The KO-507AM sludge suction machine is a special device, similar to the KO-505A vacuum machine, designed for vacuum cleaning of cesspools, wells, septic tanks, sewer networks, settling tanks from oil sludge or sludge, as well as transporting them to the unloading site. This equipment is a metal tank mounted on a wheelbase, having a hose, a vacuum pump, a pneumatic and hydraulic system, and additional electrical equipment.

Operating principle of the sludge sucker

Pumping out sediments and contaminants, carried out using a suction pump, occurs in several stages. First of all, the equipment drives as close as possible to the place where this work is required. After that, a flexible hose is unwound, with the help of which dirt and deposits are sucked in, lowered, for example, into a well or cesspool, and the vacuum pump is turned on.

When the suction pump is operating, one of the compartments in the tank is filled with waste waste. As the sludge compartment fills, the water contained in the contaminants flows into the adjacent compartment, which is intended for sludge liquid. The operator can control its level. Excess water is removed through the drain pipe. The pumping process does not take long. Then, the sludge filled with sewage is sent to the unloading site.

Types of sludge suckers

Depending on the brand of automobile chassis, design and purpose, there are four main types of sludge disposal systems:

- KO 507 - a Kamaz-based sludge pump is used for pumping out contaminants from drainage systems, as well as for subsequent transportation to the place of disposal and unloading.

- -

based sludge pump designed for vacuum cleaning of sewer systems. The specific design of the tank allows for the separation of water from sludge, for subsequent drainage of the water back into the sewer. - KO 524 based on MAZ is a sludge pump for vacuum pumping of septic tanks and cesspools, as well as for cleaning sewer systems from contaminants. It has a sealed tank that prevents the leakage of sewage.

- The sludge cleaner KO 530, based on Kamaz and Maz

vehicle chassis , is a vacuum machine for mechanical cleaning of sewer systems.

Special equipment KO-507AM based on KamAZ 65115

Special equipment KO-507AM sludge sucker KamAZ 65115 chassis is used as a base one, which has an engine power of 280 hp. Manipulators are quite often installed on the basis of KamaZA. The equipment is designed for use in areas with a temperate climate. The ambient temperature during operation of the machine must comply with the limits: minus 20, plus 40 degrees.

The KO-507AM KamAZ 65115 sludge sucker has the following characteristics:

- tank capacity – 7 cubic meters;

- vacuum pump productivity – 730 cubic meters/hour;

- total weight - 22.4 tons;

- the depth of the well to be cleaned is 8 meters;

- Tank filling time is up to 10 minutes.

Sludge cleaner KO-507 for cleaning work

In modern conditions of running urban utilities, it is impossible to do without special equipment. It is used for the construction and repair of roads, clearing them of snow, ice, dust, flushing the sewerage system, drains and treatment facilities. For these purposes, the KO 507 sludge sucker is used. Most often, it operates on a KAMAZ basis.

Sludge cleaner KO-507 based on KamAZ

The KO 507 machine is a special municipal equipment that is used to carry out cleaning work. It is used in sewer systems, storm drains and drains. A special mechanical device allows you to remove sludge, sludge water and fatty deposits from wells and cesspools. In addition to pumping out contaminants, the KAMAZ-based vehicle is designed to transport the collected mass for the purpose of its subsequent disposal. The sludge pump based on KamAZ KO 507 has the following features:

- A powerful vacuum pump allows you to cope even with heavy and dense sludge, ensuring an environmentally friendly and leak-tight process.

- The tank for collected sludge is equipped with a lid on the back. It folds back when unloading sludge and simplifies the process of emptying the container.

Photo of the KO-507 suction pump based on KamAZ

Device

Sludge cleaner ko 507 uses a unique vacuum method for cleaning sewers, cesspools and treatment facilities. The main element of the equipment is the chassis, which is responsible for moving the entire sludge suction system. The collected waste is stored in a tank. Sludge collection and unloading is carried out by sequentially launching a vacuum and pressure system. The tank itself is internally divided into two blocks. The front unit is filled with clean water, while the rear unit collects sludge and silt liquid. During transportation, solid sludge deposits move to the rear of the tank, and liquid settles in the front of the block. That is why waste is discharged through the back cover. For better cleaning of the container, you can install a mechanical piston, which forcibly pushes contaminants out.

The suction hose of the suction cleaner is equipped with a boom with a winch. These devices provide control of the hose and its fixation on the tank during transportation. The hose is controlled and its position is changed from the cabin using special devices located on the panel.

The sludge pump KO 507 allows you to install additional equipment for filtering and cleaning the collected sludge. This system processes sludge so that the output is process water. It can be used for public utility needs.

Specifications

Technical characteristics of the KO-507 sludge extractor based on KAMAZ:

| Characteristics | Unit measurements | Indicators |

| Height | m | 8,3 |

| Width | m | 2,5 |

| Length | m | 3,1 |

| Weight with loading | T | 20,5 |

| Motor type | diesel | |

| Tank volume | m3 | 7 |

| Water volume for filtration | l | 2000 |

| Discharge | atm. | 0,9 |

| Pump capacity | m3/hour | 730 |

| Working depth | m | 6 |

| Sludge pumping time | min. | 7-10 |

| Angle of rotation of boom with hose | hail | 240 |

Video review of the KO-507 suction pump based on KamAZ:

Advantages and disadvantages

The main advantages of special equipment include:

- remote control used to control the suction boom;

- a sheet made of stainless steel, which is installed at the bottom of the tank, improves unloading;

- remote system that controls the sludge level in the tank;

- use of some components from the Italian company JUROP.

The disadvantages of special equipment include weather conditions. The sludge machine cannot be used at low temperatures.

Produced by the Arzamas Municipal Engineering Plant, this special equipment has found wide application. It has an advantage over vacuum machines due to the use of a more powerful pump.

Video gallery

If you have a plot of land or a private house on the territory of which there are artificial or natural reservoirs, this is probably not the first time you have encountered the problem of cleaning them. It often happens that after spring floods the bottom of reservoirs silts up and needs to be cleaned. This can lead not only to an increase in the danger of operating such facilities, but also to a deterioration in the quality of water in reservoirs, which can negatively affect your health if you consume water from them, as well as flora and fauna. In this case, the owner has several options.

- manually clean the pond using special equipment. In most cases, this is a very labor-intensive process that may be associated with certain dangers;

- use the services of companies that have suction pumps.

Most often, people are inclined to the second option, since real professionals are able to quickly and efficiently complete the entire volume of work, unlike people who are doing this for the first time. Today we will talk about what types of suction pumps there are, list the most common models, and also name their technical characteristics.

Installation cannot be done independently. You definitely need a car that will transport the tank, the installation itself and other equipment. Most often, silt suckers are installed on KAMAZ, ZIL and MAZ chassis. Main types:

- KO 507;

- KO 510;

- KO 524;

- Ko 530.

Let's talk about each of them in more detail.

KO 507

The KO 507 sludge sucker is capable of pumping out sludge deposits and dirt from settling tanks, wells, cesspools, as well as from drainage systems and then transporting and disposing of waste. Such a machine can be equipped with the following equipment:

- the chassis, which is responsible for the movement of the entire machine;

- the tank in which waste accumulates is divided into two parts: water accumulates in one, and waste in the other, which greatly facilitates the cleaning process;

- vacuum and pressure equipment that helps suction and discharge waste;

- a hose through which all receiving and distributing work is carried out;

- a boom and winch with which workers control the location of the hose;

- a dashboard through which the entire sludge suction machine is controlled;

- It is possible to install additional equipment that allows you to purify sludge and convert it into process water suitable for use in municipal services.

KO 507 based on the KAMAZ vehicle has the following technical characteristics:

- dimensions 3100x2500x8300;

- weight 20.5 t;

- depth 6 m;

- suction power and throughput 730 cubic meters per hour;

- pumping time from 7 to 10 minutes;

- The volume of the tank is 7 cubic meters.

KO 510

Sludge pump KO-520

This sludge pump is produced on the basis of the ZIL car. It is designed in the same way as the previous one, for cleaning wells and various communications from silt. Equipment and technical characteristics:

- chassis (ZiL);

- tank (3.25 cubic meters);

- dimensions 7000x2500x3100;

- suction system with a capacity of 360 cubic meters per hour, it will take from 3 to 6 minutes to fill the tank;

- working depth of the hose – 4.5 m;

- an arrow with which the hose is controlled;

- water tanks with a capacity of 20 l;

- control Panel;

- optional equipment.

The total weight of the vehicle and the equipped sludge extractor is 11.2 tons.

KO 524

The main difference between this sludge sucker and all previous ones is the equipment and some technical characteristics. The purpose remains the same. Distinctive characteristics of KO 524:

KO 530

This is one of the most modern designs, which was created for an increased amount of waste. It is also possible to install additional tanks and other equipment. To access significant depths, workers can use additional hoses and extensions. There are several significant differences between that model and the ones described above.

- dimensions 8050x2500x3650;

- weight 24 t;

- tank volume 9.7 cubic meters;

- vacuum pump power 720 cubic meters per hour;

- KAMAZ is used as a vehicle for transporting the installation and transporting waste.

This is one of the most advanced sludge suckers to date. It is equipped with two pumps, additional tanks for clean water and so on. It is possible to install auxiliary equipment that facilitates and speeds up the process of cleaning wells, communication systems, as well as natural and artificial reservoirs. Quite expensive, but at the same time a highly productive unit.

Device

Sludge cleaner ko 507 uses a unique vacuum method for cleaning sewers, cesspools and treatment facilities. The main element of the equipment is the chassis, which is responsible for moving the entire sludge suction system. The collected waste is stored in a tank. Sludge collection and unloading is carried out by sequentially launching a vacuum and pressure system. The tank itself is internally divided into two blocks. The front unit is filled with clean water, while the rear unit collects sludge and silt liquid. During transportation, solid sludge deposits move to the rear of the tank, and liquid settles in the front of the block. That is why waste is discharged through the back cover. For better cleaning of the container, you can install a mechanical piston, which forcibly pushes contaminants out.

The suction hose of the suction cleaner is equipped with a boom with a winch. These devices provide control of the hose and its fixation on the tank during transportation. The hose is controlled and its position is changed from the cabin using special devices located on the panel.

The operator also has the ability to constantly monitor the sludge level in the tank according to the device readings. As soon as the permissible level is exceeded, pumping automatically stops.

The sludge pump KO 507 allows you to install additional equipment for filtering and cleaning the collected sludge. This system processes sludge so that the output is process water. It can be used for public utility needs.\

Sludge pumps (IVR) are used on secondary radial settling tanks of the biological wastewater treatment system and are designed to remove settling activated sludge. Operating conditions – moderate climate U1 (-45…+450 C) according to GOST 15150-69. The main model range is IVR-16, IVR-18, IVR-20, IVR-24, IVR-28, IVR-30, IVR-40.

A distinctive feature of the equipment are the following technical solutions that serve to improve performance characteristics, reduce operating costs and increase service life:

The design must be tied to the dimensions of the existing building part of the sump. This allows installation work to be carried out in a short time without adjusting parts and assemblies “in place”;

The design is more stable and rigid compared to the standard one. This is achieved by using a high-strength bridge truss and a motion drive trolley on 2 wheels (the mass of the moving part is distributed over 3 points - the wheels and the central support). The stability of the structure ensures ease of maintenance of the sump, increases the service life of bearings and wheels;

The design of the bridge truss eliminates the possibility of deformation during operation, which does not require additional reinforcement (unlike a standard bridge);

The standard delivery set includes a control cabinet and a current collector with top power supply.

High-quality imported components are used - geared motors complete with frequency converters "NORD", Germany (N in the designation). A frequency converter is used to adjust the required speed and ensure a smooth start (M in the designation);

The motion drive trolley is equipped with 2 wheels from a forklift with solid “superelastic” tires that can withstand loads of up to 3000 kg and have high wear resistance (2 in the designation);

A device is installed to clear snow from the treadmill (C in the designation), which prevents freezing of the treadmill;

The equipment has a Declaration of Conformity with the requirements of the technical regulations of the Customs Union TR CU 010/2011 “On the safety of machinery and equipment.”

Specifications

Sludge cleaner KO-510

The technical characteristics of the KO-510 are best suited for installing it on a ZIL chassis, since this vehicle has the necessary carrying capacity, and in this case fuel will not be wasted. Unlike KO-560, which can only be installed on KAMAZ (kommash) due to its significant weight.

Main technical characteristics of the suction pump and vacuum cleaner:

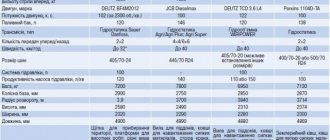

| Options: | Vacuum truck | Sludge cleaner KO 507A2 on KamAZ 65115 chassis |

| Capacity, m3 | 5 and 10 (two types) | 7 |

| Cleaning depth, m | 4 | 6 |

| Vacuum pump capacity, m3/h | 310 | 720 |

| Hose length, m | From 4 to 12 | From 4 to 18 |

When choosing between a suction pump and a vacuum cleaner, take into account the totality of all parameters and circumstances. When pumping out liquid waste, order a vacuum cleaner. If, in addition to pumping, flushing is needed, a suction pump will be required.

An important parameter is not only the maximum depth from which special equipment can pump out waste and wastewater, but also the length of the hose. Also take into account the availability of the closest possible access and the distance to the tank. Choose equipment with a longer hose if waste needs to be pumped out from a deep basement that is difficult to access.

The length of the hoses of the vacuum cleaners is quite sufficient to pump out wastewater from septic tanks, cesspools, wells in private areas, as well as from tanks of car washes and industrial facilities. If there is thick sediment in the wastewater, then choose a suction pump.

Contact Vodokanalregion specialists if you have any difficulties choosing special equipment for cleaning and removing liquid waste and sewage. We have a full set of vacuum sewer and sludge removal machines and affordable prices for sewerage services.

Specifications

- working depth is 4500 mm, the suction machine KO 524 is superior in this regard - 6000 mm;

- pump productivity is 730 m3/h, the sludge sucker ko 530 21 lags behind in this case - 720 m3/h;

- the tank volume is 3.25 m3, the sludge sucker KO 530 01 exceeds it - 9.5 m3, and the KO-560 (commash) - 11 m3;

- The lifting angle of the tank is 60 degrees; in the KO-560 (kommash) this function is not provided at all;

- tank filling time is from 3 to 6 minutes, the indicator depends on the performance of the pump and the capacity of the hose;

- weight – 11.2 t, 560 (commash) – 24 t;

- The chassis used is ZIL, KO-560 is installed on KAMAZ (kommash).

The technical characteristics of the KO-510 are best suited for installing it on a ZIL chassis, since this vehicle has the necessary carrying capacity, and in this case fuel will not be wasted. Unlike KO-560, which can only be installed on KAMAZ (kommash) due to its significant weight.