Do I need to sharpen the cultivator cutters? What is a cultivator and why is it needed?

First you need to understand what a cultivator is, how it works and what it is needed for.

So, this is a type of compact agricultural equipment designed for pre-planting soil preparation. It allows you to plow, loosen and hill up the soil, as well as make furrows and perform harrowing. This unit makes it possible to significantly facilitate agricultural work on a summer cottage or personal plot. The motor cultivator is capable of working where full-size equipment cannot access

Cultivators are divided into groups according to the type of mechanism:

- mechanical manual They are used as additional equipment for more serious equipment. Loosen the soil to a depth of no more than 5 cm and remove only weak weeds located on the very surface;

- electric . Lightweight, maneuverable equipment that is used on limited areas of land. The disadvantage is that it runs on an electrical cord;

- battery . This type of agricultural equipment combines all the advantages of electric analogues with autonomy. They are heavier, but at the same time, mobile and safe;

- gasoline. This technique is distinguished by power, performance and heavy weight. A good option for cultivating large plots of land.

Manual mechanical cultivator

Electric cultivator with cord

Battery unit

Motor cultivator with gasoline engine

Cultivators of any type consist of such basic elements as a frame, control levers, engine, rotor, wheels and cultivation devices (mills).

The operating principle of the cultivator and its main advantages

A cultivator for a walk-behind tractor is an agricultural unit for loosening, moisture conservation, and hilling up soil without turning over the top layer.

Types of cultivators

Cultivators are:

- with passive, or stationary, knives;

- with active, or driven, knives.

By type of drive there are:

- manual;

- mechanized;

- aggregated with a tractor.

Among the cultivators, the following types are distinguished:

- with disk cutters;

- with pointed paws;

- ploughshares;

- with rotary cutters;

- mulchers;

- Chisels.

For the Neva walk-behind tractor, the basic package includes 6-8 cutter-cultivators with a diameter of 360 mm and a working width of 1200 mm.

READ MORE: Junction box for electrical wiring: diagrams, step-by-step instructions

Device

The walk-behind tractor differs from the cultivator in its greater weight and the presence of a power take-off shaft. The cultivator is equipped only with cutters, and any mounted and trailed equipment that meets the characteristics of the equipment can be attached to the walk-behind tractor.

Cultivators are equipped with different engines - 2-, 4-stroke gasoline, diesel and electric, powered by mains power or built-in batteries. They are compact, but inferior in power to motors built into walk-behind tractors.

Before making a cultivator for a walk-behind tractor with your own hands, it is necessary to treat all metal elements with a special anti-corrosion compound to prevent the premature appearance of rust after frequent contact with the ground.

Simple models can be made without drawings. To make and correctly assemble more complex devices, it is necessary to plan the work, calculate the dimensions of the module and parts.

A homemade cultivator made from a pitchfork is a simple way to reprocess (remake) products. To do this, the teeth of the mechanism are bent with a hammer like a corkscrew and placed on the handle. A shovel handle is used as a handle. Electrical tape is used for fastening.

Some craftsmen manage to make a cultivator with their own hands from a bicycle frame with a wheel. A steel rod is welded or bolted between the 2 base blocks. The head is mounted to the crossbar. For this design, it is recommended to take a medium-sized wheel.

In order to correctly assemble a disc cultivator and work correctly with cutters, it is necessary to design diagrams of components and individual parts. Taking into account the deformation of the discs, special adjusting nuts are used. The discs are welded to bushings located on a rotating axis with brackets. It is necessary to provide a protrusion on the bracket where the pipe will pass. The cultivator handle is attached to the pipe surface.

Cultivator cutters perform many different functions. With their help, farmers have the opportunity to:

- Quickly destroy dense thickets of weeds;

- Cultivate the soil;

- Mix layers of soil with fertilizers;

- Level the ground surface.

Milling cutters are especially effective on clayey, waterlogged and woody soil. Mills are also often used for plowing virgin soil in pastures and meadows.

- Devices with saber-shaped knives - they are in greatest demand among buyers and allow you to perform a wide range of work. The main advantage lies in the shape of the blades and the material - the cutters are made of steel and can be removed at any time. There is practically no vegetation wrapped around them, which allows you to plow the soil many times faster;

- Crawler-foot cutters for cultivators are a new solution on the equipment market. This type of equipment is often used for plowing hard soils. It cannot be disassembled, making it more durable than the first type of cutter. Among the disadvantages is the frequent wrapping of weeds around the blades. Because of this, most farmers use these cutters to work on “clean” soil. Often, “crow's feet” are used for plowing before planting potatoes, as well as for treating the soil to prevent the appearance of Colorado potato beetles and other pests.

Today you can purchase additional cutters of the required width at any gardening equipment store. However, at a reasonable price it is most often possible to buy Chinese products that are not particularly durable. In this regard, it would be quite reasonable to try to make cutters yourself.

Device

Is it possible to sharpen cutters? Why you can’t sharpen reciprocating cutters for cultivators

It's actually simple. Most domestic manufacturers purchase knives from one plant in the Smolensk region, where knives are made from hardened steel with the cutting edge treated with high-frequency currents.

Please note that domestic cutters are always installed on the cultivator flange using bolts. This is due to the fact that hardened steel is difficult to weld. So you can understand that many Chinese cutters for welding are made of metal of worse quality than domestic ones.

Reciprocating cutters that have seen kilometers of soil

The process of creating such an edge is accompanied by melting of the edge of the blade and its rapid cooling. As a result, the knife blade under magnification will look uneven and resemble a saw.

When working in the ground and constantly hitting rocks, reinforcement, and so on, the carbide blade does not become dull, but crumbles. Forming deeper “saw” teeth. Therefore, many people call such cutters self-sharpening.

New knife shape

Frankly speaking, in my opinion this term is not entirely fair. Splitting knives are more suitable.

Now to the question of sharpening at home. You can sharpen walk-behind milling cutters using a high-temperature sharpening machine. If such a device is not in the garage, then there is no need to take a file from the shelf!

The file will remove small teeth, making the knife smooth, which can lead to a large chip or break of the knife during subsequent cultivation and contact with stone.

If a nick appears on the cutter, just continue working with it. You will see, after a while it will disappear on its own.

I hope the article is useful to you. Please like and subscribe to MY CHANNEL! It will be especially interesting for amateur gardeners who want to make their work easier with mechanical assistants.

Interesting hitch? Find out about other amazing gadgets for your gardening helper. Here are links to my articles:

About mounted snow blowers

About walk-behind harrows

About the choice of lugs for a walk-behind tractor

About motoblock hedgehogs

This and much more on my channel!

Milling cutters for walk-behind tractor. Cultivation with Neva walk-behind tractor

Mills are the main operating element in soil cultivation. They exist in several types. Each of them is suitable for processing a certain soil, and at a certain speed.

Milling cutter for walk-behind tractor Neva

The choice of cutter affects how:

- how high-quality the final result of soil treatment will be;

- how much effort will be needed to achieve this;

- what will be the controllability of the walk-behind tractor during cultivation;

- how loaded the engine will be.

First of all, the choice of cutter should depend on what kind of soil will be processed, i.e. where, on what land he will work.

Cultivator cutters are an integral part of any walk-behind tractor. This is one of the first attachments you should purchase.

However, there are situations when a standard cultivator is equipped with the wrong cutter that is needed. For example, it does not fit the width of the surface being treated or does not penetrate deep enough into the ground. In this case, you can purchase additional cutters for the Neva walk-behind tractor, which will be able to perform the required amount of work.

This is how the land is plowed using a Neva walk-behind tractor with 8 cutters:

By changing the number of installed cutters, you can optimize the operation of the entire Neva walk-behind tractor during cultivation, improve its controllability and the final result of loosened soil.

If you have to cultivate clay soil, then you should not install more than two pairs of milling cutters for cultivation. Because otherwise there will be a huge load on the walk-behind tractor engine. And instead of a good cultivation result, we will get a faulty engine. Moreover, the manufacturer does not recommend increasing the number of cutters when working with virgin lands, since the soil there has a large number of stones and other organic compounds.

Additionally, it is recommended to install cutters only when working with already prepared soil. In this case, cultivation with a Neva walk-behind tractor and a milling cutter will bring excellent results.

How deep the cutters will penetrate into the soil will depend on the preset adjustment, which is carried out using the coulter. This is a steel anchor that is located vertically at the cultivator coupling point.

The greatest immersion depth is characterized by the size of the cutter diameter.

Deep tillage

When developing new areas, it is necessary to develop virgin soil. Usually it is abundantly overgrown with turf, perennial grasses and weeds. It is quite difficult to cope with such areas with conventional tools. More often they resort to cultivation using deep processing with formation turnover. With reverse plowing, part of the layer is cut, lifted and turned around its own axis.

Similar work is done in the fall. The rhizomes of nettle, wheatgrass, dandelion and other weeds freeze in November-December, when the air temperature drops below -15...-17 ⁰С (there is no stable snow cover yet). Subsequently, they lose the ability to grow.

In the future, a similar technique is resorted to every autumn. After 2...4 years of autumn fall plowing, the number of weeds on the site is reduced many times over.

Proponents of organic farming disagree with this approach. But the experience of several centuries proves that only such agrotechnical measures can clear the area of weeds. Otherwise, you will have to use chemicals to control weeds.

READ MORE: Kitchen design 59 photos designing and choosing the design of a kitchen set How to draw a sketch of furniture with dimensions

Deep plowing allows:

- wrap a layer of soil and allow plants to use for nutrition substances that gradually shift to lower horizons during the season. This operation makes it possible to reduce soil salinization using mineral fertilizers, as well as reduce the amount of fertilizer applied;

- aeration of the lower layers of soil contributes to the occurrence of aerobic processes of decay of plant residues. Usually in the lower layers the access to air oxygen is limited. Therefore, conditions are created when the rotting of taproots lasts for several years. Anaerobic processes (without air access) occur with the slow accumulation of humus;

- When the formation is turned over, weed seeds end up in the lower layers of the soil, and they cannot germinate. The roots remaining on the surface freeze. As a result, soil contamination sharply decreases;

- Freezing lumps of earth in winter crumble more easily in spring. A light, loose surface layer is formed in which cultivated plants can receive more abundant nutrition;

- adding organic matter before plowing allows for active rotting of manure or green manure if they were sown after harvesting the main cultivated crops.

Do I need to sharpen the cutter blades of a walk-behind tractor? Milling cutters for walk-behind tractor

Equipment such as a milling cutter is necessary for any walk-behind tractor, since it can be used to carry out most work related to soil cultivation. Basically, the tiller comes complete with the unit, but in cases where you need to change the width and depth of processing, you should purchase the equipment separately.

Additional cutters allow you to increase the functionality of the walk-behind tractor and simplify the work with it. Experts recommend having several pairs of cutters in your arsenal.

Which cutters are best for a walk-behind tractor?

Such “knives” for tillage can be divided into two large groups. Each of them has its own characteristics and is suitable for a certain type of work.

Saber cutter for walk-behind tractor

The most popular and versatile models that are effective when performing various excavation work. These models use the optimal shape of knives, for the manufacture of which manufacturers choose high-quality durable steel.

The models have a collapsible design, so their installation and maintenance are as simple as possible.

Crow's feet

These models appeared on the market relatively recently. With their help, any virgin soil can be processed; they are also effective when cultivating hard and difficult soil.

Features of this type of cutter:

- solid design, which ensures high accuracy of work;

- the equipment fights weeds well;

- ease of use, ability to replace spare parts at home.

Such models, unlike saber-shaped cutters, are made of carbon steel, which is slightly inferior in strength.

Homemade cutters for walk-behind tractor

Manufacturers offer different options for soil cutters for walk-behind tractors. You can use one set of cutters or purchase two different types of devices, changing them depending on soil cultivation conditions.

Some craftsmen prefer to use homemade products, which, if assembled correctly, will be no worse than factory ones.

The main advantage of creating a plow cutter yourself is that it can be tailored to the specific features of the site.

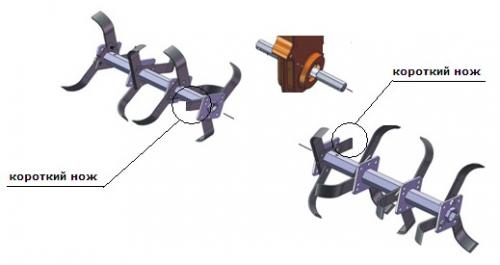

How to properly assemble cutters on a walk-behind tractor?

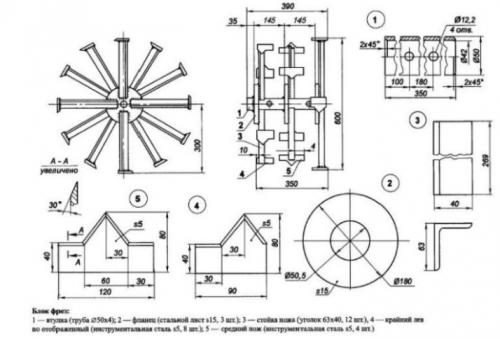

Assembling the cutter with your own hands should be done as correctly as possible. And here it is especially important to ensure that the active part crashes into the ground during operation. To do this, it is initially recommended to study the drawings and then begin manufacturing the equipment.

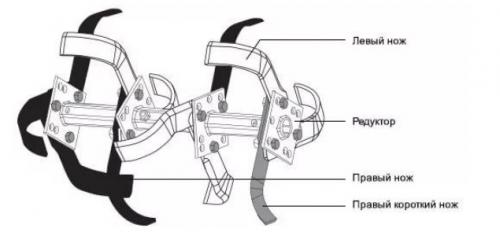

To create cutters, the following tools are required:

- The rotor axis is of the required length. It can be divided into two parts if you need to assemble a cutter from two blocks.

- Short axis.

- Gearbox with clamps.

- Left and right knives.

- Bolts, washers, nuts.

Assembling the structure does not take more than an hour, but here it is important to install the knives in such a way that they do not interfere with the rotation.

- The long rotor axis is equipped with knives at an angle of 30 degrees.

- It is necessary to combine four knives on one block, securing them to the gearboxes.

- Next, the correctness of the design is checked and all fasteners are tightened.

This design is very reliable and can withstand fairly high loads.

installing cutters on a walk-behind tractor

To install the cutters on the walk-behind tractor, you should use special wooden trestles, the height of which should be about 50 cm. The unit should be supported on the coulter and tilted at an angle of 45 degrees. then the wheels are removed from it and the cutters are put on. Special plates are installed on the outer ends on both sides, which make the unit run smoother and more stable.

Is it necessary to sharpen cutters for a walk-behind tractor?

Any tillers are self-sharpening tools. Sharpening is not necessary for them, as it can only ruin the design. Only in some cases, if you have been using a cutter for a very long time and see that it has begun to work the ground poorly, you can sharpen the knives.

The tiller is an important element of each unit. Homemade, correctly assembled cutters can be used on any modern walk-behind tractor, in particular on Neva MB 1 and MB 2, MTZ and others. Such structures will help in cultivating the land and make agricultural tasks easier.

Is it necessary to sharpen cutters for a motor cultivator?

Regardless of their design features, cutters are self-sharpening devices. In this regard, sharpening of cutting knives by the operator is not required, as this can only spoil the condition of the organs.

The only exception is very old cutters, which need to be sharpened only when the quality of plowing the soil has deteriorated significantly.

In this case, sharpening is performed in the following sequence:

- First you need to remove the equipment from the motor-cultivator, clean it of dirt and degrease it;

- Sharpening will be carried out according to the factory mark, which is clearly visible on the blades;

- Next you need to prepare the tool. It is best to use an angle grinder that is pre-equipped with a new grinding wheel. If this attachment is not available, then you can use a cutting wheel, but the quality of sharpening the cutter will be slightly worse;

- After this, you need to lay the cleaned structure on a stationary horizontal surface;

- Then you will need to take measurements of the factory sharpening using a caliper;

- During further processing of knives, you need to constantly check their thickness so as not to remove extra millimeters of metal;

- At the end, you will need to turn on the grinder and sharpen the knives to the factory bevel.

When sharpening yourself, you need to give them time to cool completely. It is important to remember that the metal heats up quickly under the action of the grinding wheel. If you do not take breaks, this can lead to overheating and deformation of the steel.

Which cutters are better for a walk-behind tractor? Milling cutters for walk-behind tractors: their purposes, differences (Salyut and Agro) and video

Farmers know that in order to get a good harvest, a complex of works is necessary, which includes soil cultivation. In household plots, a shovel has always been considered a traditional tool.

Today, many owners of legal acres of land want and are able to efficiently cultivate the soil using special “home” equipment.

Purpose of soil cutters, their role in tillage

These are walk-behind tractors that perform soil cultivation. One of the elements installed on home cultivating assistants is cutters for walk-behind tractors.

They directly affect:

- for high-quality plowing;

- the controllability of the equipment depends on the rototiller;

- influence the transmission;

- and the power unit of the walk-behind tractor.

A cutter for a walk-behind tractor is their main working part. They answer:

- for the depth of loosening of the top layer of soil;

- for creating the structure of cultivated land. Large or finely lumpy version;

- for the fight against weeds.

The difference between soil cutters

They can differ radically from each other. Design and shape may vary. The difference may be in the number of knives and location.

Knives are the main weapon of a rototiller. The material from which they are made directly affects the depth of penetration into the soil.

They can be forged with self-sharpening. Good knives for milling cutters are made by Italian craftsmen. See the video of the walk-behind tractor with cutters at the end of the publication.

Stamped sheets are often used to make knives. In this case, the cutting edge is not clearly defined. Practice shows that their installation is often carried out on inexpensive, budget models of cultivators

Milling cutters for walk-behind tractor Salute

The configuration and equipment of the Salute walk-behind tractor of different models includes a set of cutters with disks for plant protection. Manufacturers of the Salute walk-behind tractor make rototillers from steel blanks or ordinary metal strip.

The cutter knives for Salute are made of spring steel and processed in a special way. The crescent shape allows penetration into the soil with the least resistance. It has been proven in practice that the knives are very reliable.

The three pairs of cutters that come with the kit are bolted on with steel pins. Cutter grip indicators: 350 x 600 x 800 mm.

Milling cutters for Agro walk-behind tractor

The Agro walk-behind tractor includes a number of additional attachments, with which you can better cultivate the soil in a short time: loosen it, remove weeds.

This makes the tool more functional and versatile. The main violin in the “technical orchestra” is the cutter. Characteristics of the rototiller for tillage: the grip width is 610 mm.

The depth of cultivation of the top layer of soil is 80 mm. Penetration into the top layer of the earth, at around 80 mm, is possible only with knives made of high-quality material.

We can conclude that cutters for a walk-behind tractor are a necessary and useful thing. A range of work with additional equipment expands the capabilities of home appliances, increasing the demand for it. It is possible to purchase rototillers separately from walk-behind tractors. This is normal practice, which makes it possible to purchase the necessary additional equipment at the right time.