How to make a creeper for a cultivator yourself?

Why do you need a creeper for a motor cultivator? Often when operating a cultivator there are times when it is necessary to reduce its stroke. Such situations arise when the operating speed indicators are much lower than the transport speed indicators of the unit. Then a creeper comes to the rescue, which increases the traction force and torque of the equipment.

We create a stroke reducer for a motor cultivator with our own hands

- We carry out all design calculations (rated power, number of revolutions per minute, torque).

- We decide on the body.

- We take 2 gear shaft bearings and cut out the shell.

- We install a high-quality steel flange on the reverse side of the gearbox.

- We attach a steel washer and a bearing (flange) inside the flange.

- Now you need to rotate the flange to the generator housing.

- We connect all the components (gear shaft, key, drive gear) with the shaft and transmission mechanism.

- We secure the V-belt drive pulley.

DIY wheels for a motor cultivator

Many cultivators are equipped with factory pneumatic wheels, which, despite their number of advantages, sometimes do not provide good enough traction to the ground. In this case, many owners of cultivators undertake to equip them with homemade lugs. These are wheels for a cultivator that, due to their weight and design, allow you to cultivate the area with perfect traction with the ground. How to make these wheels yourself.

The popularity of using small-scale mechanization in agriculture is increasing every year. At the same time, walk-behind tractors are the most versatile weapon in the fight for the harvest. Having a large range of mounted and trailed tools, they are able to cope with almost any task that arises when working on a personal plot. If high traction power is required, a speed reducer or reduction gearbox for the walk-behind tractor is used.

The use of a creeper is advisable when cultivating “fat” or virgin soils, deep loosening, transporting heavy loads or using heavy attachments. When working in such conditions, it is necessary to especially precisely control the work process.

https://www.youtube.com/watch?v=HLKhiuZEy2E Video can't be loaded: DSCF2677 Do-it-yourself reverse from an ant gearbox to a walk-behind tractor. Valery Bryzgalov. (https://www.youtube.com/watch?v=HLKhiuZEy2E)

It would be logical to reduce engine speed and operate at a lower speed. But in this case, power is also lost, which is unacceptable. This is where walk-behind creepers come to the rescue, acting as a reduction gear. They allow you to gain acceptable control over the processing process, and even increase power, without slowing down the engine speed and, accordingly, without losing power.

If you have some experience and knowledge, you can make a gearbox yourself using available materials and equipment, or buy a ready-made product, the range of which on the modern market is high and available to buyers with different capabilities.

How to adjust the speed?

Sometimes it turns out that you want to change the speed of movement of your walk-behind tractor: increase it or, which happens quite rarely, decrease it.

To increase the speed of movement of walk-behind tractors, one of the two methods below is usually used:

- replacing wheels with larger diameter ones;

- replacing a pair of gears in the gearbox.

The usual wheel diameter of almost all walk-behind tractors is 570 mm. Most often, when replacing, tires are selected with a diameter that is approximately 1.25 times larger than this - 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows for larger tires, you can try to increase the speed gain.

A gear pair installed in a wheel reducer usually consists of two gears with the number of teeth 12 for the small one and 61 for the large one. You can change this indicator to 18 and 55, respectively (only from specialists at agricultural machinery service centers), then the gain in speed will be approximately 1.7 times

Do not try to carry out the operation of replacing gears yourself: it is very important to select not only high-quality parts with minimal errors, but also the appropriate pulley. The gearbox shaft locking plate also plays an important role.

A possible solution to increasing the speed is to adjust the gas switch: when the device turns on, move it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change the speed down, you don’t need special reducers - it’s enough not to switch to high gears.

Also possible solutions to the problem of increasing the speed of a walk-behind tractor are replacing the motor with a more powerful one and upgrading or installing a clutch system (in some outdated models it is not provided).

It can help to increase speed (especially on uneven terrain or heavy soils, where equipment often slips due to insufficient weight of the unit) and installing weights. They can also be made with your own hands from metal parts. Weighting structures are installed on the walk-behind tractor frame and wheels. For the frame you will need metal corners, from which a homemade removable structure is formed, that is, you can easily remove it if not needed. Additional ballast weights are attached to this removable additional frame. The wheels require steel discs and solid iron blanks with a hexagonal cross section. These parts are welded and inserted into the hubs. For reliable fixation, cotter pins are used, which are installed in specially prepared holes.

Of course, if you don’t have round steel elements at hand, you can replace them with almost any available material: reinforced concrete products or even flattened round plastic flasks with sand poured inside.

To speed up a walk-behind tractor with a trolley in bad weather conditions - snow, slush, soil soggy from heavy rains - you can install tracks (if the design allows). This method requires the installation of an additional wheel pair and the purchase of rubber tracks of a fairly large width. Limiters are attached to the inside of the track to securely fix the rubber and prevent it from jumping off the wheelset.

Also for this purpose, you can replace the original gearbox with a similar device with a lower gear - to make it easier to overcome obstacles.

If you take good care of the unit, follow all recommendations for operating the device, and carry out regular preventative maintenance, then the walk-behind tractor will produce the maximum of its capabilities in terms of speed and performance.

To learn how to adjust the speed of a tiller on a walk-behind tractor, watch the video below.

Many farmers are interested in how to increase the speed of a walk-behind tractor. The most common agricultural machinery is a walk-behind tractor. With its help, work on land and personal plots is greatly simplified. Let's look at how you can increase the speed of this technique. With increased speed, the performance and maneuverability of the mini-machine will increase, which can be used in any season and weather.

Mechanism elements

Regardless of whether a purchased or homemade reduction gearbox will be used in a walk-behind tractor, you need to understand how the elements of the mechanism are located, how to maintain and repair them. Reduction gearboxes for walk-behind tractors can be of several types, each of which has its own advantages and disadvantages.

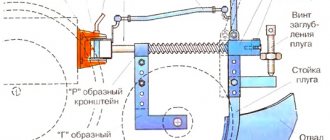

Scheme for connecting the speed reducer to the gearbox

Gear reducer

As a rule, it consists of one or two stages; The main elements are gears. This type is one of the most reliable mechanisms used in creepers. Used in the most powerful walk-behind tractors. Its advantages may include:

- durability;

- reliability;

- small dimensions;

- possibility of reverse.

Such creepers are not without their drawbacks, the main ones being maintainability and price. In case of breakdown, as a rule, they are replaced entirely, which requires significant financial costs. In addition, it is necessary to monitor the presence of lubricant, the absence of which can lead to rapid wear.

Worm gear

The main element is the worm gear. Allows you to reduce the dimensions of the walk-behind tractor and improve weight distribution due to the perpendicular arrangement of the drive shafts and wheels. Most often they are installed on light and low-power walk-behind tractors.

Main advantages:

- large gear ratio;

- small dimensions;

- light weight.

The main disadvantage of a worm gearbox is the lack of reverse. In addition, in the event of a breakdown, the stroke reducer is completely replaced.

Chain reducer

One of the most popular types of gearboxes among users. Most often they are made dismountable, which simplifies maintenance and diagnostics. The most common failure is a broken or stretched chain, shearing of sprocket teeth or drive shaft keys. All these breakdowns, as a rule, are quite easy to fix yourself by replacing the failed part.

The advantages of stroke reducers of this type include:

- simplicity;

- reliability;

- possibility of reverse;

- maintainability.

Combined gearbox

Gearboxes of this type are characterized by the presence of different types of gears in one mechanism: gear-chain or worm-chain. The need for such stroke reducers is dictated by the fact that in gear and worm gearboxes the center distance between the drive and driven shafts is regulated by the size of the gear and directly depends on the engagement module and the number of teeth. In a chain drive, the distance between the shafts can be adjusted by removing or adding links.

When assembling the design of a walk-behind tractor, it is not always possible to place all the units in an ideal position, and the need for an intermediate transmission link arises. This function is successfully performed by a chain drive, which compensates for the distance from the gear or worm gear to the wheel or drive shaft.

What does the speed reducer consist of?

Depending on the type of reduction gearbox, a homemade creeper consists of the following main parts: input (high-speed) shaft, output (low-speed) shaft, worm and worm wheel, drive and driven gears or sprockets.

In this case, the driving sprockets and gears always have a larger number of teeth than the driven ones. Auxiliary elements can be various couplings, bearings, and keys. In gear and worm gearboxes there is always a housing, which cannot be said about chain gearboxes. They may either completely lack a case or cover only part of the mechanism.

Do-it-yourself reduction gear for a walk-behind tractor

You can make a reduction gear yourself. To do this, at the initial stage it is necessary to determine the type of transmission, gear ratio, and also determine the center distance between the drive shaft and the wheel shaft.

Let's look at an example of creating a homemade creeper for a walk-behind tractor with a chain drive. A similar design can be repeated for almost any type of walk-behind tractor with minimal changes.

Required materials and parts

To build a reduction gearbox yourself, you will need the following tools and materials.

- Bulgarian;

- welding machine;

- drill;

- files and drills;

- caliper, ruler;

- clamps and vices;

- hammer;

- metal sheet 5 mm thick;

- cuttings of pipe with an internal diameter for mounting bearings.

Gearbox assembly

The main part of the designed stroke reducer for a walk-behind tractor is the housing. The quality of the entire mechanism, the relative position of the axes and shafts, and the alignment of the bearing seats depends on it. The body will be made from sheet metal by welding. To facilitate maintenance, one of the walls is made removable.

Instead of bearing housings and precision boring, pipe cuttings are used, the inner diameter of which is equal to the outer diameter of the bearing. They are placed in the required position and finally secured by welding.

For the manufacture of shafts, round rolled products from high-quality steel are used. I grind it to the required size, make collars and grooves, and mill keyways. During operation, the shafts rotate together with the sprockets, transmitting torque through the chain and keys.

Bearings serve as supports for the shafts. They take significant loads during the work process. The durability and normal performance of the gearbox will largely depend on their correct choice. It is optimal to use sealed radial bearings, which require minimal maintenance.

Sprockets and chain will most likely have to be either purchased or used from decommissioned equipment. Making such parts yourself is labor-intensive and low-tech.

The assembly sequence of a reduction gearbox for a walk-behind tractor follows the following algorithm:

- Cut the steel sheet into body and lid parts.

- Pipe cutting.

Video can't be loaded: do-it-yourself creeper gearbox for a walk-behind tractor (https://www.youtube.com/watch?v=QQfR54zbPrs)

https://www.youtube.com/watch?v=1RdECkdic7Q Video can't be loaded: Manufacturing of the ViterOK-2 creeper (https://www.youtube.com/watch?v=1RdECkdic7Q)

https://www.youtube.com/watch?v=cagUBrEN1Io Video can't be loaded: Speed reducer for Rostselmashevsky walk-behind tractor (https://www.youtube.com/watch?v=cagUBrEN1Io)

A creeper for a motor-cultivator is used at high speeds of the motor-cultivator, when it is necessary to reduce it to a speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, trailers, hilling soil and removing snow.

Self-assembly of the stroke reducer

Having all the necessary spare parts, you can begin assembling the speed reducer with your own hands. In order for the finished structure to cope well with its functions, you should act strictly according to the algorithm described below:

- First, make all the necessary calculations so that the result of the work is a well-balanced design. As a generator, you can take an element from the domestic Ural motorcycle;

- The main thing that is required from the device is high power and stable torque;

- Next, start cutting out the shell of the two bearings that will be needed for the drive shaft. It will start the gear. When working, take into account the diameter of the gearbox;

- Then you need to decide on the bearings. The flange must be located on the opposite side of the gearbox. There should be a metal washer inside it;

- Next, install the driven shaft on which the gear will sit. The product must be connected to the rotary generator shaft and transmission mechanism;

- Finally, you will need to secure the pulley to the driven shaft using a spring nut and washer.

Having made the creeper, it will need to be tested. To check the device, it should be connected to the hitch of the unit, and the wheels for the cultivator should be installed. If you did everything correctly, the wheels will spin slowly, while the cultivator itself will be pressed to the ground.

When choosing wheels for a motor cultivator that will work in tandem with a speed reducer, you need to pay great attention to their diameter. There is no need to choose too large parts so as not to load the unit’s motor. Wheels with a diameter of 25 to 30 cm will be optimal.

READ MORE: Boiler installations and units: classification by parameters

If homemade devices are planned to be used in conjunction with other attachments, for example, for a plow, then the creepers must have sufficient power to press the equipment to the soil. Be sure to take this into account when preparing spare parts for the manufacture of the device.

A creeper for a motor-cultivator is used at high speeds of the motor-cultivator, when it is necessary to reduce it to a speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, trailers, hilling soil and removing snow.

Using a factory-assembled creeper

To reduce the speed of movement of the motor-cultivator, a shaft with a reduction gear is used, which, through a belt drive, reduces the number of revolutions of the drive wheels. Also, there are creepers that are built into the cultivator engine itself and, with the help of the required equipment, reduce the speed of the internal combustion engine and, as a result, reduce the speed of passage of the land plot by this device. The operating principle of such a device is quite simple. Small sprockets are installed on the axle shafts of the motor-cultivator, and sprockets of larger diameter are provided on the creeper, thus, the revolutions from the motor-cultivator are transmitted much less than at the beginning.

Speed reducers are best used on air-cooled gasoline and diesel engines, since the traction properties in relation to the engine are quite low. On heavy soil, it is better to use diesel motor cultivators, since their traction properties are much higher than those of gasoline engines.

DIY creeper

It’s quite easy to make a creeper for a motor cultivator yourself.

. To reduce the number of wheel revolutions, larger diameter wheels can be used, depending on the required speed. We all know that rotation from the engine shaft is transmitted to the drive wheels and the speed of the shaft does not change. With larger wheels, fewer wheel revolutions can be achieved, since the shaft has rotated and will rotate at the same speed, and the wheels are now at a lower speed.

Also, there is another method of reducing the speed of a motor cultivator using a creeper. To do this, you can take several steel sheets and make a box. Drill the necessary holes in it and secure it as an attachment under the body of the motor cultivator. Then, weld a metal tube of any diameter inside and place a larger gear on it than on the drive shaft of the cultivator. Pass the chain to transmit rotation of the drive and driven gears. So our creeper for the motor cultivator is ready.

To facilitate agricultural work, a walk-behind tractor has been used for a long time. This most useful machine simply performs a wide range of tasks, and as we have said more than once, it is an indispensable thing when working with land, transporting goods, preparing animal feed and firewood, removing snow, etc. Of those who have used a walk-behind tractor at least once, those who want to return to a plow or shovel can be counted on the fingers of one hand.

In order to make the walk-behind tractor more efficient, various accessories are used. Grousers, for example, allow for more thorough adhesion to the soil, which is necessary during plowing or harvesting potatoes. These are peculiar metal wheels with spikes, which are not at all difficult to make yourself. You can read about how to do it in the previous article. In addition to the lugs, you should pay attention to the adapter, which consists of 2 wheels, a drawbar, steering and a seat. By purchasing an adapter, you will turn your walk-behind tractor into an incredibly convenient device that you don’t need to walk to get.

Another attachment for the walk-behind tractor is the creeper. There are situations in which it becomes necessary to reduce the stroke of the walk-behind tractor. This occurs when the machine's operating speed is lower than its transport speed. The creeper allows you to increase the torque and, accordingly, increase the traction force. Essentially, a creeper is the same as a reduction gearbox. With the help of the necessary chain, it allows you to transform the driving force of the unit into the operation of attachments. You can or you can make it yourself.

In order to assemble a creeper for a walk-behind tractor

with your own hands,

you will need: a generator housing, a flange bearing, a rotor shaft, a washer and a flange made of high-quality steel, a drive bevel gear, a gear housing, a key, two pinion shaft bearings, a driven gear shaft, steel for the manufacture of gear shaft bearing shells, screws for fastening the pulley and flange, V-belt pulley.

There is nothing difficult about assembling a creeper with your own hands. However, if you have not made your own attachments for a walk-behind tractor before, then you may experience some difficulties, which you should not be upset about at all. You will definitely be able to assemble the creeper with your own hands. Just be patient.

Initially, you should perform some calculations and decide on the body of a homemade creeper. This role can be perfectly fulfilled by a factory part, borrowed from well-known motorcycles such as the Irbit Ural or the Kyiv Dnepr. Regarding the calculations, it is necessary to calculate the rated power, torque and the number of revolutions made per minute.

Having finished with the calculations and decided on the choice of housing, proceed to cutting out the shell of the gear shaft bearings. To cut through steel, you will need a drill of the appropriate size and a caliper. Focus on the diameter of the gearbox. Immediately after cutting, we determine the dimensions of the gear shaft bearings and select the appropriate ones. We install the steel flange on the opposite side of the gearbox. Inside it we place a steel alloy washer and a flange bearing. Using screws, screw the flange to the generator housing. We are looking for the most suitable driven gear shaft, steel key and drive gear. All components, without exception, must be connected to the shaft of the rotary generator and the transmission mechanism. Using a nut and a spring washer, we fix the V-belt pulley to the driven shaft.

Voila! A homemade creeper is ready for installation on modern ones running on gasoline or diesel using an air cooling system. As you can see, it’s quite easy to assemble a creeper for a walk-behind tractor with your own hands. Just a few hours, and your powerful unit is ready to work in the most severe conditions; He doesn’t mind even the heaviest soil. All the power of the walk-behind tractor will be directed into useful channels. Do not forget that such an invention requires careful care, regular diagnostics and lubrication. Overhaul your custom speed reducer from time to time and take care to properly lubricate the moving parts. With normal operation and due attention, a homemade creeper will serve you for many years, becoming a worthy alternative to products from leading domestic and foreign manufacturers.

The drive and reduction gear are the main components of the walk-behind tractor. The gearbox is necessary to change the speed characteristics of rotation of the output shaft, which, in turn, is necessary to increase torque.

A reduction gearbox for a walk-behind tractor can be:

- Geared.

- Worm-like.

- Chained.

- Combined.

This unit can have 1, 5 or more stages.

How to adjust the speed?

Sometimes it turns out that you want to change the speed of movement of your walk-behind tractor: increase it or, which happens quite rarely, decrease it.

To increase the speed of movement of walk-behind tractors, one of the two methods below is usually used:

- replacing wheels with larger diameter ones;

- replacing a pair of gears in the gearbox.

The usual wheel diameter of almost all walk-behind tractors is 570 mm. Most often, when replacing, tires are selected with a diameter that is approximately 1.25 times larger than this - 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows for larger tires, you can try to increase the speed gain.

A gear pair installed in a wheel reducer usually consists of two gears with the number of teeth 12 for the small one and 61 for the large one. You can change this indicator to 18 and 55, respectively (only from specialists at agricultural machinery service centers), then the gain in speed will be approximately 1.7 times

Do not try to carry out the operation of replacing gears yourself: it is very important to select not only high-quality parts with minimal errors, but also the appropriate pulley. The gearbox shaft locking plate also plays an important role.

A possible solution to increasing the speed is to adjust the gas switch: when the device turns on, move it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change the speed down, you don’t need special reducers - it’s enough not to switch to high gears.

Also possible solutions to the problem of increasing the speed of a walk-behind tractor are replacing the motor with a more powerful one and upgrading or installing a clutch system (in some outdated models it is not provided).

It can help to increase speed (especially on uneven terrain or heavy soils, where equipment often slips due to insufficient weight of the unit) and installing weights. They can also be made with your own hands from metal parts. Weighting structures are installed on the walk-behind tractor frame and wheels. For the frame you will need metal corners, from which a homemade removable structure is formed, that is, you can easily remove it if not needed. Additional ballast weights are attached to this removable additional frame. The wheels require steel discs and solid iron blanks with a hexagonal cross section. These parts are welded and inserted into the hubs. For reliable fixation, cotter pins are used, which are installed in specially prepared holes.

Of course, if you don’t have round steel elements at hand, you can replace them with almost any available material: reinforced concrete products or even flattened round plastic flasks with sand poured inside.

To speed up a walk-behind tractor with a trolley in bad weather conditions - snow, slush, soil soggy from heavy rains - you can install tracks (if the design allows). This method requires the installation of an additional wheel pair and the purchase of rubber tracks of a fairly large width. Limiters are attached to the inside of the track to securely fix the rubber and prevent it from jumping off the wheelset.

Also for this purpose, you can replace the original gearbox with a similar device with a lower gear - to make it easier to overcome obstacles.

If you take good care of the unit, follow all recommendations for operating the device, and carry out regular preventative maintenance, then the walk-behind tractor will produce the maximum of its capabilities in terms of speed and performance.

To learn how to adjust the speed of a tiller on a walk-behind tractor, watch the video below.

Basic elements of a mechanical system

To support the main elements, the gearbox (speed reducer) is provided with a system of shafts and axles. Single-stage designs use shafts with rigidly seated driven and driving gears. Rigidity of fit is achieved through the use of keys or splines. Lateral displacements are adjusted with special nuts that press gears or sprockets against thrust collars. The material used is structural steel. It is perfect for making a creeper for a walk-behind tractor or cultivator.

Bearing units are supports for steel axles and creeper shafts on a walk-behind tractor. Bearings bear the main load during operation of the power unit.

Whether the speed reducer for a motor cultivator will work normally depends on the correctness and quality of the bearings. For homemade designs, bearings with closed cages (closed type) are better suited. This will save you from having to regularly change the lubricant. The type of gearbox bearings depends on the type of loads taken. Support bearings are installed on a creeper for a walk-behind tractor with straight gears, and thrust bearings are installed on gears with an oblique tooth profile and worm shafts. They are usually subject to longitudinal axial forces from an electric motor or internal combustion engine.

The gears and sprockets in the gearbox determine the speed and nominal rotation speed of the output shaft. For their production, special equipment and equipment are used. It is better not to make the creeper gears for a walk-behind tractor with your own hands. Buy ready-made gearing in specialized stores.

Whether the speed reducer for a walk-behind tractor will normally accept dynamic loads from the power unit depends on the correct selection of geometric dimensions and gear ratio. When installing gears, all necessary clearances must be maintained. To do this, carefully study the drawings. Clearances directly affect the ability to absorb significant loads from an internal combustion engine or electric motor.

The step-up and step-down gearbox for a minitractor is lubricated with I-20 industrial oil. The oil level is determined taking into account the operating conditions of the unit. Oil seals are used to prevent leaks.

How to increase the speed of a walk-behind tractor

You can increase the speed of the walk-behind tractor in two ways:

- installation of large wheels;

- replacing a gear pair.

Let's first look at how changing wheels helps increase the speed of a motor cultivator. The standard wheel size of almost all mini-unit models is 57 cm. When replacing, you can install tires 1.2 times larger in diameter. Typically, wheels of 70.4 cm are used. Despite the small difference, the speed of the walk-behind tractor increases noticeably. If the arches into which the tires are inserted allow you to insert wheels with a larger diameter, then you can try adding centimeters.

When using a walk-behind tractor for cultivating land, lugs are used. These are wheels with iron plates that freely grip the ground or snow. They can be purchased in specialized stores, or you can make them yourself. Their size also affects the speed of movement of the unit.

Let's look at how to increase the speed on a walk-behind tractor using the second method. Like any equipment, the cultivator has several speeds, which are controlled using gears. Typically, cultivators move at a speed of 2 to 15 km/h, with the large gear having 61 teeth and the small gear having 12. To increase the speed, the gear pairs of the gearbox are replaced. We increase the number of teeth, thus achieving the maximum speed of the walk-behind tractor.

It is recommended that replacement be carried out by professionals and preferably in specialized centers, since parts machined with minimal error will affect the operation of the motor. It is important not only to replace the gear, but also to select the correct pulley.