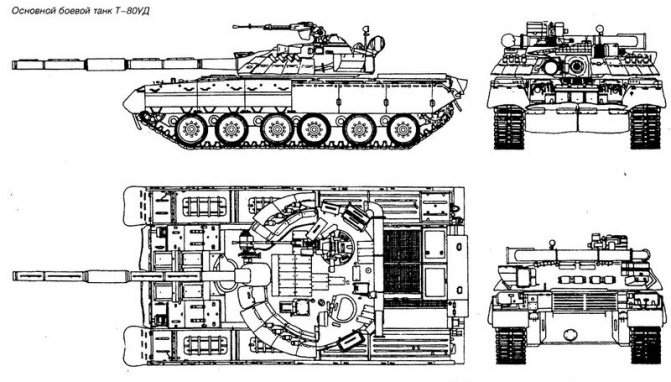

The T-80 is the world's first mass-produced tank with a gas turbine engine (GTE). Work on equipping tanks with power plants of this type began in the late 1950s. At that time, helicopter engines were installed on prototypes of combat vehicles. It quickly became clear that they were unable to operate normally in ground conditions - vibration and clouds of dust quickly disabled the gas turbine engine. We had to develop the engine from scratch. But where did the idea of installing a gas turbine engine on a tank come from? “Firstly, in this way they wanted to solve the problem of increasing the combat readiness of the vehicle in our harsh climate,” says Sergei Suvorov, a military expert, candidate of military sciences, and a former tank officer. — In order for a tank with a diesel engine to start moving at temperatures from 0 to -20 ° C, it is necessary to first warm up the engine using a special device - a heater - for 20-30 minutes, then start the power unit and warm it up for about 10 more minutes at idle until the coolant temperature in the cooling system rises to approximately 40 °C. Thus, in winter it takes a total of 30-40 minutes for a tank to leave the park on alarm, which is a lot in combat conditions. The gas turbine tank can start moving within 45 seconds after pressing the engine start button, regardless of the ambient temperature.

The second advantage of gas turbine engines is the so-called engine adaptability coefficient. The higher its value, the simpler the gearbox design can be. The T-80 gearbox is similar to that installed on the T-64, but one planetary gear has been removed - as a result, instead of seven gears, there are only four. And simplification always means increased reliability and cheaper design, reducing driver fatigue. However, the gas turbine engine itself is noticeably more expensive than the diesel engine.”

Don't suffocate in dust

Another impetus for Soviet designers was the information that the United States had become interested in the topic of gas turbine tanks. In the conditions of the Cold War and the arms race, the Soviet leadership could not ignore such information. Our defense industry had to urgently get to work, and as a result, the T-80 was born several years earlier than its gas turbine competitor, the M1A1 Abrams tank.

One of the main tasks that the designers had to solve was protecting the gas turbine engine from dust. The resulting air purification system is unique and has no analogues in the world. The gas turbine Abrams also has a cleaning system, but during the American operation in Iraq “Desert Storm” it turned out that in a sandstorm, an American tank could move or stand still with the engine running for no more than 15 minutes. Then we had to stop and shake out the sand from the paper filters. In the T-80, direct-flow cyclones - vortex gas scrubbers - fought dust. In addition, the pneumatic vibrator shook off sand from the nozzle apparatus that was most susceptible to contamination. After stopping the engine, the dust was also shaken off the turbine blades, and sand did not bake on them in the form of a glassy mass.

Weapon

Enemy Trophy: Test Drive of the Panther Tank

How does a gas turbine engine work? If we consider in more detail the process of operation of a gas turbine engine, we can distinguish several stages that, when combined, describe the complex process of converting the energy of compressed gas into mechanical work. What are these stages?

- Feed and mix. Atmospheric air in compressed form enters the combustion chamber from the compressor. Fuel also goes there, resulting in a fuel mixture that releases a lot of energy during combustion.

- Transformation. After the fuel mixture is converted into energy during the combustion process, it must be converted into mechanical work. This occurs due to the rotation of special “blades” by a gas stream under high pressure.

- Division of work. Part of the resulting mechanical work from the energy of the fuel mixture is used to compress the air for the next supply in the compressor, and the rest of the energy is transferred to the driven unit.

It is the work that is transferred to the driven unit that is called useful! By the way, a gas turbine engine is rightfully considered an engine with the highest power density among other internal combustion engines. Almost any fuel can be considered fuel for a gas turbine engine: kerosene, gasoline, fuel oil, natural gas, diesel fuel, marine fuel, water gas, alcohol, and also fine coal!

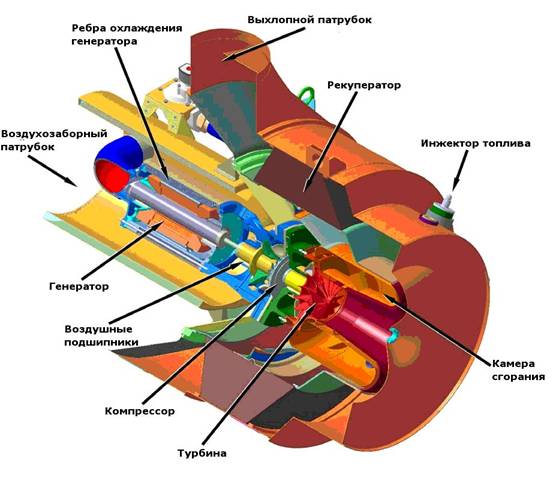

Operating principle of gas turbine engines. To achieve high efficiency in a heat engine, it is necessary to achieve a high combustion temperature of the fuel mixture, but this cannot always be achieved. Obstacles include the inability of the materials from which the engine is built (nickel, steel, ceramics and others) to withstand high temperatures and pressure. A very large amount of engineering work has been aimed at successfully removing heat from the turbine and using it where it is needed. We can safely say that their work was not in vain, because now, thanks to such developments, this goal has been achieved by redirecting the heat of the exhaust gases to compressed air. This process is called recovery. This is a very successful approach, because otherwise the heat of the exhaust gases would simply be lost, and so, it can serve as a source of heating of compressed air, before the further combustion process. Thus, we can safely say that without this process and special heat exchangers (recuperators) it would not have been possible to achieve such a high efficiency.

The maximum rotation speed of the turbine blades determines the maximum pressure that must be achieved to obtain the highest engine power. In this case, as a rule, the smaller the engine, the higher the shaft rotation speed must be in order to maintain the maximum speed of the turbine blades.

Construction of a gas turbine engine. As for the device, everything is not as complicated as you might imagine. A gas turbine engine consists of a combustion chamber, where spark plugs and an injector are also installed to supply fuel and produce a spark in the combustion chamber. A turbine wheel with special blades is mounted on the same shaft as the compressor. The engine design also includes: a reduction gearbox, a heat exchanger, an exhaust pipe, an intake duct, as well as a diffuser and nozzles.

As the compressor shaft rotates, its blades capture air that enters through the inlet duct. After the compressor increases its speed to 500 meters per second, it pumps it into the diffuser. At the outlet of the diffuser, the air speed decreases, but its pressure also increases. After the diffuser, the air enters the heat exchanger, where it is heated by the heat of the exhaust gases and passes into the combustion chamber. In addition to heated and compressed air, fuel is constantly supplied into the combustion chamber in atomized form through a nozzle. Fuel is mixed with air to form a fuel mixture, which is then ignited by a spark produced by a spark plug. As a result of combustion, the pressure in the chamber increases, the heated gases pass through the nozzle and fall on the turbine wheel blades, which are set in motion. The torque of the turbine wheel is transmitted through a reduction gearbox to the vehicle transmission. The exhaust gases enter the heat exchanger, where they heat the incoming compressed air and are released into the atmosphere.

The main disadvantage of a gas turbine engine is the cost of heat-resistant materials from which the engine must be built. In addition, the complexity of the work and the high degree of purification of the air that enters the engine are also hard on the pocket, but no matter what, the development and improvement of the gas turbine engine is already in full swing both in our country and abroad.

Types of gas turbine engines. Regarding the types, there are a very large number of them, while the essence of the work is the same, but the execution is slightly different. Depending on the type, the gas turbine engine is widely used on ships, trains, cars, airplanes, helicopters and even in tanks. By the way, today only the American Abrams M1A1 tank is equipped with a gas turbine engine. Soviet engineers also tried to use gas turbine engines on tanks, there were even several prototypes based on the T-80, but for some reason further developments were curtailed.

Comfort and cleanliness

“When the T-80 is moving towards you, you can’t hear the car at all at a distance of up to 30 m,” says Sergei Suvorov. — The first thing that reaches the ear is the clanging of the teeth of the drive wheels. The tank does not smoke, releasing almost clean hot air. I served on the T-80 and I think that in terms of comfort among domestic tanks it had no equal until the appearance of the T-90AM. Fairy tales about comfort in Western-made tanks have remained fairy tales. The level of ergonomics in all Abrams, Leopards, Merkavas and other Challengers is approximately at the level of the T-55 or T-62. In the "eighties" at -35°C, the driver took off his clothes and underwear, I sat in the turret in the commander's seat in chrome boots. No mittens - thin leather gloves. You can’t drive other cars in the cold without several layers of clothing, fur mittens, a woolen face mask and felt boots.”

The T-80U is the most advanced vehicle of the entire T-80 family today. In this modification, which appeared in 1985, a new set of weapons was used. A few years later, the same complex was installed on the T-72B tank, after which and a number of modifications the tank received the name T-90. It has a more powerful GTD-1250 engine (1250 hp versus 1100 hp for previous modifications).

Last year, reports appeared about plans to modernize the country's fleet of T-80BV tanks, which includes several thousand vehicles, and although the parameters of the program have not been officially announced, it can be assumed that the result will be a combat vehicle that is not inferior in combat properties to the T-80U (and in superior to it in some respects). The engine will probably be replaced with a GTD-1250, the tank will be equipped with a 1A45 Irtysh fire control system with a laser sight-rangefinder, a digital ballistic computer, a combined night sight and a guided missile system capable of firing Invar-M type missiles. The vehicle will also receive modern dynamic protection.

AutoXS.ru - Auto Encyclopedia

- 12-05-2019, 19:14

- Articles / Miscellaneous about cars

- Author: VexterXS

This article will discuss the pros, cons and general operating principle of a gas turbine engine (GTE), as well as a brief comparison with an internal combustion engine. The text is divided into logical paragraphs with subheadings and lists.

Due to the unstable economic situation in the world, we have to look for ways to save money. Owners and future buyers of a car first of all think about the efficiency of their car. The installation of a gas turbine engine (GTE) has gained great popularity.

A gas turbine engine (GTE) is a heat engine in which the energy of heated and compressed gas is converted into mechanical energy on the turbine shaft. A gas turbine (French turbine from Latin turbo - vortex, rotation) is a bladed machine, in the stages of which the energy of compressed and/or heated gas is converted into mechanical work on the shaft. (from Wikipedia)

Device

There are only two types of gas installations that really have an advantage over internal combustion engines:

• With several shafts

Most often, such an engine operates 2 turbines (one drives the compressor, and the other drives the car), which are not connected to each other, which increases efficiency. The compressor pumps air into the combustion chamber, creating pressure at the same time as the injector supplies fuel. Due to strong compression, the gas ignites and flies out at high speed onto the traction and compressor turbine.

• With free-piston system

Oppositely placed pistons under air pressure compress the combustible mixture, as a result of which it ignites and pushes them back, and then exits through the outlets, while rotating the turbine. Due to the design features, such an engine can only be made two-stroke.

ICEs are not divided into types, because they all have the same operating principle: the piston, returning to the bottom, creates a vacuum and sucks the combustible mixture into the cylinder (in many cars a supercharger does this). Then it moves again to top dead center, after which ignition occurs in the combustion chamber, and the pressure of the gases moves the piston back down, rotating the crankshaft.

The combustible mixture can form internally (in the cylinder) and externally (in the carburetor). Ignition occurs either due to strong pressure or is provoked by a spark.

Advantages and disadvantages

This section shows the advantages and disadvantages of a gas installation relative to an internal combustion engine!

Gas engines have gained popularity due to a number of advantages:

• High efficiency.

In advanced industrial installations, efficiency can reach even 90%, but in cars the average is 65%.

• Economical

Fuel consumption is not much different, but the price of gas is noticeably lower. Due to the fact that the efficiency is higher, fuel is consumed more efficiently. As a result, the total savings are about 60%!

• Theoretical reliability

There are almost 2 times fewer moving parts in a gas turbine engine. More flexible requirements for the lubrication system. All this significantly reduces the chance of serious damage.

Many people do not like the gas installation because of one serious drawback:

it is necessary to carry out maintenance annually (this is very often), because the gas turbine engine, unlike the diesel engine, can explode, and this is fatal.

During maintenance, small parts are replaced: filters, gaskets, etc.

Is it worth installing a gas turbine engine?

It all depends on the buyer's finances. If you have money for a new car, then it's not worth it. For the city it is better to buy a hybrid or electric car, and for long trips - a car with a standard internal combustion engine. If there is no money to buy a new car, everything depends on the consumption of the existing one. For example, on modern foreign cars it is most likely not worth changing the engine, but on an old VAZ 2109 a gas turbine engine will save a lot of money.

With proper attention and attitude, a gas installation will save a significant amount and will last at least 20 years!

On the way to a hybrid

One of the main complaints against the T-80 tank is the gluttony of its gas turbine engine. It’s hard to argue with this - gas turbine engines really consume more fuel than diesel. “The main type of fuel for this tank is diesel fuel,” says Sergei Suvorov, “but the T-80 can run on kerosene and gasoline mixtures. Once, while serving in the Urals, I was faced with a situation where my tanks were practically running on water. Our tanks were filled with some kind of white, milk-like liquid, which probably contained at least 50% water. I then asked myself the question - how long would Abrams drive on this hellish mixture? And the T-80s drove around as if nothing had happened. Moreover, the air temperature that day was below -10°C. But the battalion passed the test. However, then problems with the operation of the engine fuel system began due to moisture.”

According to Sergei Suvorov, the relatively low efficiency of the T-80 is associated not only and not so much with the use of gas turbine engines, but with the design of tank gas turbine engines. Unlike a diesel engine, the T-80 engine has lower throttle response. To reach maximum speed, and therefore power, a diesel engine needs half a second, while a GTD-1000/1250 needs three to four seconds. If there is a hole in the path of the tank, the driver must release the gas pedal, that is, reduce the fuel supply. The engine suddenly slows down and the tank actually stops. Then the mechanic presses the fuel pedal again, but it takes a few more seconds for the turbine to spin up again. To avoid standing in pits, tankers were trained to spin the turbine to maximum speed, and then slow down in the pit using the braking system. At the same time, the tank does not stall - since there is no rigid connection between the engine turbine and the transmission, the connection between them is only gas-dynamic, but the fuel continues to flow like a river. “The tank gas turbine engine initially used a not entirely correct fuel supply ideology,” explains Sergei Suvorov. — For example, in a number of aviation gas turbine engines, after startup, a given value of constant revolutions is automatically maintained, and the power on the shaft is controlled by changing the fuel supply, without changing the turbine speed. If the same system existed in a tank engine, then the fuel consumption would be almost the same as on a diesel engine.” However, the design idea does not stand still. A promising gas turbine tank engine GTD-1500 has already been developed, which is not inferior to diesel engines in terms of efficiency.

GENERAL INFORMATION ABOUT GAS TURBINE ENGINES

Lecture 1

GENERAL INFORMATION ABOUT GAS TURBINE ENGINES

1.1. Introduction

In modern technology, many different types of engines have been developed and used.

This manual discusses only one type - gas turbine engines (GTE), i.e. engines that include a compressor, combustion chamber and gas turbine.

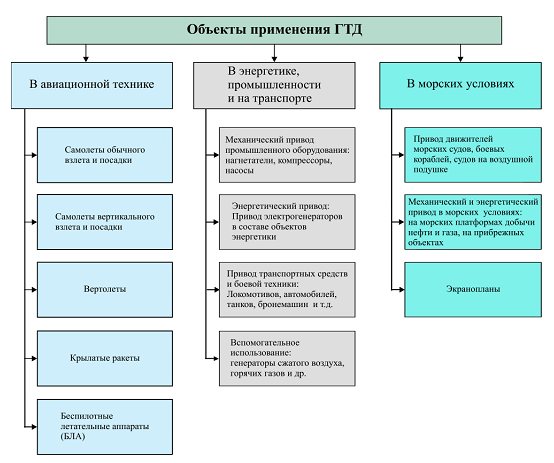

Gas turbine engines are widely used in aviation, land and marine applications. In Fig. 1.1 shows the main objects of application of modern gas turbine engines.

Rice. 1.1. Classification of gas turbine engines by purpose and objects of application

Currently, in the total global production of gas turbine engines in value terms, aircraft engines make up about 70%, land and sea engines - about 30%. The production volume of land and sea gas turbine engines is distributed as follows:

— energy gas turbine engines ~ 91%;

— GTE for driving industrial equipment and ground vehicles ~ 5%;

— GTE for driving ship propulsors ~ 4%.

In modern civil and military aviation, gas turbine engines have almost completely replaced piston engines and taken a dominant position.

Their widespread use in energy, industry and transport has become possible due to their higher energy efficiency, compactness and low weight compared to other types of power plants.

High specific parameters of gas turbine engines are ensured by the design features and thermodynamic cycle. The gas turbine engine cycle, although it consists of the same basic processes as the cycle of piston internal combustion engines, has a significant difference. In piston engines, processes occur sequentially, one after another, in the same engine element - the cylinder. In a gas turbine engine, these same processes occur simultaneously and continuously in various engine elements. Thanks to this, in a gas turbine engine there is no such uneven operating conditions for engine elements as in a piston engine, and the average speed and mass flow of the working fluid are 50...100 times higher than in piston engines. This makes it possible to concentrate large powers in small-sized gas turbine engines.

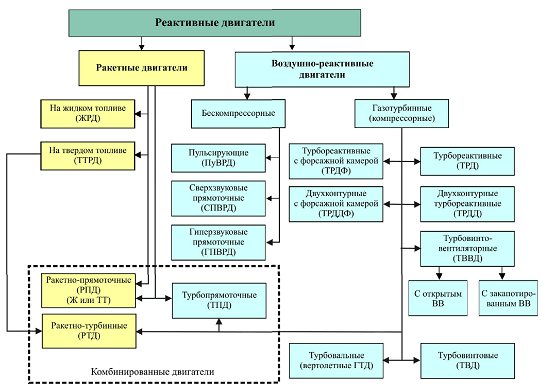

According to the method of generating traction force, aviation gas turbine engines belong to the class of jet engines, the classification of which is shown in Fig. 1.2.

Rice. 1.2. Classification of jet engines.

The second group includes air-breathing engines (WRE), for which atmospheric air is the main component of the working fluid, and air oxygen is used as an oxidizer. The use of air can significantly reduce the supply of working fluid and increase engine efficiency.

Gas turbine jet engines, which got their name due to the presence of a turbocompressor unit that incorporates a gas turbine as the main source of mechanical energy.

Jet engines, in which all the useful work of the cycle is spent on accelerating the working fluid, are called direct reaction engines. These include rocket engines of all types, combined engines, ramjet and pulsating jet engines, and from the gas turbine engine group - turbojet engines (TRE) and bypass turbojet engines (TRDE). If the main part of the useful work of the cycle in the form of mechanical work on the engine shaft is transferred to a special propulsion device, for example a propeller, then such an engine is called an indirect reaction engine. Examples of indirect reaction engines are the turboprop engine (TPR) and the helicopter gas turbine engine.

A classic example of an indirect reaction engine is a piston propeller unit. There is no qualitative difference in the method of generating traction between it and a turboprop engine.

1.2. Gas turbine engines for land and sea applications

In parallel with the development of aviation gas turbine engines, the use of gas turbine engines in industry and transport began. B1939r. The Swiss company AG Brown Bonery commissioned the first power plant with a gas turbine drive with a capacity of 4 MW and an efficiency of 17.4%. This power plant is currently in working order. In 1941, the first railway gas turbine locomotive, equipped with a 1620 kW gas turbine engine developed by the same company, went into operation. Since the late 1940s. Gas turbine engines are beginning to be used to drive marine ship propulsors, and since the late 1950s. — as part of gas pumping units on main gas pipelines to drive natural gas blowers.

Thus, constantly expanding the scope and scale of their application, gas turbine engines are developing in the direction of increasing unit power, efficiency, reliability, automation of operation, and improving environmental characteristics.

The rapid implementation of gas turbine engines in various industries and transport was facilitated by the undeniable advantages of this class of heat engines over other power plants - steam turbines, diesel engines, etc. These advantages include:

— high power in one unit;

— compactness, low weight fig. 1.3;

— balance of moving elements;

— wide range of fuels used;

— easy and quick start-up, including at low temperatures;

— good traction characteristics;

— high throttle response and good controllability.

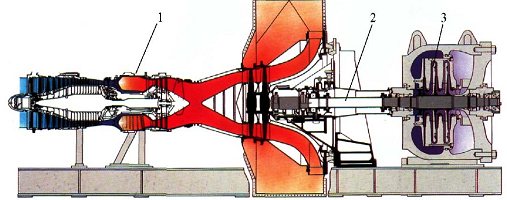

Rice. 1.3. Comparison of overall dimensions of a gas turbine engine and a 3 MW diesel engine

The main disadvantage of the first models on land and sea gas turbine engines was the relatively low efficiency. However, this problem was quickly overcome in the process of constant improvement of engines, which was facilitated by the rapid development of technologically similar aviation gas turbine engines and the transfer of advanced technologies to ground-based engines.

1.3. Areas of application of ground-based gas turbine engines

1.3.1. Mechanical drive of industrial equipment

The most widespread use of mechanically driven gas turbine engines is found in the gas industry. They are used to drive natural gas superchargers as part of gas compressor units at compressor stations of main gas pipelines, as well as to drive natural gas injection units into underground storage facilities (Fig. 1.4).

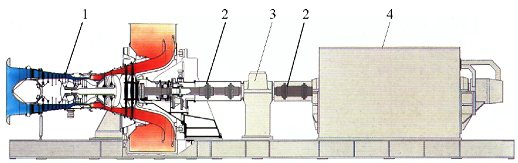

Rice. 1.4. Application of gas turbine engines for direct drive of a natural gas supercharger:

1 - gas turbine engine; 2 — transmission; 3 - supercharger

Gas turbine engines are also used to drive pumps, process compressors, and blowers at oil, oil refining, chemical and metallurgical industries. The power range of gas turbine engines is from 0.5 to 50 MW.

The main feature of the listed driven equipment is the dependence of the power consumption N on the rotational speed n (usually close to cubic: N~n3), temperature and pressure of the pumped media. Therefore, gas turbine engines of a mechanical drive must be adapted to work with variable rotation speed and power. This requirement is best met by a gas turbine engine design with a free power turbine. Various schemes of ground gas turbine engines will be discussed below.

1.3.2. Electric generator drive

GTE for driving electric generators Fig. 1.5 are used as part of simple cycle gas turbine power plants (GTPPs) and combined cycle gas cycle (CCGT) condensing power plants that generate “clean” electricity, as well as as part of cogeneration plants that jointly produce electrical and thermal energy.

Rice. 1.5. Application of a gas turbine engine to drive a generator (via a gearbox):

1 - gas turbine engine; 2 — transmission; 3 - gearbox; 4 – generator.

Modern simple-cycle gas turbine power plants, which have a relatively moderate electrical efficiency ηel = 25...40%, are mainly used in peak operating mode - to cover daily and seasonal fluctuations in electricity demand. The operation of gas turbine engines as part of peak gas turbine power plants is characterized by high cyclicity (a large number of cycles “start-up - loading - operation under load - shutdown”). The possibility of accelerated start-up is an important advantage of gas turbine engines when operating in peak mode.

Power plants with CCGT units are used in the basic mode (constant operation with a load close to the rated load, with a minimum number of start-stop cycles for routine maintenance and repair work). Modern CCPPs based on high-power gas turbine engines (N>150 MW) achieve an electricity generation efficiency of ηel=58...60%.

In cogeneration plants, the heat from the exhaust gases of the gas turbine engine is used in a waste heat boiler to produce hot water and (or) steam for process needs or in centralized heating systems. The joint production of electrical and thermal energy significantly reduces its cost. The coefficient of fuel heat utilization in cogeneration plants reaches 90%.

CCGT power plants and cogeneration plants are the most efficient and dynamically developing modern energy systems. Currently, global production of energy gas turbine engines is about 12,000 units per year with a total capacity of about 76,000 MW.

The main feature of gas turbine engines for driving electric generators is the constancy of the output shaft rotation speed in all modes (from idle to maximum), as well as high requirements for the accuracy of maintaining the rotation speed, on which the quality of the generated current depends. Single-shaft gas turbine engines best meet these requirements, which is why they are widely used in the energy sector. High-power gas turbine engines (N>60 MW), operating, as a rule, in the basic mode as part of powerful power plants, are carried out exclusively according to a single-shaft design.

The entire power range of gas turbine engines from several tens of kW to 350 MW is used in the energy sector.

1.3.3. Main types of ground gas turbine engines

Ground gas turbine engines for various purposes and power classes can be divided into three main technological types:

— stationary gas turbine engines;

— gas turbine engines converted from aircraft engines (aircraft derivatives);

- microturbines.

1.3.3.1. Stationary gas turbine engines

Motors of this type are developed and manufactured at enterprises of the power engineering complex in accordance with the requirements for power equipment:

— high resource (at least 100,000 hours) and service life (at least 25 years);

— high reliability;

— maintainability under operating conditions;

— moderate cost of used construction materials and fuels and lubricants to reduce the cost of production and operation;

— absence of strict size and weight restrictions that are significant for aviation gas turbine engines.

The listed requirements shaped the appearance of stationary gas turbine engines, which are characterized by the following features:

— the most simple design;

— use of inexpensive materials with relatively low characteristics;

— massive housings, as a rule, with a horizontal connector to allow removal and repair of the gas turbine engine rotor under operating conditions;

— design of the combustion chamber, providing the ability to repair and replace flame tubes under operating conditions;

— use of plain bearings.

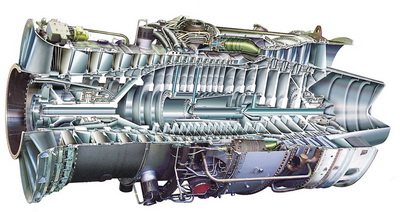

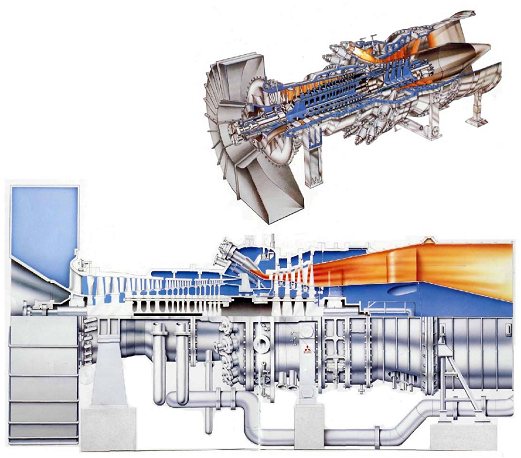

A typical stationary gas turbine engine is shown in Fig. 1.6.

Rice. 1.6. Stationary gas turbine engine (model M501F from Mitsubishi)

with a capacity of 150 MW.

Currently, stationary gas turbine engines are used in all applications of land-based gas turbine engines in a wide power range from 1 MW to 350 MW.

At the initial stages of development, moderate cycle parameters were used in stationary gas turbine engines. This was due to some technological lag behind aircraft engines due to the lack of strong government financial support, which the aircraft engine industry enjoyed in all aircraft engine producing countries. Since the late 1980s The widespread introduction of aviation technologies began in the design of new models of gas turbine engines and the modernization of existing ones.

To date, powerful stationary gas turbine engines have come very close to aircraft engines in terms of thermodynamic and technological sophistication while maintaining a high resource and service life.

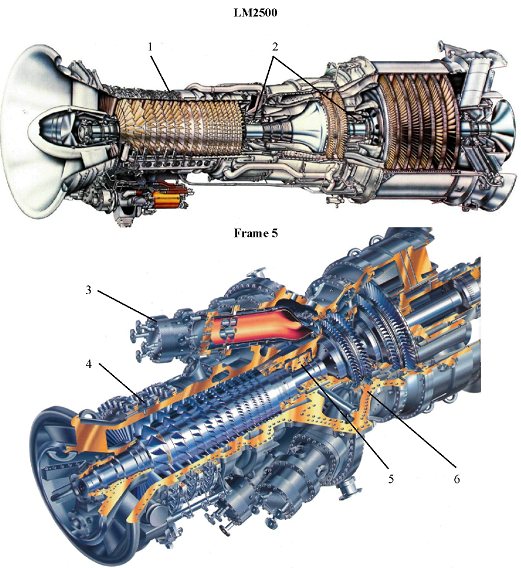

1.3.3.2. Ground gas turbine engines converted from aircraft engines

Gas turbine engines of this type are developed on the basis of aircraft prototypes at aircraft engine manufacturing enterprises using aviation technologies. Industrial gas turbine engines, converted from aircraft engines, began to be developed in the early 1960s, when the service life of civil aviation gas turbine engines reached an acceptable value (2500...4000 hours).

The first industrial installations with aircraft drives appeared in the energy sector as peak or reserve units. The further rapid introduction of aircraft-derived gas turbine engines into industry and transport was facilitated by:

— faster progress in aircraft engine construction in terms of cycle parameters and increased reliability than in stationary gas turbine construction;

— high quality manufacturing of aircraft gas turbine engines and the possibility of organizing their centralized repair;

— the possibility of using aircraft engines that have exhausted their flight life, with the necessary repairs, for operation on the ground;

- advantages of aviation gas turbine engines - low weight and dimensions, faster start-up and acceleration, lower required power of starting devices, lower required capital costs during the construction of application facilities.

When converting a basic aircraft engine into a ground-based gas turbine engine, if necessary, the materials of some parts of the cold and hot parts that are most susceptible to corrosion are replaced. For example, magnesium alloys are replaced with aluminum or steel, and more heat-resistant alloys with a higher chromium content are used in the hot part. The combustion chamber and fuel supply system are modified to operate on gaseous fuel or for a multi-fuel option. Components, engine systems (starting, automatic control (ACS), fire protection, oil system, etc.) and piping are being finalized to ensure operation in ground conditions. If necessary, some stator and rotor parts are strengthened.

The scope of structural modifications of the base aircraft engine into a ground modification is largely determined by the type of aircraft gas turbine engine.

A comparison of a converted gas turbine engine and a stationary gas turbine engine of the same power class is shown in Fig. 1.7.

Aviation theater engines and helicopter gas turbine engines are functionally and structurally more suitable than other aircraft engines to operate as ground gas turbine engines. They actually do not require modification of the turbocharger part (except for the combustion chamber).

In the 1970s, the ground-based gas turbine engine HK-12CT was developed on the basis of the single-shaft aircraft turboprop engine HK-12, which was operated on TU-95, TU-114 and AN-22 aircraft. The converted HK-12CT engine with a power of 6.3 MW was made with free CT and operates as part of many gas pumping units to this day.

Currently, converted aviation gas turbine engines from various manufacturers are widely used in the energy sector, industry, marine conditions and transport.

Rice. 1.7. Comparison of typical designs of a gas turbine engine converted from an aircraft engine and a stationary type gas turbine engine of the same power class of 25 MW:

1 - thin bodies; 2 — rolling bearings; 3 — external CS;

4 — massive buildings; 5 — plain bearings; 6 - horizontal connector

The power range is from several hundred kilowatts to 50 MW.

This type of gas turbine engine is characterized by the highest effective efficiency when operating in a simple cycle, which is due to the high parameters and efficiency of the base aircraft engine components.

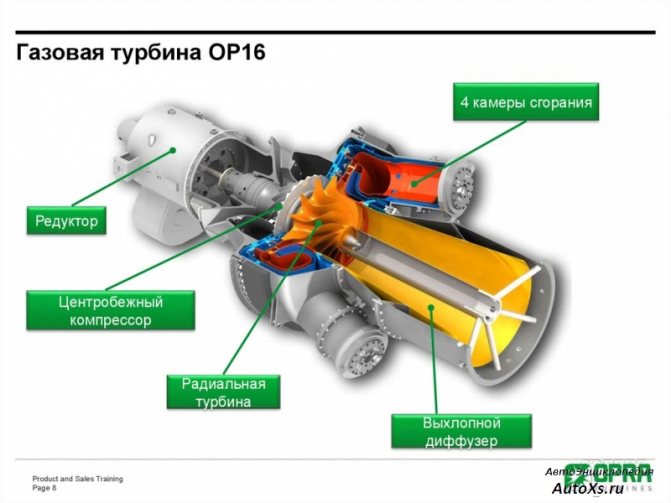

1.3.3.3. Microturbines

In the 1990s, energy gas turbine engines of ultra-low power (from 30 to 200 kW), called microturbines, began to be intensively developed abroad.

Note: it is necessary to keep in mind that in foreign practice the terms “turbine” and “gas turbine” refer to both a separate turbine unit and a gas turbine engine as a whole).

The features of microturbines are due to their exceptionally small size and scope of application. Microturbines are used in small-scale power generation as part of compact cogeneration plants (GTU-CHP) as autonomous sources of electrical and thermal energy. Microturbines have the simplest possible design - a single-shaft design and a minimum number of parts (Fig. 1.8).

Rice. 1.7. Microturbine (model TA-60 from Elliot Energy Systems with a power of 60 kW)

A single-stage centrifugal compressor and a single-stage centripetal turbine, made in the form of unicycles, are used. Due to its small size, the rotor speed reaches 40,000...120,000 rpm, which is why ceramic and gas-static bearings are used. The combustion chamber is multi-fuel and can operate on gaseous and liquid fuels.

Structurally, the gas turbine engine is maximally integrated into the power plant: the gas turbine engine rotor is combined on the same shaft with the rotor of a high-frequency electric generator.

The efficiency of microturbines in a simple cycle is 14...18%. Exhaust gas heat regenerators are often used to improve efficiency. The efficiency of a microturbine in the regenerative cycle reaches 28…32%.

The relatively low efficiency of microturbines is explained by their small size and low cycle parameters, which are used in this type of gas turbine engine to simplify and reduce the cost of installations. Since microturbines operate as part of cogeneration plants (GTU-CHP), the low efficiency of gas turbine engines is compensated by the increased thermal power generated by the mini “GTU-CHP” due to the heat of exhaust gases.

The coefficient of fuel heat utilization in these installations reaches 80%.

1.4. Major global manufacturers of gas turbine engines

General Electric, USA. General Electric (GE) is the world's largest manufacturer of aircraft, land and marine gas turbine engines. The General Electric Aircraft Engines (GE AE) division is currently engaged in the development and production of various types of aviation gas turbine engines - turbofan engines, turbofans, turbofan engines and helicopter gas turbine engines.

Pratt & Whitney, USA. Firm & Whitney (PW) is part of United Technologies Corporations (UTC). PW is currently engaged in the development and production of medium- and high-thrust aircraft turbofan engines.

Pratt & Whitney Canada, (Canada). Pratt & Whitney Canada (PWC) is also part of UTC's PW group. PWC develops and manufactures small turbofan engines, turbofan engines and helicopter gas turbine engines.

Rolls-Royce (UK). Rolls-Royce currently develops and manufactures a wide range of gas turbine engines for aviation, land and marine applications.

Honeywell (USA). Honeywell is engaged in the development and production of aviation gas turbine engines - turbofan engines and turbofan engines in the small thrust class, turboprop engines and helicopter gas turbine engines.

Snecma (France). The company is engaged in the development and production of aviation gas turbine engines - military turbofan engines and civil turbofans together with GE. Together with Rolls-Royce, it developed and produced the Olympus turbofan engine.

Turbomeca (France). Turbomeca mainly develops and produces low- and medium-power turboprop engines and helicopter gas turbine engines.

Siemens (Germany). The profile of this large company is stationary land-based gas turbine engines for power and mechanical drive and marine applications in a wide power range.

Alstom (France, UK). Alstom develops and produces stationary, single-shaft, low-power gas turbine engines.

Solar (USA). Solar is a Caterpillar company that designs and manufactures low-power stationary gas turbine engines for power, mechanical drive and marine applications.

JSC Aviadvigatel (Perm). Develops, manufactures and certifies aviation gas turbine engines - civil turbofan engines for long-haul aircraft, military turbofan engines, helicopter gas turbine engines, as well as aircraft-derived ground industrial gas turbine engines for mechanical and power drives.

State Scientific Enterprise "Plant named after V.Ya. Klimov" (St. Petersburg). State Unitary Research and Production Enterprise “Plant named after. V.Ya. Klimov" has been specializing in the development and production of aviation gas turbine engines in recent years. The range of developments is wide - military turbofan engines, aircraft theater engines and helicopter gas turbine engines; tank gas turbine engines, as well as converted industrial gas turbine engines.

OJSC "LMZ" (St. Petersburg). JSC Leningrad Metal Plant develops and produces stationary power gas turbine engines.

FSUE "Motor" (Ufa). The Federal State Unitary Enterprise "Research and Production Enterprise "Motor"" is developing military turbojet engines and turbofan engines for fighters and attack aircraft.

"Omsk MKB" (Omsk). Omsk Engine Design Bureau JSC is developing small-sized gas turbine engines and auxiliary control systems.

JSC NPO Saturn (Rybinsk). In recent years, JSC Scientific and Production Association Saturn has been developing and producing military turbofan engines, theater engines, helicopter gas turbine engines, and converted ground gas turbine engines. Together with NPO Mashproekt (Ukraine), it participates in the program for a single-shaft gas turbine engine with a capacity of 110 MW.

OJSC "SNTK im. N.D. Kuznetsova.” JSC Samara Scientific and Technical Complex named after. N.D. Kuznetsova develops and produces aviation gas turbine engines (TVD, turbofan engine, turbofan engine) and ground gas turbine engines converted from aircraft engines.

AMHTK "Soyuz" (Moscow). OJSC "Aircraft Engine Scientific and Technical Complex "Soyuz"" develops and manufactures aviation gas turbine engines - turbojet engines, turbofan engines, lift-propulsion turbofan engines.

Tushinskoe ICB “Soyuz” (Moscow). The state enterprise "Tushinsky Machine-Building Design Bureau "Soyuz"" is engaged in the development and modernization of military turbofan engines.

NPP "Mashproekt" (Ukraine, Nikolaev). The Zorya-Mashproekt research and production enterprise (Ukraine, Nikolaev) develops and produces gas turbine engines for marine control systems, as well as land-based gas turbine engines for power and mechanical drives. Land engines are modifications of marine models. GTE power class: 2…30 MW. Since 1990 NPP Zorya-Mashproekt is also developing a stationary single-shaft energy engine UGT-110 with a power of 110 MW.

SE "ZMKB "Progress" named after. A.G. Ivchenko" (Ukraine, Zaporozhye). State Enterprise “Zaporozhye Machine-Building Design Bureau “Progress” named after Academician A.G. Ivchenko specializes in the development, production of prototypes and certification of aviation gas turbine engines - turbofan engines in the thrust range of 17...230 kN, aircraft turboprop engines and helicopter gas turbine engines with a power of 1000...10000 kW, as well as industrial ground gas turbine engines with a power of 2.5 to 10000 kW.

Engines developed by ZMKB Progress are mass-produced at Motor Sich OJSC (Ukraine, Zaporozhye). The most popular serial aircraft engines and promising projects:

— theater and helicopter gas turbine engines — AI-20, AI-24, D-27;

- Turbofan engines - AI-25, DV-2, D-36, D-18T, D-436T1/T2/LP.

Ground gas turbine engines:

— D-336-1/2, D-336-2-8, D-336-1/2-10.