The EO-5126 excavator belongs to the class of heavy earth-moving equipment of the 5th size group. It is used in quarries, when digging pits, trenches, laying canals, demolishing structures, and in many other jobs that require high power and efficiency of the equipment used.

Features and advantages of the EO-5126 excavator

A single-bucket universal hydraulic excavator built on a tracked chassis, model EO-5126, is produced by Uralvagonzavod OJSC. It is designed to work with soils up to category 4 inclusive, as well as with frozen or rocky rocks, subject to their preliminary loosening.

For the convenience of the operator, the installed cabin is protected from vibrations and the penetration of extraneous noise. The large windshield is equipped with two windshield wipers. For comfortable work at low temperatures, the cabin is equipped with a heater.

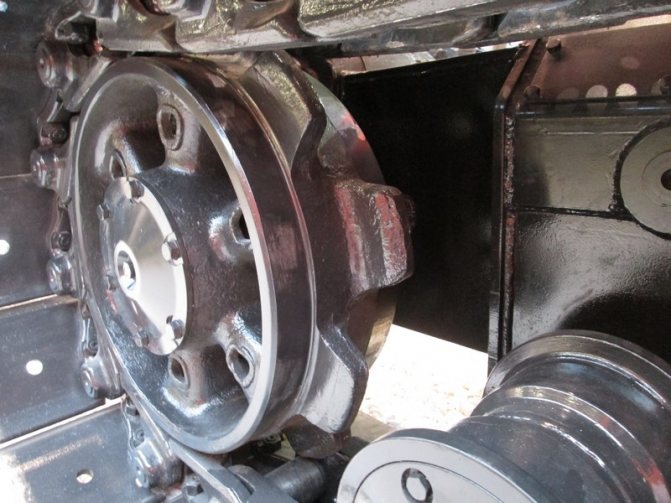

Photo of excavator EO-5126

The condition of components and assemblies is monitored by an automatic system, displaying a fault message on a light display. Ease of operation does not require extensive training of personnel to operate this model.

The EO-5126 crawler excavator combines simplicity of design, ease of access for inspection to all components and assemblies, ease of maintenance and repair, up to field conditions.

"Standard"

The “standard” version of the EO-5126 excavator is designed to work in the widest temperature ranges, in northern conditions with frosts down to -40?C, and in regions with heat up to +40?C. For such conditions, all-season oil can be used.

"Tropical"

For work in climatic conditions with high temperatures, up to +55? C, the “tropical” version of the excavator is designed.

Motor

The EO-5126 excavator, the technical characteristics of which were indicated above, is equipped with an eight-cylinder four-stroke V-shaped diesel engine YaMZ-238GM2, water-cooled and with direct fuel injection.

Motor indicators are:

In addition, the machine is equipped with a centralized lubrication system from the German company LINCOLN, as well as a pre-heater from.

Working equipment

In most cases, a backhoe bucket is used for excavation work in quarries, when laying trenches, on construction sites, and during road construction. In addition to the installed standard attachments, the excavator can use interchangeable working tools.

Standard

The main working tool is a backhoe bucket with a capacity of 1.25 m3. To open the road surface and loosen rocky, heavy or frozen soils, a loosening tooth weighing 221 kg and with a force on the working cutting edge of up to 280 kN is designed.

Standard equipment includes: monoblock boom with handle, hydraulic cylinders, pipelines.

Additional

The excavator allows you to replace the standard bucket and use the following types of replaceable attachments:

- Various buckets:

| Name | Number of teeth | Capacity, m3 | Weight, kg |

| E4.15.01.000sb reinforced | 4 | 1,25 | 1100 |

| E4.15.03.000sb trench | 3 | 0,8 | 850 |

| E4.15.04.000sb for bulk materials | 6 | 1,5 | 1200 |

| E4.15.05.000sb | 4 | 1,5 | 1220 |

| Upside-down bucket (forward and backhoe) | 5 | 1,42 |

- Grab with a lifting capacity from 1.5 to 4 tons (maximum/minimum boom reach).

- Hydraulic hammer NM-440 is designed for destruction of concrete structures, road surfaces, and other materials and structures.

- The PM-2 pneumatic hammer has an impact energy of 5 kJ and is used to destroy concrete, rock or frozen rock.

- Hydraulic shears allow you to cut metal structures or other materials containing metal with a diameter of up to 100 mm, or a rectangular cross-section of up to 90 mm.

Options

The brainchild of Ural machine builders cannot be called small in its linear dimensions. The dimensions of the equipment are as follows:

Other indicators of the excavator include:

Price and reviews

A new excavator costs from 3.7 million rubles and more. Used equipment is sold for 0.8-1.6 million rubles. The rental cost is 1200-1400 rubles, depending on the conditions of the task.

EO-5126 "Tagil" is a multi-purpose tracked single-bucket hydraulic excavator with a rotating platform and rigid suspension of working equipment. Products of the Research and Production Corporation "Uralvagonzavod", Nizhny Tagil. This special equipment is used for the development of unfrozen soils of categories 1-4 - for the development of trenches and pits, with pieces no more than 500 mm in size. It can also be used on frozen and rocky soils, after they have been previously loosened. EO-5126 was also produced at the Voronezh Excavator Plant, which finally ceased to exist in 2OO9.

This excavator model is available in two versions: standard, adapted for use in cold climates (full temperature range: −4О°C ... +4О°C), and tropical – for work in hot climates (full temperature range: −2О° C … +55°C). It was completely developed by Uralvagonzavod specialists and is produced at the enterprises of this large state corporation.

The E0-5126 excavator meets the current criteria for the structural reliability of special equipment, and the traditional quality of Uralvagonzavod and the impressive safety margin of all its components and mechanisms are guaranteed by a certified production quality system. Access to the main components of the excavator is convenient, the design is thought out in such a way that it is possible to carry out maintenance and repair of the special vehicle without problems in any, including non-specialized, workshops.

The manufacturer provides an 18-month warranty for E0-5126 excavators (or 1.5 thousand operating hours, whichever comes first); provides comprehensive service technical support for this equipment both within the warranty period and after its expiration. This is designed to ensure the longest possible operating time of the excavator and reduce the cost of its maintenance and repair.

Uralvagonzavod became one of the high-impact construction projects of the first Soviet five-year plans. The plant in Nizhny Tagil was built in 1931-1936 and was named after Felix Dzerzhinsky. At the beginning of the Great Patriotic War, tank plant No. 18Z named after the Comintern was founded on the basis of Uralvagonzavod and enterprises of the European part of the USSR evacuated to the Urals. Until the end of the war, he produced more than 25 thousand T-Z4 tanks. Every second tank that took part in the battles was made in Nizhny Tagil. Uralvagonzavod also produced armored hulls for Il-2 attack aircraft and artillery limbers.

Tank specialization, along with railway specialization, was retained by Uralvagonzavod in times of peace. T-54, T-55, T-62, T-72 and their modifications - they were all produced here. Currently, the main products of Uralvagonzavod are freight cars, tanks, T-90, and T-14 battle tanks, a modernized version of the T-72 tank; infantry fighting vehicles, fire support, mine clearance, bridge building. The enterprise plays an important role in domestic exports to the world arms market. The plans include establishing the production of modern trams and high-speed trains.

From 2000 to 2010, the company was engaged in the production of both tracked (23-ton) and wheeled (19-ton) universal excavators. At most, 500 of them were produced per year. In 2016, Uralvagonzavod again returned to the production of earth-moving equipment. The first excavators released after a six-year break were the tracked 1A with a new Korean-made diesel engine and hydraulics and the wheeled 2A, with similar aggregate equipment.

For the product line of new Tagil excavators, an improved operator cabin was developed, more spacious and comfortable for work, more ergonomically designed, equipped with a comfortable sprung seat. Sales and maintenance of all excavator equipment produced by Uralvagonzavod was organized through the ChT3-Uraltrak dealer network.

The EO-5126 excavator consists of three main parts: a rotating platform with mechanisms and hoods; crawler trolley; working equipment. The rotating platform of the EO-5126 excavator houses its engine; hydraulic pump drive; rotary drive; pipelines and other elements of hydraulic equipment. At the front left, on the EO-5126 rotating platform, there is a driver’s cabin, in which all the excavator controls are located.

Spare parts for Excavators EO-5126, EO-4326, EO-5124, EO-2621, EO-33211, EK-14, EK-18, etc.

Spare parts for Excavators - EO-5126, EO-4326, EO-5124, EO-2621, EO-33211, EK-14, EK-18 in stock.

Weight and dimensions

| Overall dimensions in transport position: | ||

| — Length, mm | 10050 | |

| — Width, mm | with 600 mm tracks | 3170 |

| with 900 mm tracks | 3470 | |

| — Height, mm | 4000 | |

Performance characteristics

| Kinematic digging depth, m | ≤ 6,2 |

| Digging radius, m | ≤ 9,6 |

| Unloading height, m | ≤ 5,8 |

| Pressure on the supporting surface, MPa (kgf/cm²): | |

| — with 600 mm tracks | 70 (0,70) |

| — with 900 mm tracks | 46 (0,46) |

| Operating cycle duration, s | 20 |

| Maximum digging force, kN (tf) | 175 (17,5) |

| Standard bucket capacity, m³ (nominal) | 1,42 |

| Operating temperature range, °C | −40 … +40 |

| Maximum platform rotation speed, rpm | 10 |

Engine

| Model | YaMZ-238GM2 |

| Type | V-shaped, 8-cylinder, diesel, 4-stroke |

| Power, kW (hp) | 132 (180) |

| Output shaft rotation speed, rpm | 1700 |

| Cooling | water |

Chassis of the EO-5126 excavator

| Travel type | tracked | |

| Base, m | 3,8 | |

| Track, m | 2,57 | |

| Track width, m | — with 600 mm tracks | 3,17 |

| — with 900 mm tracks | 3,47 | |

| Ground clearance, m | 0,475 | |

| Number of road wheels, pcs. | 14 | |

| Number of support rollers, pcs. | 4 | |

Hydraulic system EO-5126

| Maximum pressure in the working equipment system, MPa (kgf/cm²) | 28 (280) | |

| Maximum pressure in the drive system, MPa (kgf/cm²) | 20 (200) | |

| Maximum pressure in the rotation drive system, MPa (kgf/cm²) | 20 (200) | |

| Maximum pressure in the control system, MPa (kgf/cm²) | 3,5 (35) | |

| Hydraulic pumps | ||

| 313.3.112.507.303 or 313.3.160.507.303 | Type | axial piston adjustable, self-priming with power regulator |

| Quantity, pcs. | 2 | |

| 310.1206.U1 | Type | axial piston unregulated |

| Quantity, pcs. | 1 | |

| Hydraulic motors | ||

| Travel motor | Model | 303.3.112.501.U1 |

| Type | axial piston, adjustable | |

| Working volume, cm² | 112 | |

| Quantity, pcs. | 2 | |

| Swing motor | Model | 310.3.112.00.U1 |

| Type | axial piston, non-adjustable, reversible | |

| Working volume, cm² | 112 | |

| Quantity, pcs. | 1 | |

| Hydraulic cylinders | ||

| Arrow | Piston diameter, mm | 160 |

| Rod diameter, mm | 100 | |

| Stroke length, mm | 1250 | |

| Quantity, pcs. | 2 | |

| Handle | Piston diameter, mm | 160 |

| Rod diameter, mm | 100 | |

| Stroke length, mm | 1600 | |

| Quantity, pcs. | 2 | |

| Ladle | Piston diameter, mm | 160 |

| Rod diameter, mm | 100 | |

| Stroke length, mm | 1000 | |

| Quantity, pcs. | 1 | |

| Hydraulics | ||

| Quantity, pcs. | 3 | |

| Type | spool | |

| Cleaning the working fluid | + | |

| Filter element of the built-in main filter | Regotmas 6.250.180-400 | |

| Injection pump filter element | Regotmas 661-1-05 | |

Electrical equipment

| Voltage, V | 24 | |

| Accumulator battery | Type | 6ST-190 |

| Quantity, pcs. | 2 | |

| Generator | Type | G-273V1 or 1322.3771 |

| Quantity, pcs. | 1 | |

| Starter | Type | 25 3708-01 |

| Quantity, pcs. | 1 | |

| Signs and signaling devices | pressure | There is |

| fuel level | There is | |

| temperature | There is | |

| current | There is | |

| Hours counter | There is | |

| Emergency control and alarm system | There is | |

Standard work equipment

| Type | monobloc boom backhoe | |

| Part of the equipment | monobloc boom, backhoe arm, hydraulic cylinders, bucket, pipelines and ripper installed in place of the bucket | |

| Ladle | three-pronged, with a narrowed occipital part | |

| Category of developed soil | I-IV | |

| Bucket capacity, m³ | Nominal | 1,45 |

| Geometric | 1,25 | |

| Number of bucket teeth, pcs. | 3 | |

| Bucket weight, kg | 1080 | |

Options and additional work equipment

| Ladle | ||

| Model | E4.15.05.000sb | |

| Nominal capacity, m³ | 1,5 | |

| Category of developed soil | I-IV | |

| Number of teeth, pcs. | 4 | |

| Weight, kg | 1220 | |

| Reinforced bucket | ||

| Model | E4.15.01.000sb | |

| Nominal capacity, m³ | 1,25 | |

| Category of developed soil | IV | |

| Number of teeth, pcs. | 4 | |

| Weight, kg | 1100 | |

| Narrow bucket (trench) | ||

| Model | E4.15.03.000sb | |

| Nominal capacity, m³ | 0,8 | |

| Category of developed soil | I-IV | |

| Number of teeth, pcs. | 3 | |

| Weight, kg | 850 | |

| Bulk Material Bucket | ||

| Model | E4.15.04.000sb | |

| Type | 6-tooth with a narrowed occipital part, without lateral legs | |

| Capacity, m³ | Nominal | 1,5 |

| Capacity with header | 1,7 | |

| Category of developed soil | I-III | |

| Density of the material being developed, no more than, t/m³ | 1,8 | |

| Number of teeth, pcs. | 6 | |

| Side knives | removable | |

| External width along the sides, mm | 1275 | |

| Digging radius, by teeth, mm | 1570 | |

| Zev, mm | 1225 × 1158 | |

| Maximum depth of the bucket on the inside, mm | 1225 | |

| Weight, kg | 1300 | |

| Upside-down bucket | ||

| Capacity, m³ | Nominal | 1,45 |

| Geometric | 1,25 | |

| Digging force, kg | When working with the handle | 8500 |

| When working with a bucket | 10440 | |

| Unloading height, m | 3,9 | |

| Category of developed soil | I-IV | |

| Purpose | for excavator operation in both forward and backhoe modes | |

| Ripper tooth | ||

| Force on the cutting edge, kN | 280 | |

| Overcast radius along the crown, mm | 800 | |

| Weight, kg | 221 | |

| Hydraulic hammer | ||

| Model | NM-440 | |

| Manufacturing plant | "Tvertekhosnastka" | |

| Weight, t | 1,2 | |

| Impact energy, J | 4000 | |

| Impact frequency, beats/min. | 300 | |

| Working pressure, MPa | 16 | |

| Tool diameter, mm | 135 | |

| Tool working length, mm | 600 | |

| Hydraulic hammer length, mm | 2800 | |

| Air hammer | ||

| Model | PM-2 | |

| Impact energy at a pressure of 0.6 MPa, J | 1000 | |

| Impact frequency, Hz | 7 | |

| Air flow, m³/s | ≤ 0,2 | |

| Maximum length, mm | 1873 | |

| Weight, kg | ≤ 340 | |

| Ambient air temperature, °C | −30 … +100 | |

| Hydraulic shears | ||

| Maximum cutting force, tc | 500 | |

| Dimensions of cut material, no more | Circle diameter, mm | 100 |

| Square side, mm | 90 | |

| Scissors jaw height, mm | 590 | |

| Shear depth, mm | 684 | |

| Working fluid pressure, MPa | 25 | |

| Grab grip | ||

| Model | E4.24.02.002sb | |

| Type of equipment | double jaw grab | |

| Overall width of the grab (along the lower three-toothed jaw), mm | 1254 | |

| Width of the upper jaw (two teeth), mm | 760 | |

| Maximum opening of the grab jaws, mm | 2950 | |

| Minimum diameter of the cylinder held by the grab jaws, mm | 350 | |

| Maximum pick-up and unloading height, mm | 5600 | |

| Overcast radius, mm | along the teeth of a two-toothed jaw | 1740 |

| by teeth of three-pronged jaw, mm | 1800 | |

| Weight, kg | 1340 | |

| The greatest depth of capture of materials located below the ground surface, mm | 6000 | |

| The greatest distance to capture materials located on the surface of the earth, mm | 9000 | |

| Load capacity, kg | at maximum reach | 1500 |

| at boom length | 4000 | |

| Broadened caterpillar (swamp track) | ||

| Track width, mm | 900 | |

| Ground pressure, up to, kg/cm² | 0,47 | |

| Other options | ||

| Automatic centralized lubrication system | LINCOLN, Germany | |

| Optional engine pre-heater (instead of the standard one) | Model | HYDRONIC-35 |

| Manufacturer | Eberspächer, Germany | |

Review of the EO-41211 excavator produced by OJSC UKBTM, Nizhny Tagil.

Technical characteristics of the EO-41211 excavator:

| Excavator weight | 23000 kg |

| Engine power | 135 kW |

| Excavator speed | up to 4 km/h |

| Main bucket capacity | 0.85 cubic meters (5 teeth) |

| Capacity of replaceable buckets | 0.42; 0.95; 1.05 cubic meters |

| Digging depth | up to 7400 mm |

| Unloading height | up to 7300 mm |

| Digging radius | up to 10400 mm |

| Overcome angle of climb | up to 30 degrees |

| Excavation angle | up to 5 degrees |

| Cycle time | 18 sec |

| Estimated performance | 170 cubic meters/h |

| Working pressure in the hydraulic system | up to 36 MPa |

| Bucket cutting force | 15000 kg |

| Handle cutting force | 15001 kg |

| Resource | not less than 10000 h |

The new EO-41211 excavator is equipped with a DEUTZ BF6L2012C engine with a turbine, this is already a big plus; previous machines had YaMZ-238 engines on the EO-5126 crawler excavator, and YaMZ-236 on the EO-33211 wheeled excavator.

Of course, DEUTZ is a world name in engine building, and these engines are installed on a huge number of vehicles, ranging from small Chinese-made trucks to shipbuilding.

The DEUTZ BF6L2012C engine has the following parameters:

| Working volume, cm3 | 6057 |

| Power, kW/hp at 2000 rpm according to ISO 3046 IFN | 125/170 |

| Specific fuel consumption, g/kWh | 214 |

In the future there will also be configurations with a YaMZ-534 engine with a power of 135 kW, and of course with a turbine.

Refill containers:

| Cooling system, l | 24 |

| Engine crankcase, l | 14 |

| Fuel tank, l | 370 |

The cabin has a completely different shape, more reminiscent of a Hitachi cabin; the manufacturer claims that it is made of a metal frame for maximum structural rigidity and operator safety.

There was more comfort, a standard radio and an OS-7-U2-24 heater from the Murom Climate Equipment Plant appeared. The seat has become much more comfortable, the instrument panel has changed. However, the hydraulic controls remain the same.

Hydraulic control joysticks and pedals are manufactured by Pnevmostroymashina OJSC, as on their predecessors.

The hydraulics as a whole have undergone changes; the pump unit and hydraulic motors for travel and rotation are installed from the Bosch Rexroth brand; Voronezh predecessors such as EO-5225 and VEKS 30L were equipped with similar ones.

Hydraulic filter elements were also replaced with imported ones, “Sofima”. The manufacturer does not specify the brand of hydraulic units; perhaps they were also inherited from previous EO-5126 models.

The excavator is also equipped with a “Hydronic-M12” pre-heater with a timer, which greatly facilitates engine starting at low ambient temperatures. It is simply necessary for our country.

The chassis has undergone changes, but not completely. The guide wheels remained the same, as on the EO-5126, and on the earlier Voronezh models. The tracks, support rollers and sprockets were also inherited from the predecessor EO-5126.

The track rollers look different, and there is also no mechanism for tensioning the track chain.

The attachments, judging by the standard bucket with the basic configuration, have not undergone any changes; the crowns and adapters of the bucket are very similar to those from the EO-33211 excavator, as is the design of the bucket itself, as well as the rods and levers of the bucket.

The following types of attachments can be used:

- hydraulic hammer

- pneumatic hammer

- grab grip

- bucket leveler

- grab digging

- bucket 0.85 m3 (standard)

- upside-down bucket

- ripper

- bucket 1.05 m3 (for bulk materials)

- bucket 0.42 m3 (trench)

41211 will also be produced as a tractor, as evidenced by numerous photos on the Internet.

From 2020, UVZ planned to produce 50 of these excavators per year, but information on prices and sales could not be found on the Internet, only pre-orders, which did not indicate delivery times and forms of payment.

Technical characteristics of EO-5126

For its size and standard equipment, the excavator has quite good characteristics. The kinematic digging depth is up to 6 m, and the working radius is 9.5 m. The equipment is capable of unloading to a height of about 5.8 m. At the same time, the pressure on the supporting surface (very important when digging trenches so that the excavator does not push through the walls) varies from thickness of the model tracks. If this is an option with 600 mm tracks, then the pressure is 70 MPa, and if it is 900 mm, then 46 MPa.

An experienced driver completes a work cycle in 20 seconds. The digging force is approximately 175 kN. The rotating platform is capable of making up to 10 full revolutions per minute. The standard model has a bucket with a total capacity of 1.4 m3, however, depending on the version, the figure may vary, although not very significantly.