Purpose and principle of operation

A feed dispenser is a special device whose tasks include receiving, transporting and dosed distribution of feed and their mixtures. Dispensers can feed green feed, haylage, silage, unchopped haylage and forage mixtures into feeders on one or both sides.

The following requirements apply to feed dispensing devices::

- ensuring uniformity, timeliness and accuracy when distributing feed (feeding time no more than 30 minutes per room);

- dosage of forage distribution for each animal or their group (deviation from the norm is allowed for concentrated feeds - 5%, for stem feeds - 15%);

- contamination of forage is not allowed (returnable losses are no more than 1%, irrecoverable losses are not allowed);

- Segregation of feed in mixtures is not allowed;

- devices must be injury-proof for animals, including electrically safe.

Types of feed dispensers

There is a huge number of distributors, it is determined by their operating conditions, for different types and sizes of farms, for different types of animals, with varying degrees of automation, etc.

Classification of feed dispensers:

- by type of movement - stationary and mobile;

- according to the method of distribution - single- and double-sided;

- in terms of load capacity - single- and double-axle.

By way of movement

Feed dispensers used on farms can be:

By distribution type

Feed dispensers, which are used on cattle farms, can supply food to feeders from one side or from both sides.

By load capacity

The division by carrying capacity is used for mobile dispensers and characterizes how much forage a given dispenser can transport.

As a rule, this is determined by the number of axles on tractor trailers and the carrying capacity of the vehicle chassis on which the feed dispenser is installed. The average lifting capacity of a two-axle feed dispenser is 3.5–4.2 tons, and a single-axle one is 1.1–3.0 tons.

Classifications of feed dispensers

There are various models of feed dispensers, adapted to the specific maintenance and needs of animals. The main classification involves mechanisms that differ in the method of movement, distribution option and ability to transport a certain weight of feed.

The method of movement is the main characteristic by which feed distributors differ. Depending on whether the device can be moved, farm equipment is selected.

Distributors can be:

- Stationary. Such equipment is installed above or near feeders and cannot be moved. The peculiarity of such mechanisms is that they supply feed in containers directly from the bunkers, where the mixture is prepared for consumption.

- Mobile. They look like carts with a feed container. Such devices can take food for livestock at any designated place and transport it to the feeders, evenly distributing it. This equipment is intended mainly for dry and green food. Movement occurs with the help of equipment - a car or a tractor.

- Partially mobile (mixer dispensers). This is a type of mechanism that transports feed of liquid or semi-liquid consistency. Their movement is carried out along special tracks located on the floor of the building, so the movement of the devices is limited. But their advantage is that they can mix the feed before feeding it into the feeder, making the food homogeneous.

stationary dispenser

mobile dispenser

partially mobile (dispenser-mixer)

Stationary devices for cattle can be:

- tape - they have a special roller tape in their device;

- platform - there is a conveyor that dispenses feed in doses;

- scraper - chain-scraper conveyors move along a concrete chute;

- cable-washer – feed is delivered using a cable with fixed washers moving inside the pipe.

The movement of mobile distributors occurs on tractor units or a car frame, but there are also completely autonomous mechanisms powered by electricity. As for the mixer dispensers, they operate under the control of operators using levers and a remote control and are also “powered” by electricity.

By distribution type

The type of distribution of feed dispensing mechanisms can also be different. There are devices that supply food and mixtures only on one side and those that can do this on both sides of the container where the animals eat.

By load capacity

The differences in carrying capacity indicate how much weight the distributor can carry. This classification is typical specifically for mobile devices. This indicator depends on the number of axles of tractors and the carrying capacity of the chassis of the vehicles on which the distributor is installed.

The average load capacity of feed dispensing devices can be as follows:

- for vehicles with one axle – 1.1-3.0 t;

- for mechanisms with two axes - 3.5-4.0 tons.

Technical characteristics and descriptions of popular models

When choosing a feed dispenser, you should take into account its characteristics. They are common for all types (productivity, feed supply speed, volume of the working hopper) and specific.

For stationary dispensers, this is the belt speed and power consumption. For mobile devices, this is the transported weight, the speed of movement during transportation and distribution, the turning radius, and overall dimensions. Both types of models are popular.

Stationary

Stationary feed dispensers are used either on large farms with feed workshops, where it is necessary to automate and optimize feed supply as much as possible, or on small farms, where it is impossible to use mobile dispensers due to the size of the premises and feeders.

The drive is supplied from an electric motor through a gearbox to a chain that drives the belt. The feed from the receiving hopper is evenly distributed with a tape along the entire feeder, after which an automatic switch installed on one of the circuit elements is activated.

Its parameters:

- feeding front length - 74 m;

- productivity - 38 t/h;

- serviced livestock - 62;

- electric motor power - 5.5 kW.

Their use is most effective in barns adjacent to the feed shop - this avoids overloading of forage, gas contamination of the premises, and ensures an optimal microclimate. KRS-15 is a stationary scraper feed dispenser for dry crushed and succulent stalked feeds, such as silage, hay, green mass, and feed mixtures.

The working part is a chain-scraper conveyor , located inside the fence, driven by an electric motor. Forage is fed from a hopper or mobile dispenser into a fence and then distributed along a chute using scrapers. The drive switches off when the first scraper has completed a full revolution.

Its parameters:

- feeding front length - 40 m;

- productivity - 15 t/h;

- livestock served - 180;

- electric motor power - 5.5 kW.

There are two versions of this model - for 100 and 200 heads with one and two conveyor-distributors, respectively.

Read also: All the subtleties of caring for echeveria at home

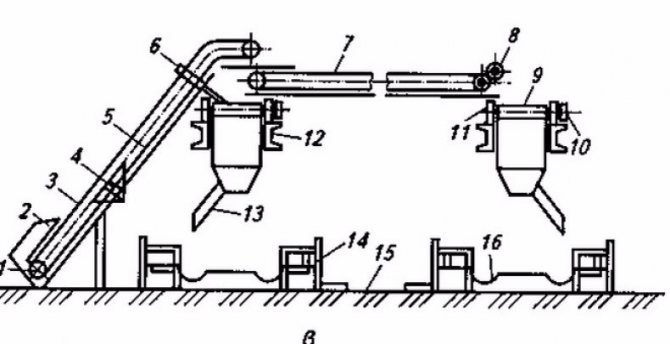

Its main elements are an inclined conveyor, a transverse conveyor, one or two distributor-conveyors and a control unit. Each conveyor has its own electric drive.

The conveyor-distributor is a belt conveyor half the length of the feeder, which moves along guides, located along the feed aisle at a distance from 1600 mm to 2600 mm from the floor.

The stern passage should not be wider than 1.4 m. It is driven by a steel cable wound on drums. The speed of movement is regulated by changing gears in the transmission gearbox, changing five positions.

Food enters the receiving container of an inclined conveyor, and from it is fed to a transverse conveyor located horizontally in the center above the dispensing conveyors. It directs the feed to the first or second conveyor-dispenser. Using a rotating tray, it is directed into the feeder to the right or left of the feeding passage.

Its parameters:

- feeding front length - 75 m;

- productivity - 3–30 t/h;

- livestock served - 200;

- electric motor power - 9 kW.

Technical characteristics of RMM 5.0:

- load capacity - 1.75 t;

- Bunker volume - 5 m3;

- productivity - 3-38 t/h;

- feed rate - 0.8-16 kg/m (number of steps - 6);

- length - 5260 mm;

- width - 1870 mm;

- height -1920 mm;

- base - 1 axis;

- track - 1.6 m.

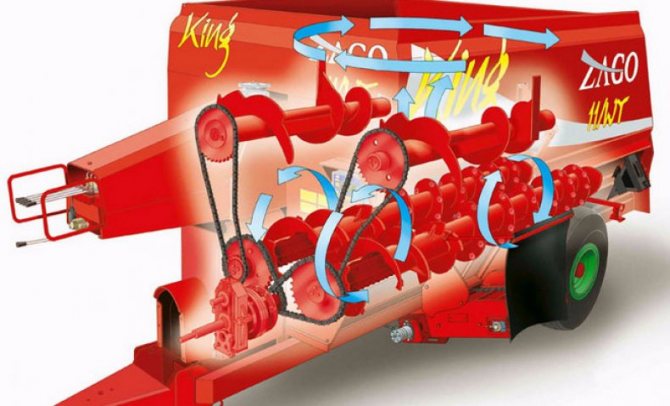

It combines a mixer equipped with a two-speed multiplier, a feed mixer and a feed dispenser. In essence, this is a mobile feed workshop that allows you to mix, prepare and distribute feed.

Thanks to its single-axle base, ground clearance and size, it is quite maneuverable and has good maneuverability. Aggregates with TC class 1.4 tractors, including MTZ-82 and MTZ-80 tractors.

Technical characteristics of AKM-9:

- bunker volume - 9 m3;

- preparation time - up to 25 minutes;

- productivity - 5 - 10 t/h;

- feed rate - 0.8–16 kg/m (number of steps - 6);

- length - 4700 mm;

- width - 2380 mm;

- height - 2550 mm;

- base - 1 axis;

- passage width - 2.7 m;

- rotation angle - 45°.

What types of feed dispensers are there for cattle farms?

Maintaining a large farm requires considerable physical effort and time.

But thanks to modern technology, many tasks, including feeding animals, can be done with the help of machines, making the activity easier and faster.

Increasingly, entrepreneurs began to provide their staff with feed dispensers for cattle farms, which significantly affects the quality of livestock feeding, thereby increasing the profitability of the business.

These units automate the work of feeding animals that was previously performed by human hands. Moreover, they provide rational and high-quality nutrition for livestock, since they regulate the distribution of food, the number of portions and the composition of the diet.

Advantages and features of feed dispensers

To simplify work on the farm, feed dispensers are now increasingly being used. The owner of an enterprise may consider it advisable to purchase such expensive equipment if his farm contains a large number of animals.

The unit has the following advantages and features:

- Grinds and prepares (if necessary) feed for livestock according to their needs.

- The mechanism has built-in dispensers that regulate the amount of food supplied to the animals. Serving size calculations can be determined by measuring the volume or weight of the food.

- Modern feed dispensers have a function that determines and regulates the temperature of the feed. Also, some types of units are connected to monitors, so you can monitor the preparation of food for livestock.

All these functions increase the cost-effectiveness of keeping the herd by controlling feed consumption. According to statistics, using such technologies it is possible to increase the percentage of annual cow milking by ten percent.

Main technical characteristics of feed dispensers

When purchasing a feed dispenser, you need to pay attention to such standard characteristics of the equipment as speed, volume of the tank or bunker, distribution speed, maneuverability.

When choosing a mechanical machine, you need to find out factors such as: belt width, dimensions, engine power, type of engine equipment (chain or belt), weight of grain being moved, transportation speed.

What are the advantages of a cattle feed dispenser when working on a farm:

- the presence of a feed distribution machine reduces the time spent on the entire feeding period and saves the energy of workers;

- when using feed dispensers to mix the feed mixture, the feed mixture becomes evenly enriched in composition and immediately goes into the feeders;

- all dispensers are equipped with built-in dispensers that place food in equal portions into the feeders;

- some models of feed dispensers can supply both dry and liquid food;

- stationary feed dispensers almost completely automate the feeding of animals, which has a beneficial effect on the entire diet of livestock, and this affects the growth of animals and their reproductive function;

- feed dispensers are used not only for distributing feed to animals, but are also used when transporting grain from fields or feed storage areas to stalls and directly to feeders;

- automation of the animal feeding process helps reduce prices for the resulting products.

Manufacturers of feed dispensers are able to adjust feed dispensers to operating conditions and customer requirements that are beneficial to the consumer.

This leads to the formation of new model ranges and improved quality and efficiency of equipment.

Types of feed dispensers

Since farming business is popular in our country, you can see very different feed dispensers on the market. It is not profitable to use them at home. However, in large industries they are necessary.

Stationary feed dispensers

Stationary mechanisms for distributing feed are distinguished by the fact that they must be installed directly in the barn, without the possibility of further transportation.

The units operate using electric motors.

Stationary mechanisms can be belt, belt-slat, belt-chain or scraper type.

Read also: How to grow gladioli in the Urals: useful tips

The main functions of such feed dispensers are to supply portions of feed into a container provided for this purpose. With the help of a transformer, food is transported and distributed throughout all pens.

Examples of the most common feed dispensers in our country:

- KRS mechanism – 15.

- TVK dispenser – 80B.

- Single-sided tape KLO – 75.

- Tape double-sided CLC – 75.

- Dispenser used on dairy farms, RK – 50.

Mobile feed dispensers

Mobile distributors distribute and serve dry and green fodder to livestock.

Semi-liquid nutrition is provided using special mixers (often purchased from pig farms).

The mobility of the mechanism is explained by the fact that it distributes feed from the bunker, and distributes it to the feeders of all pens of the farm using dispensers, which are equipped with the function of independent movement.

The mobility of mixers working with liquid and semi-liquid mixtures is relative. This is explained by the fact that units of this type move along special tracks pre-installed on the floor surface. They can carry out their mission exclusively in one building.

An important advantage of this type of dispenser is that they mix liquid or semi-liquid feed before serving it to livestock. Thanks to this function, all animals receive food of uniform consistency.

Among the mobile feed dispensers that have earned a good reputation in our country are:

- Unit RS – 5A.

- Mechanism KS – 1.5.

- Dispenser KSP – 0.8.

- Universal action unit KTU – 10A.

- Small RMM – 5.0.

- Mixer RSP – 10.

The size and volume of the feed hopper can be selected according to the number of livestock kept on the farm. The farmer can also choose the type of unit drive that suits his case, its operating speed and level of productivity.

About the owner feed dispenser - presented in detail in the video:

Noticed a mistake? Select it and press Ctrl+Enter to let us know.

Feed dispensers-mixers

Such feed dispensers are reliable in operation and produce a feed mixture with a uniform structure. For farmers who purchase feed dispensers, full service is available for a certain period of time. This technique is used for feeding every day throughout the year. The mixer-feed dispenser accurately doses the mixing of both short and long, and wet and dry feed material, and also distributes the mixture evenly. All models of feed dispensers and feed mixers are manufactured in accordance with these requirements.

The models have a hopper and a mixing auger that are perfectly matched to each other. The auger operates at low speeds, which allows you to maintain the structure of even wet food. The ribbed hopper facilitates mixing and ensures high, consistent quality. A separate frame for weighing feed ensures reliable and accurate results when distributing it.

Feed dispensers - mixers are designed taking into account the possibility of working in narrow aisles of barns. They have a low fuel requirement, but high operational reliability and fairly low wear. All these qualities are required every day throughout the year.

Currently, taking into account various incoming requests from farmers, entire lines of mixers - feed dispensers are being developed, adapted to any conditions and performing the required productivity.

MACHINES AND EQUIPMENT FOR DISTRIBUTION OF FEED ON CATTLE FARMS

According to the nature of the work process, all feed dispensers are divided into two types: mobile and stationary. In turn, mobile ones can be trailed, mounted and self-propelled, and stationary ones, depending on the type of feed-bearing organ, can be mechanical, transport, pneumatic and hydraulic. According to the design of the working element: belt, scraper, chain-scraper, spiral, cable washer or chain-washer.

The choice of option and means of feed distribution depends on the physical and mechanical properties of the feed, the type of animals, the method of keeping them, the space-planning solutions of the farm and its distance from feed storage facilities and the feed shop.

Mobile feed dispensers

To distribute coarse and succulent feed, mobile tractor feed dispensers with body hoppers mounted on the chassis are mainly used. Due to their versatility, ease of maintenance and high performance, these feed dispensers are mainly used on cattle farms. Mobile feed dispensers can increase labor productivity by approximately 5 times compared to stationary feed dispensers.

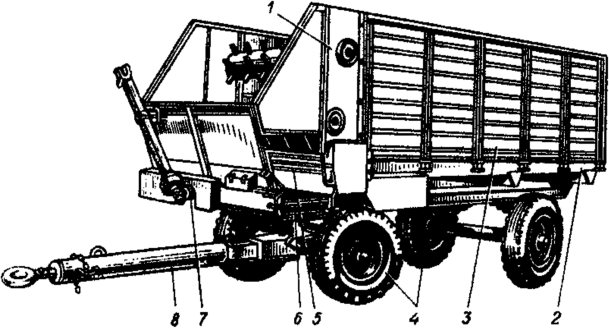

Feed dispensers KTU-10A

(Fig. 14.) are designed for transporting and unloading into feeders on one or both sides of pre-crushed coarse and succulent feed, root tubers, pulp and feed mixtures. It can also be used for transporting silage, haylage and other feed.

The main assembly units of the feed dispenser: frame with chassis 4, body 3 with bottom 2, beater unit 1, longitudinal 5 and transverse 6 conveyors, drive with cardan 7, linkage 8, kinematic transmissions, braking device and electrical equipment. Two-axle feed dispenser, aggregated with MTZ type tractors.

Chassis

The feed dispenser consists of a welded frame, front and rear axles with springs and four pneumatic wheels and a towbar. The rear wheels are equipped with hydraulically driven shoe brakes, which are controlled from the tractor driver’s cab.

Body

all-metal, with a hinged tailgate. The underbody is made in the form of a metal frame and covered with boards. Two pairs of bushing-roller chains slide along the boards, to which stamped transverse metal strips are attached, forming two longitudinal conveyors.

Drive shaft

The conveyor is located in the front part of the body and rotates in four plain bearings. It is driven into rotation from the lower beater shaft through a crank mechanism.

Figure 14 — Tractor universal feed dispenser KTU-10A:

- 1 — beater block; 2 — bottom (base of the body); 3 — body; 4 — chassis with air brakes and spring suspension; 5, 6 - longitudinal and transverse conveyors; 7 — distributor drive with cardan;

- 8 - spoke

Read also: Useful properties of different types of mint

Dispenser

consists of a block of beaters and an unloading (transverse) conveyor. The beaters rotate in bearings mounted on the sides of the body.

The working parts of the dispenser are driven from the tractor power take-off shaft through the cardan shaft of the feed dispenser.

The health status and productivity of animals and poultry depend not only on the quality, level and completeness of their nutrition, but also to a large extent on the timely and correct distribution of feed

To distribute feed on farms, feed dispensers of various operating principles and designs are used. Feed dispensing machines are subject to a complex set of requirements, including:

- zootechnical - uniformity and accuracy of feed distribution, their dosage individually for each animal or group of animals, quiet operation, elimination of contamination of the feed, its separation into fractions, injury to animals and poultry;

- technical and economic - versatility in distributing feed products of various types and consistency, durability and high reliability of the machine in operation, low energy and metal consumption, convenience and safety in operation, automation of work processes.

The method of keeping animals and poultry, feeding regimes and rations, the type and consistency of feed influence the choice of technical means for distributing feed.

Feed dispensers are classified according to the type and consistency of the feed they transport, the type of feed-bearing organ, type of use and drive.

According to the type of use, feed dispensing machines are mobile, limited mobility, and stationary, mobile include bunker-type devices that can be moved around the farm to deliver feed from the feed shop to the pig barns and dispense feed both outside and inside one or more premises. Such feed dispensers include KTU-10A, RMM-F-5A, RSP-10, ARS-10.

The RSP-10 distributor-mixer is aggregated with tractors of traction class 1.4. The working bodies are driven by the tractor PTO.

The ARS-10 dispenser-mixer is 80% unified with the RSP-10 machine and differs from it in that it is mounted on the chassis of a ZIL-130G vehicle. The working parts of the ARS-10 distributor are driven from the power take-off box.

The mobile trailed feed dispenser KMP-F-3.0 is designed for standardized distribution of wet feed mixtures on walking areas and in summer camps of pig farms. It is aggregated with Belarus type tractors. The feed dispenser consists of a hopper, a hydraulic drive mixer, a dispensing device and a running gear. The hopper with frame is installed on the bottom of pneumatic wheels and support. The hopper communicates with the dispensing device through an unloading window covered with a hydraulic gate valve.

The capacity of the distributor hopper is 3.0 m3, the feed during unloading is 35.0 t/h and during distribution 15 t/h. The machine is aggregated with MTZ type tractors.

Compared to the serial feed dispenser KUT-3, OA, the productivity (feed) of the KMP-F-3.0 machine is 15% higher, power consumption is 6% less, specific gravity is 12%, total labor costs are 1.5 times less , labor costs for maintenance (MOT) and repairs are 1.3 times.

The feed dispenser for small pig farms KTS-F-1.0 is a mobile and autonomous device mounted on a self-propelled T-16MG chassis, designed for delivery and standardized distribution of wet feed mixtures (70...80%) into group feeders and consists of a hopper and mixer , for mixing the feed mixture and delivering it to the neck of the unloading device.

Limited mobility dispensers are devices (in the form of bunkers, containers with dosing and unloading organs) that are moved along a rail or other path and dispense feed to animals in one or more interlocked rooms.

Limited mobility feed dispenser for sows and suckling piglets KSP-F-0.8A is designed for the preparation and differentiated dosed distribution of wet feed mixtures for sows and skim milk, compound feed and other dry supplements for suckling piglets into individual and group feeders. Feed is dosed into the feeders and dispensed automatically or manually.

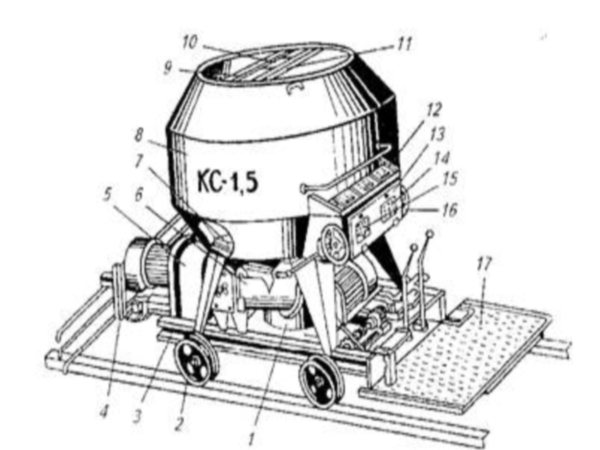

The limited mobility feed dispenser KS-1.5 is designed for the preparation and distribution of wet feed mixtures to pigs of all age groups on reproductive and fattening pig farms.

The main assembly units are a self-propelled trolley with an electric drive, a hopper, inside of which a screw mixer and a paddle mixer are mounted, unloading (distributing) augers, dampers, a distribution box, a gear motor, a traverse, a leveler and a control panel.

The limited mobility universal feed dispenser for pigs KUS-F-2 is designed for standardized distribution of wet feed mixtures and dry concentrated feeds to various age and sex groups of animals on pig farms. It is produced in two versions: KUS-F-2-1 - floor-mounted for farms equipped with rail tracks 616 and 750 mm wide, with a feed aisle width of 1200...1400 mm; KUS-F-2-2 is a trestle type, moving on a 1050 mm wide trestle above twin feeders.

The limited mobility feed dispenser KES-1.7 is designed for transportation and distribution into two adjacent feeders of dry and moistened mixtures, concentrated feed with crushed root crops and green mass on fattening and reproductive farms with group keeping of pigs.

The limited mobility dispenser-mixer RS-5A for dry and wet feed is designed for mixing semi-liquid feed with a moisture content of 60...80% and distributing it into trough-feeders located in the pigsty on both sides of the feed aisle. This unit is used in pig barns, in rooms for growing and fattening pigs.

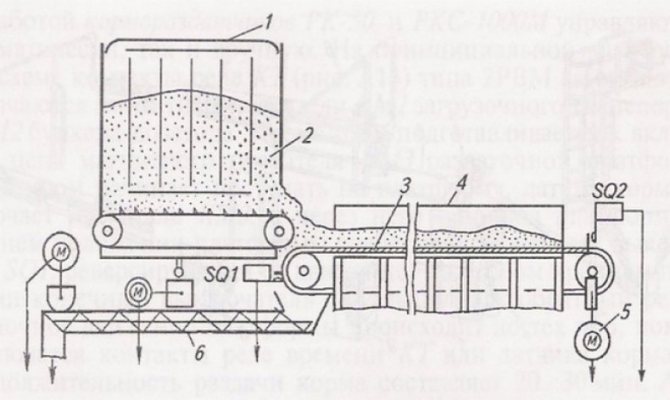

Stationary distributors are installations mounted in one or more interlocked rooms and distributing feed to animals along the feeding front using platforms, belts, chain-scraper and other conveyors (conveyors). In this case, the distributing conveyor can be located both at the bottom of the feeder (TVK-80A) and above it (RK-50). The principle of operation of stationary feed dispensers is that feed from bins installed at the end of the room is dispensed directly onto the conveyor using dosing devices and is then moved along the entire feeding front.

The advantage of stationary feed dispensers is that they can be used in almost any premises for keeping animals, where, due to narrow feed passages, mobile devices cannot be used. The installation of stationary machines allows you to increase the utilization rate of the usable area of barns and reduce capital investments in their construction by 20...25%.

The TTVK-80A feed conveyor-dispenser is used for distributing rough and succulent feed and feed mixtures to cattle, mainly with a tethered housing system. It consists of a conveyor located in a chute, drive and tension stations, receiving and unloading hoppers, an electric motor, etc. Feeders, which simultaneously serve as a chute, can be made of wood, prefabricated reinforced concrete structures, concrete and brick. The conveyor is a round-link anchor chain with wooden scrapers installed at intervals of 640 mm. The scrapers are attached to the chain using special racks. On the first scraper to the drive station there is a stop for automatic shutdown of the conveyor.

The drive station is mounted on a metal frame on the side opposite the unloading hopper. It consists of an electric motor, a worm gearbox and a chain drive.

The tensioning station consists of frames, a receiving hopper and a driven axle with a sprocket.

The direction of movement of the conveyor can be changed by reversing the electric motor. Moving in one direction, the conveyor distributes the feed, and moving in the opposite direction, it dumps its remains back into the bunker.

The TVK-80B conveyor-dispenser is designed for distributing coarse, succulent concentrated feed and feed mixtures; it operates in automatic mode. The working body is made of two parts - a belt and a chain. The feed from the bunker enters the chute onto a belt moving in it. When the last feeding place is filled, the working element automatically stops. At the end of feeding, the chain and belt, moving in the opposite direction, cleans the chute. Residues are dumped into the bunker's receiving area. The remaining assembly units and mechanisms of TVK-80B are completely unified with similar units and mechanisms of TVK-80A.

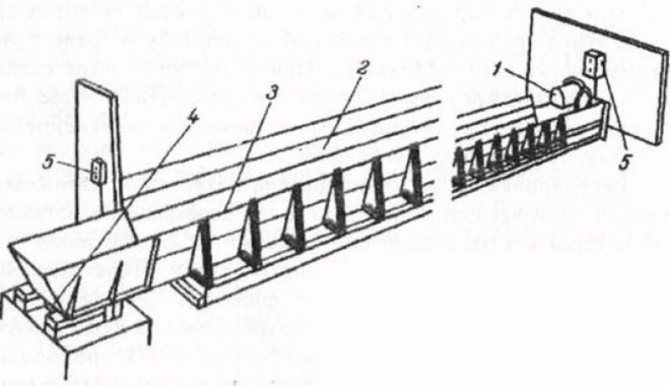

Belt feed dispensers KLO-75 and KLK-75 are designed for distributing silage, haylage, crushed roughage, root crops and feed mixtures for tethered and loose animals, with one-way and two-way access to the feeder. The use of dispensers also makes it possible to mechanize the removal of uneaten food. The working body is a metal strip of increased reliability and durability.

The KLO-75 distributor consists of a drive station with two drums and a gear motor, a feed distribution belt, traction rope blocks, and a discharge plow. It differs from the KLK-75 distributor in a smaller tape width - 550 mm (on the KLK-75 - 1100 mm), the remaining elements are completely unified.

The distributors are loaded with mechanized mobile feed dispensers KTU-10A or RMM-5. Simultaneously with the start of feeding the feed, the drive of the conveyor belt is turned on. The dispenser is switched off automatically by limit switches both during dispensing and when cleaning the feeder, and when the conveyor moves in reverse.

The RVK-F-74 dispenser (dispenser inside the feeders) was created and produced to replace the conveyor dispensers TVK-80A and TVK-80B.

The working body is designed to move the feed along the feed chute. It is a closed circuit made half the length of a round link chain. The second half of the circuit is a galvanized metal cable with a 500 mm wide rubberized tape attached to it using clamps and strips.

The feed chute is made in the form of a reinforced concrete box, which is a feeder and at the same time a connecting link between the drive and tension stations.” Along the bottom of the chute there is a wooden board with two longitudinal wooden guides. Wooden beams are fixed at the junction of the bottom and the side walls of the gutter. Wooden parts are installed to reduce wear on the working body belt.

Stationary

Stationary feed dispensers are installed indoors, and feed distribution is carried out by conveyors; their drive mechanism is electric. engines.

Stationary distributors for farms are divided according to the type of conveyor - belt, belt-slat, belt-chain, scraper, etc.

The essence of the feed supply process for this type of dispenser comes down to unloading feed from a hopper (mobile dispenser) onto a conveyor installed at the bottom of the trough-feeder. The conveyor moves the feed along the entire length of the room, ensuring its uniform distribution for all livestock in the room.

An example of a stationary feed dispenser of the scraper type is the KRS-15 of the Bratslav experimental plant, designed for transporting crushed dry and succulent stalked feed (silage, haylage, green mass), as well as feed mixtures.

KRS-15 is an open conveyor dispenser with a horizontal position; it is mounted on the bottom of a trough-feeder, consisting of two feed supply channels, ringed with each other and located parallel to each other.

Its design includes a fence, inside which a working element moves - a chain-scraper conveyor. On one side there is a conveyor drive, and on the other there is a conveyor tension device.

Let's consider the TVK-80B model as a tape dispenser. It consists of a chain-belt conveyor installed inside a trough-feeder. There is only one tape, looped type. On one side of the distributor there is a gear drive with electric drive. engine, and on the other - a driven drum with a belt tensioning mechanism.

Specifications

The production characteristics of these two feed dispensers are shown in the table:

As can be seen from the table, the TVK-80B feed dispenser is superior to the KRS-15 in all respects, except for the livestock served. The high rate of serviced livestock of the KRS-15 is ensured by the parallel movement of the scraper conveyor.

Mobile feed dispensers can be used to distribute dry and succulent stem feed. Feed dispensers-mixers are often used to dispense semi-liquid feed mixtures, but in most cases they are used on pig farms.

They are mobile because feed is dispensed into trough-feeders directly from the bunker, and feed is distributed along the entire length of the room by moving the dispenser. Tractors or trucks can be used for transportation, and feed dispensers-mixers are often self-propelled.

Unlike mobile dispensers for cattle, which transport feed in a bunker and, using conveyor belts through dispensing windows, simply unload it into feeding troughs, feed dispensers-mixers used for pig farms, before unloading the feed mixture, pre-mix it inside the bunker.

One of such dispenser-mixers is RS-5A. This mobile unit is driven by an electric motor. His cart moves along tracks in the floor. The hopper is cylindrical and horizontal. It mixes feed using a screw mixing device with a horizontal screw arrangement, then the feed enters a double-sided screw-type feed dispensing mechanism. The control is carried out by levers, while the operator is on the trolley, with a seat provided for him.

But the KSP-0.8 mixing distributor does not have a wheeled trolley; its wheel axles are attached directly to the hopper, and the distributor moves on rails.

Mobile

Mobile feed dispensers can be used to distribute dry and succulent stem feed. Feed dispensers-mixers are often used to dispense semi-liquid feed mixtures, but in most cases they are used on pig farms.

They are mobile because feed is dispensed into trough-feeders directly from the bunker, and feed is distributed along the entire length of the room by moving the dispenser. Tractors or trucks can be used for transportation, and feed dispensers-mixers are often self-propelled.

Unlike mobile dispensers for cattle, which transport feed in a bunker and, using conveyor belts through dispensing windows, simply unload it into feeding troughs, feed dispensers-mixers used for pig farms, before unloading the feed mixture, pre-mix it inside the bunker.

Mobile dispensers-mixers have a very similar design to each other. There is a hopper with a mixing device built into it. Feed dispensing mechanisms are connected to the bunker. The bunker is mounted on a four-wheeled cart, one axle of which is driven by an electric motor, which ensures its self-propelled movement. The electric motor also drives the mixing device and the dispensing mechanism. Such distributors are controlled by control panels, and power is supplied via a flexible cable.

One of such dispenser-mixers is RS-5A. This mobile unit is driven by an electric motor. His cart moves along tracks in the floor. The hopper is cylindrical and horizontal. It mixes feed using a screw mixing device with a horizontal screw arrangement, then the feed enters a double-sided screw-type feed dispensing mechanism. The control is carried out by levers, while the operator is on the trolley, with a seat provided for him.

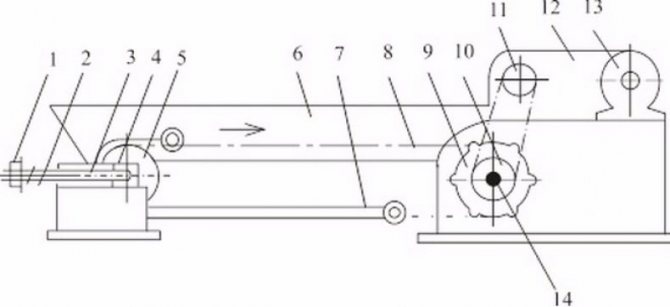

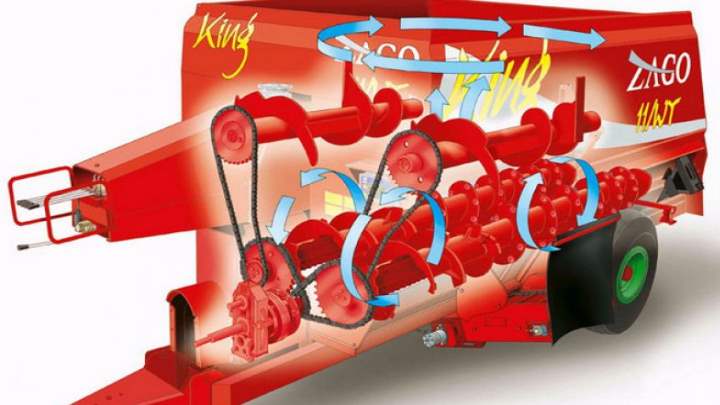

The KS-1.5 dispenser-mixer has a slightly different design. A vertical hopper is installed on the trolley. Movement around the room is carried out on rails. Inside the bunker there is a screw mixing device with a vertical screw arrangement. After mixing, the feed mixture passes through a dosing mechanism, and distribution is carried out by two screw devices. The mixing and dispensing devices are driven by an electric motor through a gearbox. The distributor is controlled by levers, the operator is positioned standing on a special platform. Diagram of the feed dispenser KS-1.5

1-divider box; 2 — chassis; 3 - frame; 4 — device for automatically stopping the feed dispenser; 5 - motor - gearbox; 6 — unloading auger; 7 - paddle mixer; 8 - bunker; 9 - travesna; 10 - auger - mixer; 11 - leveller; 12 — control panel; 13 — electrical equipment; 14 — table of feed distribution rates; 15 — scale; 16 — steering wheel; 17 - platform for the worker

KSP-0.8

But the KSP-0.8 mixing distributor does not have a wheeled trolley; its wheel axles are attached directly to the hopper, and the distributor moves on rails.