Crane arm

The crane manipulator is a hydraulic crane with a full-rotating telescopic boom with a cable suspension for lifting loads.

Such structures are valuable on construction sites due to a number of advantages and special properties of CMU.

The ability to accurately and clearly designed unloading and loading, without jolts and shocks, onto a pre-prepared site plays an important role.

The manipulator crane can lift or lower a load onto the site behind certain obstacles in the form of fences, walls or any other structures or large objects.

The CMU can also easily cope with loads that are located at a level below the device itself, for example in a well or trench.

Modern cranes are equipped with a system for monitoring the weight of the load being lifted, using sensors for boom length and tilt angle. The security system will signal if the maximum permissible load weight is exceeded.

As a rule, the manipulator is equipped with additional rear supports, which help relieve the load on the vehicle frame.

How long does it take to build a crane?

Prices for new Japanese manipulators (TADANO, UNIC) with a lifting capacity of up to 3 tons start from 1,200,000 rubles. Similar Italian equipment (“Amco Veba”) is almost 60% cheaper. A new boom with a lifting capacity of up to 3 tons costs from 740,000 rubles. “Koreans,” oddly enough, are more expensive than “Europeans.” A CMU from the Korean company Soosan in Russia costs from 800,000 rubles.

Used cranes are mainly from Japanese brands. They make up the majority of the Russian CMU fleet. Prices for used Japanese cranes manufactured in 1991-1996 (TADANO, UNIC) with a lifting capacity of up to 3 tons range from 150,000 to 500,000 rubles. Used equipment of European and Korean brands is either absent or found in isolated cases.

Crane components

- The base (frame) of the crane installation.

- CMU column (tower) with hydraulic collector.

- Manipulator crane boom.

- CMU hydraulic distributor.

- Winch gearbox with KMU drum.

- Manipulator crane rotation gearbox.

- Supports (outriggers) of the CMU.

- Hydraulic cylinder for lifting the manipulator boom.

The base (frame) of the crane installation.

The base (frame) of the manipulator crane is a three (four) support welded structure made of high-strength structural steel, which is mounted to the truck chassis and to which all other parts of the CMU are attached.

Outrigger beams are mounted into the transverse beam of the base on both sides. The base of the CMU is connected to the column structure using a supporting rotary device (SDU), which ensures rotation of the manipulator crane column.

The column rotation mechanism (rotation gearbox) is attached to the central part of the base.

The base of the CMU is mounted on the mounting installation frame of the vehicle chassis (subframe/subframe) using studs made of high-strength alloy steel.

Rotary support device (ROD)

Support-rotating devices (SPU) - with external and internal fastening, SPU fastening bolts

The control unit includes a rotating and a non-rotating part. The non-rotating part is bolted to the frame. The CMU column (tower) is attached to the rotating part

The rotating support device of the manipulator crane performs the function of rotating the rotating part relative to the non-rotating one.

CMU column (tower) with hydraulic collector

The column (tower) of the CMU is a closed welded structure connected to the base through the support support.

The column supports the boom using a boom lift hydraulic cylinder. A winch with a drum and a hydraulic collector are mounted in the structure of the CMU column. The hydraulic collector ensures the supply of hydraulic system oil from the stationary part of the CMU (frame) to the moving part of the CMU (column, boom, winch gearbox).

Crane boom

The boom of the manipulator crane consists of the main (fixed) boom section and retractable sections of the CMU boom (the number is from two to five).

Inside the boom there are hydraulic cylinders for extending (retracting) the boom and a system of cables for extending and retracting boom sections.

Hydraulic cylinder for lifting the manipulator boom.

The CMU uses a double-acting hydraulic cylinder to lift the boom.

A double-acting hydraulic cylinder is a cylinder with a bottom welded on one side and an eye, which is attached to the CMU column.

On the opposite side, the cylinder is closed with a threaded cap with a through hole for the passage of the rod.

A rod passes through the through cover, at one end of which a piston is fixed, and at the other there is a head or eye, which is attached to the boom of the CMU.

Manipulator crane rotation gearbox.

The rotation mechanism of the manipulator crane is mounted on the frame (base) of the CMU.

Consists of a rotation gearbox and a hydraulic motor. The gear shaft of the rotation gearbox rotates the control unit 360 degrees.

Winch gearbox with drum

The winch of the manipulator crane consists of a gearbox with a hydraulic motor and a winch drum.

The winch is installed inside the column structure. The hydraulic brake is included in the winch gearbox.

Hydraulic distributor KMU

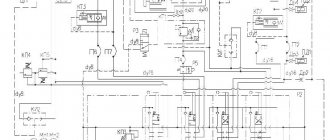

The crane manipulator is equipped with a 6-section hydraulic distributor. Designed to control the main functions of the manipulator crane (rotation, boom lifting, extension, winch, supports). The hydraulic distributor contains a bypass valve.

Supports (outriggers) of the CMU.

The outrigger beams are welded, rectangular (polygonal) cross-section, move at the base of the CMU on supporting rollers and are fixed in their final positions by a locking device.

To prevent spontaneous extension of the beams, the clamps have an additional lock that prevents their opening. Mounting flanges are welded to the outer sides of the beams, to which the support cylinders are attached with bolts. A hydraulic lock installed on the rack hydraulic cylinder prevents spontaneous extension of the rack rod in the transport position and from the fall of the crane if the rack hose breaks.

DONGYANG SS1926 loader crane

Among the model range of compact and productive cranes from the South Korean manufacturer, the DongYang SS1926 cable crane occupies the golden mean. The model has a 6-sided telescopic boom, consisting of 6 sections, which, when folded, is capable of lifting a load weighing up to 7 tons - the most popular version of mobile lifting equipment.

Having good performance characteristics, the DongYang SS1926 crane installation has another irreplaceable quality - versatility. It can be installed on the chassis of any domestic or foreign car, or other special equipment with increased cross-country ability and load-carrying capacity. In the fleets of specialized companies you can often find the DongYang SS1926 CMU based on KamAZ, MAZ, Ural 43202 or 4320.

Advantageous features of the DongYang SS1926 crane installation

The retractable boom of the manipulator crane can reach a length of 20 meters. At the same time, the DongYang SS1926 crane installation is capable of lifting and lowering loads weighing up to 400 kg from a height of 22 meters, which is in great demand among specialists in construction teams involved in low-rise construction. Many people prefer to choose the DongYang SS1926 crane because of the unique feature of the manipulator crane - its boom allows loading and unloading operations even when the cargo is below the surface of the earth: in a trench, hole, pit. In the transport position, it is securely fixed in a stationary state, which prevents accelerated failure of the manipulator crane.

The undeniable advantage of such equipment is that there is no need to operate an additional truck. The lifted load is carefully placed by the DongYang SS1926 crane unit on the side platform of the truck on which it is installed. If necessary, the cargo can be transported to any place, and then unloaded. A compact crane is mounted between the car cabin and the body.

Retractable hydraulic outriggers with wide support platforms allow the DongYang SS1926 CMU to work even on rough terrain - the manipulator crane, installed at a slight slope, is characterized by good stability and safety of the operations performed.

If it is necessary to perform high-altitude repair or installation work, the DongYang SS1926 crane installation can quickly be equipped with an additional element - a cradle with a protective fence. Thanks to its versatility and reliability, the DongYang SS1926 CMU is widely used by electricians, cargo carriers, advertisers and housing and communal services specialists.

Our company offers to buy DongYang SS1926 at a profit and quickly. Qualified and experienced employees will assist in the selection and conduct of pre-sale tests, and provide competent advice on issues of interest.

All our clients have the opportunity to further purchase original spare parts for DongYang kmu, supplied from the warehouse, at affordable prices. You can buy spare parts for the DongYang crane installation at the manufacturer's price both at retail and wholesale with delivery throughout Russia.

| Load moment, tm: | 19,0 |

| Maximum load capacity, kg: | 7000 |

| Maximum reach, m: | 19,8 |

| Maximum working height, m: | 22,7 |

| Boom Reach / Load Capacity | 2.7 m / 7000 kg 4.7 m / 3900 kg 7.7 m / 2100 kg 10.7 m / 1250 kg 13.7 m / 850 kg 16.8 m / 600 kg 19.8 m / 400 kg |

| Rotation angle, degrees: | 360 |

| Width of supports, m: | 5,7 |

| Machine tonnage, t: | 5.0 and more |

| Recommended chassis: | KAMAZ-65117; KAMAZ-43118; KAMAZ-65115; MAZ-6312 Ford Cargo 2535; MAZ-6312A8; HINO-700; Hyundai 170 |

Which loader crane to choose

What would a specialist involved in providing transportation and delivery services prefer in the face of an impending crisis? When lending on favorable terms becomes impossible, the choice will most likely be made in favor of inexpensive used Japanese manipulators, since the price and quality allow them to compete even with new CMUs from Italian and Korean manufacturers. Moreover, the manipulator can be installed on any vehicle that has the ability to install a power take-off, and not just on KrAZ, KAMAZ and MAZ.