Huter chainsaw

For a long time, Huter specialized in the production of electrical equipment, gasoline and diesel generators. People first started talking about this company in 1979, but the company began supplying products to the international market ten years later - in 1989. By that time, a large plant had already been built in Erfurt, which made it possible to expand the range of goods produced.

Huter chainsaws

Huter appeared on the territory of SND in 2004 and immediately attracted attention with the high quality of the products supplied. In recent years, due to the expanding demand for garden equipment, the company has opened a factory in China, where most models of electric chainsaws and chainsaws are assembled. Chinese assembly is of fairly high quality; all technological processes are controlled by German engineers and mechanics. Today, Huter products are certified in most countries of the world; they meet all modern quality and safety standards.

Electric snow blower Huter SGC 1000E

Snow blower Huter sgc 6000

Motoblock Huter GMC-9.0

We are pleased with the wide range of equipment from Huter. In addition to chain saws, the plant's workshops produce snow blowers, stabilizers, gas generators, trimmers, high-pressure washers and much more. An important factor that increases demand for the company’s products is a reasonable pricing policy. Even professional-grade tools are available at affordable prices.

In domestic stores, chainsaws can cost from 5,000 to 8,000 rubles, depending on the model.

Chainsaw carburetor design

A carburetor is a device in which fuel is mixed with air and this mixture is supplied to the cylinder for combustion. When burned, the crankshaft is activated, to which the drive sprocket is connected to drive the saw set - the chain. The absence or malfunction of the mechanism in question will lead to the instrument being inoperable, so it is important that the device is in good working order and adjusted.

The design of a chainsaw carburetor consists of the following components:

- Solid cast aluminum alloy body. The use of aluminum for the manufacture of this mechanism helps to lighten the weight of the tool

- Air supply diffuser located on the inlet side of the mechanism

- Jets are valves that serve to regulate the flow of the mixture.

- Atomizer - a device from which the fuel mixture enters the combustion chamber of the cylinder

- Float chamber - a device for creating and maintaining a certain level of fuel

A detailed design diagram of the device in question is shown in the photo below.

Setting up a chainsaw carburetor is an important step that every sawyer has to deal with. A chainsaw needs adjustment not only after purchase, but also in the following cases:

- Before running in the tool. How to set up the mechanism for proper running-in of a chainsaw is described in detail here

- After finishing the running-in process

- After engine overhaul

- During the operation of the tool, when malfunctions occur during operation and starting the motor

At the heart of the mechanism there are 3 screws for adjustment (on some Chinese models there are 2 screws), which serve as a control panel for the user. It is with the help of these screws that the chainsaw carburetor is adjusted independently and quickly. You can adjust an important component of the tool even in the field, without the help of specialists.

Model range overview

As we have already noted, the company focuses on the production of electrical equipment. Equipment such as chain saws is not a priority, and therefore only six models of Hooter chainsaws are available on the market. They differ in their purpose, operational and technical characteristics, but they are united by consistently high quality.

Chainsaw Huter BS-40 in operation

Advantages and disadvantages of the Huter chainsaw:

- Stylish design and ergonomic body;

- Serviceable tire with driven sprocket;

- Comfortable rubberized handles;

- Thoughtful placement of controls;

- Effective multi-point vibration damping system and protection against saw kickbacks;

- Clear Russian-language manual;

- Acceptable price.

Disadvantages of the Huter chainsaw:

- The heavy weight of the Hooter chainsaw;

- Some models have a poor starter design;

- Low quality chain in the basic configuration.

Huter BS-52

The models that are in greatest demand among buyers include the BS-52 chain saw. This is a high-quality, inexpensive tool that can cope with most tasks.

Chainsaw Huter BS-52

The chainsaw has a powerful (3.4 hp), high-speed engine, and is equipped with modern safety and vibration protection systems. High quality and excellent performance characteristics are combined with a budget price; today this saw can be ordered at a price of 5,900 rubles.

Characteristics

| Characteristics | Huter BS-52 |

| Engine capacity, cm cube | 52 |

| Power, W | 2,2 |

| Tire size, cm | 50 |

| Chain pitch | 3/8 |

| Number of links, pcs | 76 |

| Fuel tank volume, l | 0,5 |

| Oil tank volume, l | 0,2 |

| Weight, kg | 7,5 |

Huter BS-25

The most compact and lightest chainsaw in the manufacturer's catalog. For its small size it received the nickname “pocket”. However, its performance characteristics look very impressive.

Chainsaw Huter BS-25

800 W motor. And the 30-centimeter tire allows you to use this tool to solve a wide variety of tasks. The price for a Huter BS-25 chainsaw starts at 6,570 rubles.

When is tuning needed?

In particular, in rare cases it is necessary to adjust the carburetor of a chainsaw; more often problems arise related to fuel consumption or wear of parts. But sometimes “symptoms” indicate the need to regulate the mechanism. Here are some signs:

- When the engine starts, it stops immediately. Alternatively, it won't start at all. The reason is too much air and not enough fuel.

- Fuel consumption increases as a result. Large amount of exhaust gases. This is due to the reverse process. Oversaturation of the mixture with fuel.

READ Husqvarna Chainsaw Oil Leaks Chains

Reasons for failure may be mechanical:

- Due to severe vibration, the protective cap is damaged, causing all three bolts to become loose.

- Due to wear on the engine piston. In this case, adjusting the chainsaw carburetor will only help temporarily; it is better to replace the worn part.

- Due to clogging caused by poor quality fuel, scale or filter damage. The carburetor requires complete disassembly, cleaning and adjustment.

If the chainsaw suddenly stops working, it must be disassembled to find out the reasons.

User manual

You are buying a rather expensive unit, so we advise you to carefully inspect the chainsaw for visible damage and malfunctions. If any are found, contact the seller with a request to eliminate the defect or replace the chain saw. However, according to the law, you will have 14 days from the date of purchase to return the product if a manufacturing defect is discovered.

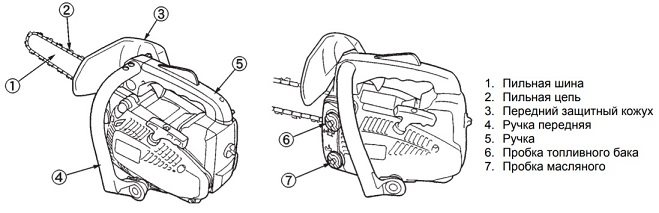

Chainsaw device

Before operating a chain saw, carefully read the manual, study the device and safety rules when working with such tools at the link: Your browser does not support frames

Your chainsaw is delivered assembled; the new owner only needs to mount the saw set.

How to adjust the carburetor on a chainsaw - instructions

A chainsaw is a complex unit whose operation is based on a two-stroke internal combustion engine. To operate an internal combustion engine, a carburetor is required. In this mechanism, fuel is mixed with air, and this mixture is supplied to the engine cylinder for combustion. The operation of the internal combustion engine largely depends on the carburetor, which needs periodic adjustment. You can adjust the carburetor of a chainsaw yourself, but to do this you will need to know the instructions described below.

Ivan Khmelkov, 46 years old, Yekaterinburg:

“My wife gave me the saw for my birthday. This is how it happens too - and you don’t have to laugh. I don’t know who chose her, but she bought it from Hooter. At first I was distrustful - Chinese assembly. But in operation the chainsaw performed very well. The engine is powerful, holds speed without problems, cuts smoothly. Huter has excellent body balancing, to a large extent, compensates for the considerable weight of the unit, so don’t be afraid - it’s not that heavy.”

Yakov Sinelnikov, 38 years old, Rostov region:

“I’ve been using the Hooter chainsaw for the fourth season. Mostly housework, firewood is brought in and needs to be cut. I mainly cut hardwoods. The engine is a beast. It doesn’t stall, doesn’t lose speed, and even starts in half a turn. At first I was surprised by the fact that I practically did not feel the vibration. The neighbor said that Hooter chainsaws are all like that - an excellent vibration damping system.”

Nikolay Kornilov, 32 years old, Primorsky Krai:

“I’ve had my Huter chainsaw for three years now, so I can judge it first-hand. Overall, a very decent unit for the money. First of all, it is worth noting the high-quality engine: it starts and runs flawlessly. A well-thought-out clutch system – no problems either. But the quality of the plastic on the oil line is poor, my oil is leaking. There are also complaints about the original chain - it sits down too quickly.”

Adjusting the carburetor fuel-air mixture supply mechanism - when it is needed

The first adjustment of the chainsaw carburetor is performed immediately after purchasing a new tool. This is done for the purpose of running in the tool’s motor. To run in the internal combustion engine of a chainsaw, you need to limit the maximum speed, which is done using adjusting screws. As soon as the run-in is completed, which lasts 2-3 tanks of burned fuel, it is necessary to make adjustments again, but only this time with the aim of establishing the maximum number of revolutions.

In addition to break-in, chainsaw carburetors are adjusted when:

- Knocking down the settings set after running in

- If the internal combustion engine is difficult to start

- If the engine does not develop speed or when you press the gas, the chainsaw stalls

- Wear of the piston group, but only in this case, adjusting the chainsaw carburetor is a temporary measure, since the internal combustion engine needs a major overhaul

- If the engine does not idle

- Unit vibrations

- Presence of carbon deposits on the spark plug

- Increased fuel consumption. This phenomenon can be detected by an excessive amount of smoke. If you unscrew the spark plug, it will be black with soot.

Many malfunctions during the operation of a gasoline unit arise precisely because of incorrect settings of the chainsaw carburetor or when they are knocked down. To restore the previous performance of the tool, you will need to adjust the mechanism. Many beginners entrust this process to specialists, for which the masters charge a lot of money. It's time to figure out the adjustment and do it yourself, since this process does not require disassembling the mechanism.