Historical aspect

The YaMZ 236 motor was developed in 1951 on the basis of the YaAZ 204 and YaAZ 206 power units. The production of these internal combustion engines was carried out by the Yaroslavl Motor Plant, which later became Avtodizel OJSC.

Assembly shop of the Yaroslavl Motor Plant.

During the installation and modernization process, YaMZ engines began to be permanently installed on MAZ, URAL, KRAZ trucks, K-700 tractors and some military equipment, especially tanks and all-terrain vehicles.

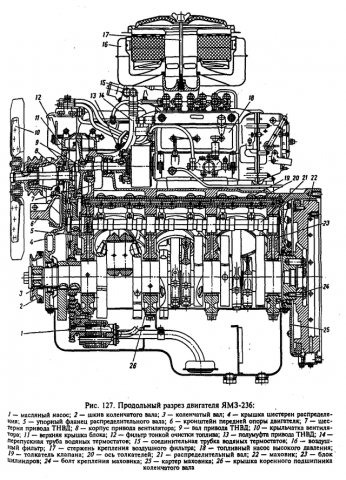

Technical characteristics and device

The technical characteristics of the YaMZ 236 engine have not changed much since the start of engine production. Only some technical and design elements have been added, such as turbocharging, power supply or exhaust gas systems.

Technical characteristics of the YaMZ 236 motor.

The main technical characteristics of the internal combustion engine 236 YaMZ.

| Name | Characteristic |

| Type | Diesel, turbocharged diesel |

| Volume | 11 liters (11,150 cm3) |

| Configuration, parameter | V-shaped |

| Number of cylinders | 6 |

| Number of valves | 12 |

| Econorm | from Euro-0 to Euro-4 |

| Cylinder diameter | 130 mm |

| Compression ratio | 17,5 |

| Cooling | Liquid |

| Valve mechanism | OHV |

| Material of block and head | Cast iron |

| Resource | 800,000 - 1,000,000 km |

| Fuel | Diesel fuel |

| Cylinder operating order | 1-4-2-5-3-6 |

| Applicability | MAZ, KRAZ, URAL, T series tanks, K tractors, LAZ buses, CHETRA all-terrain vehicle and more |

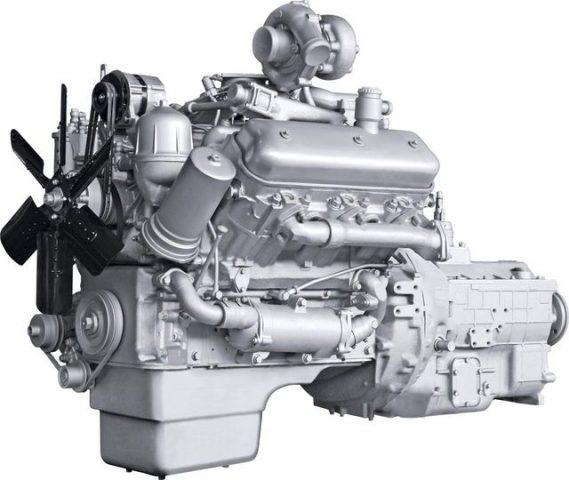

Motor modifications

At different times, there were different modifications of engines manufactured by the Yaroslavl Motor Plant. So, what types can be found on cars:

Engine YaMZ 236.

- YaMZ-236G - 150 hp. (110 kW) at 1700 rpm.

- YaMZ-236DK - 175 hp. (129 kW) at 2100 rpm, 667 N•m (68 kgf•m) at 1400 rpm.

- YaMZ-236ND - 210 hp. (154 kW) at 1900 rpm, 882 N•m (90 kgf•m) at 1300 rpm.

- YaMZ-236N - 230 hp. (169 kW) at 2100 rpm, 882 N•m (90 kgf•m) at 1300 rpm.

- YaMZ-236BK - 250 hp. (184 kW) at 2000 rpm, 1030 N•m (105 kgf•m) at 1200 rpm.

- YaMZ-236B - 250 hp. (184 kW) at 2000 rpm, 1030 N•m (105 kgf•m) at 1300 rpm.

- YaMZ-236BE2 - 250 hp. (184 kW) at 2000 rpm, 1078 N•m (110 kgf•m) at 1200 rpm.

- YaMZ-7601 - 300 hp. (220 kW) at 1900 rpm, 1275 N•m (130 kgf•m) at 1200 rpm.

Applicability

YaMZ 236 engines have become quite widely used. Thus, about two dozen brands and more than 40 models of cars, buses, military vehicles and construction equipment are still equipped with legendary engines.

URAL with YaMZ 236 engine.

The URAL-4320 with the YaMZ 236 engine has become quite popular. In addition to this brand of engine, there is also an older brother - the YaMZ-238. This motor is much more powerful, and therefore is installed on heavy construction equipment, tractors, and even strategic military vehicles.

Why have YaMZ engines become widespread? Unlike their Western counterparts, domestically produced power units are quite easy to repair and do not have a large amount of electronics, which makes repairs possible in the field.

Also, the motors have the necessary power so that the vehicle can pull a load even in the most difficult conditions. For example, sand that gets into the fuel system is not a hindrance, and it is easily removed from the engine.

So, let's look at which vehicles the YaMZ-236 power unit can be found on:

- The first in line, of course, are MAZ cars. The engines can be found on such models as: 500, 503, 504, 509, 516, 5335, 5549, 5551 and others.

- The second most widely used vehicle is the KRAZ: 255, 250, 257, 260 and 6322.

- Also installed on URAL series vehicles: 4320, URAL 5323.

- Also, the YaMZ-236 engine was also used on KAMAZ. So, the model 5320 was equipped from 1976 and 2000.

Ural 4320 fuel consumption per 100 km.

Page content

The production of medium-duty off-road trucks Ural-4320 began back in 1977. Initially, the car was produced for the needs of the army, but soon the capabilities of the truck were appreciated in the national economy - it became indispensable for the needs of the logging, oil and gas industries and in other cases when it was necessary to work in complete off-road conditions. Over the years of its production, the Ural-4320 went through several modifications, but all of them were limited to minor cosmetic changes to the cabin and the installation of different power units. Currently, production of the Ural-4320 continues, in parallel with the start of production of the new civilian version of the Ural-NEXT.

Ural-4320

Depending on the year of production, various versions of naturally aspirated V8 diesel engines were installed on the Ural-4320 truck. Until 1993, almost all models were equipped with a KamAZ-740 diesel engine, but since 1993 they began to install 11.5-liter V6 engines YaMZ-326 or 14.9-liter V8 engines YaMZ-238, developing power of 210 and 230 hp. respectively. Since 2011, all Ural-4320 have been equipped with modern, economical in-line YaMZ-536 engines with a volume of 6.7 liters and a power of 230 hp. or turbodiesel V6 YaMZ-6565 with a volume of 11.1 liters and a power of 300 hp. The transmission is a 5-speed manual gearbox with a two-stage transfer case that transmits torque to all three drive axles.

Real reviews about the fuel consumption of the Ural-4320 per 100 km.

- Oleg, Miass. Consumption in the Urals greatly depends on the cost of the engine. At our enterprise we have several Urals with different engines, mine still has an old KAMAZ engine - the consumption is about 30-35 liters, but this is only for pure mileage, without load. It can carry up to 40 liters loaded.

- Sergey, Tyumen. I work on a timber carrier Ural-43202-01, with a gross weight of 15 tons. It’s stupid to compare this car with foreign trucks - they are in completely different categories. I previously worked in a Mercedes Atego, of course there was comfort and all that. In the Urals, the concept of comfort and convenience for the driver is completely absent - but in terms of cross-country ability, hardly anyone can compete with it. The truck's consumption is high - with a trailer of 15 tons in the taiga it comes out to about 50 liters per 100 km, no less.

- Alexey, Krasnoyarsk. Before the Urals, I had a Shishiga, but the body was small, so I took the Ural. I did a complete tuning - I installed comfortable seats in the cabin, replaced the axles, installed a winch, a snorkel, installed a radio station and a couple of berths in the back. There is plenty of space in the back – you can easily stow a couple of inflatable boats, camping equipment, a supply of provisions and even an ATV if necessary. Fuel consumption depends on the terrain - if on the highway, then I fit in 30-32 liters, off-road from 45 to 70 liters.

- Konstantin, Kirov. In the Urals he served in the army - he served as a driver. I wouldn’t wish anyone to drive such a car in my life – it shakes my whole soul, Kamaz is much better and more comfortable. Diesel fuel consumption is simply outrageous - with a platoon of soldiers in the back, 50 liters, like straight out of a bush. I would never take one like this for work.

- Andrey, Krivoy Rog. A couple of years ago I got a job in an office that had a bunch of different special equipment. I received a crane on the Ural-4320 platform - what a gift. The car is, of course, passable, but because of this they sent me into every hole where it was difficult to send other cars. The consumption is huge - on the highway 35 liters, in a quarry or off-road easily 50 liters, or sometimes even more.

- Anton, Ufa. I own a Ural-4320, manufactured in 2011. The Yaroslavl turbodiesel engine, 11 liters, produces 300 horses. I will say this - this is even a lot for the Urals - all-wheel drive allows you to overcome any mud and off-road conditions. Well, the truth is that the consumption is appropriate - it doesn’t eat less than 40 liters, or even more.

- Sergey, Omsk. I used to drive a Kamaz 6x6, then the authorities bought new Urals with YaMZ-535 and YaMZ-5656 engines. I got a shift car with a 230-horsepower engine - this engine is just right for it, the power is not particularly needed, since apart from the duty crew and a small number of spare parts, I don’t drive anything special. Consumption is high - from 35 to 42 liters per 100 km, but no other car will get to where I take the guys; the same KamAZ trucks get stuck tightly, despite all-wheel drive.

avtozhor.com

Service

Maintenance of the YaMZ 236 engine is identical, as for all identical domestically produced diesel engines. Thus, service intervals are carried out every 15,000 km for the basic version, and for a turbodiesel - every 20,000 km.

The maintenance process is slightly different from regular gasoline engines. Each maintenance is a whole complex of operations aimed at maintaining the technical condition of the car. What is included in the maintenance of YaMZ 236 series engines:

T-150 with YaMZ 236 engine.

- Change of oil.

- Valve Mechanism Adjustment

- Replacing filters. So, depending on the engine modification, the following filter elements may or may not be present: a fine and coarse oil filter, a filter element for coarse and fine fuel purification, an air filter, an eco-filter for exhaust.

- Cleaning the injectors.

- Adjustments related to the high pressure fuel pump.

- Other operations aimed at maintaining the power unit.

YaMZ AD-100, technical characteristics

Prime power - for continuous operation of the 100 kW YaMZ-236BI diesel generator in accordance with GOST 13822-82. For 1 hour, a load of up to 110% of the main (nominal) power is allowed. Between overloads there must be a break necessary to establish normal thermal conditions. The total operating time in the 10% overload mode should not exceed 10% of the time worked by the diesel engine from the start of operation or after repair.

Reserve power (Stand-by power) - for operation of a 100 kW YaMZ-236BI diesel generator in accordance with GOST 10150-88. The annual operating time should not exceed 500 operating hours. Overloads are not allowed.

The price of diesel generator 100 kW YaMZ-236BI , unless otherwise stated, is indicated on the website for the open version of the diesel generator set 100 kW YaMZ-236BI (AD-100-T400), with a synchronous generator Linz Electric (Italy), in the minimum configuration (without battery and muffler) when purchasing a 100 kW YaMZ-236BI diesel generator on the terms of 100% prepayment of the cost of a 100 kW YaMZ-236BI diesel generator, during the period when the engine manufacturer provides a special auction price for the supplied components. The price of a 100 kW YaMZ-236BI diesel generator (AD-100-T400 diesel generator set) in a specific configuration directly depends on the set of installed equipment, the type of execution of the 100 kW YaMZ-236BI diesel generator, payment terms when purchasing a 100 kW YaMZ-236BI diesel generator set, etc. The indicated price for a 100 kW YaMZ-236BI diesel power plant is for informational purposes only and under no circumstances can it be considered a public offer determined by the provisions of Art. 437 part 2 of the Civil Code of the Russian Federation. If you want to buy a 100 kW YaMZ-236BI diesel generator with additional equipment or buy a 100 kW YaMZ-236BI diesel generator set of a different type, be sure to contact our managers to clarify the characteristics and price of the 100 kW YaMZ-236BI diesel generator (AD-100-T400 ) in a specific configuration. You can find out complete up-to-date information on the availability of promotions, delivery times and prices for the 100 kW YaMZ-236BI (AD-100-T400) diesel generator set by phone: 8-800-3333-701.

Images of the 100 kW YaMZ-236BI diesel power plant, as well as its individual elements, may not fully correspond to the actual equipment supplied, including images of additional equipment. equipment not included in the standard package of diesel power plant 100 kW YaMZ-236BI (AD-100-T400), various design options. Diesel Company LLC reserves the right to change the configuration, appearance and characteristics of the AD-100-T400 YaMZ-236BI diesel generator set without prior notice.

Repair

Repair of the YaMZ 236 engine is carried out quite standardly for the entire series of engines produced by the Yaroslavl Motor Plant. Thus, in-line repair work is carried out directly on the car.

Depending on the make, model and design features of the vehicle on which the engine is installed, even major repairs can be performed without removing the power unit. Moreover, this is a condition that no boring is required.

The process of overhaul of YaMZ 236.

Often, if a restoration or major overhaul is underway, the engine is bored. As recent practice shows, most old cylinder blocks are not subject to boring and honing, and therefore they undergo a liner process. The block heads are quite durable, which makes it possible to go through them not often, but when overhauling, this is a mandatory procedure.

Another element with a modest lifespan is the oil pump. It is this that is often changed even before a major restoration of the power unit is carried out. Along with this part there is a water pump, which is unbearable and, as practice shows, quickly fails. But there is a way out - installing a repair kit, which is quite cheap.

Modern YaMZ-236

Cast iron was used as the base material at the plant until 2010. But later engineers and designers decided that it was time to use aluminum. Now the block and cylinder head are made from this metal, which has greatly simplified the repair of the YaMZ-236 and the boring of the combustion chamber journals. Also, the honing procedure has become much more accurate. At the same time, the block did not lose its strength. For YaMZ-236, the price in this form is 460 thousand rubles. On the secondary market you can buy copies for 50-200 thousand rubles. It all depends on the condition.