Neva walk-behind tractor engine

The main working unit of a walk-behind tractor is the engine. It is activated only by turning the key; if the Neva walk-behind tractor does not start, then there are several possible reasons.

The walk-behind tractor does not start

No spark

In this case, it is necessary to check its functionality. Remove the spark plug from the engine and insert it into a special candle holder, and place the housing on the cylinder. Next, turn on the engine. If there is no spark, then you can replace the spark plug; if it does not appear, you should check the starting mechanism and ignition operation. Most often, it is the start button that fails; it can be replaced with a new one.

How to remove a candle correctly?

A special key is used to remove the spark plug. You must be careful, because the spark plug heats up during operation, so remove the spark plug before starting or after the walk-behind tractor engine has cooled down. We install a new one, and then check the clearance. It must be, but not big. The recommended lumen width is 0.5-0.6 mm.

Gasoline does not reach the engine

The second reason that the engine does not start is a problem in the supply of the fuel mixture. In this case, you should go through the complete gasoline delivery scheme. From the fuel tank to the carburetor.

- First check if there is fuel in the gas tank. It should not only be, but be 2-3 cm higher than the bottom, since the gas tank in the Neva walk-behind tractor is designed in such a way that fuel is taken at exactly this height.

- If there is fuel, you should check the operation of the gasoline intake valve. To do this, remove it from the hose and look, if gasoline flows out, then everything is fine, if not, you can clean the tap itself or replace it with a new one.

- Next, check the hose that connects the faucet to the carburetor. Remove it and try to blow it out. If air flows freely, it is functioning well. If not, clean it or replace it.

- And the last in this chain is the carburetor. Disassemble it and thoroughly wash all parts with 95 gasoline. Thanks to this, carbon deposits and impurities will be washed off. After completing the work, thoroughly blow all joints and joints with a compressor to minimize residual gasoline, which evaporates under air pressure. After this, put all the parts back together.

Here are a few more problems that may arise with the engine of the Neva walk-behind tractor:

The walk-behind tractor turns off during operation. Here the main reason is the low amount of fuel, since if it starts, it means it is in good condition. Since we discussed the design of the gas tank earlier, for reliable operation the fuel should be approximately 5 cm above the bottom.

The walk-behind tractor does not start the first time. Check the performance of the spark plugs and replace them with new ones if necessary. Also use a primer to additionally pump gasoline to the carburetor.

Running in the walk-behind tractor

After you have purchased a walk-behind tractor, you need to test it. This process must be carried out efficiently. Because it is the basis for the correct and durable use of equipment.

Running in a walk-behind tractor is, in essence, not operating it at full capacity. Here you need to select the correct load on the walk-behind tractor.

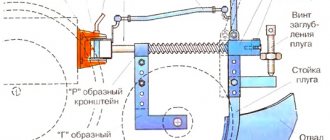

It is recommended to run-in the Neva walk-behind tractor with Subaru engines at half the maximum power. For example, if a plow in working condition should be lowered into the ground by 30 cm, then during operation it should be submerged only 15 cm.

The break-in period is prescribed for each individual model. It is measured in engine hours and usually ranges from 5 to 20 hours.

For a more gentle operation, it can be done without any attachments at all.

Important! Before starting the break-in, you should fill the crankcase with oil. Starting operation with an empty crankcase is not allowed. The choice of oil brand must be made in accordance with the operating instructions. Typically 10W series motor oil is used.

The walk-behind tractor smokes at idle

Most often the reason is that the air filter is clogged and dirty. In this case, you can remove it and see if the smoke continues to come out. If it stops, then the cause has been found.

If it still smokes, check the oil level. Perhaps there is too much of it and it gets thrown away.

Speed adjustment

The working spring is responsible for the number of revolutions. The opening and closing of the throttle valve depends on how it is tensioned. One end of it is connected to the working lever, it goes from the handle to the spring. And, when the position of the handle on the Neva walk-behind tractor changes, its position will also change. To adjust the number of revolutions, you need to adjust its tension.

Adjustment of valves

In operating condition, the gap on the intake valves should be 0.15 mm, and the exhaust valves should be 0.2 mm. In this case, the dipstick should be freely located under the valves. If this is real, then everything is fine. If not, then they should be adjusted.

- To do this, you need to do the following:

- Warm up the engine and then allow time to cool

- Remove the casing

- Remove the valve cover to gain access to the flywheels

- Unscrew the locknuts

- Adjust their position with a key so that the thin blade can pass freely under them.

- Reassemble everything in reverse order.

Motoblock Neva MB 1 detailed technical specifications

The Neva MB-1 walk-behind tractor has been produced since 1984 and during this time has gained the trust of many users.

It has been modernized and improved, but there are still working copies from the 90s of the last century. The manufacturer of Neva walk-behind tractors is the Red October plant, St. Petersburg. This is a specialized enterprise for the production of motorcycle and agricultural machinery. The first Neva brand walk-behind tractor was released in 1984.

The walk-behind tractor is constantly being modernized and is still popular among buyers, as it has stood the test of time. The manufacturer has developed and equipped this equipment with a new Multi Agro gearbox with an increased number of gears.

The Neva MB1 MultiAGRO walk-behind tractor has 3 forward gears and 1 reverse gear. By rearranging the belt on a double-strand pulley, you can get another set of gears that also have a functional purpose. Thus, for each agricultural technical and economic operation it is possible to select the appropriate speed, thereby increasing the productivity of the work performed.

In addition, the MultiAGRO gearbox is characterized by an increased gear ratio, which improves the traction and grip qualities of the walk-behind tractor.

The gear shift lever is located on the steering wheel, which is convenient when using the MB 1 walk-behind tractor as a vehicle.

In the MB1-FS/MB1-FS Premium modification, the presence of an electric starter, which is powered by an installed battery and a generator on the engine, makes it easier to start it, and also makes it possible to use the headlight at night. Now, in order to start the device, it is not necessary to pull the manual starter; you can simply turn the ignition key.

Motoblock Neva MB-1 detailed technical specifications

| Type of walk-behind tractor (GOST 28523-90) | Average |

| Overall dimensions: length * width * height, mm no more | MB1: 1600x660x1300 MB1 Premium: 1600x660x1300 MB1-FS: 1650x660x1300 MB1-FS Premium: 1650x660x1300 |

| Weight, dry, kg, no more | MB1: 75 MB1 Premium: 75 MB1-FS: 85 MB1-FS Premium: 85 |

| Traction force on transport wheels with a load of 20 kg, kgf, not less | 140 |

| Angle of transverse static stability, degrees, not less | 15 |

| Ambient temperature limits, C | From minus 25 to plus 35 |

| Forward speed (second value when rearranging the belt) of movement on pneumatic wheels, at an engine speed of 2500 rpm (max, engine torque), km/h | MB1/MB1-FS: First gear 2.1/2.6; Second gear 7.4/9.2; Reverse 1.8/2.3; MB1 Premium/MB 1-FS Premium: First gear 1.9/2.4; Second gear 3.7/4.6; Third gear 6.6/8.3; Reverse 1.6/2.0; |

| Forward speed (second value when rearranging the belt) of movement on pneumatic wheels, at an engine speed of 3600 rpm (maximum engine power), km/h | MB1/MB1-FS: First gear 3.0/3.8; Second gear 10.6/13.3; Reverse 2.6/3.3; MB1 PremiumMB1.FS Premium: First gear 2.7/3.4; Second gear 5.4/6.7; Third gear 10.0/12.6; Reverse 2.3/2.9; |

| Power take-off shaft (BQM) (GOST28524-90) | Side pulley for V-belt transmission, located perpendicular to the longitudinal axis of symmetry of the MB. The rotation speed is equal to the engine crankshaft speed. |

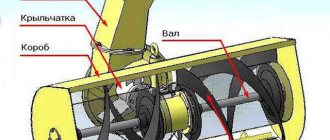

| Possibility of installing attachments | there is - active (harvesting brush, snow blower, water pump, lawn mower) and passive through a coupling (hiller, plow, cart, snow blade, potato digger). |

| Chassis system | Single-axle, wheel formula - 2×2 |

| Ground clearance, mm | 120 |

| Clutch | Constantly switched off, activation mechanism - tension roller for the V-belt |

| Gearbox | Mechanical, gear-chain with double-sided axle release |

| Number of gears | MB1/MB1-FS ((2+1) *2): Four gears - forward; Two gears - reverse. MB1 PremiumMB1-FS Premium ((3+1)*2): Six gears - forward; Two gears - reverse. |

| Tire | Pneumatic - 4.00*8; 16×6.50-8 |

| Track | Variable, adjustable in steps |

| Track width, mm | Normal 320 With extensions 570 |

| Diameter of milling cultivators, mm | 360 |

| Axle (hub) diameter | 30 cm |

| Working width, m | 6 cutters 1.2 4 cutters 0.86 |

| Tillage depth, cm | up to 20 |

| Steering gear | Rod, with the possibility of intermediate settings of the steering wheel in vertical and horizontal planes |

| Fog lamp | MB1/MB1 Premium: — MB1-FS/MB1-FS Premium: 202A,3743 |

| Lamp | MB1/MB1 Premium: —MB 1-FS/MB1-FS Premium: NC 12V 55W |

| Battery | MB1/MB1 Premium: — MB1-FOMB1-FS Premium: DT 1218 |

| Auto fuse | MB1/MB1 Premium: — MB1-FS/MB1-FS Premium: F133 10A |

| Engine | MB1/MB1 Premium: 4-stroke, carburetor, gasoline, single-cylinder with forced air cooling MB1-FS/MB1-FS Premium: 4-stroke, carburetor, gasoline, single-cylinder with forced air cooling, electric starter and generator |

| Fuel type | Pure gasoline AI - 92, AI - 95 |

| Engine oil | SAE 10W30, SAE 10W40, SAE 10W50, SAE 15W30, SAE 15W40, SAE 30, SAE 40. Brands of fuel, engine oil and refills - according to the Engine Manual |

| Engine cooling | air |

| Gearbox (oils used and operating temperature) | Transmission oil SAE85W-90 API GL-5 (it is allowed to use TM-5 oil (from -25 to +35) GOST 17479.2-85). Filling volume l., 1.5. |

| Belt | A53 |

| Air pressure in pneumatic tires: | 4.00-8 - 1.5 +0.2 kgf/cm 2 16×6.50-8 - 2-0.2 kgf/cm 2 |

Engines of the Neva MB 1 walk-behind tractor

| MB modification | Engine brand and type |

| (2+1)*2 | |

| MB1-S7.0 | EX21 from Subaru (4-stroke, single-cylinder, air-cooled, with manual starter) |

| MB1-S6.5 PRO | EX17 from Subaru (4-stroke, single-cylinder, air-cooled, with manual starter) |

| MB 1-B6.5 | I/C 6.5 from Briggs & Stratton (4-stroke, single-cylinder, air-cooled, with recoil starter) |

| MB1-B6.0 | I/C 6.0 Compact from Briggs & Stratton (4-stroke, single-cylinder, air-cooled, with recoil starter) |

| MB1-B6.0-FS | I/C 6.0 from Briggs & Stratton (4-stroke, single-cylinder, air-cooled, electric starter and generator) |

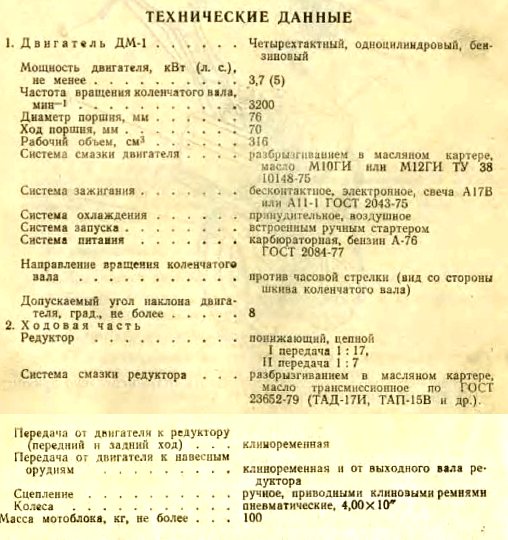

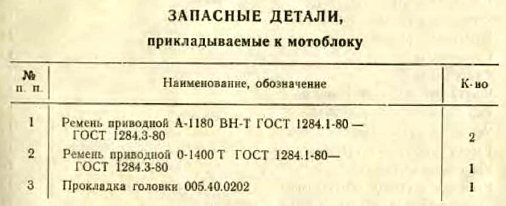

Some technical characteristics for the old model Neva MB-1 walk-behind tractor

Belt for old model Neva MB-1 walk-behind tractor (forward and reverse belt)

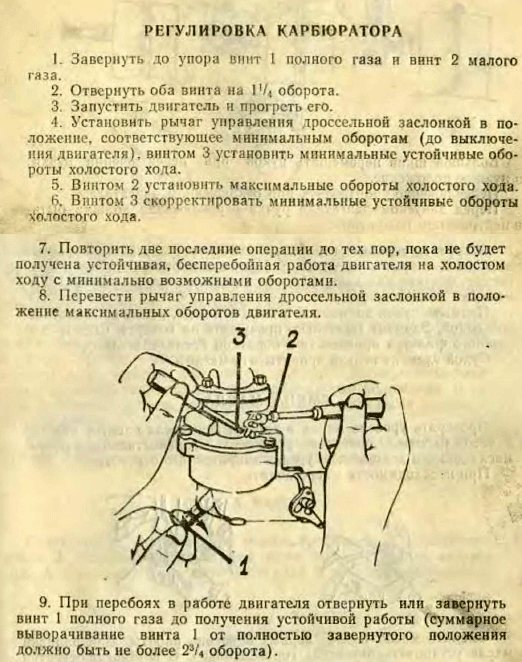

Carburetor adjustment Neva MB 1

Motoblock NEVA MB 1B 6.0 OFS Premium with headlight, electric starter and battery - video

Gearbox, faults, device

The gearbox is designed to transmit rotation that comes from the engine to the wheels and attachments. It regulates the speed and direction of movement.

Gearbox device

The gearbox is designed in such a way that to regulate its operation there is no need to disassemble the entire mechanism. All regulators are located on the outside.

The gearbox has 5 positions. When you press the lever, the clutch is disengaged; when it is released, it returns to its place.

If the drive is connected to the right axle shaft, then at this moment of switching the walk-behind tractor stops. When the handle is recessed, the left sprocket catches and the gear shifts down. If it is necessary to increase the gear, the handle moves forward.

Major gearbox failures

- The clamps or springs have failed. In this case, they should be replaced with new ones;

- The settings of the gearbox itself have gone wrong. Loosen the screws, set the first gear, and tighten it back;

- Oil appears on the shaft. The main reason for this behavior is the failure of the cuff. It needs to be replaced with a new one. It is also recommended to replace the seals. To do this, just pry off the old ones, pull them out and install new ones;

- The transmission is jammed. There's a problem with the chain. It should be inspected and, if its integrity is damaged, replaced with new ones;

- The transfer is not recorded. Most likely the fork is worn out. It cannot be repaired, only replaced with a new one.

- Grinding noise in the gearbox. Most often it occurs with increased loads on the walk-behind tractor. This indicates that the gearbox axle shaft has failed, or the drive belt tension needs to be changed.

Disassembly and repair of the gearbox

Brief video review of the Neva walk-behind tractor gearbox: design, disassembly, repair

Gearbox design of Motoblock MB 2

Doing the job of maintaining the site has now become much easier. After all, our client doesn’t have to do what remains to be done manually. To cultivate small plots of land, compact equipment is used, and it should be noted that it is excellent - walk-behind tractors. These devices allow you to cultivate the soil, say, when growing potatoes, remove leaves with a rake, and remove snow with a blade. In a word, the functionality of walk-behind tractors is amazing. And thanks to their profitable compactness, using them in small areas turns out to be an effective measure.

Next we will consider one of the fundamental parts of this mechanism - the gearbox. Let's see what it is, using the example of the Neva, Salyut, Tselina and Cascade models. Let's figure out how it can be repaired and what standard breakdowns there are. We will provide some nice video and photo materials.

Content

About the device

The gearbox is needed to transmit the rotational motion of the motor to the wheels and suspended equipment. It determines the gear ratio and also the direction. A model installed on Neva MB-1 walk-behind tractors will be considered. By and large, the design of other manufacturers is very similar, almost similar, so it will be a pleasant example of how this unit looks and works. Let's look at the photo - the gearbox assembly for the walk-behind tractor.

READ What Oil to Pour into the Champion Motoblock Engine

Motoblock gearbox design

coordinated in such a way that at the top of the body there are elements responsible for engaging the gears. The gearshift lever can have 5 positions.

By pressing the lever, the fork disengages the clutch. By releasing the lever, the fork moves to its original position. The drive is connected to the right axle shaft, the walk-behind tractor slows down.

The torque is transmitted from a sprocket fixed to the input shaft (left or right). When the handle is recessed, the left sprocket catches, and the downshift is triggered. High gear starts when the handle is extended all the way.

Motoblock Neva MB2 Gearbox: device, disassembly-assembly, repair

Walk-behind tractor gearbox

Neva

MB2

, produced in 1998, never repaired before.

gearbox

revision : increased.

The difference between the design of the Neva MB-1 gearbox and, for example, the Cascade is in the features of the output shaft. In the latter case, it is mounted on ball bearings.

Repair

For gearbox

it will need to be disassembled. But to do this, the unit needs to be cleaned, dirt removed and oil drained. Next you need to disassemble and identify defective elements. This is achieved through inspection or mechanical strength testing. Spare parts for the walk-behind tractor gearbox must be used new and only original ones if there is no desire to risk the performance of the unit.

READ How to Cut Gvl Video

After assembly, you need to remember to fill the gearbox of the Neva walk-behind tractor

. Otherwise it will lead to its failure.

Possible breakdowns and repairs of the gearbox of the Neva MB-2 walk-behind tractor and analogues

- Oil flows through the shaft. The cuff is probably worn out. To fix the problem, remove the cover and replace the worn part.

- Failure of the semi-axle disconnection unit. It may be caused by the failure of one of the drive parts. Disassembly and replacement of broken products will be required. If the problem is caused by a violation of the drive adjustment, then only a change in the cable tension will be required.

- The unit jams—the circuit is broken. Having untwisted the unit, you need to install a new chain.

- No connection. The problem is caused by damage to the welded contact between the gear and the block shaft. The unit will need to be disassembled and the shaft replaced.

- The transfer is not recorded. There may be several reasons:

- The performance of the fork brush has deteriorated - after unwinding the unit, the element should be replaced;

- The spring or clamps of the unit have failed - replace it, make adjustments;

- The settings in the switching device have changed - after loosening the board screws, you need to make the first gear and then tighten the screws.

READ Stihl Fs 38 Disassembly And Assembly

The described breakdowns and their causes are the most typical and “popular”. It should be noted that if you cannot eliminate the defects with your own hands, then it is better to contact a specialist.

Proper quality of service – long service life

Source

Clutch, levers, cables

The Neva walk-behind tractor is equipped with several simple elements: levers and cables. The number of engine revolutions depends on the operation of the gearbox lever and all connecting cables. Such a device tends to wear out and fail during operation. Therefore, they should be periodically checked for integrity and replaced if necessary.

Also, don’t forget about the clutch. It fails much less often, but the plug should also be inspected periodically. If necessary, all these parts are freely available in the store.

Some people think about not buying a new cable, but making one from improvised materials. But it’s better not to experiment with this part and buy a new one. Because it cannot be replaced equivalently. The only temporary replacement option is to take it from a car clutch or scooter.

MOTOR-BLOCKS "NEVA" WITH CLASSIC GEARBOXES

| Walk-behind tractors | Name | Description | Price with VAT |

| Motoblock MB2-KS (GB225) | Engine brand - Zongshen GB225 Power - 7.5 hp Working volume - 224 cm3 Fuel consumption - 2.8 l/hour Tank capacity - 2.6 l Number of gears - (2 forward, 1 reverse)x2 Weight - 85 kg. | 42,500 RUB. | |

| Motoblock MB2-B&S (CR950) | Engine brand - Briggs&Stratton CR950 Power - 6.5 hp Working volume - 208 cm3 Fuel consumption - 1.75 l/hour Tank capacity - 3.1 l Number of gears - (2 forward, 1 reverse)x2 Weight - 95 kg. | RUB 46,950 | |

| Motoblock MB2-B&S (Vanguard 6.5) PRO | Engine brand - Briggs&Stratton Vanguard Power - 6.5 hp Working volume - 203 cm3 Fuel consumption - 1.69 l/hour Tank capacity - 3.1 l Number of gears - (2 forward, 1 reverse)x2 Weight - 95 kg. | 54,900 RUB. | |

| Motoblock MB2-YAMAHA (MX200) PRO | Engine brand - Yamaha MX200 Power - 6.5 hp Working volume - 192 cm3 Fuel consumption - 2.2 l/hour Tank capacity - 3.9 l Number of gears - (2 forward, 1 reverse)x2 Weight - 93 kg. | 55,600 RUB. | |

| Motoblock MB2-GX200 | Engine brand - Honda GX200 Power - 5.8 hp Working volume - 196 cm3 Fuel consumption - 1.7 l/hour Tank capacity - 3.1 l Number of gears - (2 forward, 1 reverse)x2 Weight - 93 kg. | 55,900 RUB. | |

| Motoblock MB2-B6.0FS | Engine brand - Briggs&Stratton I/C6.0 Power - 6.0 hp Working volume - 205 cm3 Fuel consumption - 1.86 l/hour Tank capacity - 2.7 l Number of gears - (2 forward, 1 reverse)x2 Weight - 105 kg Headlight, electric starter | 57,000 RUB. | |

| Motoblock MB23-B10.0 | Engine brand - Briggs&Stratton I/C10.0 Power - 10.0 hp Working volume - 306 cm3 Fuel consumption - 2.93 l/hour Tank capacity - 5.3 l Number of gears - (2 forward, 1 reverse)x2 Weight - 100 kg | 63,800 RUB. | |

| Motoblock MB23-YAMAHA (MX250) PRO | Engine brand - Yamaha MX250 Power - 11.0 hp Working volume - 296 cm3 Fuel consumption - 2.3 l/hour Tank capacity - 5.5 l Number of gears - (2 forward, 1 reverse)x2 Weight - 100 kg | 69,950 RUB. | |

| Motoblock MB23-B10.0-FS | Engine brand - Briggs&Stratton I/C10.0 Power - 10.0 hp Working volume - 306 cm3 Fuel consumption - 2.93 l/hour Tank capacity - 5.3 l Number of gears - (2 forward, 1 reverse)x2 Weight - 109 kg Headlight, electric starter | 77,000 RUB. | |

| Motoblock MB23-N9.0 PRO | Engine brand - Honda GX270 Power - 9.0 hp Working volume - 270 cm3 Fuel consumption - 2.0 l/hour Tank capacity - 5.3 l Number of gears - (2 forward, 1 reverse)x2 Weight - 100 kg | 68,900 RUB. |

Belts for the Neva walk-behind tractor

Basically, Neva walk-behind tractors use V-belt drives. There are a large number of them presented. And for each individual walk-behind tractor, you should know the belt that needs to be used.

Replacing the belt on the Neva walk-behind tractor:

- Remove the shield, unscrew the two bolts (7) and remove the protective casing from the pulleys (6);

- Remove the reverse belt (3) by removing the spring (8), loosening the bolt (2) of the guide pulley;

- Unscrew the screws (5) holding the bracket (a);

- Position the bracket so that the pins allow the front pass belt (10) to be removed from the pulley;

- Put a new belt in its place (first it is put on the gearbox pulley, then on the engine pulley);

- Reassemble everything in reverse order.

Adjust the belt tension! When the clutch levers are released, the belts should sag freely, and the gear pulley should not rotate when the engine is running.

Pulleys are designed to tension transmission belts. There are a large number of them on the Russian market. To replace a pulley, you need to measure its diameter. The following sizes are available: 18, 20 and 25.4 mm.

Motoblock Neva MB 1

To facilitate difficult and time-consuming activities in the agricultural industry, the MB 1 “Neva” walk-behind tractor was produced. This type of equipment is a device with a powerful engine, based on wheels. The unit is adapted to work with a large number of attachments presented on the Russian market. The efficient operation of the device is ensured by engines from foreign manufacturers, such as Subaru, Honda and BriggsStratton. The walk-behind tractor first rolled off the assembly line in 1984 at . This enterprise is located in St. Petersburg and has been successfully carrying out its production activities for more than 50 years. Over the past period, the unit has undergone numerous improvements and modernizations, as evidenced by various modifications of the machine, produced under different indices.

Walk-behind tractor ignition system

Ignition adjustment

The ignition coil for the Neva walk-behind tractor is adjusted as follows:

- Take a sheet of paper and fold it 4 times;

- Unscrew the bolts that hold the module;

- Place a piece of paper under them and screw the bolts into place;

- In manual mode, turn the flywheel;

- Check for spark.

Video review of adjusting the ignition of a walk-behind tractor engine

One of the main factors for the correct operation of the ignition system is the gap between the starter and the flywheel. It should be in the range from 0.1 to 0.15 mm.

To adjust it on the Neva walk-behind tractor, you need to remove the housing and unscrew the stator bolts. Then place the feeler gauge and set the required gap, tighten the bolts back and check the gap over the entire surface of the flywheel.

Generator, faults, elimination

The generator is an important component of the entire mechanism. It is designed to charge the battery and operate the headlights.

When choosing a generator, you need to pay attention to its power. It must exceed the power of all connected devices to ensure uninterrupted operation. For the Neva walk-behind tractor, it is possible to use an old car generator.

Important! During its installation, you must follow the diagram presented below. Otherwise, the generator may catch fire.

There are 4 wires in total in the generator. Two of which are blue. It is thanks to them that the converter is connected. Red, connects to the headlights and supplies voltage to them.

Electric starter

Many people strive to improve the performance of their walk-behind tractor. During the winter seasons, it has difficulty starting due to the fact that the manual starter does not turn over. To solve this problem, a special electric starter was invented for the Neva walk-behind tractor. This is an autonomous device that, when the ignition is turned on, begins to rotate and gives a spark.

An electric starter is a complex design, and it is not possible to make it at home. You can use any other car electric starter that could be left over from an old car.

Candles

We have already figured out what spark plugs are for and how to change them. Let's look at the brands that are needed for each specific type of Neva engine:

Wheel lugs

Lugs are a modified group of wheels that do not have tires or tubes.

The main purpose is to carry out work in the fields (the key value is adhesion to the soil).

They mean steel wheels with special external inserts that provide significant assistance when moving.

Kum 680 wheels for hilling

A distinctive feature is the presence of:

- solid rim;

- the spikes protrude 7 cm.

Wheel sizes of the Neva walk-behind tractor of this modification:

- diameter along the spikes – 43 cm;

- rim diameter – 35 cm.

The width of the lug is 20 cm.

The total weight of the structure is 16.5 kg.

Installation is carried out on the gearbox shaft - no additional connections are provided.

Universal wheels Kum 540 for hilling

A distinctive feature from the 680 model is not a solid rim, but the presence of only a side - it is full inside. In addition, the spikes do not have an inclination to one side, but have a V-shape.

When moving into the ground, traction with the ground is provided not only by the studs, but also by the rim itself, due to which the maximum effect is achieved.

Diameter is:

- along external spines - 54 cm;

- along the rim – 46 cm.

- width – 9 cm.

Important! For installation, it is additionally necessary to purchase an extension cord, since the standard version does not provide any fasteners - only holes with a diameter of up to 65 cm.

Universal wheels Kum 540 with long hub

KUM 540 is often used for hilling, but the bushing is already installed - it is connected directly to the gearbox shaft.

An additional distinctive feature is the width of the stake, which can reach 68 cm.

Main characteristics:

- number of hoops – 2 pcs.;

- diameter along the wheel at the studs – 540 mm, at the hoop – 460 mm. Spike width – 90 mm;

- The bushing diameter is 30 mm.

Installation is carried out on the gearbox shaft. The total weight does not exceed 13.5 kg.

H lugs for plowing

Features include large diameter and width. They are used when it is necessary to work with virgin soil or plots after winter inactivity, when the surface is still hard and requires preparation.

Characteristic:

- width – 20 cm;

- diameter along the spikes - 43 cm, along the hoop - 35;

- spike height – 8 cm.

Installation is possible on the shaft of the Neva walk-behind tractor or on extensions - depending on the specific situation.

In the case of direct installation, the track width will be 40 cm; when using an extension, it will vary from 65 to 70 cm.

Mini H lugs for plowing

The lugs for Neva cultivators are similar to the KUM model range.

Main characteristics:

- wheel diameter – 32 cm;

- width – 16 cm;

- pair weight – 8 kg.

The best option for plowing soil.

H lugs for plowing with long sleeve

Full identity with the considered model range. The only difference is the presence of an already mounted bushing.

In this modification, the track size is fixed - 65 cm.

Mini H lugs for hilling

Today they are considered one of the lightweight MINI N models for plowing. During hilling, the soil is already prepared and not hard, which is why there is no need for a massive type.

The diameter of the hoop is set to 28 cm, and the width for hilling is 9 cm.

Weight does not exceed 4.85 kg.

Designed for use in summer and winter.

Technical characteristics of the Neva MB-1 walk-behind tractor

The wide demand for the walk-behind tractor is due to its excellent performance characteristics.

As standard, the model is equipped with engines from Subaru or Briggs & Stratton, which, with modest fuel consumption, produce excellent performance. Unit characteristics include:

- Power – 7 l. With;

- 4 speeds – 3 forward and 1 reverse gear;

- The weight of the walk-behind tractor without attachments is 75 kg;

- The rotation rate of the cutter elements is up to 125 rpm;

- The transmission is equipped with a gearbox with a “multi-Agro” unit;

- The ability to turn off the torque on one of the wheels to increase the maneuverability of the machine.

Good characteristics bear fruit - the Neva MB-1 walk-behind tractor is capable of uninterruptedly plowing the soil to a depth of 20 cm, capturing a strip of soil up to 1.3 m wide. The model’s spare parts are manufactured according to the latest quality standards, and the assembly level meets all technical standards.

"Neva MB 2B 6.5"

This model is similar in almost all respects to the Neva MB-2B 6.0 walk-behind tractor. The last index “6.0” shows the engine power. The Neva MB-2B 6.5 unit has an engine power of six and a half horsepower. The motor of this equipment is more powerful than that of the previous modification, which makes it more efficient.

There is also a walk-behind tractor "Neva MB-2K-7.5" from the same series, only with a seven and a half horsepower engine. It has a working volume of ten cubic centimeters more than previous similar models.

Common breakdowns and methods for eliminating them

The Neva MB-1 walk-behind tractor often breaks down. Moreover, this is not due to poor quality of parts or assembly, but rather to improper operation of the model. In any case, you should carefully study the repair instructions for the unit in order to be able to repair it yourself if necessary.

Most often, the car requires minor repairs. This could be replacing gearbox seals or worn out clogged filters. In the first case you will need:

- remove the top engine cover;

- disconnect the valves from the gearbox;

- Using a flat screwdriver, remove the old oil seals;

- install new elements;

- connect the valves.

To replace old filters, you will need to remove the top cover of the engine and disconnect the pipes connected to the throttle valve. Then you need to remove the old air filter, clean it, or install a new part. After this, the dismantled parts are assembled in reverse order.

Often the walk-behind tractor requires more serious repairs, for example, replacing belts. In this case, you will need to dismantle several important components - the gearbox, pulley and protective covers on the engine.

Most often, problems arise when dismantling the pulley. It is attached to the motor and frame using screws hidden on the inside of the motor. Therefore, before removing the pulley, you need to study the instructions for the unit and find out where the fasteners are located. After this, you need to unscrew the screws with a Phillips screwdriver, dismantle the gearbox and disconnect the cables. After replacing the worn elements, the motor is assembled in the reverse order.

Motoblock "Neva MB 2": operating instructions

Do not forget that it is still better to take care of your unit and not bring it to a faulty state. Operating the Neva MB-2 walk-behind tractor is a delicate matter. You need to feel when to stop and when you can continue working. In order not to overheat and overwork the engine, it is best to give your car a rest every couple of hours. You should always monitor the oil level. The quality of the oil itself is also important - if it is bad, then the parts will wear out quickly, and then you will need spare parts for the Neva MB-2 walk-behind tractor. Fortunately, spare parts for it are not that expensive.

The MB-2 Neva walk-behind tractor is quite popular; repairing it for this reason will be inexpensive. This is very good for all owners of this unit. Although it is reliable and durable, working in harsh conditions will break anyone. So it’s best to have universal equipment for which you can find spare parts at a low price.

Do you want to purchase a Neva-MB 2 walk-behind tractor? The operating instructions, which should be read before using the machine, warn that the owner should always monitor the condition of his unit. It is important that all working units are in order and working properly.

Do-it-yourself repair of the Neva MB-1 and MB-2 walk-behind tractor according to all instructions

The first Neva walk-behind tractors appeared back in the 80s. Today, they not only have not lost their popularity, but have even become even more in great demand.

Thanks to the constant modernization of models, Neva units delight their customers with an affordable price, good wear resistance, high quality of all components and a long service life. Among the many models of this brand, we will talk about the two most popular: walk-behind tractors MB-1 and MB-2. We will learn not only their features, but also try to analyze the most common causes of their breakdown.

Engine for walk-behind tractor Neva MB-2

The MB-2 walk-behind tractor is a modified version of the MB-1 model. It turned out to be even more reliable and durable. At the same time, the manufacturer managed to reduce the fuel consumption when operating the walk-behind tractor at maximum permissible loads.

Like the Neva MB-1, the MB-2 modification is equipped with different 1-cylinder 4-stroke engines with carburetors and manual start, which is done using a retractable cord. Each of the power units is equipped with an air cooling system operating under the influence of centrifugal forces.

The engine is attached to the power frame using reinforced bolts. A 3-groove pulley is responsible for transmitting the rotational force generated by the motor to the gearbox or attachments in the basic motor device. To stabilize engine speed when it is first started, an air damper is provided in the agricultural unit.

The most popular modification of the Neva MB-2 walk-behind tractor, the MB-2K agricultural machine, is equipped with a Russian-made engine, the DM-1K internal combustion engine. The stock crankshaft of this power unit is located horizontally, and the factory valves are located at the top of the engine. The operating volume of the internal combustion engine is 317 cm 3, and its maximum permissible power is 6.5 liters. With.

Each engine for the Neva MB-2 walk-behind tractor meets several important parameters.

Among them, the presence of:

- a ball bearing built into the standard crankshaft supports - it is designed to stabilize the vibration load of the engine and make it operate more smoothly under high loads;

- factory automatic decompressor;

- an aluminum block and a repairable standard cast iron sleeve - this design solution gave the manufacturer the opportunity to extend the service life of the sleeve;

- durable foam air filter, which features a 2-level cleaning system;

- reduced noise levels and modest fuel consumption - this was achieved thanks to the location of the valves in the upper part of the engine;

- an improved ignition system that allows you to start the engine without problems in the most difficult weather conditions.

Another important feature of engines is their factory protection against overheating, dust and dirt. Thanks to this, Neva MB-2 walk-behind tractors can be confidently used to solve almost any problem.

Motoblock MB-1: frequent breakdowns of the unit and their solutions

This walk-behind tractor can easily be called the “first-born” in Niva production. Of course, by now it has been modernized in many ways and has acquired a more modern design. With the help of such a unit, you can effectively treat the area in absolutely any weather. It will perform well both on soft sandy soil and on hard ground. And the cast iron cylinder liner ensures its reliability and long service life.

Now we will look at the most common cases of breakdowns of this unit. Usually all repair instructions can be found in the instruction manual, so if you still have it, you can safely use its instructions. But if this item is lost, then you can use our advice.

Let's look at the most common malfunctions of the MB-1:

- If there is an oil leak on the output shaft, the first thing to do is remove the axle cover and replace the seal.

- What to do if the gearbox jams? In this situation, you need to disassemble the walk-behind tractor, where you need to replace the broken chain.

- If there is no kinematic connection inside the gearbox, then the broken sprocket in the block needs to be replaced.

- Gear malfunction: does not engage at all or does not shift. There may be several reasons for such a breakdown. The first is a destroyed switching pin. The second is that the threaded part of the shift knob is cut off. In these cases, we simply replace the defective parts with new ones.

- Oil leakage on the shift shaft. The first thing we do is check the oil level in the gearbox. If an excess of it is detected, then drain off the excess, and if on the contrary, top up.

- Wear of the shaft seal edge. Everything is simple here: we disassemble the gearbox and replace the worn cuff with a new one.

- Restoration of the overrunning clutch should be carried out as follows: remove the starter, take out the clutch, and grind off the grooves for the balls. You need to pour a little oil inside to minimize friction between the coupling and shaft. We install everything back.

Motoblock MB-2

This unit is an improved model of the MB-1 walk-behind tractor. It features a reinforced gearbox, differential lock, imported engine and other features. All this allows it to be maneuverable and easy to use, have good traction force, and be multifunctional when using attachments.

It is thanks to these qualities that MB-2 is very popular among buyers.

Malfunctions of Neva MB-2:

- It is impossible to separate the axle shafts. In this case, check the drive adjustment. If it is incorrect, we change the cable tension.

- Self-switching gears or lack of locking. This problem can occur in three cases, or the switching adjustment system is broken. Then you need to loosen the screws that hold the board, engage 1st gear and tighten the screws back. Either the spring is broken or the board retainers are worn out. In this case, you just need to replace the broken parts. Or the fork cheek has worn out, then you need to disassemble the gearbox and replace the broken part.

- If there is no kinematic connection inside the gearbox, then the shift fork itself needs to be replaced. Another possibility is that the welding of the gear to the block shaft has broken.

It is worth remembering that before you repair the Neva walk-behind tractor yourself, you should carefully read the repair instructions that the manufacturer offers you. If you don’t have such instructions, then you should use the tips above. Of course, if you do not have special skills in repairing such equipment, then it is better to entrust the Neva MB walk-behind tractor to specialists. There are many service centers that will conduct a full diagnostic of the equipment and be able to identify the exact cause of the malfunction.

Remember, in order for the walk-behind tractor to serve you for many years and not succumb to any malfunctions, you need to change the oil in a timely manner and adhere to all operating conditions.

Which Engine to Put on Motoblock MB 1

Motoblock Neva MB 3.5

The Neva MB 2.7 walk-behind tractor is a product of the St. Petersburg enterprise “Red October”. This model has been known to Russian gardeners and gardeners for quite a long time. Serial production of the model began back in the 80s. Devices of the Neva series became one of the first walk-behind tractors on the Russian market. Here the technology was constantly modernized.

Today Neva MB 3.5 is available in several modifications, differing in the model of the installed motor:

- Neva MB 2K is equipped with a Russian engine with a huge service life and a low price;

- Neva MB 2B is equipped with power stops manufactured by BriggsStratton of various capacities;

- Nevay MB 2C is equipped with professional units of the EX Robin Subaru brand.

Video

The choice of motor is usually made taking into account the area of land to be cultivated. In its traditional design, the model is suitable for plots of 10-15 acres. Large farms require equipment with a massive engine (9 hp). It must be emphasized that the manufacturer, in principle, does not use Chinese power plants to complete the Neva MB 2.4 equipment.

The walk-behind tractor includes a gear-chain reducer, made in a duralumin body. It works great with the massive engine and provides a wide range of speeds (4 front and 5 reverse gears). In first gear, the equipment produces a traction force of 180 kgf at a speed of 1.8 km/h. This helps to plow, hill and cultivate the soil with the highest quality, even on heavy soil. The maximum speed of the walk-behind tractor is 12 km/h, which makes it a good assistant when transporting goods.

A fundamental feature of the Neva MB 4 model is the presence of a mechanism for separating the axle shafts. The drive from the motor remains attached to the right axle shaft, which allows you to turn the car “on one wheel”, providing a small turning radius. The control column of the walk-behind tractor can be adjusted in vertical and horizontal planes, increasing ease of use.

Despite the fairly large weight (the heaviest modification of the Neva model

MB 2.4 has a mass of 98 kg), the equipment is small in size and fits in the trunk of a car.

READ Screwdriver Charging Doesn't Charge

Huge operating costs walk-behind tractor

doesn't ask. Thanks to a wide network of post-warranty service centers deployed in all regions and some foreign countries, and affordable technical service, Neva MB 2.4 is very popular not only in our country.

Features of the model are:

- a wide range of operations performed (pumping water, watering, hilling, plowing, cultivation, cleaning areas, cutting grass, digging up root crops, transportation);

- highest efficiency due to the ability to work with 8 cutters;

- a special tread pattern that increases the cross-country ability of the walk-behind tractor and ensures self-cleaning of the wheels;

- modified gearbox design;

- low fuel consumption;

- the presence of a power take-off shaft, allowing you to connect additional equipment.

The Neva MB 3.5 walk-behind tractor is a modern and robust unit with an affordable price. The model is distinguished by its rational assembly and is perfect for those people who want to mechanize soil cultivation work, but do not have the right due to the limited volume of operations performed, or the availability of funds to purchase a mini tractor.

Specifications

The Neva MB 4.5 walk-behind tractor is made according to the classic scheme for this sector.

Dimensional parameters of the model:

- length – 1740 mm;

- width – 650 mm;

- height – 1300 mm;

- standard gauge – 320 mm;

- track with axle extensions – 567 mm;

- ground clearance - 140 mm;

- small turning radius – 1100 mm.

Part 1. Replacing the engine of the Soviet MB-1 walk-behind tractor with the Chinese Forte F-200G

Engine replacement

Russian

walk-behind tractor MB

-

1

per Chinese Forte F-200G. // Replacing the engine in the walk-behind tractor.

The structural weight of the equipment is 98 kg, the operating weight is up to 200 kg. The maximum transport speed is 12.96 km/h. The angle of transverse static resistance for the Neva MB 2 model is 15 degrees.

Performance characteristics of the equipment:

- cutter diameter – 360 mm;

- tillage depth – up to 200 mm;

- maximum working width – 1200 mm;

- processing speed – up to 0.12 ha/hour.

READ Trimmer Engine Doesn't Speed Up

Fuel consumption

The fuel tank of the walk-behind tractor holds 3.6 liters of fuel. Specific fuel consumption for this model is 1-1.6 l/hour.

Engine

The Neva MB 2.7 walk-behind tractor is equipped with various 4-stroke 1-cylinder carburetor engines with manual start from the starter (retractable cord) and air cooling. The power plant is secured to the frame with special bolts. To transmit rotation to a suspended implement or gearbox, a three-groove pulley is used. It is recommended to regulate the operation of the engine during initial startup using the air damper.

The Neva MB2K model runs on the Russian DM-1K model engine. Its manufacturer is the Red October enterprise. This power plant is characterized by overhead valves, a horizontal crankshaft and high torque. The engine has a displacement of 0.317 liters and a power of 6.5 hp.

Some modifications of the walk-behind tractor are equipped with imported units. Models with the Robin-Subaru EX21 power plant (rated power - 6.5 hp, rotation speed 3600 rpm) and a rated BriggsStratton unit (rated power 5.5 hp) are in great demand here.

The engines of all modifications of the walk-behind tractor are characterized by the following features:

- the presence of a ball bearing in the main crankshaft bearings. They ensure smooth operation of the motor;

- the presence of a repairable metal sleeve and a special duralumin block. A conclusion of this nature makes it possible to maintain the initial dimensions of the sleeve for a long period;

- automatic decompressor;

- reliable air filter with double cleaning element;

- low fuel consumption and low noise level due to the overhead valve arrangement;

- an advanced ignition system that allows you to start the engine without fail.

Reviews

Walk-behind tractor

Neva MB 5 has gained popularity in our country, so many reviews have accumulated about this model.

Owners of equipment highlight the following positive aspects:

- The walk-behind tractor plows the soil perfectly and plants root crops without cutting them. The operator does not have to expend additional effort, which greatly simplifies his work;

- The machine always does the tasks assigned to it. With all this, little fuel is consumed even under the highest loads. Specifically, efficiency is considered one of the advantages of the model;

- Neva MB 2 works when you need it and in any weather, and there are no “sneezes” or interruptions.

- The walk-behind tractor has small dimensions, which allows it to fit even in the trunk of a car;

- The machine has the highest performance. When working with cutters, 5 acres can be cut in 2 hours. At the same time, the ground becomes level and light. Neva MB 3.2 is perfect for work on a small plot of 20-30 acres;

- availability of spare parts. You can buy them in virtually every specialty store;

- Despite the affordable price, the model is of the highest quality and is rapidly justifying its worth.

READ Stihl 180 Not Gaining Speed

The walk-behind tractor also has many negative sides. Among them we should highlight:

In the number of reviews, positive assessments of the Neva MB 3.5 walk-behind tractor predominate, and some of the model’s shortcomings are the result of incorrect operation. The percentage of defects at the manufacturing plant does not exceed 1.5%, which indicates the highest quality of equipment. Neva MB 2 is a good and reliable walk-behind tractor

, and he also asks for attention and careful work.

Cost of new and used

The price of the Neva MB 2.7 walk-behind tractor is almost entirely determined by the price tag for the engine that is installed in the model. So, buy the Neva MB 2K modification in monetary terms from 36,000 rubles, Neva MB 2B - from 37,600 rubles, Neva MB 2S - from 40,800 rubles.

There are also a huge number of used versions of walk-behind tractors in the industry. Here the price tags also vary greatly. The average price of a device in good working order is 17,000-22,000 rubles.

Analogs

More complete analogues of the Neva MB 2 model are the Chinese walk-behind tractor

Greenfield MB-7 N and the Russian device Forte MK 2K.

Source