Against the background of tracked and wheeled special equipment, large equipment that moves in peculiar steps stands out separately. The reason for the radical modification of the chassis is the weight of the car. The boom length of a walking excavator alone can reach 100 meters. The total weight of the unit amounts to thousands of tons. It is possible to reduce the pressure on the ground by using large-area supports; standard tracks are not enough.

You can get acquainted with the variety of models of imported excavators and purchase special earthmoving equipment inexpensively here. Professional advice from BF-Logistic LLC will allow you to reduce the cost even more. The company’s specialists will help you select the optimal excavator for the intended use, eliminating overpayments for unused functionality.

Walking excavator design

The running gear of large-sized special equipment consists of a base plate and peculiar skis, their alternative name is boots. The first structural element serves to reduce pressure on the ground. Result:

The specific load on the soil of an excavator weighing 2000 tons is 100 kPa. Additionally, a rotating platform with equipment is mounted on the base plate. The number of shoes varies in the range of 2 - 4 units.

Dimensions of the chassis

“It’s convenient to give a specific example:

ESH-20/90

.

This is the most common model. The marking stands for a walking excavator, with a bucket volume of 20 cubic meters and a boom length of 90 m.

Parameters of the machine's chassis:

- diameter of the support frame

– 14.5 m; - roller circle

– 10.8 m; - length and width of the shoe

– 13×2.5 m.

The total area of the slab of the ESH-20/90 excavator is 165 sq.m. A similar parameter for one ski is 32.5 sq.m. The total area under the shoes is 65 sq.m. As a result, the specific pressure on the ground when moving is 210, in the working position - 103 kPa.

Classification of single-bucket excavators

Single-bucket excavators are classified according to:

- chassis type;

- drive type;

- type of working equipment;

- the possibility of rotating the working equipment relative to the supporting surface.

2.1 Classification based on the possibility of rotation of the working equipment relative to the supporting surface

Based on the possibility of rotating the working equipment relative to the supporting surface, single-bucket excavators are divided into semi-rotary and full-rotary.

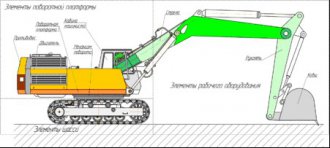

Full rotation (Fig. 6).

Rice. 6. Diagram of a full-rotary excavator. Click on the picture to enlarge

The working equipment, drives, driver's cabin and engine are installed on a turntable, which in turn is mounted on the chassis by means of a slewing support device (SDU), and can be rotated relative to it in any direction at any angle. Parts of the hydraulic system of the chassis and rotating platform of full-rotary excavators are connected using a manifold, which allows an unlimited number of full revolutions in one direction.

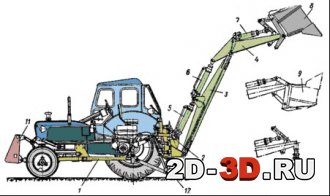

Partial rotation (Fig. 7). The working equipment is fixed to the chassis using a rotating column. On many machines of this type, the rotary column is mounted on transverse guides, which allows it to be moved together with the working equipment from right to left, followed by rigid fixation for a more convenient position of the working equipment. The rotation of the working equipment is carried out at an angle of 45-90 degrees from the initial position. The engine, mechanisms, and driver's cabin are located on a fixed chassis. Currently, excavators mounted on tractors are part-rotary.

Rice. 7. Diagram of a part-turn excavator on a wheeled tractor chassis. Click on the picture to enlarge

1 — excavator frame mounted on the tractor; 2 - Rotary column; 3 - Arrow;

4 - Handle; 5 - Boom drive hydraulic cylinder; 6 - Hydraulic cylinder for handle drive;

7 — Hydraulic cylinder for bucket drive; 8 - Bucket; 9 — Option for installing the bucket in the backhoe position; 10 — Replaceable cargo hook; 11 - Bulldozer blade; 12. — Outriggers

2.2. Classification by chassis type

Single-bucket excavators by chassis type can be tractor-mounted, automobile-mounted, pneumatic-wheeled, tracked, walking, railway, or floating.

Mounted on a tractor (Fig. 8). A tractor, most often a wheeled one, is used as the base chassis. Partial rotation excavator equipment is installed at the rear (less often on the side) of the tractor, on a special frame. The characteristic volume of the bucket is 0.2...0.5 m?. They are used to perform small excavation or loading work, most often when repairing utility networks. The design of the working equipment allows you to quickly rearrange the bucket for working with a front or backhoe. The bucket can be replaced with a grab, forks or a hook. The engine of the base tractor is used for drive. The drive of the working equipment is hydraulic. Thanks to the relatively high speed, they can quickly arrive at the work site located at a distance of 20...30 km from the base. A tractor with attached excavator equipment can also be used to perform transport and bulldozer work.

Rice. 8. Single-bucket excavators mounted on a tractor

On a car chassis (Fig. 9). A truck, most often an off-road vehicle, is used as the base chassis. They have a high speed of movement. They are used in cases where high mobility is required: in military affairs (engineering troops, road troops), when performing rescue operations, during road construction, and canal cleaning. The working equipment is mainly a backhoe. Excavators are produced with a telescopic boom and a rotating bucket, which allows you to quickly switch from a straight shovel to a reverse shovel. The drive can use either the engine of the base vehicle or a separate engine installed on the turntable.

Rice. 9. Single-bucket excavator on a car chassis

Pneumatic wheeled excavators (Fig. 10) have their own special chassis, supported by wheels with pneumatic tires. To increase stability and prevent slipping when loading the bucket, they have outriggers. They have a travel speed of up to 30 km/h. Can be towed by trucks at speeds up to 40 km/h. Passability on soft soils is limited. They are produced in a wide range of size groups - from microexcavators with a bucket volume of 0.04 m2 to heavy wheeled excavators with a bucket volume of up to 1.5 m2. Due to the specifics of the work performed: development of pits, trenches, leveling work - working equipment - mainly a backhoe. Can be used with a grab, jaw grip, or hydraulic hammer for loosening soil. They are widely used when performing various types of construction and repair work.

The chassis wheels can be driven either from the engine of the working equipment through mechanical or hydraulic transmissions (hydraulic motors), or from a separate engine.

Rice. 10. Crawler single-bucket excavator

Crawler single-bucket excavators have their own special chassis with a caterpillar drive. They have high maneuverability and low specific pressure on the ground with a large mass. They can work on weak and waterlogged soils, including peat mining. They have a travel speed of 2…15 km/h. They are transported to the work site by tractors on special trawls.

The working range of bucket volumes is very wide: from mini excavators with a bucket volume of 0.04 m3 to quarry excavators with a bucket volume of 10 m3. There are also particularly heavy mining crawler excavators with a bucket volume of 26 m3 produced by DEMAG (Germany).

Working equipment: straight shovel, backhoe, dragline. Can be used with a grab, jaw grip, hydraulic hammer for loosening soil. They are widely used in construction and mining. A number of models of crawler and pneumatic wheeled excavators have a unified rotary platform and working equipment.

Walking single-bucket excavators (Fig. 11). The rotary platform with the walking excavator equipment is installed on the base plate. The paws are connected to the turntable, which are raised when the excavator is operating (do not touch the ground). When the excavator moves, the paws rest on the ground. In this case, the base plate is lifted off the ground. The excavator moves one step forward (for some models it is possible to move backward). After this, the paws rise and return to their original position. Large mining excavators with a bucket volume of 15...40 m3 and a boom reach of up to 65...150 m are produced at walking speed. The working equipment is a dragline. Walking excavators perform stripping work (clearing mineral deposits from waste rock), as well as extracting minerals and moving them to a dump (up to 40 m high). Loading of minerals by walking excavators into vehicles cannot be carried out.

Rice. 11. Walking bucket excavator

Railway single-bucket excavators (Fig. 12). A railway platform is used as an excavator chassis. Used for repair work on railways. They have a bucket volume of up to 4 m3. The rotary platform and equipment are often unified with crawler excavators.

Rice. 12. Railway bucket excavator

Floating single-bucket excavator (Fig. 13). The working equipment (dragline or grab) is installed on the pontoon. They are used for loading and unloading operations, extraction of sand, gravel from reservoirs, bottom cleaning and dredging work. Floating excavators differ from floating cranes equipped with grabs by their smaller height and simplified boom design.

Rice. 13. Floating bucket excavator

2.3. Classification of single-bucket excavators by engine type

Single-bucket excavators can be steam, internal combustion, or electric by engine type.

Steam excavators - a steam engine is used as an engine. They were common at the beginning of the 20th century. Currently not in production.

Excavators with internal combustion engines are the most common type. The excavator has its own engine, most often a diesel one. This ensures autonomy of operation. The power range of engines installed on modern excavators is very wide.

Electric excavators - electric motors are used to drive working equipment, receiving energy from an external network or from its own diesel-electric unit. An electric drive powered from an external network is used for mining excavators. Such excavators are economical and do not pollute the quarry atmosphere. An electric drive powered by its own diesel-electric unit is used in floating excavators. The electric motor produces torque when the armature is braked, so an electric excavator does not require complex mechanical transmissions.

Excavators operating in explosive environments (in mines) do not have a prime mover. Their hydraulic equipment is supplied with high pressure fluid from an external oil station.

2.4 Classification by type of mechanical transmissions (drives of working equipment)

Based on the type of mechanical transmission, single-bucket excavators are divided into mechanical, electromechanical and hydraulic driven.

Mechanical. The traction force to the working parts is transmitted through ropes (or chains) driven by winches.

Mechanical rope drive has been widely used on excavators in the past.

On modern models, a mechanical cable drive is used only for a dragline or grab.

Electromechanical. The traction force to the working parts is transmitted through ropes (or chains) driven by winches. Each winch and auxiliary mechanisms are driven by an individual electric motor. This drive is used on heavy mining (including walking) and industrial excavators

Excavators with hydraulic drive. In hydraulically driven excavators, the force on the elements of the working equipment is created by hydraulic cylinders and hydraulic motors. The excavator engine rotates a hydraulic pump, which creates pressure of the working fluid in the pressure line of the hydraulic system.

Currently, hydraulic excavators are predominantly used.

Multi-ton vehicle propulsion technology

It was the method of movement that gave the name to the machine, like walking. Instead of continuous movement, characteristic of tracked and wheeled vehicles, the vehicle “ goes

"in a discrete manner

. The moving principle of a walking excavator is described as follows:

- Preparatory activities are being carried out.

The bucket is emptied, the boom is positioned along the motion vector. - The raised shoes of the excavator are lowered to the ground

in the direction of the step. - The center of gravity of the unit shifts towards the skis

, causing the supporting chassis to rise. The excavator moves in the direction of the shoes. - The slab is lowered

, fixing itself on the ground. - The skis rise

, transferring the special equipment to a static, working position.

The average time it takes for an excavator to step is 55 seconds. The length of a single stroke is about 1 meter. The resulting moving speed of a walking excavator is 60 – 80 m/h, the maximum design value is 200 m/h.

Types of high-performance earthmoving equipment

There are two types of walking excavators, differing in the working body: draglines and rotary. The first type of equipment is characterized by a single bucket driven by a pulley system. The machine operates in cycles: excavation and loading of soil mainly to the dump.

Rotary walking excavators, like trenching units, are special equipment of continuous operation. The functional unit of the device is a wheel with a set of buckets. The rotation of the rotor system allows you to simultaneously scoop the soil and load the mass onto the conveyor belt. The machines have higher productivity, reaching 5000 t/h.

The portal of special equipment https://bf-logistic.com.ua offers to select and buy used imported excavators inexpensively. The company's consultants will make the selection process extremely fast and efficient.

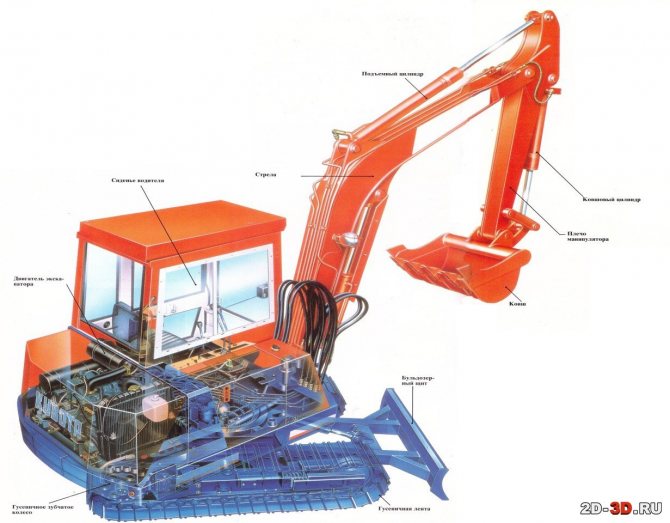

Design and principle of operation of single-bucket excavators

A single-bucket excavator (Fig. 1) is also a means of transportation, although it is designed for digging, lifting and raking soil and materials. The chassis of these vehicles is very similar to the chassis of a tank: the same engine and the same caterpillar track. The excavator has several arms, and the last one ends in a bucket for scooping up soil. Many excavators, like the one shown below, have a heavy steel shield in front to level the area. Just like a crane, an excavator uses hydraulic cylinders to drive its booms and bucket. Other hydraulic motors and control valves located in the cab control the movement of the tracks and dozer shield. The hydraulic cylinders are driven by the same internal combustion engine that moves the excavator tracks.

Rice. 1. Single-bucket excavator. Click on the picture to enlarge

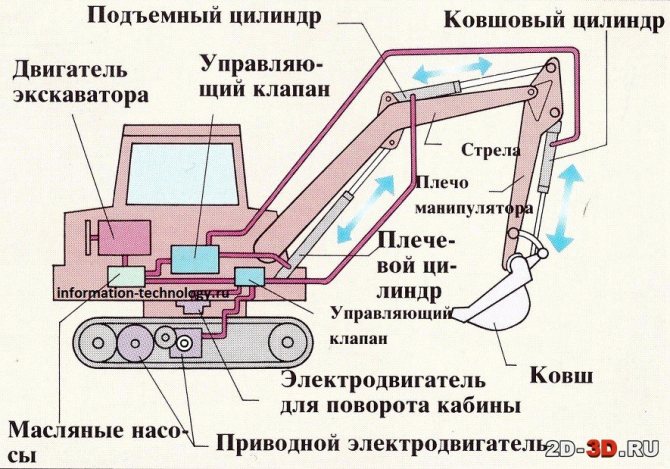

The main engine drives pumps that create excess oil pressure in the hydraulic cylinders, which extends the boom. The driver in the cab uses levers to control the movements of the bucket and shield (Fig. 2).

Rice. 2. Operating principle of a single-bucket excavator. Click on the picture to enlarge

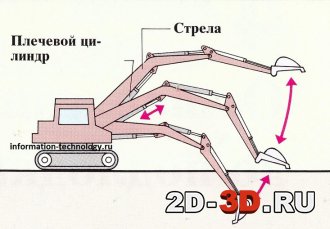

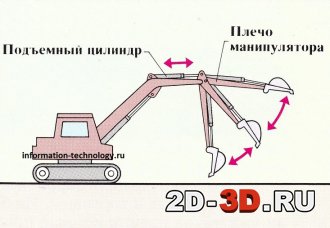

The boom rises and extends as the piston in the cylinder moves upward. And when the piston lowers, the boom shortens and also lowers (Fig. 3).

Rice. 3. Variable boom

The shoulder cylinder piston controls the movement of the shoulder (Fig. 4).

Rice. 4. Manipulator shoulder

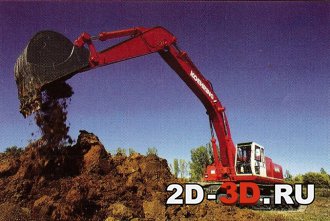

The ladle scoops or pours when the piston of its cylinder is extended or retracted. Working in an open pit, an excavator easily drags stones and boulders (Fig. 5).

5. Photo of work in an open pit. Our website has a section with drawings of single-bucket excavators.