Why does the chain get dull?

When studying information on how to set up a chainsaw, be extremely careful, since incorrect settings are the first reason for the rapid failure of the chain and abrasion of its teeth. Usually the chain becomes dull for the following reasons:

- use of low-quality oil or oil that does not meet the parameters specified in the instructions;

- incorrect setting of the gaps between the edge and the limiter;

- lack of lubrication in the system;

- poor chain tension.

Also be careful when sawing old boards because they may contain nails, which will also dull the edges of the teeth. Important factors for wear of the element are also considered to be inept handling of the saw, frequent contact when working with hard objects - stones, bricks, and intensive use.

How to know when it's time to sharpen your chain

If you have already studied information on how to sharpen a chainsaw chain with your own hands, you need to know exactly the characteristics indicating the gradual failure of the cutting elements. The main ones:

- you notice that you are putting in much more effort when working;

- smaller sawdust appeared;

- there is noticeable vibration during operation or braking;

- the cut does not have a clear cut and is characterized by a large number of irregularities with sharp edges.

Anyone who does not want to fix more serious damage to the device in the future needs to know information about how to sharpen a chainsaw chain. For example, the tight movement of the links puts additional stress on the engine, thereby stimulating rapid wear.

Correct sharpening angle values

The sharpening angle of chainsaw chains is not a constant value and does not depend on the manufacturer or model of equipment. It is selected taking into account what kind of tree you will be dealing with. You can choose some average value, but the cutting efficiency may be ineffective. For this reason, it is necessary to choose the correct value, taking into account the specific type of wood.

Read also: Diagram of the charger zu 55a

If we are talking about solid wood, including those trees that have been “frozen” for a long time, it has a high resistivity. In this regard, the sharpening angle should be reduced. This will practically avoid the occurrence of vibrations, and the movement of the chain will be softer. The minimum value is 25°.

For soft types of wood, the sharpening angle can be increased, but not more than 35°. This will significantly improve productivity. As for the sharpening angle of the chainsaw chain for rip sawing, the value is 10°. In this case, the cut will be as smooth as possible, and equipment vibration will be minimized. Knowing these features, you can move on to considering different sharpening methods.

File

If you decide to use this method to restore the functionality of your chainsaw, prepare:

- a round file designed for processing the edges of teeth with a rounded shape;

- a flat file is needed to deepen or form stops that regulate the depth of cutting of the chain into the wood.

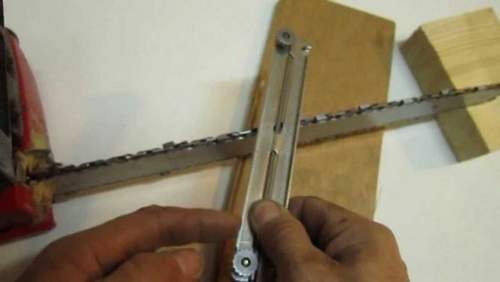

To properly sharpen a chainsaw chain using files, it does not need to be removed from the bar (base). In this case, the tension should be standard, and the system should be put on the brake. Next, follow a simple algorithm:

- inspect the chain for chips, cracks and other damage;

- the sharpening angle must be indicated in the manufacturer's instructions and determined by special marks;

Among the main recommendations of experts on how to properly sharpen a chainsaw chain using files, the following should be mentioned:

- uniform pressure on the file when moving;

- movements of the sharpening tool should be directed only in one direction;

- to sharpen a vertical plane, the file should be placed strictly at a right angle;

- if the teeth differ in height, you should choose the lowest size and adjust the rest to it.

How to Properly Sharpen a Chainsaw Chain with a File

Content

Do-it-yourself chainsaw sharpening

The chain tooth planes wood like a plane, and the thickness of the chips is adjusted by the height of the stop.

The intense work of the saw leads to rapid dulling of the chain. How to properly sharpen a chainsaw chain with your own hands. Several sharpenings may be required during the first day. The problem is also made worse by the fact that the tooth quickly becomes dull when it meets the ground. How to sharpen a chainsaw chain correctly. It is enough to hook the tire into the soil once or twice, and you can stop working. the chips become small and the saw stops going deeper into the tree.

The earlier dull teeth are sharpened, the less material must be removed during sharpening, as a result. The service life of the saw chain is longer. Finding the moment when sharpening is required is quite easy. The main feature is the feed force. A correctly sharpened chain is pulled into the cut even with a slight pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth have become dull. A dull chain can also be recognized if, instead of large thick chips, only small chips fly out of the cut.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. the result is high tension in the body, high repetitive load, and poor cutting results. How to sharpen a chainsaw chain with a file yourself. How to properly sharpen a file before sharpening a chainsaw chain. In addition, this means a decrease in productivity, high fuel consumption and increased wear on all components of the chainsaw.

Chain teeth parameters

To achieve good cutting parameters, the tooth blades are given certain angles. The back of the tooth falling at an angle backwards forms the rear corner of the upper blade . This angle is needed to cut the upper blade into the wood.

The back-tapering blade of the tooth forms the rear angle of the end blade. Tips on how to sharpen a chainsaw chain with a grinder. This angle is needed for side cutting of chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. Rake angles for different types of chains vary from 60 to 85°.

READ Carburetor Settings for Shtil 230 Chainsaw

The rear angle of the upper blade describes the backward tilt of the upper blade .

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50° to 60°. The top blade is the main blade, and the rear corner is the top blade. this is the most important angle. The back angle of the upper blade is difficult to measure; its correct value is formed by observing other prescribed values.

The sharpening angle or leading angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed depending on the application. The basic rule: the larger the sharpening angle, the higher the cutting performance when cutting unfrozen soft wood. Reducing the sharpening angle when cutting frozen and/or hard wood makes the saw run smoother and reduces vibration. However, sharpening angles of more than 35° and less than 25° should be avoided (the exception is rip saw chains, in which this angle is 10°).

The rake angle, sharpening angle and top blade angle change during sharpening. These angles have a decisive influence on the cutting ability of the chain. Be sure to observe the prescribed values.

A depth limiter is located on each cutting link in front of the tooth blade. The difference in height between the top edge of the depth stop and the leading edge of the back of the tooth is defined as the depth stop distance.

The depth of cut of the upper blade into the wood (chip thickness) and thus the productivity depends on the distance of the depth stop. The depth stop distance is set depending on the chain pitch and type of design. How to properly sharpen a saw attachment. Normally it should be 0.5-0.8 mm, more often 0.6 mm. Higher values will make the chainsaw more prone to kickback, excessive grip and chain vibration. Low values lead to poor performance. You can sharpen a chainsaw chain by hand or how to sharpen a chainsaw chain with a file. Since the distance of the depth stop decreases with each sharpening of the saw due to the reduction of the upper edge of the tooth, the depth stop also needs to be filed periodically. after 5-10 sharpenings of the chain.

How to sharpen a chainsaw chain by hand without removing it from the bar with a round file. How to properly sharpen a chainsaw chain with a file, what subtleties you need to know - oral and video advice! Stihl. with your own hands

Many people don’t know how to sharpen

teeth on

the chainsaw chain

and this is quite simple.

round file

4.8 mm and that’s it

READ How Much Does a Cube of Boards Cost?? / Chainsaw Sawmill in Action

The best chainsaw sharpening at home. How to properly install a chain and bar on a chainsaw. WITH A FILE! ! !

The video talks about sharpening a chainsaw with a file

, as well as about the angles that must be observed

General rules for sharpening a chainsaw chain

Chain sharpeners

The round file holder has lines that allow it to be positioned correctly relative to the chain. The holder is installed on the tooth being sharpened in accordance with the orientation lines. In this case, the plate itself rests on the upper edge of the tooth and the depth stop, and the file is located under the cutting edge.

Using a holder ensures that the file rests on the tooth at the correct height. There are different holders available for different saw chain pitches. The correct choice of holder in combination with the correct file diameter ensures that the file extends 1/5 of its diameter above the back of the tooth. Use only special files for sharpening saw chains.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, while maintaining the position of the holder and pressing the file against the edge being sharpened, to make several (2-3) turning movements away from you. There is no need to try to press the file too hard; movements should be smooth and measured. Turn the file regularly to avoid one-sided wear. How to sharpen a chainsaw chain correctly? All other teeth are sharpened in the same way. Discs for sharpening chainsaw chains, how to sharpen a chainsaw chain, share the article: saw chain - cutting tool. Designed for. It is more convenient to first sharpen the teeth of one direction, then change the position and do the same with the teeth of the other direction.

When sharpening all teeth, make the same number of file strokes using the same pressure. How to sharpen a chainsaw chain with your own hands? This will ensure that the teeth have the same length. All cutting teeth must be the same length. Different tooth lengths cause uneven movement of the chain and the formation of cracks in it. If the tooth lengths are not the same, all cutting teeth should be filed to the length of the shortest tooth.

After several sharpenings of the cutting teeth, the depth stop is ground off. To do this, a template is placed on it so that the stop fits into the slot, and the tip protruding from the slot is ground off with a flat file.

Such sets, with different configurations, are sold in many stores that sell tools, for example, various sets and individual files are sold here (it’s better to buy through an online store, because in a regular store of this network the price may be higher).

READ Husqvarna chainsaw stalls at idle

The principle of using another kit for sharpening chainsaw chains is no different from the first, although its design is different.

A round file is also used to sharpen the cutting tooth, and a depth stop is used to sharpen the depth stop. flat. A special template provides sharpening parameters for both cutting teeth and stops. In the first case, it is placed on the chain so that it fits into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. How to sharpen a chainsaw chain at home: video. The direction of movement of the file should be parallel to the side edges of the template.

When grinding the stopper, the template is applied so that the stopper fits into the slot, next to which it says SOFT (for soft wood) or HARD (for hard wood). As in the case of the first device, grinding is done with smooth, even movements of the flat file away from you.

Chainsaw chain sharpening machines

Stihl produces two modifications of hand-held machines. stationary FG 2 and mobile FG 1, installed directly on the bus. How to properly put a chain on a chainsaw photo. How. Ways to sharpen a chainsaw chain at home. There are analogues from lesser-known companies, comparable in price to the simpler devices described above, for example this one.

The working part of these devices is structurally reminiscent of a bow saw, into which a long round file is inserted instead of a saw blade. FG 1 and FG 2 not only sharpen chains, but also straighten them, adjusting the length of the upper edge of all teeth to the same size. according to the smallest tooth, which is taken as the control one. A rather complex configuration mechanism allows you to set all the necessary parameters. Sharpening is done in 2-3 movements, after which they proceed to the next tooth, maintaining for it all the settings that were made for the control tooth. This ensures the same sharpening parameters for all teeth. When grinding the stopper, the round file changes to a flat one.

An electric sharpening machine for chainsaw chains is simple and easy to use. It has an adjustment system that allows you to set the chain at the desired angle and bring the disc exactly to the edge to be sharpened. There are machines that automatically clamp the vice when lowering the disk onto the chain.

Source

Application of special machines

For those who are not just interested in the question of how to properly sharpen a chainsaw chain, but also do it regularly, and are simply tired of working with a file, you should pay attention to universal power sharpening machines. These are devices with provided settings, using which correctly, you will position the chain at the required angle, with maximum accuracy and carefully bring the sharpening disk to each tooth.

There are also installations equipped with automatic vices, which turn on when the disk approaches the edge of the cutting elements. Models differ in a variety of additional functions and prices, so you can always choose the one that suits you.

Sharpening on a machine

Manually operated installations are effective. In terms of design features, such devices resemble a bow saw. The principle of working with such a machine is somewhat more labor-intensive than that described for the previous method, however, using this device you can perform several options at once:

- adjust the proportionality of the upper edges of the cutting elements;

- accurately set dimensions and parameters;

- When working with a file, 3-4 movements with a file are enough to sharpen one tooth.

The round and flat files provided with the unit can be quickly changed if necessary. Using a manual machine, you will quickly figure out how to properly sharpen a chainsaw chain, without much physical effort or loss of time, restore its functionality and the quality shape of the teeth.

How to sharpen chainsaw chains with your own hands

Sharpening a chain with your own hands is a rather complicated process, and in order to do it correctly, you need to know some nuances. After carrying out the work, the chain must comply with the parameters set by the manufacturer. This is very important, since the parameters of the engine and drive sprocket are calculated based on the characteristics of the saw chain. If it does not correspond to them, the tool may not work correctly. You cannot grind the teeth too much, changing their geometry and dimensions. Such actions can lead to uneven wear and breakage of the chain, which is always very dangerous.

When sharpening a chain, you need to know its structure. The chainsaw chain consists of cutting links: right-handed and left-handed, the configuration of which is mirrored. The links are installed one by one.

The link itself consists of several parts:

- Front and back bevels.

- Holes for bushings and axles that connect the chain together.

- Cutting depth limiter.

- Top edge.

- Working angle.

- Side cutting edge.

It is the sharpness of the last two parts that affects the operation of the entire instrument, which is why they are sharpened.

There are two ways to sharpen a chainsaw chain:

- Manually, using a special file for this.

- On a special sharpening machine.

Sharpening using a machine makes sense for large volumes of work, when the tool has to be serviced frequently. It is usually used in tool shops of logging and processing companies. There is no point in buying a machine that costs a lot in order to sharpen a chain a couple of times in a decade. Sharpening teeth by hand, although it takes time, is not so expensive.

Some expert advice

Experts advise that before starting work, break in the chain a little, that is, spin it at high speeds for no more than 1 minute. To lubricate the chain, it is recommended to soak it in oil. This way the lubricant will get to all the necessary parts, and the sprockets will rub against each other more tightly. The tension can be adjusted when the chain cools down.

Do not forget about regular lubrication, control the chain tension, and never fill the system with used engine oil. Check the cutting depth after a couple of sharpenings.

If you do not pay attention to the fact that the chainsaw chain has become dull, be prepared for the fact that, at best, there will simply be uneven cuts and a high load on a person’s hands. Much worse and more expensive is high fuel and oil consumption, critical - failure of the saw itself. Repairing or buying a new one will cost much more than sharpening the teeth.

back to blog