Engine, power elements

In countries with higher environmental standards, the Caterpillar D9R bulldozer is equipped with the 3408E HEUI™ engine. For other regions, it is possible to equip it with a 3408C diesel engine. The difference is the absence of the HEUI electric fuel injection system, which provides 44% more torque.

To achieve high power at low crankshaft speeds, diesel engines are equipped with turbocharging and a charge air cooler. And reliability is achieved by reducing the number of mechanical connections. The same purpose is served by electronic protection of the power unit in case of idling, cold start and other unfavorable conditions.

Photo source: cat.comPhoto Caterpillar D9R

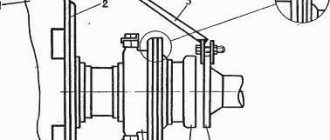

The traditional solution for Caterpillar bulldozers is a torque divider. The torque converter is responsible for transmitting 75% of the torque developed by the engine, the remaining 25% goes through the planetary gear directly to the drive shaft. The result is an increase in the efficiency of the power transmission, as well as an increase in the amount of torque.

Another solution well known to Cat dozer owners is raised final drives. The designers ensured the isolation of these elements from the effects of soil and the elimination of the consequences of shock loads.

| Engine model | 3408E HEUI™ |

| Inner diameter of cylinders | 137 mm |

| Piston stroke | 137 mm |

| Working volume | 18 l |

| Fuel tank | 908 l |

Caterpillar C12 Engine Specifications

Caterpillar is an American company that produces heavy equipment and engines. The company was founded in California in 1925 and is based in Illinois. Caterpillar manufactures heavy equipment such as backhoes, backhoes, motor graders, off-road trucks, wheel loaders and farm tractors. Caterpillar also produces engines for a wide range of applications, from industrial trucks and buses to highways. The Caterpillar C12 is a diesel engine designed for use in both trucks and buses.

Engine Specifications

The Caterpillar C12 is a 732cc air-cooled diesel engine. Inch, 12-valve engine. The engine bore is 5.1 inches and the stroke is 5.9 inches. This engine is turbocharged and the gears on the flywheel rotate counterclockwise. This engine is air and liquid cooled, and the liquid cooling system can hold 2.7 gallons of coolant. The lube oil system can hold up to 9.4 gallons of oil. The battery has an electrical reserve, as well as a self-diagnosis system.

Specifications

The Caterpillar C12 runs at 1,200 to 2,100 rpm, while the engine will run at 2,100 rpm. The C12's maximum claimed power is 430, but the engine is capable of producing 445 hp. at 1600 rpm. The governor is programmed to shut off the engine when 2100 rpm is exceeded. The maximum torque of this engine is 1650 ft-lbs at 1200 rpm. The percentage increase in torque is 53 percent. The C12 can operate at altitudes up to 10,000 feet. The maximum recommended engine speed in cruising mode is 1700 rpm. The minimum recommended engine speed at a cruising speed of 55 mph is 1400 rpm.

Dimensions and other information

The alternator on the Caterpillar C12 is rated at 12 volts and 105 amps. This engine is equipped with a dry charge coolant conditioner, fan drive mounting bracket, front engine mounts, and a lube oil filter. The C12 is 50.6 inches long, 35.68 inches wide, 41.85 inches tall, and weighs 2,020 pounds.

Related articles:

- Engine Specifications for Caterpillar

- Cat C-12 Torque Specifications

- Specifications for HP and Torque on a Caterpillar 3176 Engine

- Caterpillar Engine Torque Specifications

- Caterpillar D-343 Specifications

- CAT C15 Engine Specifications

Cabin, controls

The system for monitoring the current state of the Caterpillar D9R bulldozer, developed by the company’s specialists, is equipped, among other things, with warning indicators.

The cabin is placed on insulating supports, which reduces vibration and noise levels to 84 dB (A). Ergonomic controls are distinguished by the fact that they do not require significant effort from the operator. Also, for the convenience of the driver, a high-comfort seat is installed; it is fully adjustable.

Photo source: cat.comVibration and noise levels in the Caterpillar D9R cab are reduced to 84 dB

The Caterpillar D9R bulldozer has levers that are used to both disengage the side clutches and stop the tracks. Direction of movement and speed are controlled using a single control handle.

To improve visibility, in addition to the sloping hood, a fuel tank with a recess is installed. Wide door windows provide good lateral visibility.

The control system can be selected: either a standard version with onboard clutches and brakes, or a differential steering and braking control system is available. In the second case, power is continuously supplied to both tracks.

A feature of the hydraulic system of the Caterpillar D9R bulldozer is that one of the two pumps is activated when turning, and the second is responsible for the operation of the blade and other attachments. This allows all elements to be provided with the necessary power.

OPTIONAL EQUIPMENT Caterpillar C9 (50 Hz)

ENGINE (OPTIONS)

- Air Cleaner: [ ] Single Element Air Cleaner [ ] Dual Element Air Cleaner [ ] Heavy Duty Air Cleaner

- Muffler: [ ] industrial [ ] household [ ] critical

- Batteries: [ ] standard [ ] heavy duty

- Starting motors: [ ] standard [ ] heavy duty

- Charger: [ ]

- Starting aids: [ ] jacket water heater

CONTROL SYSTEM

- Controller: [ ] EMCP 4.1 [ ] EMCP 4.2 [ ] EMCP 4.3 [ ] EMCP 4.4

- Local annunciator: [ ] NFPA 110

- Remote annunciator: [ ] NFPA 110

- Additional options: [ ] I/O expansion module [ ] Remote monitoring software

GENERATORS

- Excitation: [ ] Permanent Magnet Excitation (PM) [ ] Internal Excitation (IE)

- [ ] Anti-condensation heater

- [ ] Large size generators

- [ ] Coastal protection

POWER TERMINALS

- [ ] Bus [ ] circuit breaker, IEC compliant [ ] circuit breaker, UL listed

TOTAL

- [ ] Seismic safety certificate in accordance with applicable building codes: IBC 2000, IBC 2003, IBC 2006, IBC 2009, CBC 2007

- [ ] Pre-approved by OSHPD and compliant with OSP-0321-10 for use on healthcare projects in California [ ] UL 2200 kit

- [ ] EU Certificate of Conformity (CE)

- [ ] CSA Certificate

- [ ] EEC Declaration of Conformity

- Slide base [ ] narrow [ ] wide

- Enclosures [ ] reduced noise level [ ] weather protection [ ] protection against high ambient temperatures

- Fuel tanks [ ] single-walled built-in [ ] double-walled built-in [ ] single-walled base [ ] double-walled base

- [ ] Automatic transfer devices (ATD)

EXTENDED SERVICE CONTRACT (ESC)

- Extension Service Contract (ESC): [ ] 2 years [ ] 3 years [ ] 4 years [ ] 5 years

Dimensions Caterpillar D9R

| Overall width (by axles) | 3 303 mm |

| Machine height | 3,996 mm |

| Ground clearance | 507 mm |

| Shoe width | 610 mm |

| Number of shoes per side | 43 |

| Track width | 2 250 mm |

Chassis

When developing this part of the machine, Caterpillar specialists set out to improve the balancing of the machine and extend the service life of individual elements. The optimal solution was the high location of the drive sprockets. The design is also characterized by an elastic suspension, which helps minimize the impact of shock loads.

A special feature of the rollers and idlers is the presence of 2-cone seals. And the end rings included in the track links prevent lateral play and help achieve maximum seal fit. By additional order, it is also possible to install protective guards for the guide wheels.

Photo source: cat.comPhoto Caterpillar D9R

Frame

The main frame of the Caterpillar D9R bulldozer includes box-section side members (this shape ensures reliable alignment of all components). Robust steel castings also add strength to the main frame, balance bar saddle, front cross member and blade stabilizer axle. The upper and lower spars are solid rolled. The blade is located as close to the body as possible - this was achieved due to the special design of the stabilizer beam, and the result is better controllability of the working equipment.

Cat D9N Bulldozer

Bulldozer Cat D 9 N – year of manufacture 1995, operating time before repair less than 10,000 m/hours. Serial number _______, engine _______ Bulldozer characteristics: -Machine weight – 48.2 tons (with blade, cabin, ROPS protection, giant ripper) -Engine power 385 hp. Engine model 3408 (with direct injection of diesel fuel) - Blade capacity (according to SAE J1265) 13.5 cubic meters. The bulldozer has undergone a deep overhaul. The renovation is complete. At the first stage, a complete disassembly and troubleshooting of all units and systems of the machine was carried out. The assembly was carried out by replacing worn parts with new or restored ones (if this is possible without compromising the reliability and quality of the bulldozer). As a result of the repair, a machine was produced with a reliability life of at least 80% of a new original assembly machine. A difference of 20% was made possible due to the installation of a new Italian-made chassis (Berco), which has a service life slightly lower than the original one (Caterpillar). The following types of work were carried out: major overhaul of all components and assemblies, replacement of rubber goods, refueling with fuels and lubricants, painting, post-repair running-in and testing. During the repair, the following new spare parts were installed (enlarged):

- tracks assembled with shoes, rollers, idler wheels, segments

- cart bushings, roller balancer cartridge pins, balancer beam supports (outer and middle), track tensioner repair kit

- piston group, crankshaft, fuel system components, complete engine repair kit, turbocharger, starter, generator, exhaust tract, timing components

- Complete repair kits (seals, bearings, axles) for gearboxes, final drives, torque converter, final drive

- Transmission and hydraulic pump

- Complete repair kits for all hydraulic components - valves (5 pcs.), hydraulic cylinders (7 pcs.)

- Radiator sections

- Hydraulic and transmission hoses

- Bushings and fingers of working parts, knives and side cutters, shovel yokes

- Fuel and lubricants throughout the bulldozer

- Sensors, indicators, electrical wiring elements, windshield wipers, interior heater)

- Paintwork)

Most of the engine body parts, carts, bulldozer frame, gearbox body parts, final drives, valves, hydraulic and fuel tanks, cabin, ROPS protection, engine empennage and lower armor, ripper frame, blade with beams were left with the family. Currently, the Caterpillar D9N bulldozer (1996, machine weight 47.8 tons) is being overhauled, and the D9R machine (year 1998, 50.2 tons) is also being assembled.