Vegetable growing » Potatoes

1

678

Article rating

Kira Stoletova

In order for potatoes to produce a good harvest, it is necessary to properly care for the crop. Thus, hilling up potatoes with a cultivator is considered an important event.

Rules for hilling potatoes with a cultivator

The procedure is needed to control weeds, to protect potatoes from direct sunlight, and to retain moisture in the soil.

Many have noticed that some of the dug up potatoes are green in color - this negatively affects not only the appearance of the vegetable, but also its taste, as a specific bitterness appears. It is classified as unfit for food. Green potatoes are the result of insufficient hilling.

Potato cultivators

There are many types of cultivators. They are divided into claw and milling, single-row and multi-row. Available for manual and tractor use. To make it easier to make a choice, consider the characteristics of popular cultivators that are used to care for potatoes.

Milling cultivator KF-2.8

A native of the Belarusian plant Tekhmash. Used simultaneously for inter-row processing and fertilization of 4 rows of vegetables. The processing width is 2.8 m, the loosening depth is from 2 to 12 cm.

Milling cultivator KF-3.6

A graduate of the same Techmash. Used simultaneously for inter-row soil cultivation and fertilization of 6 rows of vegetables. Processing width is 3.6 m, loosening depth is from 2 to 12 cm.

USMK-5.4

With the help of this cultivator, inter-row loosening is carried out with the possibility of simultaneous fertilization. In one pass, the unit covers 30 rows of beets. UMSK-5.4 is also used for continuous pre-sowing soil treatment. The coverage width is 5.4 m, the loosening depth with tines is from 4 to 14 cm. The cultivator is convenient because it can fold up to 2.5 m when driving on roads.

USMK-5.4 with feeding device

The tine cultivator from Tekhmash allows you to loosen the soil between the rows and at the same time apply fertilizer. Covers 30 rows of beets in one pass. Used for continuous tillage of soil. The coverage width is 5.4 m, the loosening depth with paws is from 4 to 14 cm.

USMK-5.4 with AVPU-12

It is convenient to use because it folds up to a width of 2.5 m when driving on roads. A special device is built into the unit that allows you to add herbicides to the soil. In one pass, it fertilizes 30 rows of beets with simultaneous inter-row soil cultivation. It is also used for continuous pre-sowing treatment. 1 pass covers 5.4 m with a loosening depth of 4 to 14 cm.

A native of the Belarusian Techmash, it allows not only to cultivate the soil, but also to apply liquid fertilizers.

Mounted cultivator KRN-4.2

In one pass, it cultivates 8 rows of row crops, the distance between which is 60, 70 and 90 cm. It thoroughly loosens the soil and trims weeds. Allows simultaneous fertilizing with mineral fertilizers.

Mounted cultivator KRN-5.6

The working width is 5.6 m. It has adjustable processing depth. It is used for hilling, loosening, removing weeds, and cultivating row spacing. Protective discs protect plants as much as possible during soil cultivation.

Mounted cultivator KMN-8.4

In one pass, the soil is completely prepared for sowing. Performs several functions simultaneously:

- rolling of plowed soil;

- harrowing;

- cultivation.

Combs out weeds, cultivates to a depth of 3–10 cm, retains maximum moisture and levels the soil. Reduces energy costs by half.

Types of potato cultivators

1. By purpose:

- steam cultivators – used for cultivating land before planting crops;

- row crops – used for loosening, weeding and hilling plants.

2. By type of working tools:

- disc - capable of cultivating soft soils and cutting weeds;

- with pointed paws - help loosen the soil and apply fertilizers;

- plowshares - used to prepare the soil for planting;

- milling – suitable for loosening dense soils;

- chisel – for deep soil cultivation.

3. By type of traction:

- gasoline (two-stroke and four-stroke) - capable of working in remote areas, but require complex maintenance;

- electric – low maintenance, but requires frequent battery charging or a connection to the power supply;

- mounted or trailed - attached to a tractor or walk-behind tractor;

- manual - simple, reliable, economical, but require the use of physical force during operation.

4. By power and weight:

- heavy – they have a power of up to 10 l/s and a weight of more than 60 kg, are used for large areas, with heavy soils, loosen the soil to a depth of 30-35 cm;

- medium - have a weight of up to 40 kg and a power of 4-6 l / s, go deep into the ground by 20-25 cm;

- light – with a power of 2-3 l/s and a weight of up to 20 kg, they process the soil to a depth of 15 cm;

- ultra-light - their power is 1-1.5 l/s and their weight is up to 10 kg, they are capable of loosening the soil to a depth of 10 cm.

5. According to the number of hilled rows:

- single row;

- multi-row.

One of the most popular disc cultivator designs

Loosening potato rows using a walk-behind tractor

To use a walk-behind tractor for loosening the soil, potatoes are initially planted according to the appropriate parameters:

- distance between rows - 70 cm;

- the longest rows;

- There must be space at the edges to turn the unit.

Loosening is combined with the first hilling; it is carried out 15 days after planting the potatoes. For this purpose, a hiller plow or disk attachments are used. In order for the walk-behind tractor to better engage the ground, it is recommended to replace conventional wheels with metal ones with lugs.

If loosening is carried out by a hiller, a universal hitch is hung on the walk-behind tractor, installing one or more hiller plows on it.

When using disk attachments, you need to adjust the angle of rotation and the distance between them. The distance can vary from 40 to 70 cm, it all depends on the type of potato and the height of the bushes. The angle of rotation depends on the density of the soil.

Application of the inter-row cultivator of the Bolero series

The cultivator is designed for high-quality inter-row cultivation to a given depth of high-stemmed row crops during various periods of their growing season.

Inter-row cultivation of tall crops is one of the key types of proper and timely care of crops, without which it is not possible to obtain a rich harvest. Thanks to inter-row cultivation, the soil crust is destroyed, the top layer is loosened to a fine-grained state, weeds are pruned, and insect pest larvae die. After cultivating the soil with an inter-row cultivator, for example for potatoes, optimal density and clumping is achieved in the tuberization zone, and a voluminous ridge is obtained. Moisture retention, soil air exchange and nutrient regime are improved, and the costs of applying fertilizers, herbicides and pesticides are reduced.

Thanks to being equipped with working bodies of various profiles and adjusting the row spacing, inter-row cultivators can care for crops of row crops with tall stems. Optionally, the Bolero cultivator can be equipped with systems for feeding plants with dry or liquid mineral fertilizers.

The cultivator is equipped with working parts taking into account the crop being cultivated, soil conditions, weeds, the presence of stones, and soil moisture. There is a wide range of easily replaceable working parts: pointed tines, chisels, and you can also purchase razor tines, chisels, hillers, rotary hoes, spring teeth separately, all this allows you to adapt the cultivator for the first and subsequent cultivations in row spacing from 45 cm to 70 cm .

As a standard, Bolero interrow cultivators are supplied equipped with pointed tines without a fertilizer application system. Quick-change working bodies are assembled into sections, which in turn are installed on the supporting beam of the cultivator. The original hinged fastening of the cultivator sections to the supporting beam ensures movement of the section in the vertical plane, allowing you to copy the relief and ensuring a constant angle of entry of the working parts into the soil.

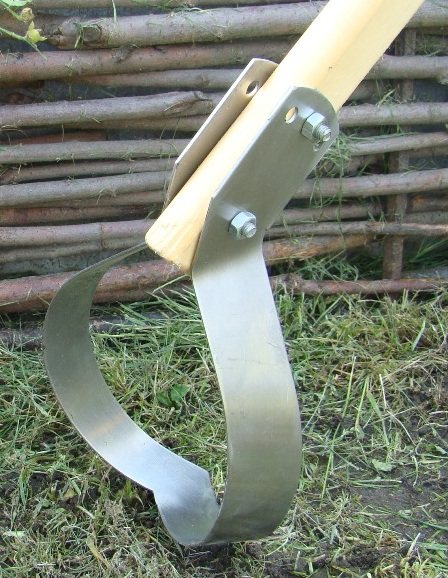

Homemade cultivator for processing

Of course, it is easier to buy a cultivator for inter-row tillage. But not everyone has this opportunity. In this case, you can make the device yourself. In principle, if you follow the instructions, there is nothing difficult about it. The manufacturing process takes several stages:

- You need to find 3 metal disks or rings with a diameter of 10, 20 and 30 cm. If you use rings, the design will be lighter.

- Select a pipe with a diameter of 25 mm. Place the disks on it (from largest to smallest) at a distance of 15 cm from each other.

- Next, the spikes are welded. Usually metal rods are used for this. The unit will need about 40 spikes about 12 cm in length. The smaller disk has 5 spikes, the medium one - 10, the large one - 15. The rest are distributed onto the pipe.

- Using abutments and bushings, the discs are secured to the frame at an angle of 45 degrees.

- Wheels are mounted. A bracket is made from a metal strip 7 cm wide and 4 mm thick . To secure the guide wheels, holes are made in it. For a cultivator, two wheels are enough.

Development of working parts for a cultivator for inter-row tillage

Diploma project on the topic: “Development of working parts for a cultivator for inter-row tillage”

The farm in question specializes in the production of meat and dairy products, as well as grain and potatoes.

The delivery points for agricultural products are located: grains are delivered under government orders, the rest is sold under contracts and in the markets of the regional center and other nearby cities. The farm is served by the Volozhin branch of “Agricultural Equipment”, as well as the Minsk Engine Repair Plant.

We carried out an analysis of potato cultivation under the conditions of the agricultural enterprise “Kukmoragrokhimservice”. This sheet of the graphic part presents general indicators of potato cultivation on the farm, such as: cultivation area, yield, as well as costs associated with potato cultivation

We analyzed the working bodies for inter-row processing of potatoes. An overview of some working bodies is presented on this sheet of graphical part. The advantages and disadvantages of the working bodies are also presented here. On the basis of which we drew conclusions on the effectiveness of using one or another working body and proposed the design of the working body and cultivator, which is presented on the following sheets of the graphic part. Advantages of the developed working body for inter-row processing. It consists in the fact that the design of the working body includes a shock-absorbing device that protects the working parts of the hiller from damage when encountering stones, and also partially reduces damage to potato plants when the fingers of the hilling body come into contact with the potato stem.

For a more visual representation of the operation of the cultivator, this sheet of the graphic part shows a technological diagram of the operation of the cultivator.

As a result of the development, it will be necessary to produce the following parts shown on the sheets of the graphic part.

I performed kinematic, structural, and energy calculations. The design calculation includes calculation of the dimensions of the separator drum, chain drive, as well as calculation of the top separator drum for bending and torsion.

To determine some technical characteristics, and in particular the speed of movement and productivity, an operational and technological map was calculated, which is shown below on the sheet of the graphic part.

The diploma also addresses issues of life safety and justification for the environmental safety of the environment when cultivating potatoes. We determine the economic efficiency of the developed machine by comparing the KON-2.8 cultivator and the used KAMO-2.8 cultivator with an automatic hilling worker. Thus, during the design, the annual income amounted to 288.6 thousand rubles, the net present value is equal to 1345.1 thousand rubles. At the same time, direct labor costs were reduced by -0.02 h/ha, the return on investment ratio was -3.1.

Weeding potato rows with a walk-behind tractor

The walk-behind tractor is a universal tool. With its help, you can plow the soil, plant and hill up root crops, harvest crops and carry out weeding. There are 3 types of walk-behind tractor devices with which you can perform these functions.

The most popular device. The tines are easy to install and use, but most importantly, they work neatly between rows. Paws can be one-sided or two-sided. The latter allow you to weed potatoes simultaneously from both sides.

Weeder

This is an iron frame onto which several knives are attached and a special drum is installed. The more knives, the higher the quality of weeding. The function of the blades is to cut weeds. The drum, carefully hooking its paws, throws them back.

This unit consists of ring blades, on the sides of which there are pins to rid the machine of weeds. There are two types of hedgehogs: cone and rotary. The former are used for weeds that have not yet emerged, the latter for fluffing, weeding and hilling.

Weeding is an important step in the process of growing potatoes. This procedure allows you not only to remove all weeds from the garden, but also to loosen the soil. Thus, nitrogen freely flows to the roots along with the air, stimulating the growth of potatoes. Recently, gardeners have given preference to special motor cultivators, which make it much easier to cultivate the soil. Let's look at how weeding potatoes with a motor cultivator is carried out, and which harrows are best used for these purposes.

Weeding potatoes using a flat cutter

Many gardeners claim that a flat cutter is the most convenient tool for weeding potatoes. These devices are distinguished by width. There are 4 types in total:

Accordingly, a flat cutter with the designation 240 processes a row spacing of 240 mm wide in one pass, and a flat cutter with the number 700 can handle a distance almost 3 times larger. It is not necessary to use only one type of flat cutter. They can be combined or used one at a time.

The holes on the stand of the flat cutter allow you to adjust the height and depth of plowing. Such devices are made of high quality steel and can serve you for many years. The metal for the cutting part undergoes heat treatment, which makes the flat cutter durable and hardy.

There are flat cutters with a ripper that process the soil better. The ripper is made of eight round plates, which have peculiar cutouts. Such disks are located on an axis and begin to rotate when moving. There is also a spring on the structure that presses the ripper to the soil. This is a great tool for those who don't like to do the same job twice. The flat cutter-ripper copes well with the task, removing all weeds from the rows, as well as loosening the soil.

Homemade cultivator for processing potatoes

The cost of a purchased cultivator reaches tens of thousands of rubles, so craftsmen have mastered the independent production of this useful mechanism.

You may be interested in: Do-it-yourself pump for decorative fountains and waterfalls at the dacha Dates for planting potatoes in May-June 2020 according to the lunar planting calendar Rating of the best mini-tractors: models with characteristics and descriptions with photos

Materials for making a cultivator:

- Metal sheet 5 mm thick;

- Steel strip 20 mm wide, 4 mm thick;

- Steel strip 45 mm wide, 10 mm thick;

- Rod with a diameter of 10 mm;

- Square profile 50 mm wide;

- Corner width 50 mm;

- Metal pipe with a diameter of 25 mm;

- Rod with a diameter of 20 mm;

- Bolts, nuts.

Tools and accessories:

- Gas cutter;

- Welding machine;

- Roulette, compass, scriber;

- Emery;

- Angle grinder (grinder) with discs.

Four circles with diameters of 300, 200, 100 and 26 mm are drawn on a metal sheet. Next, three rings are cut out along these circles using a gas cutter, and the unevenness of the rings is processed using sandpaper.

Pins 100 mm long are cut from the rod, one end of each pin is sharpened at an angle of 45 degrees. The pins are evenly distributed around the circumference of the disk and welded to the outer rib. 14 pins are welded to the large ring, 10 to the medium ring, and 6 to the small ring.

From a steel strip 20 mm wide, 12 strips 90 mm long are cut. Using 8 strips, weld the large ring to the middle one at a distance of 75 mm, using 4 strips, weld the middle ring to the small one at a distance of 75 mm. The strips are welded, evenly distributed around the circumference of the ring.

Note: To make it easier to weld the strips to the rings, their ends are cut with a grinder at an angle of about 30 degrees.

A piece of pipe with a diameter of 25 mm and a length of 170 mm is inserted perpendicularly into the small ring and welded.

Another loosening cutter is made in a similar way.

A trapezoid is welded from the corner, 60 mm wide at the bottom and 40 mm at the top; rods are welded to the sides of the trapezoid, onto which loosening cutters are put. Before putting the cutter on the rod, it is generously smeared with lithol. At the end, the rod secures the cutter with a bolted connection. In the center of the trapezoid, two metal plates are welded perpendicular to the base, between which the cultivator stand will be fixed.

A vertical stand is cut out of a strip 45 mm wide, 10 mm thick, 500 mm long, placed between metal trapezoid plates and secured with a bolt. At the opposite end of the rack, adjustment holes with a diameter of 10 mm are drilled in increments of 50 mm.

In a similar way, two more double-sided cultivator cutters are made.

An W-shaped cultivator frame is welded from a square profile, a towbar for a tractor is welded to the middle, and slots are made at the ends of the frame. The vertical stand of the cutter is inserted into the slots and secured with a cotter pin connection. By raising and lowering the vertical stand, the depth of soil loosening is adjusted.

The resulting structure is painted with nitro paint.

Weeding potatoes using a walk-behind tractor and a hedgehog

Everyone will agree that weeding potatoes with a regular hoe takes a lot of time and also requires enormous effort and endurance. It is especially difficult for owners of large plots of land. In this case, there is no way to do without a motor cultivator. In addition, the choice of harrows for weeding is quite large. For example, a cultivator for inter-row cultivation of potatoes called a hedgehog will do an excellent job of removing weeds in potato plantings.

This device consists of rings of different sizes on which teeth and spikes are located. The hedgehog has a cone-shaped appearance. Usually, 2 such devices are used to cultivate a vegetable garden, placing them at the same distance from each other at an angle. You can make the hedgehog yourself at home. The main thing is to choose high-quality material and assemble the structure correctly. Often, discs that did not perform well during the weeding process are used for this purpose. The fact is that soil and picked weeds are constantly packed between the discs.

The Hedgehog is a smaller version of the large rotary harrow for tractors and operates on the same principle. It penetrates into the ground with ease. And then, rotating, it loosens the soil, simultaneously pulling out weeds with roots from the rows.

Cultivator for inter-row cultivation of potatoes

(12) NATIONAL INTELLECTUAL PROPERTY CENTER CULTIVATOR FOR INTERROW PROCESSING OF POTATOES (71) Applicant Educational Institution Belarusian State Agrarian Technical University (72) Authors Timoshenko Vasily Yakovlevich Zhdanko Dmitry Aleksandrovich (73) Patentee Educational Institution Belarusian State Agrarian Regional Technical University(57) Inter-row cultivator processing of potatoes, containing a frame with flat-cutting one-sided paws attached to it, characterized in that the blades of the paws are directed towards the ridge and are installed at acute angles to the surface of the field and the direction of movement, and their lower ends are located under the potato nest. 38722007.10.30 The utility model relates to agricultural machinery and can be used for processing potato plantings. A known cultivator for inter-row cultivation of potatoes includes a frame with flat-cutting one-sided paws attached to it, installed on both sides of the potato ridge, the blades of which are directed from the ridge 1, 2. The disadvantage of this device is the inability to loosen compacted soil near the potato nest and under it. As a result, the soil compacted under the influence of precipitation and its own weight near the potato nest and under it prevents the development of stolons and leads to a decrease in potato yield. The purpose of the utility model is to improve the quality of potato processing and its yield. This task is achieved by the fact that the cultivator contains a frame with flat-cutting one-sided paws attached to it, located on both sides of the potato ridge, where the blades of the paws are directed towards the ridge and are installed at acute angles to the direction of movement and the surface of the field, and their ends are located below the potato nest . The figure shows a useful model of a cultivator for inter-row cultivation of potatoes (general view, top view). The utility model is a cultivator for inter-row cultivation of potatoes, containing a frame 1, flat-cutting one-sided tines 2, hilling tines 5, support wheels 6. The utility model works as follows when the flat-cutting one-sided tines 2 move in compacted soil near the potato nest 3 and underneath it is loosened, thereby providing the necessary conditions for the development of stolons 4, increasing their number and the number of tubers in the nest. The inclination of the blades to the surface of the field and their direction towards the ridge ensures loosening of the soil near the nest and under it. Installing the blades at an acute angle to the direction of movement prevents them from becoming clogged with vegetation. The use of the utility model will make it possible to loosen the soil in the area of the potato nest and under it, thereby ensuring the development of stolons and increasing productivity. National Center for Intellectual Property. 220034, Minsk, st. Kozlova, 20.

Mesh harrow for weeding potatoes

Some gardeners prefer so-called mesh harrows. This device consists of a hinged frame, inside of which a toothed mesh is stretched. The mesh has hexagonal or square cells measuring about 20 cm. The teeth are wrapped down towards the ground. A hexagonal mesh is more convenient, since the teeth in it are staggered. But, if you install a square mesh at an angle of 45° relative to the direction of the walk-behind tractor itself, you can also achieve a staggered arrangement of teeth.

The harrow has its advantages and disadvantages. The positive aspects include the following:

- The harrow covers a large area at the same time.

- The device can be easily built with your own hands.

- Can be used together with other plowing devices.

Using a walk-behind tractor

A motor cultivator is a universal equipment used to perform agricultural operations. A popular brand among farmers is Neva.

The technique is used for:

- weeding potato rows with a walk-behind tractor;

- plowing the soil;

- planting crops;

- hilling bushes;

- harvesting.

If necessary, the walk-behind tractor is used to combat grass thickets on the site. The unit can be easily upgraded to suit household needs by adding special parts.

PLANTING POTATOES WITH A MOTOR-BLOCK USING A PLOW

You can plant potatoes using a plow, which is used to plow the garden before winter, turning the soil over. We will talk about this method using the Favorit walk-behind tractor as an example. We attach the plow and lugs to it.

There is no need to mark the garden with lines. First, we cut one furrow with a plow. The peculiarity of this method is that you need to immediately throw the potatoes into the garden bed. Let's throw in some potatoes, turn the cultivator around, put the outer wheel in the garden bed, and fill it up with soil from the newly cut furrow. There is nothing to worry about if the lug goes over the potatoes; the potatoes are not afraid of this. So we plant bed after bed at the first speed of the walk-behind tractor. This method of planting potatoes with a walk-behind tractor seems to us more convenient, since we immediately cut one bed and fill another, and the beds turn out smoother due to the fact that the wheel follows the cut furrow. Planting potatoes with a walk-behind tractor is completed.

Watch the video

When to weed potatoes

Typically, potatoes are weeded twice a season:

- the first - approximately three to four weeks after planting, when the hatched sprouts reach a height of 2-4 cm;

- the second - when the potato bushes reach a height of 20-30 cm (depending on the variety).

Weeding is usually combined with hilling. However, if the tubers were not properly germinated before planting, weeds may appear in the garden much earlier than the shoots. In this case, you will have to carefully (preferably with a flat cutter) weed the beds without waiting for the sprouts to appear.

The second weeding is carried out before the potatoes bloom. During and after the bushes bloom, the beds require virtually no maintenance.

Loosening potato rows with a walk-behind tractor

Two weeks after planting the potatoes in the ground, the rows are loosened, combined with the first hilling. To use a walk-behind tractor in this process, potato rows are made as long as possible, the distance between the rows is 65-70 centimeters, and space is left at the edges of the rows for the machine to turn.

For better engagement of the walk-behind tractor with the ground, conventional wheels are replaced with metal ones with powerful lugs, and weights weighing 70-100 kilograms are also attached. For loosening, either disk attachments or a hiller plow are used.

When loosening with disk attachments, before starting work, adjust the distance between the disks, as well as their angle of rotation. Depending on the potato variety and plant height, the distance between the discs is set to 40-70 cm. The rotation angle is selected according to the density of the soil and is set the same for both discs.

When loosening row spacing with a hiller, a universal hitch is hung on the walk-behind tractor, onto which one to three hiller plows are installed. The process is regulated by a universal hitch by tilting the hiller relative to the ground or by raising and lowering the hiller itself in the fastening of the stand.

Tools for weeding potatoes

The choice of tools for weeding potato beds depends on the size of the plot, physical capabilities and individual preferences of the gardener.

All weapons can be divided into groups:

- simple hand tools (hoes, hoes, flat cutters);

- cultivators;

- walk-behind tractors

1. The simplest hand tools. A variety of saps and hoes are the most common tools for small areas. If planting potatoes takes up only one to two hundred square meters, it makes no sense to purchase more expensive equipment. But even such simple tools are distinguished by a variety of forms.

An ordinary sapa is a rectangular or trapezoidal piece of metal, sharpened on one side and attached to a long handle. However, this tool is more suitable for row spacing than for beds: with such a squeegee you can chop off fragile potato stems, or even catch the root. Therefore, two-horned hoes are more often used for weeding beds.

The simplest sapa

It is convenient to process hard clay soil with a sickle-shaped glander: its cutting surface has the shape of a crescent. This tool is similar to a hoe, in which not only the ends of the “horns” are sharpened, but also the arc connecting them.

Many gardeners love flat cutters: working with them requires much less physical effort. The Fokin flat cutter is especially often used: it is good because the gardener himself can change the angle of the knife in a way that is convenient for him.

Fokina flat cutter

A flat cutter has been created especially for weeding potatoes, similar to a poker, the “horns” of which are connected with a sharp knife. This tool cuts weeds perfectly, and is absolutely safe for the stems and root system.

The only drawback of all of the listed tools is the need to put significant physical effort into weeding.

2. Cultivators. There are: manual, electric, with a gasoline engine.

Even a manual cultivator is a godsend for older people or those who suffer from arthrosis and other diseases of the musculoskeletal system. For example, the Tornado cultivator resembles a pitchfork, the teeth of which are twisted in the shape of a corkscrew. Such a tool is sold in hardware stores, but you can make it yourself. The cultivator is “screwed” into the ground over the entire length of the teeth, easily pulling out the entire weed root. This tool is best used for row spacing.

Cultivator design "Tornado"

For garden beds, cultivators equipped with two blades located at an angle of 45° to each other are often used. Cultivators, which instead of knives have miniature forks with three teeth, pull out weeds even more carefully. For greater convenience, such tools are placed on wheels: the gardener rolls the tool, pressing it to the surface of the bed, as a result of which labor productivity significantly increases.

Hand wheeled cultivator

Weeding potato rows with a walk-behind tractor

A walk-behind tractor is a tool that combines many different functions. With its help it is possible:

- Plow the soil;

- Hill up the area;

- Plant root vegetables;

- Harvest.

The user can also carry out weeding. This is just a small list of possibilities.

They are the most popular accessories for walk-behind tractors. Special paws (in fact, they are flat cutters) have many advantages over their analogues. They are easy to install and use, and they are also characterized by unique accuracy in processing row spacing.

The paws are capable of loosening the soil by several centimeters.

The standard tillage depth is 4 cm, but if there is an excessive amount of moisture in the ground or it is trampled, then the figure increases to 7 cm.

Before starting work, the paws are attached to the appropriate mounts on the walk-behind tractor. The distance between the flat cutters corresponds to the width of the grooves. It is also necessary to provide a small overlap through which waste will pass. The remaining distance will allow you to avoid clogging the paws with collected weeds and prevent premature cleaning of the device.

The tool is divided into:

- Double-sided or lancet;

- One-sided.

If one side of the flat cutter is sharpened, then the blades face each other. There is another mounting option. When using such paws, you can weed the potato furrow from both sides at the same time.

Cultivators for planting potatoes

Devices for cultivating land are called cultivators. The cultivator can loosen the soil, plow the ground, remove weeds, apply fertilizers, plant, and hill up.

Motorized equipment used on personal plots and farms is divided into three types: motor-cultivators, motor-blocks, and mini-tractors. They differ in power and scope of functions.

Motor cultivators are divided into classes depending on weight. Mechanisms up to 30 kg belong to the first class and are designed to work in small areas. Motor cultivators up to 60 kg belong to the second class and work over large areas. Units up to 100 kg belong to the third class. For work on personal plots, second-class cultivators are purchased, and attachments are purchased separately.