The Tarpan cultivator is a domestic product. The devices are produced by Tulamashzavod, a diversified enterprise that produces military and civil products, including small-scale mechanization equipment and road-building equipment. The technical capabilities of the plant allow it to carry out a full range of metalworking and protective coatings, and numerous subsidiaries make the plant almost completely independent of third-party organizations.

Tarpan motor cultivators are known not only in Russia, but also far beyond its borders - the equipment is supplied to the CIS countries, as well as near and far abroad.

Now we will look at the design features of walk-behind tractors and cultivators made in Tula, and give recommendations for selecting a model based on technical characteristics and the needs of owners of summer cottages and farms.

Advantages and disadvantages of Tarpan brand cultivators

Since Tarpan motor cultivators are assembled at an enterprise belonging to the defense industry, the plant’s products are distinguished by high quality and reliable assembly. The first models began to be assembled in the early 90s, when the production crisis forced the company to look for alternative directions of development. Lack of experience left its mark on the first cultivators - they could not compete with the products of foreign manufacturers. However, after introducing new technologies and concluding contracts with leading manufacturers of engines for agricultural machinery, Tulamashzavod was able to assemble equipment that meets the most stringent technical requirements and standards.

The competitive advantages of modern Tarpan motor cultivators include:

- Reliable, durable motors from leading industry manufacturers;

- High build quality, technical performance;

- Adaptation to domestic operating conditions;

- Low maintenance, high maintainability;

- A wide selection of attachments allows you to expand the range of work performed.

The disadvantages of the devices include a fairly small number of service centers and company representative offices, which creates certain difficulties in the process of servicing and repairing equipment. However, this drawback is compensated by the simplicity of the design - if necessary, following the instructions in the user manual, the owner of the cultivator will be able to independently eliminate most of the malfunctions.

Characteristics

All cultivators offered by the company are equipped with standardized control handles mounted on a fixed steering column. The handles are adjustable in angle of inclination; during transportation, the parts are folded, reducing the dimensions of the equipment. On the handles there are controls connected to the actuators by steel cables passed through the shells. Cable drives are equipped with special adjusting couplings.

The width of the processed strip is 350-1100 mm, depending on the power and modification of the cultivator. Motors can be removed for installation on a four-wheel lawn mower, which is purchased separately. This design expands the scope of application of agricultural equipment and makes it easier to care for lawns in front of country houses.

Model range and modifications

The model range of Tarpan cultivators is represented by electric and gasoline devices, which makes it easy to choose a model based on personal preferences and operating conditions.

Let's look at the motor cultivators that are most popular among domestic buyers.

Electric cultivator Tarpan 07 2.2 kW

| Engine | Electric |

| Power, kW/l. With. | 2,2/3,0 |

| Number of speeds | 1 forward |

| Soil cultivation width, mm | 560 |

| Soil cultivation depth, mm | 150 |

| Weight, kg | 45,0 |

A small-sized cultivator equipped with an electric drive that requires constant connection to a household AC network with a voltage of 220 V. This circumstance limits the range of the device by the length of the power cord.

The model is designed for loosening the soil, weeding, and applying organomineral fertilizers to the soil. The drive power is sufficient for processing clayey areas. A high-quality worm gearbox ensures reliable transmission of torque.

It is worth noting that the manufacturers took care of the safety of users - the rubber handle and double insulation provide reliable protection against electric shock.

The main advantage of the model is the absence of harmful exhausts that pollute the atmosphere, which allows you to carry out work inside greenhouses and greenhouses. The electric motor requires no maintenance throughout its entire service life, reducing operating costs.

The disadvantages of the model include the short cable length for connecting to the network - only 0.7 m, which forces owners to use extension cords. In addition, the delivery package does not include transport wheels, which creates some difficulties when moving the cultivator around the site.

Tarpan TMZ-MK-03 (B&S 675EXi) 5.5 hp

| Engine | Petrol |

| Make, drive model | Briggs&Stratton 675EXi |

| Power, kW/l. With. | 5,5/7,5 |

| Working volume, cm³. | 163 |

| Number of speeds | 1 forward |

| Soil cultivation width, mm | 700/1000 |

| Soil cultivation depth, mm | 200 |

| Weight, kg | 45,0 |

Motor cultivators Tarpan TMZ-MK-03 are productive, middle-class machines designed to perform work on small plots of up to 20 acres. The designers provide the possibility of installing attachments, which expands the functionality of the device.

The cultivator is equipped with a reliable American Briggs&Stratton 675EXi engine, which is characterized by stable operation and easy starting, regardless of the ambient temperature. Please note that EXi SERIES engines do not require periodic oil changes - for normal operation it is enough to simply check the level regularly and, if necessary, add lubricant. The float-type carburetor ensures optimal fuel delivery, and the integrated mechanical governor maintains the required level of power even under intensive use.

The drive power is sufficient to process any areas, including virgin lands.

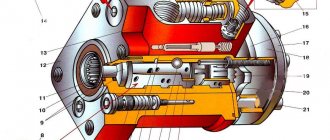

This model is equipped with a fairly reliable single-stage worm-type gearbox, the moving elements of which operate in an oil bath.

A distinctive feature of the model is its folding design. Before transportation or during preparation for off-season storage, the cultivator can be divided into two parts. If necessary, the device can easily fit in the trunk of any car. Manufacturers have provided the possibility of installing additional cutters to increase the working width of the soil.

The only drawback of the model is the lack of reverse, which could increase the maneuverability of the equipment and simplify the work in confined spaces.

Tarpan TMZ-MK-03 (Tarpan 173) 5 hp.

| Engine | Petrol |

| Make, drive model | Tapran 173 |

| Power, kW/l. With. | 5,0/6,0 |

| Working volume, cm³. | 173 |

| Number of speeds | 1 forward |

| Soil cultivation width, mm | 700/1000 |

| Soil cultivation depth, mm | 200 |

| Weight, kg | 45,0 |

This model is a modification of the popular Tarpan TMZ-MK-03 series devices. The only difference from other cultivators is the type of engine.

This unit is equipped with a Tarpan 173 gasoline internal combustion engine - an overhead valve engine with a vertically positioned crankshaft, characterized by reliability and ease of maintenance.

Please note that this engine is supplied dry - you must purchase and fill engine oil yourself.

Tarpan TMZ-MK-03 (Kohler XT775) 6 hp.

| Engine | Petrol |

| Make, drive model | Kohler XT775 |

| Power, kW/l. With. | 6,0/8,2 |

| Working volume, cm³. | 173 |

| Number of speeds | 1 forward |

| Soil cultivation width, mm | 700/1000 |

| Soil cultivation depth, mm | 200 |

| Weight, kg | 45,0 |

The most powerful representative of the Tarpan TMZ-MK-03 line of cultivators. The device is powered by a Kohler XT775 - a reliable American single-cylinder engine with overhead valves, equipped with a cast iron liner with increased wear resistance. The Twin-Cam design allows for efficient cooling, as well as increased power and longer engine life.

Tarpan 03-02 WM168FB

| Engine | Petrol |

| Make, drive model | Weima WM168FB |

| Power, kW/l. With. | 6,5/8,2 |

| Working volume, cm³. | 196 |

| Number of speeds | 1 forward/1 reverse |

| Soil cultivation width, mm | 700/1000 |

| Soil cultivation depth, mm | 200 |

| Weight, kg | 45,0 |

A multifunctional agricultural device that will be useful both in the country and on the farm. The power reserve is enough to handle the most difficult areas with dense soils.

The cultivator is driven by a reliable WEIMA WM 168 FB gasoline engine with forced air cooling and an emergency shutdown system when the oil level is low, which ensures high operational safety. The engine runs quietly on low quality fuel, guaranteeing a long service life.

The main advantage of the model is the presence of reverse gear, which increases maneuverability, allowing you to effortlessly turn the device on the spot.

It is possible to install various attachments, including plows and hillers.

Tarpan Zongshen

| Engine | Petrol |

| Make, drive model | ZONGSHEN ZS XP175 |

| Power, kW/l. With. | 4,0/5,5 |

| Working volume, cm³. | 175 |

| Number of speeds | 1 forward/1 reverse |

| Soil cultivation width, mm | 700/1000 |

| Soil cultivation depth, mm | 200 |

| Weight, kg | 45,0 |

Another variety of the Tarpan TMZ-MK-03 series. The model is equipped with a ZONGSHEN ZS XP175 engine - a powerful engine designed to be refueled with AI-92 unleaded gasoline.

The advantages of the design include the Easy Start system and transistor ignition, which allow quick and easy engine starting even at sub-zero temperatures.

Attachments

and its subsidiaries produce universal attachments that are suitable not only for Tarpan cultivators, but also for other domestic and foreign-made devices.

A wide range allows you to choose devices for any job:

- Plows - for deep plowing of soil with a full rotation of earth layers;

- Hillers - used for cutting ridges and furrows before planting. They are used in conjunction with weeders, which help create the necessary traction force;

- Weeders - lugs with knives attached to the hub, designed for weeding rows and loosening the soil;

- Lugs - improve traction when processing loose soils;

- Side protective discs – prevent damage to plants by cutters during work;

- Crawler's foot cutters - designed for plowing hard soil;

- Frames with transport wheels are used for transporting various goods.

Service Features and Operating Instructions

The instruction manual is the main document of the cultivator, which contains a description of the design, as well as rules for operation, maintenance, storage and transportation. Compliance with the rules will help the owner increase the service life of the equipment and ensure safe working conditions.

First launch and run-in

After assembly, the new cultivator undergoes a conservation procedure necessary to protect the mechanisms from corrosion. Before the first start, the owner must unscrew the spark plug, wash it with gasoline, and also rotate the crankshaft 10-15 revolutions to remove preservative lubricant.

In most cases, engines are supplied without engine oil. It should be remembered that malfunctions caused by dry operation of the motor are not covered by warranty. The oil must be selected based on the ambient temperature and the recommendations of the engine manufacturer.

During the first 12 hours of operation, the cultivator is run in - the friction pairs of all moving units are run in. During the break-in process, it is not recommended to use the cultivator at full power.

Upon completion of the break-in, it is necessary to replace the engine oil, which contains chips and other by-products of running in the cultivator components.

Changing the oil in the gearbox

According to the requirements of the operating manual, after the first 5 hours of operation it is necessary to change the oil in the gearbox. When selecting a lubricant, you must follow the requirements of the operating manual.

Most gearbox models are designed for oils with API GL-4 or GL-5 approval. Using the wrong lubricant, for example TAD-17 or NIGROL, can quickly damage the gearbox.

Replacing oil seals

During operation, under the influence of external factors, mechanical damage to the gearbox seals may occur, which leads to oil leaks from the mechanism. If the cultivator is still under warranty, we recommend contacting your nearest service center. An alternative option is to replace the seals yourself.

Before performing work, it is necessary to drain the oil from the gearbox. You should also note the spatial position of the shaft relative to the housing to eliminate the possibility of incorrect assembly.

Possible faults

| Malfunction | Probable Causes |

| Difficulty starting the engine | · The speed controller settings are lost; · Fuel supply to the carburetor is interrupted; · Malfunction of the ignition system; · Carburetor clogged. |

| The engine gets very hot | · The air filter is clogged; · The cooling system is clogged. |

| The engine cannot reach maximum speed | · The air filter is clogged; |

| Motor output shaft does not rotate | · The engine runs at low speed; · Centrifugal clutch does not work. |

| The engine output shaft rotates at idle speed | · Clutch springs are stretched or damaged; · The engine speed controller control is incorrectly configured. |

| Oil is leaking from the gearbox | · Reducer seals are damaged; · Crack in the gearbox housing. |

If you do not have experience in repairing or servicing cultivators, we do not recommend troubleshooting them yourself. Unqualified intervention can aggravate the situation.

The starter squeals, the cord comes out

It may squeal if there is a lot of grease on the balls. You need to clean the balls and the places in the ratchet where they are inserted.

The cultivator made several pops, the speed began to “float”

Most likely, the power system cannot cope, or the fuel level in the tank is low, the float axis may be skewed and debris may have gotten under the needle valve, you need to remove everything and check the air filter and jets.

The material will be updated, we are waiting for comments with questions, stories about identifying a particular malfunction and ways to eliminate it. Also, see the answers to questions about a particular walk-behind tractor model on its description page.

A walk-behind tractor is a technique that has many functions and is a faithful and indispensable assistant on any plot of land. With the help of additional attachments, such a unit performs many different jobs. With prolonged use of this or that equipment, it begins to fail. If maintenance is carried out on time, malfunctions may appear only due to wear and tear of parts.

A frequently asked question among users of such equipment is “why does the walk-behind tractor stall under load.” In most cases, it turns out that the problem is in the engine. It is better to entrust troubleshooting of the walk-behind tractor to a specialist, but if you also understand this matter, you can repair it yourself. If you nevertheless encounter a problem when your equipment does not start or starts, but sneezes and stalls when the air damper is opened, you need to immediately find out what the reason is and repair it.