Dispenser for MTZ 80

https://fermer.ru/forum/rtm-remontno-traktornaya-masterskaya/35632?page=9

Power steering repair

T. Boris

writes:

There is no need to change the steering column to a dispenser. I tried everything on my MTZ 80. I replaced the NSh 10 pump with a new one, a repair kit, and all rubber rings. Piston ring. It didn't give any results. Then I pulled the spool out of the distribution box and welded it on both ends in four places using electric welding. Then I carefully sanded the drips so that they could move in the body without scoring.

This increased the oil flow. The steering wheel began to turn at idle speed with the wheel loaded. The spool needs to be extended at each end by 1.5 millimeters. You can do all this on a lathe. Grind the washers. Try it, the result will be positive. Andreyka.

writes:

Guys, don’t throw away your money in vain, the man actually wrote how to bring the power steering to perfection. At first I doubted the effectiveness of such repairs, but today everything, I think, has come to an end to my nerves. I disassembled the distributor and turned out two washers 1.5 mm thick, then they grabbed it by welding, but carefully, from the inside to the distributor spool on both sides, they assembled everything in place. I started the tractor and tried to steer it and thought that I had not connected the cardan to the power steering, only by the movement of the wheels I realized that everything was working. I now steer with one finger. THANK YOU to the person who set me on the path. The asking price was two homemade washers and a repair kit for rubber bands, + 4 hours of time for repairs. Now I want to change the steering wheel, either from a car, or from a passenger car, with a smaller diameter, plus a sloth, and the power steering was produced in 1985 and has been losing its brain all the time until today. Andreyka.

writes:

I turned the washers, as they say, on the knee, first I found a 1.5 mm strip of metal, drilled two 24mm holes in it and cut it with a grinder, then I adjusted everything in place with a file and emery. And it turned out to be PAROVZ. I measured the dimensions on the go, but didn’t write down or remember anything, I thought I’ll try, if I put everything back and save up money for a dispenser. Today I checked and adjusted the steering play approximately once again, as for me it’s about 50-60 degrees, but my brother says that it’s less, well, everything is according to the EYE. I checked the force on the steering wheel with an ordinary bazaar CANTER, pulled the steering wheel spoke, and at idle engine speed it shows 2 kg. My 5 year old son now steers on the spot like in a computer game, he couldn’t do it before. I tried to reduce the play by using the eccentric to adjust the worm-sector engagement, but when the play was reduced, the power steering distributor did not work, since the spool must move in the distributor precisely due to the worm-sector play. Well, the play is of course a bit large compared to the factory one, according to the alphabet book, 30 degrees, but according to the book, the force is 2 kg at medium speeds, but I’d rather twist it with a little play with my finger than pump my hands without play. Alexsey 53

writes:

I couldn’t stand it anymore and disassembled the spool and took the dimensions. The outer diameter is 33.5 mm, the inner diameter is 27 mm, and the thickness, as already mentioned, is 1.5 mm. I'll grind out the washers, install them and post the results.

I hope for a positive result. And such play is not terrible, as long as it is easy to turn. Alexsey 53 writes:

Today I carried out modifications to the power steering, as Andreyka described. The effect is positive, the steering wheel has become very light. The price of the issue is 2 washers that the turner turned for free, the power steering itself was rebuilt in the fall, but there was no effect from this. It’s expensive to install a dispenser, so if you upgrade your power steering, you won’t regret it. Well, a few photos, in the first 2 photos on the right there is a washer (spare). These are welded onto the spool. Thanks to the author of this idea!

Metering pump MTZ-80: installation, malfunctions, device - MTZ-80.RU

Steering pump dispenser MTZ 80

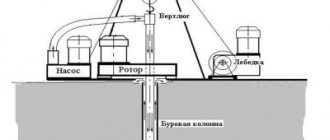

One of the components of the hydraulic system of MTZ tractors is a metering pump, designed for more comfortable and safe control. It consists of a hydraulic distributor, a metering unit made according to a gerotor circuit, one safety valve, two anti-shock valves, two anti-vacuum valves and two check valves.

MTZ dispenser pump: device, principle of operation, installation, repair

The MTZ metering pump is an integral part of the tractor's hydrostatic control system. He is responsible for the correct distribution of fluid in the system and for its supply to the hydraulic cylinders. This strengthens the control system.

In this case, the operator needs significantly less effort to turn the wheels. This point is of particular importance if the tractor is heavily loaded.

- Design and principle of operation of the metering pump at MTZ

- How to properly install the dispenser on the MTZ 82?

- 2.1 Do-it-yourself installation of a metering pump on MTZ (video)

- 2.2 Malfunctions of the MTZ dispenser pump and their symptoms

- 2.3 Device maintenance

Installing a metering pump on the steering column yourself

Here it is necessary to immediately note that this procedure, although not particularly complicated, requires increased attention, as well as the presence of specific skills and knowledge.

However, there are no impossible tasks, so with the necessary patience and the right approach, the work can be completed at home. During installation, it is recommended to use a special installation kit, which will save on the purchase of a hydraulic tank, which will be the body of the power steering itself.

The pump itself will also be attached to it. Among other things, this solution will keep the differential locking system intact. The work is carried out in the following order:

- The distributor is removed from the power steering;

- All necessary bearings are replaced;

- The worm is removed and a new shaft is put in place;

- The ND is attached to the die, for which a special countersunk bolt is used;

- The assembled unit is installed in place and connected to the system.

Recommendations from experienced tractor drivers for changing the pump

Of course, among tractor drivers, as in other sectors of human life, there are their own craftsmen (Kulibins) who decide how to install a dosing pump, where it is best to pull it (remove it) and where to install it. These are not original ideas, but they have the right to life. So, in order:

- Having unscrewed the steering column, they throw it out along with the rods to hell (or store it away).

- Instead, install a self-made bracket, identical in height to the column, to secure the dispenser there.

- The pump is removed from the Balkankar (this is a loader) along with the cylinder.

- Full-size solid rods are made onto the axle.

- Again, they make a bracket for the hydraulic cylinder with their own hands to mount it on the frame.

- The installation is made by connecting from the frame to the cylinder, then to the rod, and connect it all through NSh - 10 and voila!

Of course, this method is simple in some ways, but only if you have properly growing arms and replaceable units from other equipment. Otherwise, it is better to use factory pump models.

Design and principle of operation of the MTZ steering pump

To increase reliability and ensure ease of maintenance, the design of the MTZ 82 dispenser has been simplified as much as possible. Below we will consider its main components.

The sleeve, which is part of the hydraulic distributor structure, is connected to the spool using a special pin. Their position relative to each other is aligned by centering springs. Through a splined connection on the shank, the spool is attached to the axis of the steering column, on which the steering wheel is mounted. The spool can rotate relative to the sleeve at an angle of up to 6 degrees. This is possible due to the fact that the hole in the spool is larger than the diameter of the pin attached to the sleeve.

The design of the gerotor dispenser has the following features: a stator is attached to the pump body, along the teeth of which, when the steering wheel is turned, a rotor moves, connected through a cardan and sleeve to the spool.

The operating pressure in the system is limited by a safety valve. Its maximum lies in the range of 175 - 195 kgf/cm2. The pressure is adjusted with a special screw.

Anti-shock valves, as the name suggests, neutralize shock loads on the hydraulic cylinder if the tractor runs into an obstacle. The maximum pressure is in the range from 220 to 240 kgf/cm2. The pressure in the cylinder is set with an adjusting screw.

Valves that come into operation when the corresponding anti-shock valve is activated are called anti-vacuum or anti-cavitation. By sucking up liquid, they protect the hydraulic system from damage when vacuum and cavitation occur.

The check valve is designed to protect the feed pump from shock loads from the wheels, and prevents air from leaking into the system during manual control.

Through the channel and holes in the spool, hydraulic oil is discharged to drain. Special longitudinal grooves applied to the surface of the spool serve to allow oil to enter the corresponding voids of the gerotor dispenser and the cylinder cavities of the pump.

Through the holes in the sleeve, hydraulic fluid is distributed throughout the cavities of the dosing unit, the cylinder of the turning mechanism, or sent to drain.

Design types (advantages and disadvantages)

By design, dosing pumps can be of only three types:

- piston (plunger) - with direct displacement;

- membrane (with a diaphragm) - suction-ejection;

- peristaltic (on a roller basis).

In the first case, the pump consists of a piston entering the cylinder, which changes the volume of the reservoir space, thereby squeezing out the required amount of working fluid. The advantages of the piston type are that it can work at absolutely any pressure, providing a stable and constant flow rate.

In the second (diaphragm) type of pump, the diaphragm is essentially the wall of the chamber through which liquid is sucked in due to vibration. Having no moving parts, it is designed to dispense very pure water and/or reagents, which indicates its ability to cope with abrasive (destructive) liquids.

And finally, in the third type of pumps, a pushing (roller) method of action is used. Unfortunately, this method of operation limits the use of the pump with dense liquids and elevated temperatures. But they operate for an infinitely long time at low speeds and are also capable of performing the functions of a dosing device.

Malfunctions of the MTZ dispenser pump and their symptoms

Any malfunction of the metering device or the volumetric steering system leads to complications in the operation of the control system. To restore the functionality of the system, you should clearly know which node has failed. There are a number of signs for this:

- The front axle has become more unstable. This symptom in most cases indicates a displacement of the axis of the rotary shaft. It is also possible for gaps to form in the steering linkage or pump components.

- Turning the steering wheel has become more difficult and requires additional effort. The cause is insufficient oil inside the dispenser. The second option is a large amount of air inside the hydraulic system and, as a result, partially idle operation of the device.

- Willful change in the position of the steering wheel. Self-turning of the steering wheel is a consequence of the incorrect position of the spool inside the pump. Two tension springs are responsible for its neutral position. If one of them breaks down, oil is constantly supplied to one of the cylinders, and the steering wheel turns accordingly.

- Weak support during turning or its complete absence. This phenomenon occurs when there is not enough oil in the dispenser. Accordingly, its functionality decreases. The second cause of the problem may be abrasion of the sealing gaskets on the cylinders responsible for turning the machine.

- When you turn the steering wheel, the tractor wheels turn in the opposite direction. In this case, the problem is that the leads to the machine's hydraulic cylinders are not connected correctly to the metering pump. As a result, the spool supplies oil to the wrong cylinder, and accordingly the wrong side is strengthened.

Distinctive features of our store

We do not purchase products from unknown manufacturers. Our warehouses receive only those spare parts that meet all technical parameters specified by the manufacturer of MTZ tractors, have stood the test of time and their reliability is beyond doubt.

Having extensive experience in selling spare parts for special equipment operating in difficult conditions, we can say for sure that a low-quality spare part will be identified in the shortest possible time due to rapid breakdown, therefore we sell only high-quality goods.

The Minsk Tractor Plant produced a large amount of equipment. And for any of the possible modifications we have spare parts. Our catalog contains about 1000 items of not only fast-wearing, but also infrequently needed items, and you don’t have to look for the parts you need in different stores.