Creation and release of a car

GAZ 322132, like other cars in the line, was produced at the Gorky Automobile Plant and first tested in 1994. The initial launch of the model was designed for private cargo transportation, so the vehicle’s characteristics are fully adapted to the technical requirements for cargo transportation. Later, the car established itself in the field of public transport: passengers massively appreciated the mobility and compactness of the minibus.

GAZ 322132

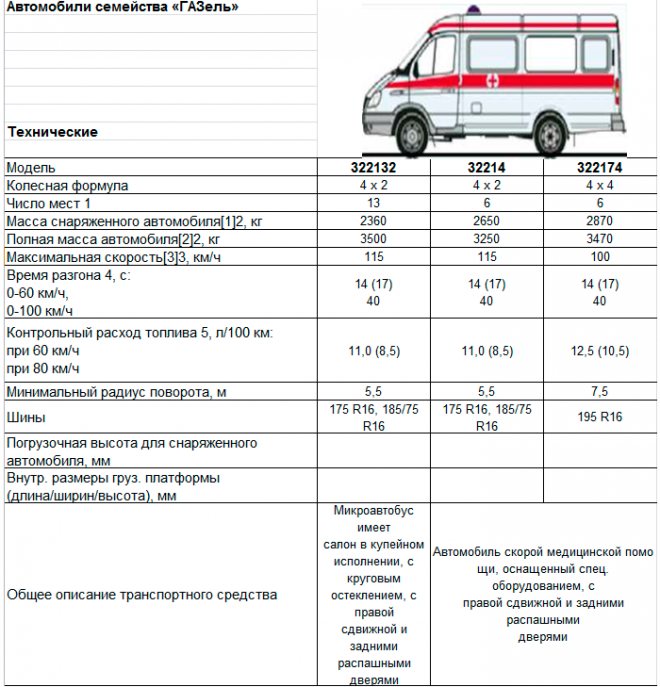

Technical characteristics of GAZ 322132 represent a set of the following qualities:

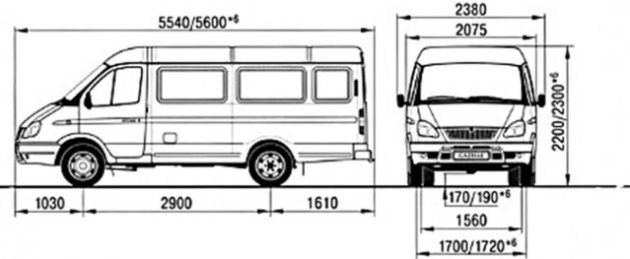

- compact dimensions (width - 2380, length - 5600, height - 2300 cm);

- high load capacity (max = 1.5 t);

- gasoline engine (power = 140 hp);

- anti-lock wheel system;

- upgraded heating and interior improvements;

- sliding or swing door;

- boarding up to 13 passengers.

GAZ 322132 - dimensions

This car is also loved by drivers for its ease of maintenance and excellent technical characteristics. An additional step attached to the main profile of the body makes it possible to safely climb into the car interior. The GAZ 322132 model easily transports passengers along numerous city, tourist and excursion routes.

The van is divided into two conventional zones: the driver’s cabin and the space for passengers. There are two additional passenger seats next to the driver in the cabin, and 13 people can be seated in the main cabin.

Technical characteristics of GAZelle GAZ 322132 “Ambulance”

This GAZ model is equipped with side windows with an adjustable gap and a roof hatch that improves the natural ventilation of the space. The rear doors are normally locked, but in emergency situations, evacuation can be carried out through them.

GAZ-11-40 | Russian technology

data-ad-layout=”in-article” data-ad-format=”fluid” data-ad-client=”ca-pub-5255833501835364″ data-ad-slot=”8753833479″>

GAZ-11-40 - an experienced phaeton

GAZ-11-40 second sample with the top up

In 1936, when I.V. The first copies of the GAZ-M1 were presented to Stalin in the Kremlin; the Soviet leader expressed his desire to build a modification with an open top for the southern regions of the USSR on the basis of a closed passenger car. Although the Gorky Automobile Plant was overloaded with orders at that time, representatives of the automobile plant in the Kremlin still had to promise to build such a car.

Here is what Avtostroitel magazine wrote about this event in 1938:

“The desire to most fully satisfy the growing needs of the southern regions of the USSR with a mild, even climate and short winters raised the question of creating a new phaeton.”

The prototype for such a car, which received the index GAZ-11-40, was the Ford Model B. The new model with a light fabric top was intended both for the southern regions of the country and for the command staff of the Red Army.

From the diaries of the chief designer of the Gorky Automobile Plant A.A. Liphart, March 19, 1936:

“At the suggestion of comrade. Stalin, we must organize the production of new passenger cars with open bodies. Designing an open car with a good body is not an easy task. The body is a labor-intensive and serious part of the car. A car with an open body should not look like a poor peasant's phaeton, as Comrade Putin put it. Stalin, what a good cultural machine.”

The first and second samples of GAZ-11-40

The first two bodies of the GAZ-11-40 phaeton were built at the end of 1937 and installed on the chassis of conventional GAZ-M1.

A 3-speed gearbox (three forward speeds and one reverse) and a 3.28-liter gasoline, in-line, four-cylinder, low-valve engine were attached to a reinforced X-shaped cross member with a trapezoidal-shaped steel frame with box-section spars and traverses in the front part. and power 50 hp. at 2800 rpm. A water cooling radiator was mounted in front of the engine. A single-plate, dry clutch was used to transmit torque. Electrical equipment was 6 volts. The tank was located in the rear overhang of the frame, and fuel was supplied to the carburetor using a fuel pump.

The axles of the GAZ-11-40 were suspended from the frame on longitudinal springs, and lever-type hydraulic shock absorbers were used to ensure a smooth ride. The rear axle had a bevel gear and was connected to the gearbox using a cardan shaft, which was enclosed in a pipe and rigidly attached to the main gear housing. Disc wheels with rubber tires measuring 7.00-16 were attached to the car axles. The service shoe brake had a mechanical drive and acted on all wheels, the parking brake was also a shoe brake with a mechanical drive and also acted on all wheels.

An open four-door all-metal body was installed on the chassis, the rear of which was shaped with rounded sides. The doors were hung on front hinges. Two windshield wipers were attached to the upper frame of the windshield to facilitate visibility in bad weather, which had a vacuum drive, the hose of which was connected to the carburetor inlet manifold. Metal bumpers served to protect the body from minor damage. The spare wheel was mounted on the front fender of the car and covered with a removable metal casing. At night, the road was illuminated by two electric headlights and two side lights with brake lights, which were attached to the wings. Also, side lights were located on top of the front fenders. Footrests were located between the front and rear fenders to facilitate entry into the car. At the rear of the body there was a trunk with a metal lid. There was a tool storage box in the trunk floor. To protect from bad weather, there was a folding awning, for storage of which there was also a box in the trunk. Also, in inclement weather, soft side panels were attached to the body using special fasteners on metal stands. For better sound insulation, the body walls were covered with mastic, and the floor was covered with rubber mats.

Inside, the seats, which were upholstered in dermantine or leather, were located in such a way as not to cause fatigue on a long journey. The front seat of the GAZ-11-40 was a comfortable and spacious sofa, designed for two people. The rear seat was designed for 2-3 people, while a niche was made in the lower part of the front seat, allowing the passengers sitting behind to stretch out their legs. The front doors had comfortable armrests for the driver and passenger, which also served as a handle for closing the door. To protect against the wind, the A-pillars had rotating side windows, and for protection from the sun, there was a visor on the subframe.

data-ad-layout=»in-article»data-ad-format=»fluid»data-ad-client=»ca-pub-5255833501835364″data-ad-slot=»8753833479″>

The phaeton is equipped with a new instrument panel on which a push-button engine starter is installed.

In August 1938, both bodies were moved to a modernized GAZ-M11 chassis with a Dodge D5 engine, which featured a reinforced front axle and swing arms, elongated springs for better ride smoothness, double-acting lever shock absorbers, a semi-centrifugal clutch and a new radiator. Another year or two later, the same bodies were installed on all-wheel drive GAZ-61-40.

The first two samples were distinguished by flat windshields and the same wind window frames, and among themselves - by the contours of the trunks and hinged detailing: the dark phaeton had an evenly sloping stern and an awning recessed into the body.

GAZ-11-40 second sample with open top

The third sample of GAZ-11-40

In 1938, a third model of the phaeton with a Dodge D5 engine was built on a modernized chassis, which was distinguished by a wind-driven frame with wedge-mounted glass, separated by a massive jumper.

GAZ-11-40 third model with open top

In July 1939, this body was also transferred to an all-wheel drive chassis and received the GAZ-61-40 index, and by November it was again transferred to the new GAZ-M-11 chassis and repainted in a dark color with new parts based on the model of that year. In 1940, this body was again transferred to an all-wheel drive chassis and painted gray.

Note: After installing the body on a new chassis, the car is counted as a new sixth copy, although its body was already in use.

GAZ-11-40 body on the new GAZ-M-11 chassis

The overall dimensions and weight of the third GAZ-11-40 sample were:

- length – 4655 mm;

- width – 1750 mm;

- height with the top up – 1760 mm;

- wheelbase – 2855 mm;

- curb weight – 1570 kg;

- maximum speed – 120 km/h. GAZ-11-40 second and third samples

The fourth sample of GAZ-11-40

In the same 1938, a fourth model of the phaeton with a Dodge D5 engine was built on a modernized chassis, which was distinguished by a flat trunk profile, a round-nosed radiator lining and a composite window frame with a transom: the two-section glass was slightly opened for ventilation.

On September 22, 1938, at 6 pm, four copies of phaetons, along with a GAZ-M415 pickup truck and a GAZ-60 half-track truck, were presented in the Kremlin by I.V. Stalin.

Below is a note about this event by the director of the Gorky Automobile Plant I. Loskutov, published in the Pravda newspaper:

note about GAZ-11-40 phaetons

At the end of the summer of 1939, the body was moved to an all-wheel drive chassis and, after a series of factory tests and climbing steep flights of stairs in Moscow and Gorky, after which it was sent to a military training ground in Kubinka. Then the GAZ-61-40 was transferred to Voroilov, and in July 1941 it was sent to the commander of the 19th Army, General Konev, near Smolensk.

Model components

This GAZ model borrowed the front shock absorber suspension and body elements from the base van. Over 20 years of active production, GAZ of this configuration has undergone numerous changes. The design of the main profile, the design of the command panel and the layout of the seats have been improved in accordance with modern requirements.

GAZ 322132 - suspension

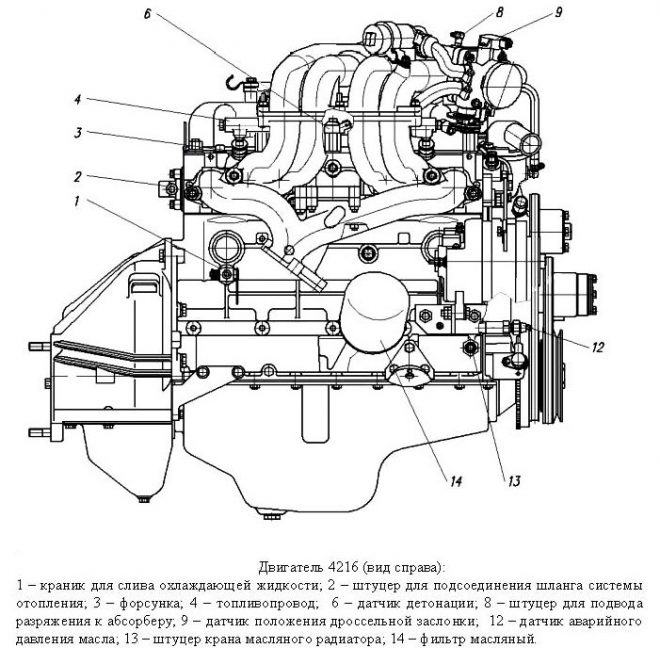

Various modifications of the Gazelle 32213 differ in the technical characteristics of the engines. The first option is a domestically produced UMZ-4216 motor. The power mechanism of this engine has 4 cylinders and has the following characteristics:

- volume – 2.9 l;

- power – 123 l. With.;

- torque – max 230 N/m;

- piston stroke – 92 mm.

UMZ-4216 engine - diagram

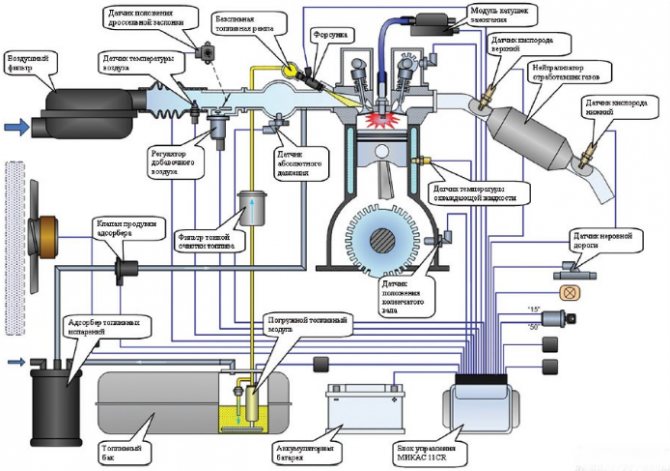

The second engine option is a Chinese-made Chrysler 2.4L DOHC unit. This gasoline engine has 4 cylinders and is characterized by the following technical qualities:

Chrysler 2.4L DOHC Engine Management System

- volume – 2.4 l;

- power – 137 hp. With.;

- torque – max 224 N/m;

- piston movement coverage – 101 mm.

The GAZ 322132 minibus is equipped with a special cooling system. Both engine variants operate with the same power transmission mechanism. The vehicle's transmission is provided by a 12-speed manual gearbox. The shock absorber system, responsible for absorbing external shocks and shocks, is presented in the form of front and rear suspension with telescopic sensors.

The brake system of GAZ 322132 is a combination of front disc mechanisms and rear drum mechanisms. Power steering facilitates vehicle control and ensures comfortable driving. The steering wheel with a hydraulic system is also responsible for the safety of transporting passengers.

GAZ - 233114 » TIGER » full review of the car

All-wheel drive vehicles were born largely thanks to the aspirations of military people. They are the ones who are more interested in cars that can travel not only on good roads. The best cross-country vehicles still serve in the army, although, of course, civilian products have made great strides forward. The flagship of the Russian army in terms of compact SUVs, that is, not trucks, must be recognized as the Tiger car, or GAZ-2331xx. Let's get acquainted.

We are unlikely to be mistaken if we say that the average person perceives the Tiger as our answer to the Hummer. In fact, as you know, this answer is not entirely ours - King Abdul II of Jordan planned to create an alternative to the famous American military SUV.

The story of placing an order in Russia is well known. Indeed, there is something in common between the Hummer H1 and the Tiger, despite the significant differences in the appearance and design of these cars. Apparently, related associations arise due to the overt aggression in the appearance of the cars, and here, perhaps, the American model will even be ahead - probably because of its predatory squatness. However, these are all subjective sensations. If we talk objectively, then our car is more modern - its development was carried out in the early 2000s, while the first Hummers appeared much earlier.

FROM SAFE TO TIN

Tigers were accepted for supply relatively recently - in 2007. We will find them both in the units of the Ministry of Defense and in the structures of the Ministry of Internal Affairs. Cars bearing different digital indices, while having a single essence, differ slightly in bodywork. In particular, options with opening windows are possible, as in our case, but there are solid hulls, the sides of which only have loopholes. More important are the differences in booking class.

The vast majority of Tigers are equipped with heavy armored bodies, and the degree of protection for the crew may vary depending on the specific purpose of the vehicle. But since everything is for sale these days, because everyone around them wants to make money, there are also unarmored options, so to speak, for civilian use. They are produced in single copies for exclusive orders. Not every off-road enthusiast can buy such a car - the price starts from about $100,000. However, some of our contemporaries, whose names are well-known, have such cars in their fleet. But let's focus on the technical side of the issue.

INNER WORLD

At the central training ground 21 of the NIMI MO in Bronnitsy, GAZ 233114, or Tiger-M, was waiting for me. In this modification, the SUV acts as an AMN - a multi-purpose vehicle, i.e. it is designed to transport personnel and cargo along roads and terrain both in peacetime and in conditions of active hostilities. In addition to the driver, the car can accommodate 8 people: one in the front right seat and seven in separate seats installed along the sides. Along, but not closely, as I noted, significant space is eaten up by the rear wheel arches. They tell me that in machines designed for mounting various equipment, space is used more rationally. In our version, I found fastenings near the sides, the purpose of which is easy to determine - AKMs are fixed in them.

The driver-mechanic and commander are separated by a wide tunnel partition. The box protrudes strongly and backwards, again eating up useful space. Two levers protruding from it leave no doubt - a manual gearbox and transfer case are hidden under the casing. The first is five-speed, the second is two-speed, both units are domestically developed, especially for the Tiger. On cars of early years of production, imported units were used. All-wheel drive is permanent, but the center differential can be forcibly locked. You don’t need to pull any lever for this - the control is pneumoelectric: press the corresponding button on the front panel - and you’re done. It’s just some kind of comfort unusual for military equipment, however, time moves forward.

Useful: Acura announced ruble prices for two crossovers

The front panel, by the way, is impressive: no plastic - metal everywhere! They tell me that, firstly, there used to be plastic - not the best option for an army vehicle, and secondly, the panel was three-sectional, and not solid, from side to side. This significantly increased maintainability. Now, if there is a malfunction, for example, in the wiring, you do not need to dismantle the entire panel; it is enough to remove one section. Everything is screwed - maybe not very aesthetically pleasing, but reliable.

I wouldn’t envy the tall commander; even I didn’t find it very comfortable to sit on the right. Your knees rest against the Torpedo, you can’t stretch your legs - it’s noticeably tighter than in a regular car. Of course, there is no glove compartment, although, by analogy with civilian cars, the eye is looking for it here. There is only a commander's backlight, and your hands involuntarily grab the wide handrail. On the left - on the tunnel and on the front panel, in front of the thick semi-resistant windshield - there are powerful steel plates for attaching special equipment.

However, the description of the interior had to begin with the process of entering the cabin. The metal door handles recessed into the niches, which are thick curved steel strips, must be pulled down with all your might - then the locks will open. The surprisingly massive and thick door opens and closes easily, there is no need to slam as hard as you can. If mines are exploding around you, you can seal yourself in the belly of the Tiger by sliding the lock bolts into the grooves on the upper edges of the doorways, like in a safe. To complete the experience, you can also lower the blackout curtains on the windows. But closing the door with one hand is not so easy: as soon as you open it completely, a metal latch pops out and rests against the counter. This simple design will be more reliable than any door stops used on conventional cars! But every time you have to release the latch with your second hand when closing the door, it’s inconvenient when you’re not used to it.

THE WEAK LINK

The vast majority of "Tigers" are made with this type of body - with three doors. The third, large double hinged door for disembarking/embarking the crew, is located at the rear. By the way, armored hulls are supplied to the Arzamas Machine-Building Plant, from Vyksa, from a plant called “Hull Plant”. A full-size spare tire hangs on the right door leaf, as we write in our reports on regular SUVs. A wheel with a KI-115AM tire measuring 12.00 R18 (the same ones, for example, we will find on the GAZ-33081 “Sadko”) weighs a lot, so a manual winch is provided for its removal and installation. “Won’t the door sag?” - I foresee the question of the corrosive reader. We are not entirely accurate: the spare tire is not attached directly to the door, but to a gate welded from a powerful pipe. And the gate hinges are located on the edge of the body, and for this complex articulated structure to work, the gate rests on the door through a roller. Advanced jeepers are probably familiar with this type of gate; it’s a high-tech tuning, but it’s a factory design.

To complete the topic of wheels, we note that, according to the military, this is the only element of the Tiger design that needs modernization. Tires are the Achilles heel of the wheeled vehicles of our armed forces, and all stakeholders recognize this. Almost all equipment runs on ordinary civilian tires, which in modern conditions do not satisfy the military either in terms of permissible load or reliability in difficult road conditions. It comes to the use of imported samples on prototypes of military equipment, which does not meet the basic principle: domestic military equipment - domestic components. In particular, the current Tiger wheels limit the use of an SUV for mounting equipment based on load capacity. In addition, they are not bulletproof and do not have a mine insert. In combat conditions, the Tiger can lose mobility only because of its wheels, but an armored vehicle capable of protecting its crew must be able to leave the battlefield under its own power. Of course, there is a centralized wheel inflation system, but if the tires are significantly damaged, when several wheels are punctured, it is powerless. The issue of special wheels that meet the purpose of the vehicle is now being actively studied, and there is hope that within this year the Tiger will receive new wheels.

Useful: New Ford Mustang: a step into the future

HEART OF THE TIGER

Although the body here is very strong, it is not load-bearing - a real SUV should be framed. The suspension of all wheels is independent, on wishbones, torsion bar, which, together with the final drives, provides the car with an impressive ground clearance of 400 mm. Looking under the car, I saw that no elements protrude below the frame - the ramp angle here is excellent. Front and rear overhangs are also minimal.

I ask the driver to open the hood. It is very heavy, since it is also made of armor plate, but the four gas shock absorbers on the sides do a good job of compensating for the heavy weight. However, these are minor things. What's impressive is the engine. Diesel YAM3-5347-10 rises above the edge of the engine compartment, like some kind of giant. By the way, the products of the Yaroslavl "Avtodiesel" appeared under the hood of the "Tiger" relatively recently; Cummins diesel engines were previously used. Nearby is a huge 100 Ah battery. The air filter housing, located on the other side, is connected to the snorkel, and upon closer inspection, all air path connections look very solid. According to the technical specifications, the car is capable of fording waters up to 1.2 meters deep, but it seems that it will safely endure more serious swims. They say that there is not much water entering the cabin, everything is fitted so well, the doors fit tightly. In general, the Tiger’s water resistance is significantly better than that of most of our AMNs that share platforms with civilian models.

YOU CAN'T KEEP UP WITH HIM!

But we won’t dive - some other time. Just take it for a drive to get an idea of the car. Of course, the ground is frozen; there is no strong mud that I observed here during my previous visits to the test site. But all the same, the Tiger’s capabilities are impressive: the driver steers the SUV up steep hills, descends them, storms caponiers on the move, breaks ice in a puddle - the car falls into liquid mud up to the bumper, but confidently gets out of an ambush. By the way, in addition to the center differential, you can also forcibly lock the cross-axle differentials, again using an electro-pneumatic drive.

I ask you to drive. No premium-class Toyota or Nissan, which cost about the same as a civilian Tiger, will drive like that over rough terrain! The torsion bar suspension, made by analogy with the one on the armored personnel carrier, works wonders. We flew along the dirt road broken by heavy equipment and along the ruts at full speed, practically not feeling what a nightmare was happening under the wheels. By the way, modern Tigers have two shock absorbers in the rear suspension (previously there was one), so the energy intensity of the suspension has been increased. I also liked the steering: the power steering works great, but there is also feedback. It didn’t take me even a second to get used to the car. With such external severity, the Tiger turned out to be very friendly to both the driver and the crew. Frankly, in the case of domestic military equipment, this is perhaps the first opportunity for me to be pleasantly surprised. Usually one is struck by the cross-country ability and reliability of the design, but not by its adaptability to humans, but here there is complete harmony of appearance and content.

Interior arrangement

GAZ 322132 - passenger seats

Before launching the van into mass production, the developers approved several variations of the layout of the car showroom seats. The dimensions of the car allow it to accommodate 13 passenger seats. The high-quality distribution of seats in the cabin of the GAZ 322132 guarantees comfortable movement along the desired routes.

The spacious passenger compartment is combined with a semi-open driver's cabin. The large dimensions of the windshield provide the driver with an excellent view of the surrounding area. The driver's seat has a high seating position and lateral support. The good design of the machine is also confirmed by the compact control panel, which includes a speedometer, three-speed stove control and other command levers.

The car showroom is additionally heated using a tank and ventilated through a skylight.

In general, the body of the GAZ 322132 minibus has excellent technical characteristics, but its key drawback is the finishing material. The metal from which the van's cover is made is of rather low quality. With prolonged use, the body will rust. Many car enthusiasts extend the life of the coating by using anti-corrosion impregnations and oils.

Driver's workplace GAZ 322132