely using a shovel. However, it should be noted that some blades are 0.8mm thick, which is unacceptable. The exact value can be found using a micrometer or from the information on the manufacturer's website. The regulation is as follows:

- Screwdriver;

- Loosen the nut, insert the blade and begin tightening;

- You should focus on the blade while carefully tightening the nut;

- The adjustment is carried out until the free play of the valve is eliminated. It should fit fairly snug.

- Reassemble the casing in reverse order, placing your hands in the oil bath in place.

READ How to Remove the Gearbox of the Neva Motoblock

If all manipulations were performed without errors, the engine will operate smoothly and without unnecessary noise.

Transport attachments

A walk-behind tractor with a sufficiently strong motor can be easily converted into a small cargo vehicle capable of carrying from 100 to 400 kg of cargo. This will require a special type of hitch and a single axle trailer.

The average speed on rough terrain is up to 10 km/h, on the road you can move up to 15-18 km/h. Most of the inconveniences associated with the use of such equipment are due to the fact that the transmission gear ratios do not combine well with the optimal speed and speed of the walk-behind tractor. Considering the lack of full-fledged control and braking controls on the walk-behind tractor, in order to control the unit on a hitch with an overloaded trailer, quite serious experience and skill in driving such motor-units is required.

If desired, using an additional attachment adapter, you can turn the walk-behind tractor into a microtractor that is quite maneuverable and powerful. By adding grass cutting equipment to it, you can get a full-fledged motorized lawn mower.

Many interesting examples of attachments for walk-behind tractors were created by enthusiasts, for example, a tracked transporter. Or a system for spraying and chemical plant protection. Most of these models are subsequently copied quite successfully and used to develop industrial equipment designs.

Motoblock device

An important point: almost all machines have the same device and differ only in small details. In order for a person to have a basic understanding of the design, it should consist of a chassis, engine, controls and transmission. It is necessary to consider the diagram of a walk-behind tractor using the example of the MTZ-05 model:

As for the engine, in this regard modern manufacturers give preference to classic internal combustion options. Many not particularly powerful products are accompanied by four-stroke gasoline internal combustion engines, and diesel engines are installed on heavier options.

A single-cylinder four-stroke engine (gasoline) can be used in those units that are designed for a small cultivated area and a small garden. It consists of:

- crank mechanism;

- control systems;

- gas distribution mechanism;

- component parts;

- lubrication, ignition, cooling systems;

- starting systems, exhaust gas removal, air supply.

As for the transmission, its main task is to transmit rotating motion from the engine to the wheels. It also determines the direction and speed of movement.

The gearbox changes the gear ratio and transmission of rotation from the gearbox pulley to the wheels. You should consider the diagram of this component in more detail.

Thanks to the gearbox, gears are changed. Often these are 6 (forward) and 2 (backward).

The chassis is very similar to a frame with wheels and basic components of a walk-behind tractor attached to it. The controls themselves consist of a steering column, gear shift rod, gas and clutch control levers, etc.

To make working with a walk-behind tractor in the garden from planting to harvesting comfortable and productive, you should choose among the varieties of walk-behind tractors those that can productively carry out the tasks assigned to them.

How to choose a reliable walk-behind tractor for your garden and garden? What criteria should be followed?

If the questions are: “What to choose? Which walk-behind tractor is better? How to choose the right “garden helper” and not make a mistake?” are relevant to you, then you should listen to the advice described below.

- First you need to decide on the conditions in which the unit will operate. The design specifics must fully correspond to the area of the site;

- In order to efficiently cultivate virgin lands, you should choose professional models that are heavy and powerful, since lightweight models will “jump” and cause discomfort to the operator;

- The best choice for constantly cultivated soil will be light walk-behind tractors, since they will be able to move freely and not load like heavy ones;

- You should decide on the types of work to be performed, because large walk-behind tractors are perfect for working with attachments, while to focus on cutters you need to choose simpler options;

- If a person plans to use the rear accessories most often, he needs to choose models weighing more than 100 kg. Fans of maneuverability and convenience are better off saving up money and buying models with a power take-off shaft and an active cutter;

- Always pay attention to the characteristics and do not ignore the information provided in the operating instructions, since each walk-behind tractor has its own characteristics.

The domestic market offers an incredible selection of walk-behind tractors, so anyone who sets the goal of purchasing a truly reliable and functional unit will be able to find a model that meets all requirements. The main thing is to take this issue seriously and have an idea of what capabilities a mechanical assistant has.